Signs of bearing damage

The primary marker of a problem with a Niva wheel bearing is a characteristic sound, a noise that is difficult to distinguish from the sound of driving on asphalt. Therefore, you need to carefully check the condition of the wheel for characteristic signs:

- the wheel is warm and there is no smell from the pads;

- strong vibrations in the steering column and body from the front wheels;

- pulling the car to the side at high speeds from the direct course;

- heavy steering control off-road;

- a clearly audible crunch when turning the wheel (audible even with the engine turned off, if the car is rolled by hand).

Even one of these signs is a reason to replace the front wheel bearing of Niva 21214. Complete destruction of the element at speed very often provokes the car to roll over. This is due to the short wheelbase of models 21213, 21214 and suspension features.

Without a special stand, diagnosing a front bearing problem is quite possible. The wheel hanging on the jack must be taken from both sides and rocked. A broken part will give significant play. Rolling and cracking sounds will also be heard. This is a clear reason for replacing the wheel bearing in Niva 21214 and 21213.

Installation

When the turning work is completed, we begin assembling the unit. Everything is simpler here - no adjustment is required, and the locknut is tightened “from the heart.” There is no need to worry about over-tightening the hub; it is almost impossible.

Stages of work:

- place the steering knuckle on a flat, hard surface;

- install the support washer and, using a head or steel pipe, carefully press the bearing into place;

- install the second support washer, then use the same tools to carefully hammer in the oil seal;

- repeat these works on the opposite side of the steering knuckle;

- put the steering knuckle on the hub and tighten the locknut to a torque of about 200 Nm or with moderate force;

- put on the wheel, rotate it and check the functionality of the bearing;

- We fasten the steering rack and ball joints.

During installation, installing an oil seal is not necessary, because the Iveco bearing is a closed type, dust and dirt do not penetrate there. However, to increase the service life of the unit, it is recommended to install at least the cheapest oil seals.

We carry out similar work on the opposite side of the car. After the installation is completed, we go and enjoy - now replacement may be required no earlier than after 100 thousand kilometers, and maybe later. The manufacturer provides the same warranty provided that the installation was carried out correctly.

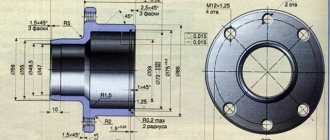

And finally, if you contact a turner, do not forget to take the drawings with you. They are presented below:

Hub: Steering knuckle: Support washer (2 pieces per side):

Replacing the front wheel bearing yourself

Replacing a Niva Chevrolet wheel bearing with your own hands will require an inspection hole or a lift. Let's look at how to change the front wheel bearing. You need to hang the front of the car to provide full access to the components. Further dismantling after removing the wheel occurs exclusively in strict sequence.

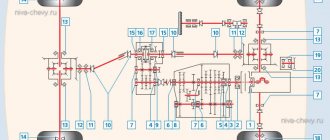

Front hub Niva 2121 diagram:

- Remove the guide block and caliper. Secure it with something under the bottom of the car so as not to completely dismantle the brake.

- We remove the boot.

- Remove the Niva Chevrolet wheel bearing nut and take out the cone bushing.

- Using a chisel, bend the locking nut of the front knuckle arm.

- Repeat the procedure on the rear fastener.

- Remove both nuts and the stopper plate (you will need a 19 mm wrench).

- Move the lever away from the knuckle and disconnect the brake hoses.

- Remove the fasteners and the entire fist.

- Disconnect the hub base (brake disc) from the knuckle.

Replacing the Niva front wheel hub bearing is the same as on the rear one

Reinforced, non-adjustable hubs

For Niva 4x4 you can find on sale reinforced, non-adjustable hubs with double-row bearings from the Iveco Daily truck. According to the manufacturer, this modernized unit has the following advantages over Nivovsky:

- there is no need to adjust (the bearing tightening is precisely set during its production);

- no need for regular lubrication;

- eliminates rotation of bearings on the hub;

- eliminates wear of bearing seats on the steering knuckle and hub;

- a ball bearing reduces friction in the hub assembly;

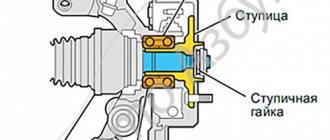

- The service life of the hub is increased due to thickening (see photo).

Instructions for installing steering knuckles with non-adjustable bearings are included. To download files you need to log in to the site. There is at least one drawback of such a modified Niva hub - high cost.

We remove the hub in the field:

- Pull out the oil seal using a screwdriver.

- Remove the lower ring, the inner sector of the outer bearing and the cage

- The wheel bearing itself is removed

- Unfolding the hub

- Repeat the procedure with the second bearing.

- The outer ring of the second element is removed in a similar way.

Next, the destroyed element is removed and the used lubricant is completely removed.

The cavity for the new part is treated with a new compound and lubricated with a good layer. We coat the bearing itself, coat the internal places.

Then we install the hub bearing on the Niva in the reverse order.

To press in parts, it is worth choosing a pipe section of suitable diameter. Replacement of the Niva Chevrolet wheel bearing is completed.

Advantages of iveco non-adjustable bearings

The new modification of 2123 hubs for the installation of non-adjustable bearings is gaining popularity - it is convenient and practical, and if you have certain skills, you can do all the work yourself.

The advantages of installing Iveco parts are obvious:

- long service life - about 100 thousand kilometers;

- the units can withstand high loads, which are three times higher than those of factory bearings;

- You can install wheels with a large offset on the car;

- the bearing does not need adjustment and does not require maintenance during the entire period of operation;

- you can do the alteration yourself.

If you decide to remake, immediately check the brake disc, CV joints and side seals of the front gearbox. When replacing them, you will have to disassemble the hubs again and press in bearings, which will become unusable.

Bearing adjustment

Adjusting the wheel bearing involves rocking the wheel.

The wheel plays on a bearing. We don’t pull it too hard, if there is a small elevator, we pull it further until the elevator disappears.

Afterwards we punch the wheel with a sledgehammer, or you can take it for a ride in a car. After which the elevator appears again, we remove it in the same way. There is a small elevator left. Let's remove the nut and put everything back as it was. We rode for a day and are adjusting again.

Installation of double-row roller bearings from the IVEKO Daily truck into the front hubs of Niva 21213

Wheel unit VAZ 21(21,213,214,218,30…)

one of, I’m not afraid of this word, the most colorful, in terms of purely Russian (obscene) words addressed to him by Nivavodov, an engineering sophistication, and today the managerial stupidity of AvtoTAZ is completely archaic.

When assembling, to adjust the clearance in the bearing according to the book, you need to: “...Install a new adjusting nut. We tighten it to a torque of 19.6 N.m (2.0 kgf.m), simultaneously turning the hub in both directions. Loosen the adjusting nut and tighten it again to a torque of 6.86 N.m (0.7 kgf.m). Then loosen the nut 20–25o. We check the clearance in the bearings: it should be in the range of 0.02–0.08 mm. We lock the nut by pressing its collar into the grooves of the shank of the outer drive joint...” It would be fine if I did it once and forgot, but the need for adjustment often arises, especially if you drive on bad roads. And if you miss the moment a little, the hub will begin to rotate in the inner race of the bearing, and that’s it - the play can no longer be eliminated by simply tightening the nut and I ran to the shops to buy bearings (2 pieces for 250 rubles each), a new hub (750-1000 rubles), and the sellers Thanks to AvtoTAZ engineers, meanwhile, they are happily rubbing their hands.

Size and characteristics.

A distinctive characteristic of these products is their increased load-carrying capacity, which affects the duration between replacements.

Table of sizes and characteristics.

| Bearing | Inner diameter (mm) | External diameter (mm) | Width (mm) | Weight (kg) | Load capacity (Kn) | |

| Dean. | Stat. | |||||

| 7804 | 19,05 | 45,25 | 15,494 | 0,13 | 27,5 | 27,5 |

| 7805 | 26 | 57,15 | 17,462 | 0,22 | 37,8 | 42,8 |

| 256907 | 34 | 64 | 37 | 0,44 | 31,5 | 27,9 |

| 256706 | 30 | 60 | 37 | 0,4 | 30,1 | 25,9 |

| 7700432405 | 37 | 72 | 37 | 0,62 | — | — |

| 8450030826 | 25 | 55 | 43 | 0,5 | — | — |

| 2007108 | 40 | 68 | 19 | 0,27 | 40 | 28,4 |

| 180508 | 40 | 80 | 23 | 0,45 | 30,7 | 19 |

Manufacturers.

Domestic manufacturers:

- SPZ-Group

- LADA

- VBF

- Volzhsky standard

Foreign manufacturers:

- SNR (NTN)

- SKF

- INA

- NSK

- KOYO

- Timken

When choosing a quality product, it is better to buy from manufacturers of foreign brands. Domestic brands have a low price and are more widespread on the market than their foreign counterparts.

When replacing a product, it is extremely important to use high quality replacement parts. Low quality aftermarket products may not be sufficiently suitable for the application, causing end play problems. This can cause drivability problems that lead to costly returns. It is recommended to purchase only from official dealers or directly from the manufacturer.