The problem with standard Niva wheel bearings (VAZ 2121, 2131) is that they need to be constantly adjusted during vehicle operation. If this is not done in time, they will fail, creating a howl or hum when moving. You can save yourself from such problems by installing non-adjustable hubs or double-row bearings.

Reinforced, non-adjustable hubs

For Niva 4x4 you can find on sale reinforced, non-adjustable hubs with double-row bearings from the Iveco Daily truck. According to the manufacturer, this modernized unit has the following advantages over Nivovsky:

- there is no need to adjust (the bearing tightening is precisely set during its production);

- no need for regular lubrication;

- eliminates rotation of bearings on the hub;

- eliminates wear of bearing seats on the steering knuckle and hub;

- a ball bearing reduces friction in the hub assembly;

- The service life of the hub is increased due to thickening (see photo).

Instructions for installing steering knuckles with non-adjustable bearings are included. To download files you need to log in to the site. There is at least one drawback of such a modified Niva hub - high cost.

Algorithm of actions

Ever since designs with double-row bearings appeared, everything has gone wild. Let's put everything in a row. I know of about 5 different designs, and perhaps only one does not cause serious complaints about its performance. Now a specific algorithm of actions. If you are lucky and your standard unit has traveled more than 20-30 thousand km, the car has a roll and only needed tension adjustment, then you have coaxially bored knuckles. Install good Russian or German bearings and good hubs as needed and ride on, happily ever after. The most important and important thing is that the Niva wheel bearing must have a steel cage. If you are unlucky and the wheel bearings are “consumables”, or regardless of replacement, the car does not roll forward - you have misaligned knuckles and then it is better to think about other designs, since you have nothing to lose. about the option with a wheel bearing from an IVEKO truck .

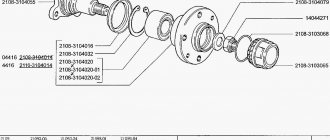

Converting the hub to a double-row bearing

Do you want to modify your Niva, but have a small budget? Then we’ll show you how to remake the front hubs on a Niva with your own hands. Required:

- double-row bearing from Moskvich 2141 (catalog number: 2141-3103020), or an analogue from Craft (article: CR4172370);

- two retaining rings from the same vehicle (part number 366553-15).

We take the drawings and seek the services of a turner. The master must bore the hub to fit new bearings, grind the steering knuckles and make parts according to the diagram. By the way, some Niva 4x4 owners also use an AUDI 74x40x74 wheel bearing, in this case only the steering knuckles are ground.

After the parts are manufactured, all that remains is to press in the double-row bearing and reassemble the already non-adjustable hubs. At the end of the work, tighten the hub nut with a large torque “from the heart”. Their adjustment is no longer required, you can forget about the hum and howl while driving!

Have you ever encountered a similar modification to the Niva hub? Leave recommendations and reviews about your options for upgrading the VAZ 2121, 2131. Let us remind you that the domestic SUV has other shortcomings, which are also eliminated by modifications. You can also find information about the car you are interested in by its content.

Where can I buy

: in our online store (4x4 hubs, Niva hubs).

Keywords: 4x4 front suspension | Niva front suspension

0 0 0 0 0 0

Share on social networks:

Russian variant

These bearings can be found in several versions. The most important thing is to find series A. What is it? This is a series with increased load capacity. Don't be afraid of these words. It’s just that in ordinary bearings for cars, the rollers in the cage are installed one after another, but in this series (industrial), “roller to roller”. That is, there is virtually no distance between them. There are two good options on the market. The first option is 15-gauge bearings, and you can still find them in the Soviet version on the market. This will be visible by the markings on the bearings. The second option is EPK (European Bearing Corporation) bearings.

hub assembly repair kit, EPK bearings

Signs of malfunction and wear of the rear axle bearing of Niva Chevrolet

As was said at the beginning of the article, radial and axial loads are concentrated on the axle bearing of the rear axle of the Niva Chevrolet. Since the ball bearing itself is radial, this means that axial loads should be minimal or absent, but they appear if there is play in the inner race along the seating surface. Play also appears inside the bearing itself when the raceway, balls, and cage wear out.

Other causes of failure: – Wear and leakage of the oil seal; – Ingress of dirt and moisture; – Shaft runout; – Movement of the locking (locking) faceplate along the shaft journal, resulting in play at the bearing; – Shaft imbalance.

Installation and Lubrication

Probably one of the most important points in this knot. A lot of Nivovodsk people complain that Papuan services do not know anything other than lithol and grease. There are currently a lot of bearing lubricants in the world, compared to which the old generation lubricants are as old as mammoth poop. In lubricants, as in motor oils, there is the concept of a base oil, or sometimes the formulation is found, an oil carrier. For a popular science story, we can talk about mineral and semi-synthetic lubricants. A number of mineral lubricants, when the temperature reaches 40-50 degrees, simply flow, almost like water. And at a temperature of -20 degrees they rise almost like a stake. If this lubricant is included in the hub assembly and axle shaft bearings, there is no need to talk about the car rolling over. To lubricate the bearings of axle shafts and hubs, I recommend Total Ceran XM 220 lubricant. The characteristics even exceed the requirements for our hub unit. I sent it to services that work with motorcycles and quads, as well as trucks. This lubricant has only one drawback: its availability. All so-called “dealers and distributors” import and certify only consumer goods in Russia. That is, a product that sells well. And special products are not profitable. My colleagues and I have to do this ourselves, through Finka. If everything is really bad with the lubricant, you can use S2A.

Total Ceran XM 220 grease

Other options

Of course, besides these manufacturers, there are a lot of others, but I don’t experiment with clients. For a long time we worked with LHA bearings (Slovakia). The quality was a solid four. The bearings were in “blackened housings”. I won’t say what kind of coating it is, but the mileage was very good. As happens quite often in this life, the price of “Slovaks” began to slowly rise. I won’t say who is to blame, but as soon as they became comparable to EPK bearings, there was absolutely no point in working with them.

A very large number of wheel bearings with a plastic cage have appeared on sale. Manufacturers and sellers talk about reduced noise of the unit. But they are silent about the humiliatingly small service life of these bearings. Many times they disassembled the fist, the plastic separator was not even found, sometimes it grinds into dust. Be careful.

Summary. Installation of bearings only with a steel cage. It is highly desirable that the bearings have increased load capacity, series A. Proper installation and use of good lubrication. Periodic adjustment of the unit. It is enough to do this during an oil change. That is, once every 7 thousand km.

FakeHeader

Comments 43

Tell me, do your hubs themselves have 22 splines?

Yesterday I did the same. The hubs are from MVN and the fists are machined according to the same pattern with the rest. Slippers 32″ =). What’s interesting is that the original bearings ran on these 29″ wheels and the original factory hubs for almost 60k km. I adjusted it from time to time. Then I went to change the CV joints and saw a chipped inner race, well, I thought it was time to change it. Changed it to normal VBF. Since then I change it every three months =). The problem seems to be in the hub-inner race pair. At the factory, apparently mountains of hubs and bearings and on the conveyor allow a certain gap between them, the rest is rejected for spare parts =). In theory, if the hub has not yet died from wear, you take it and go to the store and start fitting the inner races until you find a normal fit. Who will let me do this? Well, as for the original wheels, everything said above is offset by the +58 offset and the original wheel diameter. If you have a 0 offset and a 32″ shoe, even a small gap with a sharp impact on the wheel easily breaks the rollers and inner race. Which is exactly what happened just two days ago. I got tired of all this and went to redo it the normal way. After installation, the looseness really disappears and the steering becomes clearer. There is no strained hum, now you can hear the whole transmission working hard =) We wax for 29″ + must-have slippers, or go and pick up the gaps on the soles.