A timing belt is a rubber part with notches on the inside that connects the crankshaft and camshaft to ensure vehicle movement. The responsible owner of a Lada Vesta, who has driven more than 50 thousand km, had to replace the timing belt at least once - so as not to find out prematurely whether the valves are bending.

Unfortunately, on the VAZ this ailment is transmitted from engine to engine, they cannot work on it in any way and the valves are bent due to the assembly: belt, pump, rollers.

This unit is vulnerable and the valve will bend if one of these parts fails. The situation would have changed, or not, the problem would have gone away completely - install the AvtoVAZ pump separately, but alas, the pump is in one unit on all VAZ engines.

If the hr16de engine had entered the series, then this ailment would also be absent, you would only need to undergo maintenance on time, monitor the chain, and yes, valve adjustment, VAZ engines would again come into use.

After a significant mileage of the car or improper operation, the timing belt often breaks. Oil getting on the surface, untimely replacement of components, use of the car in severe frosts or, conversely, in sultry heat - this can damage the gas distribution mechanism drive.

Damage can be detected during maintenance of the Lada Vesta. Maintenance consists of inspecting the condition of the unit from time to time.

A rather significant problem for owners of Vestas with 16 valve engines in the event of a break is valve bending. This happens after the timing belt breaks or the links are stretched. When the links are stretched, the crankshaft continues to work, but the camshaft abruptly stops its movement. Next, the car engine stops completely. If you start it again, you can cause failure of the pistons, which will cause expensive repairs to the piston group of the cylinder block.

Read the article and your engine will be safe - you will replace the belt and rollers on time, preventing unexpected breakdowns.

Part numbers

Since the engines installed in the piston bottom do not have grooves for the valves to prevent them from bending when the belt breaks, there is no need to save on this consumable. It is preferable to install an original belt or a replacement from Contitech and Gates.

Original

In the spare parts catalog of JSC AvtoVAZ, the required spare parts are indicated by the following numbers:

- 2108-01006040-82 for engine 11189;

- 8201069699 for engines 21129 and 21179.

The minimum price on exist.ru is 360 and 2500 rubles, respectively.

Substitutes

| Manufacturer | vendor code | Minimum price on exist.ru, rub. |

| For 2108-01006040-82 | ||

| Bosch | 1 987 949 095 | 340 |

| Contitech | CT-527 | 330 |

| Dayco | 94738 | 410 |

| For 8201069699 | ||

| Contitech | CT-1179 | 1050 |

| Dayco | 94847 | 930 |

| Gates | 5671 XS | 1800 |

| Npa | NP511-01622 | 450 |

| Renault | 8201069699 | 1700 |

AVTOVAZ recommendations

It is immediately worth noting that on the official LADA website in the maintenance calculator (it is only up to 90 thousand km) nothing is said about replacing the timing belt and rollers. However, information about this is in the service book of some LADA models.

Lada Priora:

No information available.

Lada Granta, Kalina:

- The 2015 service book indicated that for the 8-valve engine, replacement is provided at a mileage of 75,000 km.

- The 2022 service book states that the timing belt, tensioner and support roller (if equipped) should be replaced at a mileage of 180 thousand km.

- From June 2022, the timing belt must be replaced at 90,000 km.

Lada Largus:

- Engine Renault K4M (1.6 16V). The timing belt and rollers should be replaced at 120 thousand km or 6 years.

- Engine VAZ 11189 (1.6 8V). The timing belt and rollers should be replaced at 160 thousand km or 8 years. It is noteworthy that the Lada Vesta service book (until 2022) indicated that on the VAZ-11189 engine, replacement is provided at a mileage of 180,000 km (until 06.2021) or 90,000 km (from 06.2021).

Lada Vesta, XRAY

:

- Engine VAZ-21129 (1.6l., 16kl.). The timing belt along with the rollers should be replaced at a mileage of 180,000 km (until 06/2021) or 90,000 km (from 06/2021).

- Engine VAZ-21179 (1.8l., 16kl.). The timing belt along with the rollers should be replaced at a mileage of 180,000 km (until 06/2021) or 90,000 km (from 06/2021).

Conclusion

:

- AVTOVAZ periodically changes the regulations for replacing timing belts and rollers.

- From June 2022, according to the regulations, the timing belt must be replaced at a mileage of 90,000 km.

Replacing the timing belt on Vesta with engine 11189 (1.6 liters, 8 valves)

The procedure is as follows:

- Place the car on the inspection hole and raise the parking brake lever. Loosen the nuts on the right front wheel.

- Remove the decorative engine cover.

- Raise the car on a jack, install a stand and remove the jack.

- Remove the wheel.

- Remove the gas distribution mechanism cover by unscrewing 3 bolts with a 10mm head.

- Loosen the bolt securing the generator to the bracket on the cylinder block, move it towards the block and remove the generator belt.

- Align the marks on the camshaft pulley and the cylinder head by rotating the crankshaft clockwise with the head “17”. To make rotation easier, it is recommended to unscrew the spark plugs.

- Lock the crankshaft by inserting a screwdriver into the flywheel teeth through the starter hole. To remove the starter, you need to disconnect the power wire by unscrewing the nut with a “13” head and unscrew the 3 mounting bolts with a Torx E10 head.

- Unscrew the bolt from the crankshaft using a 17mm socket with an extension from a hollow tube and remove the generator pulley and the washer underneath it.

- Loosen the nut securing the tension roller by half a turn with the socket “15”.

- Remove the belt.

- Install the new part by sliding the left leg onto the water pump pulley and roller, and then onto the camshaft pulley.

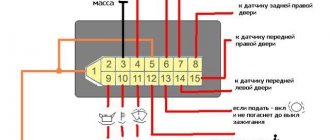

- Insert pliers into the grooves on the tension roller and turn it until the 2 rectangular marks coincide and tighten the nut with the head “15”.

- Check for correct installation by turning the crankshaft 2 turns. If the marks on the pulleys and the engine do not match, reinstall the belt. Otherwise, install all the removed parts back.

Analogue belt brands

If we talk about the best brands, then Gates, Contitech, Dayco and Bosch are the most promising in the segment and enjoy decent popularity.

Drivers trust spare parts from the Belgian company Gates, whose manufacturers supply their products to car factories.

An analogue of Geitz is the German company Contitech; its parts are also used during vehicle assembly.

When choosing timing belts, you should choose the original, which may be more expensive in price, but will last a long time. We wish you that your timing belt never breaks and is serviced on time!

Replacing the timing belt on Vesta with engine 21129 (1.6 liters, 16 valves)

- The procedure is as follows:

- Follow steps No. 1-4 from the previous method.

- Remove the right engine mount:

- Remove the engine splash guard (protection) by unscrewing 13 bolts with a 10mm head.

- Place a jack under the oil pan and lift the engine.

- Using a 16mm head, unscrew the 2 bolts securing the support to the body.

- Lower the right side of the engine until the support is below the lower edge of the side member.

- Unscrew the 2 bolts securing the support to the engine using a Torx E12 head and remove it.

- Unscrew the 5 bolts from the upper cover of the gas distribution mechanism with a hexagon and remove it.

- Unscrew 10 screws using a T20 Torx bit and use a screwdriver to pull out the fasteners securing the right fender liner to the body and remove it.

- Remove the accessory belt:

- Use a slotted screwdriver to pry up the plug on the tension roller.

- Using a 13mm head, loosen the nut on the roller

- Insert the T55 bit into the groove on the roller. Turn the part clockwise, loosening the tension, and remove the belt.

- Turn the crankshaft with the head “17” until the marks on the camshaft pulleys (convex points) coincide with the marks on the cylinder head cover (triangular slots in the plate).

- Follow step No. 8, 9 from the previous method

- Unscrew the 3 screws using a hexagon that secure the lower timing case cover to the cylinder block.

- Follow steps No. 10, 11 from the previous method.

- Place the right branch of the new part on the crankshaft pulley, the intake camshaft (right), and the exhaust camshaft (left), one by one.

- While holding the right arm taut, place the belt over the water pump pulley and tensioner pulley.

- Follow steps No. 13 and 14 from the previous method.

Lada Vesta: When to change the timing belt, frequency and cost of repairs.

The vehicle's registration certificate provides for replacement of the unit after 180 thousand kilometers.

In practice, it is advisable to change the drive more often - after 80-100 thousand km, because the part does not always correspond to the original production.

The cost of replacement will be calculated taking into account the work of specialists and the cost of the part. Usually the cost of work is 3000-5000 rubles, and the price of the part depends on the manufacturer.

So, the average price:

- CT 1179 (CONTITECH) - from 1000 rubles;

- 5671 XS (Gates) — 3890 RUR;

- GATES K015631XS 16 class — 3890 RUR;

- Bosch 1987949686 (Bosch) - 1360 rub.

- Trialli GD770 - 2900;

- Lynxauto PK1300 - 2430 rubles per set.

Replacing the timing belt Lada Vesta SV Cross - progress of work

1. First of all, you need to put the car on the handbrake and remove the negative terminal of the battery.

3. Place the car on a jack and remove the front right wheel. 4. Then we dismantle the front right fender liner. 5. Remove the Lada Vesta generator belt.

6. Use a 17″ wrench to turn the crankshaft pulley mounting bolt so that the upper marks of the camshafts coincide with the recesses on the plastic timing case.

7. Using a 17″ wrench, unscrew the crankshaft pulley bolt. We remove the crankshaft pulley and the limit washer from it. 8. Using a 5″ hexagon, unscrew the remaining lower part of the timing belt casing. In total, you need to unscrew three bolts - 3 on top and 2 on the bottom.

9. Using a 15″ wrench, loosen the bolt securing the tension roller. 10. Remove the belt and completely unscrew both rollers - tension and bypass. 11. Install new rollers in place of the old ones. The deflection roller can be tightened, the tension roller can only be tightened slightly. 12. Install a new belt in place of the old one. Let's make sure once again that the tags are installed correctly. The new belt is first put on the camshaft, then stretched to the crankshaft gear with a tensioner and put on the far camshaft (exhaust valves). 13. Use a snap ring puller to turn the tension roller until the marks align and pull the roller through with a wrench.

14. Make two revolutions of the crankshaft to make sure that the marks are not lost. If everything is in place, then we put the disassembled parts back together. And we check the operation of the engine.

Korean-made coolant pump for VAZ-21179 engine

The owner of any elderly foreign car with a timing belt will confirm that repairmen insist that during a scheduled belt change, they replace both the pump and the pressure rollers with bearing assemblies. And these parts are often sold as a set. Moreover, at a discount - the whole set is cheaper than the belt, rollers, and pump separately.

I don’t want to once again convince you that the stingy pays twice, but over the years I have come to the conclusion that Western manufacturers include in the regulations changing the belt not because of the belt as such, but because of the pump and tensioner bearings. They just needed a reason to reliably replace the entire set of parts associated with the camshaft drive, and they found it.

Real indicators based on reviews from car owners

The standard 1.6-liter engine is paired with a 5-speed manual transmission and a robot. The quality of the transmission as a whole does not cause any complaints from owners. Also, drivers often wonder what kind of gasoline is best to fill in the Lada Vesta? The manufacturer recommends refueling only with 95-octane gasoline; this information can be found in the vehicle documentation. This is important to take into account, because the nominal resource was determined taking into account many indicators, in particular, taking into account the octane number of the fuel.

Motor 1.6

- Egor, Moscow. I've been driving Vesta since 2016, 1.6 engine, current mileage is 25 thousand km. When buying a domestic car, I was, of course, interested in the resource of the main power unit. The dealership assured that Vesta can cover more than 200 thousand km without problems. So far I have not had any problems with any breakdowns. I change the oil on time and fill up with AI-95 gasoline. A friend’s VAZ-2109 has driven about 400 thousand, so I think that the lifespan of the car depends on the owner himself.

- Maxim, Rostov. I purchased a Lada Vesta 1.6 in 2015 and have already covered about 50 thousand km. In my opinion, it turned out to be a great car. AvtoVAZ has really reached a new level, producing cars of European level. The engine runs like a clock, I use Lukoil Lux 5W40 oil. I think that the real life of the engine before major overhaul is about 250 thousand.

- Gennady, Voronezh. Before switching to Lada Vesta, I spent a lot of time driving a VAZ-21099. I spent 200 thousand and then carried out the first major overhaul. I have no doubts about the quality of our engines. On the same KIA Rio, the manufacturer assured the same mileage as on the Vesta. I’m almost sure that our car is in no way inferior to the “Korean” in terms of power unit reliability.

The service life of the VAZ-21129 engine is about 200-250 thousand km, after which further operation of the power unit is possible only if the driver devotes the proper amount of time to the car, undergoes scheduled maintenance, and carries out timely replacement of engine oil and air filters.

Motor 1.8

- Yuri, Ekaterinburg. I've been driving a Lada Vesta 1.8 for two years now. What can I say about the car, I don’t particularly like the interior, they could have done better, but the build quality of the engine is at an acceptable level. It works quieter than the “Korean” one; the robot sometimes “thinks” for too long, but not critically. Generally speaking, for two years the car has not caused me any trouble. There is no doubt about the resource that over 200,000 km. I myself saw the “nine”, which traveled more than 400,000 km.

- Stanislav, Astrakhan. I try not to turn the engine over 3000 rpm, I drive calmly. Driving the West I relax and have fun. A revolutionary domestic car, nothing less. It remains to live until the overhaul. After 20,000 miles, I changed the oil and filled it with Lukoil, which AvtoVAZ recommends. 200,000 will pass without any problems, there’s no doubt about it. Those who have problems with domestic engines need to devote more time to their car.

- Maxim, Moscow. I have already covered 12,000 km on a 2016 Lada Vesta 1.8. At the turn of the first thousand mileage, the “Check Engine” light came on, I went to the service center, they looked at it, and they said there was a problem with the ignition system. It turned out later that he had filled up with low-quality gasoline. Now I try to fill only AI-95. Although this engine is “friendly” with the 92, I don’t want to take any more risks. In general, the car is worthy of its money, it will last 200,000 km, and then we’ll see.

The manufacturer has assured the resource for this power unit to be 200,000 km, but in reality it can last much longer. The service life depends on the quality of the fuel and engine oil used.

In the fall of 2015, the Lad family of passenger cars was replenished with a top model - the Vesta car, produced in a sedan body. When asking the question “do the valves bend on the Lada Vesta,” you need to clearly imagine what kind of engine we are talking about: a 1.6-liter Russian or Nissan, or maybe the latest VAZ development with the name “21179”.

Here we consider options related to cars currently being produced or those that will begin to be produced in the near future. An 8-valve engine was also developed for Vesta - it definitely does not bend the valves and will definitely not be installed on top-end sedans in 2016.

Read more about the engines equipped with the Lada Vesta line in the material: !

ICE VAZ-21129, 106 “hp” (valve bending)

Under the hood of the 106-horsepower Lada Vesta

A little history. Motor 21129 is a modified version of another engine, namely 21127. The last of them, when the timing belt broke, successfully bent its valves, although grooves were made on the pistons (Fig. 1). The point is that the depth of the grooves was not sufficient: if certain conditions were met, the valve “met” the piston with all the ensuing consequences.

With the transition to a new generation of internal combustion engines, that is, 21129, the design of the pistons was modified. But the external shape has not changed much, and although the recesses remain, their depth is still insufficient.

Here we considered the question of whether the Lada Vesta valves with the “21129” engine are bent. And the answer was clear: yes, oppression.

In theory, the problem with valve bending is typical for all VAZ engines equipped with 4 valves per cylinder. Each new 16-valve engine “inherits” it. The exception is one rarity - the VAZ-2112 internal combustion engine, the volume of which is 1.6 liters.

There, the recesses are made conscientiously (Fig. 2).

122-horsepower engine “21179” (valve bending)

In terms of its design, the internal combustion engine of the VAZ-21179 is not very different from its predecessors. The working volume was increased to 1774 ml, which was achieved by changing the piston stroke length: it was 75.6 mm, it became 84.0 mm.

Elements of the connecting rod and piston group

The piston itself is now better fitted to the cylinder than in engines 21127 and 21129. The distance from the piston pin to the piston bottom has increased by 1.3 mm - to 26.7 mm.

But deeper grooves in the bottom never appeared. The timing mechanism still drives the belt, and if it breaks, the possibility of bending the valves has not been canceled.

Now we know whether the valves bend on a Lada Vesta with a 1.8-liter engine. The answer will be the same as for all 16-valve VAZ internal combustion engines (with the exception of 2112). The problem with the transition to a new generation remains the same. But VAZ does not intend to return to “heavy” pistons.

The timing drive on 21179 engines is equipped with not one, but two tension rollers. What was done to make the design less susceptible to timing belt stretching.

It says here: the number of tension rollers is two

One of the automatic tensioners may jam, but then its function will be taken over by the second automatic roller.

Pistons that do not bend valves

Piston kits for some “old” 16-valve engines are produced by third-party companies. These parts are equipped with deep recesses. The point is that the piston does not reach the plates and cannot bend the valves.

Tuning piston for internal combustion engines 21126-21127

ShPG elements of different engines (21127, 21129, 21179) are compatible. But there is no need to install pistons from “old engines” into the Vesta engine:

- In ICE 21129, after such “tuning”, friction losses will increase;

- If pistons from the 26th or 27th engine are installed in the ICE 21179, the working volume will immediately change.

The “29th”, as well as the “79th” Lada Vesta engine bends valves only with “VAZ” pistons. But after installing a “tuning” part, do not expect an increase in power. Also, by using non-standard elements, you can greatly reduce the resource (lose the warranty, get unforeseen consequences).

Nissan HR16DE engine (does not bend, there is a chain)

HR16DE engine disassembled

There are no “deep recesses” provided here. Now let's pay attention to how the timing drive mechanism works.

Nothing but gears and chains

There is no toothed belt here - it is replaced by a chain. It is difficult to imagine the following two situations:

- The chain could have jumped over the teeth of one or more gears;

- One of the elements was damaged so badly that the presence of damage led to rupture.

As long as the chain remains intact, the valves and pistons cannot meet each other, no matter what happens to the engine. The only bad thing is that the chain may jam.

Do the valves of a Lada Vesta with a Nissan internal combustion engine bend? The answer “no” would be wrong - a circuit break is not excluded. But in reality it will be almost impossible to face such a situation. Let's look at why.

Refueling volumes

As mentioned above, three different engines were installed on the Lada Vesta - 11189, 21129 and HR16DE-H4M. It was also equipped with different gearboxes - 2180, 2182 and JHQ. Based on this, some Vesta filling containers have different volumes, while others are the same for everyone.

| Nominal filling volumes of Lada Vesta | |

| Capacities | Volumes (l.) |

| Engine lubrication system (including oil filter): 11189/21129 (stamped oil sump) 11189/21129 (cast oil sump) HR16DE-H4M | 3,2 (2,9) 4,4 (4,1) 4 |

| Cooling and heating system*: 11189/21129 HR16DE-H4М | 5,95 7,0 |

| Gearbox: Gearbox 2180/2182 JHQ | 2,25 3,34 |

| Hydraulic clutch and brake system | 0,559 |

| Hydraulic brake system (for cars with AMT) | 0,517 |

| Washer reservoir | 4,7 |

| Expansion tank (for cars with 21129 | 5.75 (max) 5.35 (min) |

| Air conditioning system (freon R134 “A”) | 0,475 (± 20) |

*A mixture of coolants of different brands should not be allowed.

In the same repair and maintenance manual for Lada West there are also the following volumes of coolant for the engine cooling system:

- for 11189/21129 with pre-heater - 9.3 l., without heating - 8.7 l.;

- for HR16DE-H4M with pre-heater – 7.6 l., without heating – 7.0 l.

Four Well-Known Facts

The service life of the timing chain always exceeds the service life of the engine. This is the first fact, but a condition must be met: the oil change must be timely. In general, the circuit fails gradually, and this is accompanied by symptoms:

- Audible sounds (chirping) at idle speed;

- When the “problem area” passes, a phase shift may be observed.

The last defect is detected using computer diagnostics.

From the appearance of any symptom to the complete rupture of the chain, a certain time passes. And in general, a “defective circuit” can work for a long time. This was another, fourth fact.

What is the service life of factory timing components?

The components of the timing belt set for twin-shaft Lada Vesta engines are considered to be idler and tension rollers. They are replaced at the same time as the belt at 180 thousand, but many experts recommend cutting this period in half.

However, the belt also passes through the pump gear. Its durability is considered the same as that of other components of the unit.

TZA produces pumps in two versions: Standard and PowerFull LUX. The first goes to the assembly line, but there are cases of failures at 30-50 thousand mileage. The second is improved in quality and performance. Has a larger bearing.

Timing belt resource (Page 1 of 2)

Here in the video about the timing belt they said that it runs for about 180 thousand km, and that there is not a word about it in the service book - strange. . Owners, you can confirm (ask your personal manager) - this seems abnormal.

Everything in the service book is written:

2 Reply from Patriot 2016-01-19 03:00:34

- From: Irkutsk region.

- Messages: 3,156: 443

Re: Timing belt life

vaako , Don't trust her, she will deceive you

3 Reply from vaako 2016-01-19 09:05:58

- From: Sevastopol

- Messages: 96: 31

Re: Timing belt life

vaako , Don't trust her, she will deceive you

Yes, there was simply a statement that nothing was written in the service book, but it turns out that this is not so. But I can’t pretend to say whether what is written in it is true or not.

4 Reply from Dmitriy.Kazantsev 2016-01-19 10:43:51

- From: Bashkortostan

- Messages: 135: 51

Re: Timing belt life

And the numbers are not even bad.

5 Reply from Abrams 2016-01-19 15:47:24

- Messages: 598: 120

Re: Timing belt life

The chain probably doesn't run that long anymore.

6 Reply from Dmitriy.Kazantsev 2016-01-19 16:13:06

- From: Bashkortostan

- Messages: 135: 51

Re: Timing belt life

On my previous car I drove 50,000 miles in four years. God willing, I’ll get by without a replacement if these numbers remain!

7 Reply from Filka_Luzer 2016-01-19 16:15:34

- Messages: 171: 23

Re: Timing belt life

I think the numbers were mixed up with the Nissan engine, it just has a chain. Belts have never lasted that long.

8 Reply from Dmitriy.Kazantsev 2016-01-20 07:10:45

- From: Bashkortostan

- Messages: 135: 51

Re: Timing belt life

I think the numbers were mixed up with the Nissan engine, it just has a chain. Belts have never lasted that long.

I can’t say anything about VAZ. Owned an Aveo. 101 hp, timing belt replacement at mileage 130,000. And this is according to the regulations

9 Reply from lada 2016-01-20 13:36:42

- From: Moscow

- Messages: 1,284: 268

Re: Timing belt life

The chain probably doesn't run that long anymore.

The chain moves differently, the more powerful the engine, the more often you will need to change it. The latest generation of engine in the Audi averages 60 thousand and is greatly stretched despite the fact that it is far from single-row and not made of plastic.

10 Reply from Bobik 2016-01-20 13:51:02

- Messages: 109: 14

Re: Timing belt life

On a UAZ Patriot, the chain could even break after several thousand kilometers.

11 Reply from Axel 2016-01-28 06:18:02

- Messages: 973: 139

How much does it cost and what timing belt to put on Vesta

Replacement belts: the original belt from production catalog number 21126100604000 will cost 2,200 rubles. A number of timing belts are available for equivalent replacement from foreign manufacturers: Gates 5631XS; Bosch 1987949662; Finwhale BD137. The price ranges from 1100 to 1300 rubles.

Also, during the replacement process, you will need to replace the timing tensioner pulley, the original Lada production code is 21126100623800. It costs 1900 rubles. And the bypass one - 211261006135 will cost 1250 rubles.

In order to save money, it is better to immediately buy set 21126100604086 (set from Gates K015631XS), there are two rollers (bypass, tensioner and the timing belt itself). We also note that the procedure for replacing the belt is combined with replacing the pump, so you also cannot do without purchasing a water pump 21126130701082.

Prices are valid for autumn 2017 for Moscow and the region.

How is the timing belt changed without the help of specialists?

It is worth thoroughly preparing for the operation. Ideally, an electro-hydraulic two-post lift of the P-3.2G type is suitable, but you can get by with an overpass or inspection hole. First of all, collect the necessary set of tools:

- Traverse.

- The key is "17".

- Hex wrench "5".

- Driver and set of Torx sockets.

- Set of sockets and open-end wrenches.

- Extension for wrench and set of slotted screwdrivers.

- Device 67.7811-9516 or 67.7811-9704 for fixing camshafts.

- Lock ring pliers or special wrench type 67.7812.9573-01.

Preparatory activities

Having placed the car on the lift, we are in no hurry to lift it. First, set the parking brake handle to the upper position, and then remove the negative terminal from the battery. Before replacing the timing belt on a Lada Vesta car, it is necessary to raise the car and dismantle the alternator belt drive and remove the starter.

To do this, you will have to remove the wheel and the mudguard in the wheel arch. The remaining operations are performed according to the following scheme:

- Use a screwdriver to stop the engine flywheel from turning by inserting it into the hole in the starter.

- Using a 17mm socket, unscrew the crankshaft damper mounting bolt.

- Remove the damper and washer, and then screw the bolt into place.

- Remove the screwdriver that was inserted into the starter hole to prevent the flywheel from rotating.

- Lower the lift.

By the way, after the repair it would be wise to treat the body with Movil , since the matter is related to the lift. The preparatory part of the process is not limited to the listed actions. For subsequent manipulations, you will need a special device - a traverse, with which we will lift the right side of the engine:

- Install the crossbar (No. 1) on the vehicle.

- Thread the hook (No. 2) into the eye (No. 3).

- Raise the right side of the unit.

- To simplify the subsequent installation of the right engine mount, it is recommended to outline its contours with a marker.

- Using a Torx E12 socket, unscrew the two bolts securing the right power unit support. Using a 16mm socket, unscrew two more mounting bolts.

- Using a 5mm hexagon, unscrew the five bolts on the top and three bolts on the bottom protective covers of the drive and remove them.

“Resource” Lada Vesta and Lada XRAY: we answer readers’ questions. Part three

In our special section dedicated to resource tests of Vesta and Xray, Autoreview readers leave their questions about two new AvtoVAZ products. We continue to answer some of them.

Tell me, please, does your Xray also accumulate water in the doors after rain or washing? This is a problem in my car.

AR: No, we haven’t seen anything like that. There are only comments about the door seals: the thresholds are wet and dirty in wet weather, and dusty in dry weather.

I would like to know about Vesta’s air conditioner: how it behaves, whether it cools enough in the heat of +30 degrees, whether it stalls the engine in urban conditions and on the highway.

AR: Cools enough. For example, in the heat of over +30 degrees, the car stood for more than half an hour in the sun (the outside temperature sensor showed +51 degrees!), and the air conditioning system did an excellent job.

Bukreev Oleg Sergeevich

I am the owner of a Lada Vesta car. When you start the car in the morning and start driving at low speed, you hear a distinct crackling sound lasting about two seconds. I tried for a long time to find the source and found out that this sound was produced by the ABS system (when I pulled out the fuse and started driving without it, there was no noise, as soon as I inserted it and drove it, it appeared). Tell me, is there such a sound on “resource” cars?

AR: This is not observed on any of our “resource” Ladas.

Does Xray have engine detonation when shifting gears? How does air conditioning work at low speeds (in traffic jams)? Does the car occasionally jerk when starting from a stop?

AR: We have no questions about the efficiency of the air conditioning system at low engine speeds. Periodic jostling of the “robot” - yes, such a sin is common for AMT. The car moves unevenly, which looks like the clutch pedal has been thrown - but this only applies to a smooth start, this is not the case with a dynamic one. There is no detonation when changing gears.

Aferenok Viktor Anatolievich

I would like to know: 11,300 rubles - is this one pipe of the exhaust system or together with the converter?

AR: The middle part of the exhaust tract (resonator with bellows coupling) cost us that amount. Vesta’s converter is combined with the exhaust manifold.

Thanks for the comprehensive car reports! I would really like to know how many thousand kilometers the timing belt on a Vesta engine needs to be changed? There is an opinion that on a Priora 126 engine, if it is not replaced after 45 thousand kilometers, it will lead to disaster. And on new (after 2013) VAZ family cars with 16-valve engines, is such a replacement necessary in principle?

AR: The Vesta engine with index 21129 is a further modernization of the Priora engine. The frequency of replacing the updated timing belt (according to the factory instructions) is every 180 thousand kilometers.

Bekleshov Alexey Borisovich

How well do Vesta's rear passenger air ducts work? Do the feet of those sitting in the back seats get cold during the cold season? The problem is relevant because, for example, in Grant, passengers in the back are freezing.

AR: Vesta actually has air ducts for the feet of the rear passengers, located under the front seats. There is airflow, and for now it is sufficient. But whether it will be enough even in severe frost is difficult to say, winter will tell.

Sviridov Konstantin Vladimirovich

Like Andrey Neverov, I don’t like the lack of illumination on the Xray when the daytime running lights are on. Are there ways to activate the backlight and does AvtoVAZ plan to solve this problem?

AR: The instrument panel backlight mode has appeared quite recently. We changed the ECU firmware, and now the instrument panel lights up constantly, changing only the brightness in Day-Night modes.

Lyapunov Evgeniy Andreevich

I'm interested in the sound insulation in the Vesta wheel arches. As many people write in reviews, if it rains, you will instantly have water there (the foam rubber will absorb everything). So I wonder if this thing will rot there?

AR: “Felt” fender liners are also used on many foreign cars today. They protect the wheel arches from noise and from sandblasting. Water penetrates into such fender liners, but flows down them quite quickly and dries out. And due to the fact that the fender liners themselves breathe well, the arches under them are better ventilated and rot less.

In our case, there is no hint of corrosion underneath them.

Matveev Anton Vladimirovich

On the forums, Vest owners often complain about the creaking of the stabilizer bushings, the knocking of the stabilizer struts, and the knocking in the rear strut supports. How are things going with this on the machines being tested? I would also like to know about glass - do they scratch quickly?

AR: Vesta’s suspension was distinguished from the very beginning by its noisy character. But we did not detect any knocking from the rear struts or creaking of the stabilizer bushings.

Turkish glass is really soft: the door windows are scratched from constant lowering, and the windshield has traces of abrasive wear, although Vesta has not been driven in traffic at all.

How to choose a belt and components for Lada Vesta

VAZ installs timing drive components from Gates and Contitech on Lada Vesta engines. These are trusted manufacturers of spare parts whose product quality you can trust, but as they say: “beware of fakes.”

By the way, Gates has an original code on the packaging, which can be used to determine the authenticity of the spare part. However, it is not necessary to use only original spare parts. There are other manufacturers whose reputation is undoubted. Why not use Bosch components if it is convenient to buy them, but you have to wait for the original.

This part is not the most expensive in the car, but it is extremely important.

Powertrain options

The car was initially equipped with three different power units: two engines with a displacement of 1.6 liters and one 1.8 liter. The AvtoVAZ plant designed the so-called 27th and 29th engines, or their full markings - 21127 and 21129. The first one had to be abandoned over time. The VAZ-21127 engine had a long service life and good technical characteristics, but its non-compliance with Euro-4 standards forced AvtoVAZ engineers to look for a way out of this situation. The solution was found in the following - to bring environmental performance indicators to perfection by modernizing the engine.

The difference between these two power units is as follows:

- The compression ratio was reduced from 11.0 to 10.45 in the 29th engine;

- The control unit controller received new firmware with a completely different algorithm;

- The exhaust and resonance starting system has undergone modernization;

- The parts of the connecting rod and piston group have been lightened.

The new engine has joined the ranks of 16-valve engines. In general, the manufacturer managed to technically improve the Lada Vesta engine without changing the displacement or loss of power. You can also find a modification with a Nissan HR16 DE power unit under the hood. It was designed with the help of foreign engineers. The Nissan engine works effortlessly on both the AI-92 and AI-95. At the same time, the internal combustion engine was equipped with a chain instead of a timing belt, which allowed it to outperform its counterpart somewhat in terms of actual service life.