An external sign of wear on the oil seals (valve seals) is the short-term appearance of blue smoke from the exhaust pipe when starting the engine after a long period of parking or when braking the engine after a long period of driving under load. Moreover, constant smoking is usually not observed.

Also, indirect signs are increased oil consumption, oily spark plug electrodes, and oil leaks on the valves.

Similar signs are observed when the caps jump off the seats of the valve guides.

The caps can be replaced without removing the cylinder head. It is more expedient to carry out this operation in conjunction with the replacement of timing parts or during a planned adjustment of the thermal clearances of the valves.

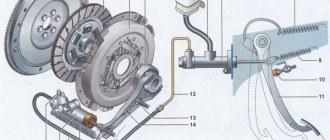

For this we need: - A set of valve stem seals Ø8 mm - A pair of crackers (optional) - An installation sleeve (if available) or a heat shrink tube Ø8-10 mm - A rod of tin solder Ø7-8 mm or other soft metal - A piece of cord or wire - Torque wrench - Wrenches and socket wrenches for 7,8,10,13,17 - Valve depressurizer - Collet puller-mandrel (preferably) or narrow-nose pliers for removing caps - Mandrel for pressing in caps - 0.15 mm feeler gauge or rack for adjusting the thermal gap valves - Tweezers or magnetic screwdriver - Screwdriver, hammer

So, turn off the engine and let it cool. Remove the cylinder head cover and align the timing marks at the top dead center (TDC) of the 4th cylinder.

In this position, the pistons of the 1st and 4th cylinders will be installed in the TDC position, which will prevent the valve from falling into the cylinder during “drying” and will make it easier to fix it with a tin rod.

Loosen the chain tensioner, unscrew the fastening nut and remove the camshaft sprocket along with the chain. Without allowing the chains to jump, we tie them together and secure them from falling into the engine crankcase so that the valve timing does not go astray.

We remove the bed with the camshaft.

We unscrew the spark plugs and use a flashlight to make sure that the piston of the 1st cylinder is in the upper position. Having overcome the force of the spring, remove the rocker (lever) of the valve, and then the spring itself.

Using a suitable socket, we apply a light blow with a hammer to the upper plate of the valve tension springs to facilitate the process of “de-drying” in the future.

We insert a tin rod into the candle hole under the valve, put on the desiccant and, pressing the plate, remove the released crackers with tweezers or a magnetic screwdriver. Then remove the desiccant, the upper plate with springs, and the support washer of the small spring.

Using a collet inertial puller, with light blows of the striker, remove the cap from the valve guide. If this device is not available, as a last resort, you can use narrow-nose pliers.

However, you should work very carefully, since they can easily damage the guide bushing made of fragile metal-ceramic, which threatens unscheduled repair of the head.

We wipe the seat, put an installation sleeve on the valve stem (usually included with the caps) or a heat-shrinkable one of suitable diameter, so as not to damage the working edge of the cap on the groove for the crackers.

If there is significant play and wear on the working surfaces of the guide bushings and valve stem, it is desirable and necessary to thoroughly degrease the seats to prevent the caps from slipping off the guides.

We put the cap on and move it to the guide, having previously lubricated its working edge with engine oil. We remove the installation sleeve, remove the spring from the cap, put on the mandrel and lightly press the cap until it stops, put the spring back on.

We install the springs, plates and “dry” the valve back, remove the desiccant.

After this, while the piston is still at TDC, remove the rod and apply several gentle blows with a hammer to the valve stem to make sure that the crackers are securely in place.

We install the spring and rocker in place.

Similarly, we change the caps on the second valve and on the valves of the 4th cylinder. Then, holding the sprocket with the chain, rotate the crankshaft 180°, and the camshaft, respectively, 90° and replace the caps of the 2nd and 3rd cylinders. To do this, it is very convenient to use the rear wheel in 4th gear.

We set the crankshaft again to the TDC position of the 4th cylinder and install the camshaft with sprocket in place. We tighten it with a torque wrench with a force of 2.2 kgf m according to the tightening diagram.

After installing the camshaft and tensioning the chain, be sure to adjust the thermal clearances in the valves.

Process video:

Good luck on the roads!

WHY ARE SEALS NEEDED AND HOW THEY ARE STRUCTURED

Engine cylinders need protection from foreign substances entering the combustion chamber. It is the oil seals (or valve stem seals) that play the role of a kind of protector. Their task is to prevent oil from penetrating while the valve stems are operating. If the caps have lost their function, they must be replaced. Otherwise, carbon deposits will begin to appear on the walls of the engine, which will lead to increased oil consumption.

A running engine causes all elements of the gas distribution mechanism to constantly move. They rub against each other, which inevitably leads to wear. To reduce the wear rate, oil gets onto the surface of each element. In this case, you need to ensure that the oil does not end up in the working area of the valves. Otherwise, the motor will begin to malfunction. To ensure that not a drop of oil penetrates into the combustion chamber, oil seals are installed.

Valve seals have a very simple structure. They consist of only three elements:

- Base. This is the oil seal frame, which is made in the form of a steel bushing. This element ensures the strength of the spare part.

- Spring. It ensures the tightness of the mechanism by pressing the rubber tightly against the valve stem.

- Cap. This is the main element of the device, made of rubber. With its help, excess oil on the rod is eliminated.

Installing new caps

To prevent damage to the edge of the valve stem seal of the VAZ-2107 (the photo shows the installation of the element), it is necessary to put a soft bushing on the valve stem. It is advisable to lubricate the inside of the cap with engine oil. Heat-shrinkable insulation can be used as a sleeve, which must be lightly burned on one side. The main thing is that its diameter is the same as that of the valve stem. It is advisable to install the new element on the guide after the old one has been completely removed. After this, a spring and a plate are put on, and the mechanism is compressed with a desiccant. The crackers are installed in the groove. The procedure for installing the caps on the guide is as follows:

- An auxiliary bushing is located on the valve stem.

- The oil seal is put on and installed until it stops.

- The auxiliary bushing is removed.

- Using a special mandrel or a “10” tubular wrench, you need to hammer the cap into place.

- Install the support washer, plate and spring.

- Fix the desiccant and squeeze it.

- Carefully install the crackers and release the puller.

SIGNS OF BREAKAGE

To prevent serious problems in engine operation, it is necessary to promptly diagnose and correct oil seal failure.

You can judge the wear of valve stem seals on a VAZ 2107 by the following signs:

- There is an increased release of white or blue exhaust gases.

- Engine oil consumption increases significantly.

- The candles become covered with black soot.

If you find these signs of failure, you need to make sure that the entire gas distribution mechanism is working properly, and not just the caps. Pay special attention to valve diagnostics. If necessary, replace the valve stem seals on the VAZ.

If the problem is not diagnosed and corrected in time, the following consequences may occur:

- the motor will lose dynamics;

- it will begin to work unstably and will often stall at idle;

- the pressure in the cylinders will decrease;

- carbon deposits form not only on the valves, but also on the walls of the cylinders and pistons;

- the tightness of the system will be compromised.

When carbon deposits appear on the engine walls, its service life decreases sharply. If the problem is not corrected in time, the situation will lead to an expensive overhaul of the engine. But these difficulties can be avoided by simply replacing the oil seals on the VAZ 2107.

Causes and signs of wear on valve stem seals

The caps are continuously exposed to engine oil and exhaust gases while the engine is running. Over time, the inside of the cap becomes dull and abrasion occurs. Oil seals (valve seals) last approximately 50-100 thousand km. mileage The life of the caps is influenced by the quality of the engine oil used, as well as the frequency of replacement.

There are several main signs of cap wear:

- High consumption of engine oil (more than 1 liter per 1000 km).

- Deposits on spark plugs (simply black plugs).

- Blue smoke from the exhaust pipe (especially noticeable at high speeds).

Also, these symptoms may indicate other problems, for example, wear of the CPG in general.

WHEN IS IT TIME TO REPLACE

Over time, the sealing material of the valve stem seals becomes hard. As a result, it loses its elasticity, which leads to oil leakage into the cylinder. The same problem occurs when the piston rings are faulty.

The caps are changed in cases where oil leaks occur without visible places. Watch how the exhaust behaves while driving. Brake the car sharply with the engine, and then also sharply press the gas pedal. If this leads to the appearance of thick smoke from the muffler, then it is time to replace the seals.

Thick, bluish-colored smoke may appear on the car even after a long period of parking.

It's easy to explain. If the caps are worn out, this leads to oil entering the engine cylinder. If the piston rings are worn out or coked, the engine behaves a little differently. Smoke will remain behind the car only when driving uphill or during rapid acceleration.

If, in addition to smoke, you observe an increase in fuel consumption, a decrease in engine dynamics and problems during startup, this may all be evidence of wear and tear on the mechanisms.

Replacing oil seals on valves.

The most labor-intensive job of replacing engine seal parts is replacing the oil reflective caps. The main factor in replacing valve stem seals is their natural wear after long-term use, and a possible reason may be that a low-quality product was initially installed.

Signs of cap wear:

- Immediately after starting the engine, bluish smoke appears for a short time.

- Constant oiling of spark plugs.

- High oil consumption.

In order to replace oil seals there is no need to remove the head from the block. Next, I will describe the actions that you need to do.

- You will need to remove the air filter and valve cover.

- Put the gear in neutral, and using a crooked starter, rotate the crankshaft so that the mark on the camshaft sprocket coincides with the mark on the bearing housing. This will allow you to install the pistons of the first and fourth cylinders at the highest point, and when the valve is loosened, it will eliminate the possibility of it falling into the cylinder cavity, which will contribute to more durable fixation with a metal rod with a diameter of approximately 8 mm.

Your further actions depend on which device you are going to use to compress the valve springs; below we will describe two different methods:

HI ALL . If you are interested in turning the nuts yourself, while saving your family budget, as well.

Friends, I want to offer you a very cool program for making money

Looking ahead a little, let's say that in order to press on new oil seals, it is necessary to unscrew the studs securing the bearing housing, since they will interfere with the correct installation of the mandrel.

Since if you use a hardened tool, some part of it, the valve, may break off during desiccation and end up in the cylinder.

If you have applied significant force to compress the valve spring, and the crackers remain in place of the valve groove, place a mandrel on the spring plate and give one gentle blow with a hammer so that the crackers are released.

Installing the oil seal

Having previously lubricated the inner surface of the oil cap with the same brand of oil that you pour into the engine, put the cap on the valve stem and lower it down to the bushing itself. Next, you need to install the mandrel and press the cap until it stops with gentle blows of a hammer.

Assemble the springs and crackers in the reverse order of disassembly.

It is recommended to make sure that the valve is assembled correctly and the crackers are in place; to do this, remove the rod from the spark plug hole that was inserted to fix the valve, and use a hammer to give several light blows to the valve stem. There are cases when the crackers become skewed and do not provide reliable fixation; the valve fails and leads to serious engine damage and quite costly repairs.

Replace the intake valves of the first and fourth cylinders in the same way as described above. Next, to replace the oil seals on the valves of the second and third cylinders, use a “crooked starter” to turn the crankshaft half a turn, while holding the sprocket together with the chain.

After the oil seals have been replaced on all valves, also use a crooked starter to turn the crankshaft another half a turn and install all previously removed parts in the reverse order of removal.

Adjust chain tension.

Using feeler gauges, adjust the valve clearances. Install the valve cover and air filter.

HOW TO REPLACE CAPS ON A VAZ 2107

- Drain approximately two liters of coolant.

- Remove the air filter housing and throttle linkage if you have a carburetor.

- Remove the valve cover.

- Place the first cylinder in top dead center mode.

- Loosen the chain tension nut.

- Remove the camshaft gear mounting bolt.

- Remove the sprocket and chain and secure them with wire to prevent a possible fall.

- Remove the bearing housing and rockers.

- Remove the candles. To prevent the valve from falling into the cylinder, be sure to plug the spark plug hole with a tin rod.

- Using a valve remover, remove the "crackers".

- Using a screwdriver, carefully pry and remove the oil seal.

- Before installing the new one, do not forget to lubricate the surface of the rod with oil.

- Replace the springs and other parts.

- Repeat all the described operations with each cylinder, installing them at TDC.

After completing all the work, return the crankshaft to its original state, install the bearing housing, camshaft gear and chain. The remaining elements are installed in reverse order.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

- desiccant;

- tweezers;

- oil seal remover;

- mandrel for pressing caps.

Replacing valve seals VAZ 2110 8V

Replacing the MSK is shown using the example of engine 2111 (8kl). To do this, you do not need to remove the heads from the cylinder block, but you will need a tin rod with a diameter of about 8mm (for example, solder).

We begin the procedure by removing the air filter, fuel pump, ignition distributor and auxiliary drive housing, unscrewing the bolt securing it with a 5-point hexagon. Disconnect the negative terminal from the battery. Remove the timing pulley from the camshaft, and then the cylinder head cover.

| Remove the ground wires by unscrewing the two nuts “1”. Then unscrew two nuts 2 and bolt 3 securing the rear cover of the cylinder head. Please note that there is an O-ring under the bolt head. Remove the back cover from the block head. | |

| Unscrew evenly the four nuts securing the front 1 and six nuts securing the rear 2 camshaft bearing housings and remove the washers. Then remove both housings. | |

| If the key in the camshaft groove does not fit tightly, remove it so as not to lose it. | |

| Remove the camshaft from the cylinder head. | |

| Remove the oil seal from the camshaft. | |

| Rotate the crankshaft so that the piston corresponding to the caps being replaced is at top dead center. After unscrewing the spark plug, insert a tin rod through the spark plug hole between the piston and the valve (to prevent the valve from falling down). | |

| Install the valve spring compressor as shown in the photo. In this case, use a nut without a serrated shoulder. Compress the valve spring with the tool. | |

| Use tweezers to remove two crackers. Then remove the fixture. | |

| Remove the upper spring retainer and the inner and outer valve springs. | |

| Press the oil seal onto the valve guide. | |

| To do this, install the collet of the tool for removing oil seals onto the cap. | |

| Strike the tool bushing sharply with the striker. Then just as sharply hit the striker of the handle of the device, thereby pressing the cap off the sleeve. | |

| Remove the cap from the fixture collet. If you do not have a tool for removing caps, use pliers. In this case, the force must be applied strictly upward and not rotate the caps, so as not to damage the valve guides. | |

| Before installing new valve stem seals, it is recommended to remove the springs from them, otherwise the caps can be damaged when they pass through the grooves under the cracks on the valves. | |

| Dip the valve stem seal in engine oil and insert it into the mandrel. | |

| Carefully press the cap all the way into the bottom plate. | |

| Install the spring on the cap if it was removed. Replace the remaining oil seals in the same way. | |

| Install the springs and valve plate in the reverse order of removal. Install the cotters using the tool so that they fit into the grooves of the valve stem. Remove the tin rod from the candle hole. | |

| After installing the crackers, hit the ends of the valves with a hammer through a metal rod so that the crackers sit in place. Lubricate the camshaft journals and cams, as well as the bearing surfaces under the camshaft journals in the cylinder head and bearing housings with engine oil. | |

| Install the camshaft into the cylinder head supports so that the cams of the 1st cylinder are directed away from the valve tappets. | |

| Apply sealant to the cylinder head in the area of the outer camshaft supports. | |

| Install the camshaft bearing housings, place the washers on the studs and tighten the nuts securing them in two stages in the order shown: – tighten the nuts until the bearing housings touch the surface of the cylinder head. | |

| Make sure that the guide bushings fit into the holes in the bearing housings. Finally tighten the nuts in the specified sequence. | |

How to replace valve stem seals on a VAZ-2107

Fortunately, a process such as replacing valve stem seals on a VAZ-2107 is far from the most difficult thing you may encounter when repairing your car. The main thing in this matter is to be as careful as possible, and then replacing the valve stem seals will be quick and successful. The entire procedure is no different depending on what is under your hood, an injector or a carburetor, except that the carburetor will need to be removed before starting work. It is important to make the replacement without removing the head - this is an easy and simple method that most car enthusiasts can handle.

Preparatory work

Before starting work, it is necessary to wash the engine compartment of the machine. This must be done carefully so as not to wet the sensors, pads, and elements of the ignition system. Before washing the engine compartment, you must disconnect the ground wire from the battery.

It is advisable to carry out the work in a garage - this will help to avoid dust getting on the timing parts during assembly. It is also necessary to secure the machine with the handbrake and turn on neutral speed so that you can turn the crankshaft during operation.

When is it time to change caps?

Experienced car drivers can easily understand when a replacement is necessary. Moreover, this is easy to do with your own hands, without resorting to the help of specialists from the workshop. If you see the following signs, it means it's time to change the caps.

- Black carbon deposits appeared on the spark plugs. It is important to understand that we are not talking about soot, but about soot. Soot may indicate other problems.

- Presence of blue smoke. The reason for this is a strong oil coating.

- Very high oil consumption. It is difficult to bring an engine to this state and is considered a serious problem. When the oil seal in the engine is too worn out, it will “drink” oil with such thirst that it will simply fly out through the exhaust. Therefore, you should not be surprised when, after driving just a couple of hundred kilometers, you find that you have no oil left at all, even though it was recently filled in.

Signs for repairing valve stem seals

However, this is not a panacea; there are several signs that it is time to change the valve stem seals:

- Increased oil consumption. Of course, you shouldn’t bring the engine to this state, but this situation can still arise. So, with severe wear, the oil seal becomes a filler neck, which only leads to even greater consumption. If this situation occurs, then goodbye oil after a couple of hundred kilometers. It's hard to believe, but it comes straight out of the exhaust pipe;

Blue smoke from the exhaust pipe. It is accompanied by an oil deposit at the end of the pipe;

- Black carbon deposits on spark plugs. Moreover, it should be carbon deposits, not soot.

Replacing caps

Before you start working on the carburetor, it must be removed. Before that, you need to disconnect the negative terminal of the battery.

Don't forget to also remove the air filter, then follow the following diagram:

- Remove the valve covers and carefully place all the nuts and washers in a separate container.

- Then you need to start cranking the crankshaft. It is very important to obtain a position where the pistons of the fourth and first cylinders are both at top dead center. Only in this case are both valves completely free.

- Then remove the chain tensioner by unscrewing the nuts that secure it.

- Now you can begin to unscrew the housing mounting nuts. After the nuts have been unscrewed, it must be removed directly from the camshaft.

- It is important to insert a tin rod into the spark plug hole, and then use it to support the bottom of the valve.

- Then you need to take the desiccation tool and secure it to a pin. We will dry out the first and fourth valves, and the main thing is to do it sharply.

- At the next stage you should be extremely careful, because it’s time to get out the plates, crackers and springs.

- Once we got all this out, it is important to put on the puller and remove the caps. Then insert a new cap.

- Then we return the plates, crackers and springs.

- After the operation with the first and fourth cylinders is completed, rotate the crankshaft 180 degrees and do the same with the remaining cylinders.

- Then we put everything back together in reverse order.

At this stage, we have successfully replaced the valve stem seals. Now you don't have to worry about your car losing oil faster than it gets it. Always monitor the condition of your engine and oil level, because this will have a positive effect on the life of the car.

Replacement process

- Completely dismantle the air filter housing. Immediately remove the cover and pull out the filter, then unscrew the fastening nuts from the carburetor and remove the entire housing.

- We remove the gas pedal linkage, as well as the choke cable on the carburetor.

- We unscrew all the valve cover fastening nuts around the perimeter and remove all the spark plug wires for convenience. You can also remove the distributor cover.

To see the process of replacing valve stem seals on a VAZ 2107, see this video:

Source

Symptoms of oil seal failure

Signs that the valve stem seals need to be replaced are:

- increased oil consumption;

- smoke and soot from the exhaust pipe;

- soot on candles.

Of course, such symptoms may also indicate other malfunctions, for example, severe piston wear or stuck rings, as well as incorrectly set ignition (for carburetor models). But all this is determined experimentally. For example, measuring compression in the cylinders can help assess piston wear.

In the book on car repair and operation, it is recommended to change the valve stem seals after 30,000 km.

Tools for repair

To carry out the repair you will need the following tools:

- a set of keys;

- valve puller;

- tweezers (to pull out crackers);

- oil seal remover;

- a mandrel (or something similar for pressing, for example a piece of tube slightly smaller than the diameter of the oil seal);

- hammer;

- tin solder rod 8 mm.