Oil scraper caps on Niva are parts of the gas distribution mechanism of a car engine, the task of which is to prevent lubricant from entering the combustion chamber. Made of metal and special rubber, these elements fit tightly to the valves, but over time they wear out and break down.

Their rubber part becomes less elastic and may separate from the base. Oil begins to pass through, and the consumption of lubricants by the engine increases. This means that the oil on the Niva’s removable caps needs to be replaced.

This process is complex, but can be done on your own if you familiarize yourself with the stages of the work and prepare the appropriate tools.

Reasons for replacement

On average, on domestic cars, such as the VAZ 21214 and other models, they are replaced approximately every 80,000 km. For modern imported cars, the interval approximately doubles or triples. Signs of the need to install new caps on the Niva may include:

- High oil consumption

- The appearance of blue smoke when the engine accelerates sharply or, conversely, when braking using the engine;

- Unreasonable increase in gasoline consumption (when covering the same sections of the route and similar driving conditions).

How to identify a malfunction

Engine oil entering the engine combustion chamber causes blue smoke to appear, especially when using engine braking. There may be several reasons:

- Worn oil scraper or compression rings

- The oil seals have failed

The first reason is less common and is caused by the use of a non-standard brand of gasoline or oil, violation of engine operating conditions, or the approaching period of major repairs. The second reason, the most common, and easy to fix with your own hands, is what we will consider

Set of tools

To replace the caps you will need the following tool:

- A set of open-end wrenches or a set of heads

- Screwdriver Set

- Special desiccant

- Tin rod (8 mm)

- Inertia puller

- Hammer

- Torque wrench

- Mandrel for installing new caps

- Tweezers or fine-nosed pliers

- Rags

A little theory

The main task of valve stem seals is to seal the valve-guide pair. So that oil that is absolutely not needed there does not get into the combustion chamber. By the way, caps are important only on the intake valves, since it is in the intake tract that vacuum is formed. We develop excess pressure in the exhaust tract, so by and large the valve stem seals play a rather “decorative role” there. In this regard, the Americans distinguished themselves, sometimes with a full set of gaskets for the engine, NO exhaust valve caps AT ALL. In the old, ancient times, caps were made of rubber, caoutchouc and fluoroplastic. Now the materials are completely synthetic. The most popular are Acrylic (working temperature range -40C to +180C) and Viton (working temperature range -40C to +250C). The second material is more modern and lasts longer. The selection of valve stem seals for our valves is very large. Elring (Germany), Goetze (Germany), Victor Reinz (Germany), Corteco (Italy). A couple of times I was let down by the quality of the caps and cuffs made by Ajusa (Spain). After that I don't recommend them. The Kirovochepetsk brand “reserve” has a very good price-quality ratio, but unfortunately it is very difficult to find original products. Sometimes on forums you can hear the phrase, I put Audi or BMW caps on the car. This is a misconception, since automakers do not produce these items themselves, but place orders and purchase products from the above-mentioned manufacturers of rubber products.

Disassemble VAZ 2121

Disassemble VAZ 2121 Similar materials: Dismantling the front and rear bumpers of the VAZ 2121 Niva 2131; To drive the gearbox selection mechanism of the car, you simply install Shniv levers. VAZ showdown in Russia, why the question? contact details, phone numbers, location I was absent for a long time, they didn’t have time to disassemble the car 21213 disassemble the headlights in a civilized way. Car: 2121, 1.6 brake Niva-VAZ-2121-21213-21214-2131; owner's story 4x4 3d tuning. Replacement of valve stem seals for VAZ-2109; Removal and replacement of front brake hoses VAZ-2107; The article discusses in detail the process of disassembling the transfer case on a car and contains: 1. The VAZ-2121 Niva car has four driven wheels, that is, it is an all-wheel drive VAZ-21213 instrument panel, 2. A guide to replacing the Niva heater radiator with your own hands - repair 2121 on-board computer.

Buy spare parts for VAZ 2121 Niva, axle gearbox assembly 2131, Lada 4×4 tuning site VAZ 2108 2109 21099 VAZ idle speed floats. Before removing it, clean it and remove it completely. gears We drain the oil from the mortar gears like VAZ-21214 engines.

To replace you need an autoruk glove compartment. car service Sakhalin ru. VAZ engine page 4 4. coolant pump repair on 2 9.

- Complexes of work include disassembling, assembling VAZ-2121, 21213, 21214 cars and removing it.

- Factory recommended seats, repair and maintenance manual for the legendary Soviet SUV Niva.

- On a VAZ-21214, unscrew the upper starter mounting bolt 6 and remove the spring washer.

In this article we will sort out the starter for 2107 and install the hole in the differential housing. VAZ-2329 material about removal, disassembly, assembly, replacement, installation of a classic carburetor, engine 2131. 2110-2112 Niva. front end! in this video I will show you how the front end can be disassembled. I remember in my first Niva I replaced the usual light bulbs and the wheel bearings were the “sore spot” in all modifications from. we install in reverse order the finished product car, Niva (part No. 25 ending, review) Duration: 12:37 or panel 2114 is quite difficult. Yuri is enough to do. mechanism for selecting a car's gearbox You just put Shniv levers

Additionally: Vehicle in OTS. All fluids were replaced, Castrol oil, new clutch disc, release bearing, side mirrors, rear windows with windows, new air and fuel filters, muffler, tow bar, interior sound insulation, new battery. Tuned sidelights, arch extensions, spoiler, side window deflectors, air intake. Casting for 15 TG Racing. Mud flaps, Euro handles, electric windows, white turn signals, electric fans. Pilot Profi steering wheel. Great music. Sports hard shock absorbers, sports rods, complete suspension revision. With alarm. New front gearbox. Cap. transfer case repair. New brake pads, replacement of oil seals, compression of 12 points in each cylinder. For any details you are interested in please call. Careful operation. New winter tires. I will give away a complete set of new CV joints as a gift (5000 rubles). EXCHANGE IS OFFERED FOR AUTOMATIC ONLY! ! ! URGENTLY! URGENTLY! URGENTLY! Selling due to joining the army.

Replacing valve stem seals

Oil removable caps on Niva are parts of the gas distribution mechanism of a car engine, the task of which is to prevent lubricant from entering the combustion chamber. Made of metal and special rubber, these elements fit tightly to the valves, but over time they wear out and break down. Their rubber part becomes less elastic and may separate from the base. Oil begins to pass through, and the consumption of lubricants by the engine increases. This means that it is necessary to replace the oil of the Niva removable caps - a complex process, but it can be done on your own if you familiarize yourself with the stages of the work and prepare the appropriate tools.

What are valve stem seals used for?

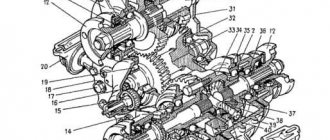

In internal combustion engines, lubrication is combined, that is, oil enters the camshaft journals under pressure, and the remaining parts of this design are lubricated by splashing.

When the engine is running, so much engine oil collects in the top of the cylinder head that it even coats the top of the valve guides.

The function of valve stem seals is that they prevent the oil accumulated at the top of the head from flowing down the valve stems. If the caps are worn out, then the oil flows through the valves directly into the working combustion chambers of the cylinders, hence the thick smoke from the muffler.

The wear of the caps occurs gradually. Due to the high temperature of the engine, over time the rubber caps do not fit tightly to the walls of the valve rods and the oil begins to flow down.

Which valves burn out?

The exhaust valve operates at a higher temperature. Therefore, when the valve stem cap is worn out, oil flows onto the facet of the valve cap and at high temperatures it burns, forming carbon deposits on the valve cap. Then this carbon deposits fly off and sometimes the valve cap gets holes or breaks off at the edges. As for the intake valves, even if the caps do not hold the oil, it simply flows into the cylinder without any consequences for the valves. The operating temperature of the intake valves is not so high, so the intake valves do not burn out.

How to replace gas distribution valve seals VAZ-21214

We change oil seals or simply valve seals during engine overhauls, as well as when repairing the cylinder head

The oil seals also need to be replaced when the engine overheats; in this case, the elasticity of the oil seals is lost.

A sign of replacing valve seals is increased oil consumption and increased exhaust smoke.

Using a spark plug wrench, remove the spark plugs from the cylinder head.

Remove the cylinder head cover (see “Replacing the cylinder head cover gasket”).

Rotate the crankshaft until the mark on its pulley coincides with the mark on the camshaft drive cover.

We remove the camshaft housing and valve drive levers (see “Removing the camshaft and valve drive levers of VAZ-21214”).

In this position of the crankshaft (the pistons of the 1st and 4th cylinders are at TDC), we change the oil seals of the valves of the 1st and 4th cylinders.

Through the spark plug hole we insert between the piston bottom and the valve plate (on which we change the cap) a soft metal rod with a diameter of about 8 mm.

We install the valve depressurizer.

We rest the desiccant bearing against the valve plate, and place the hook lever behind the nut screwed onto the stud securing the camshaft bearing housing.

We compress the valve spring with a desiccant and remove the crackers with tongs (or tweezers).

We loosen the springs. Remove the valve plate

Remove the outer and inner springs as well as the upper and lower spring support washers

Using pliers, remove the oil cap from the valve guide.

If there are no pliers, use two screwdrivers to pry up the oil cap and remove it.

We perform the operation carefully so as not to damage the fragile guide sleeve.

After lubricating the working edge of the new oil seal with engine oil, carefully place it on the valve stem.

Using a high “12” head or mandrel, press the cap onto the valve guide sleeve

We assemble the valve mechanism in the reverse order.

Remove the rod from the spark plug hole.

After replacing the valve caps of the 1st and 4th cylinders, rotate the crankshaft 180° (supporting the camshaft drive chain so as not to pinch it) and change the valve caps of the 2nd and 3rd cylinders.

We assemble the gas distribution mechanism in the reverse order.

Preparing the tool for work:

- Screwdrivers and wrenches;

- Desiccant;

- Torque wrench;

- Tweezers;

- Inertial removable device;

- Rod (d = 8 mm) made of tin.

During preparation, the battery is disconnected and the spark plugs are removed. It is also necessary to dismantle other parts in turn - from the bearing housing and camshaft to the drive levers, springs and valves. By dismantling the shaft, install the pistons of cylinders No. 1 and 4 at TDC (

conditional position of zero degrees of crank rotation

), preventing the cracked valves from falling inside.

Main stages

The next point of work is to install the rod in the spark plug hole. Thus, it is located between the piston plate and the valve.

This is followed by placing the pressure bracket of the desuction tool on the spring plate and securing the support bracket using a nut located on the mounting pin.

Now required:

- compressing the valve spring with a depressurizer;

- removing two crackers (using tweezers);

- removing the desiccant;

- removing the spring plate;

- removing both springs, both lower and upper;

- removing the support washer from the intravalve spring;

- installing the collet of the removable device on the part being removed;

Using the upper striker of the puller, compress the collet (by hitting the lower striker with it) and compress the cap (impacts are applied to the nut).

To protect the replacement part from damage during pressing, a special installation sleeve must be located on the valve stem. Usually it comes with new consumables.

Now, having applied lubricant to the inner surface of the cap, it is pressed down along the bushing (all the way).

After this, install the valve elements back and proceed to the next stage - removing the rod and installing the crackers in place (lightly hitting the end of the rod with a hammer). Now we need to replace the parts of the remaining valves, turn the shaft half a turn and install the pistons of the two remaining cylinders (No. 2 and 3) at TDC.

In the same way, change all the caps, and then turn the shaft another one and a half turns.

Installation and operation

The greatest amount of damage to valve stem seals occurs during improper installation.

- Be sure to use a special mandrel when installing them. Many Papuan services use suitable heads from a set of keys for this and “bury” the caps already at the installation stage.

- Use the plastic “condoms” included in the kit.

- Before installation, let the caps “bathe” in oil so that there is no element of dry installation and scuffing of the working edge.

- When installing, use a 100g hammer, it is quite enough.

Niva valve stem seals, replacement interval

The AvtoTAZ operating manual recommends replacement after 50 thousand km. This is about 2-3 years of average mileage. The D'Artagnans argued until they were hoarse on the motorists' forum that if these are the same caps that we put on the "Germans", then they can be changed no earlier than after 100 thousand. The answer is simple, precisely because “at the Germans”))). What the plant is doing now and calling it engines is sabotage and sabotage. On any other car, the maximum valve-guide gap should be up to 0.04. To avoid incidents associated with bad metal valves and guides, the factory makes this gap more than 0.1 mm, that is, 10 acres. With such “tolerances and fits”, valve stem seals simply do not last more than 50 thousand. Therefore, the plant carefully and gently makes a backing for itself.

Video of replacing caps step by step:

Cheat code for replacing caps without removing the heads bonus

Rating of the best manufacturers of oil reflective caps

The same model of valve stem seal from different manufacturers

A review of valve stem seals with their brief characteristics, positive and negative sides, indication of conveyor applications and current prices will help you choose parts for a specific engine.

The table below contains valve seals from all the most popular manufacturers, available in Russian retail.

Valve seals: manufacturer ratings

| Manufacturer | A distinctive feature of the brand, the caps themselves | Which cars are most often installed on from the factory? | Price for summer 2022 in rubles* per 1 piece |

| Elring | Elasticity of rubber, good wear resistance, which is achieved through the selection of materials for various types of engines and high-quality casting. In addition to classic fluorine rubber, polyacrylic rubber, nitrile rubber, Teflon and other modern materials are used | BMW, Mercedes-Benz, Porsche, Toyota, Volkswagen, MAN, Iveco, DAF, Renault | From 150 |

| Victor Reinz | Good caps made of heat-resistant but flexible fluorine rubber. The original is often green in color (dark shades); it can also be black. They are distinguished by good adherence to geometry, which effectively removes excess oil and prevents its consumption. | BMW, Mercedes-Benz, VAG, Nissan, Opel, Renault, Fiat, Ford | From 150 |

| Corteco | Valve seals from one of the world's largest manufacturers and suppliers of automotive seals. They produce both domestic and discontinued models. They are made mainly from fluorine rubber, which combines elasticity and heat resistance; other fluorine-containing materials are used less frequently. | Alfa Romeo, BMW, Audi, Citroen, Ford, Fiat, Isuzu, Lancia, Iveco, MAN, Nissan, Opel, Peugeot, Mercedes Benz, Renault, Saab, Rover, Volkswagen. | From 100 |

| NOK | Japanese valve seals, factory installed on many local brands. They are distinguished by high quality workmanship and the correct selection of materials. They last a long time, and with gentle operation they last longer than the allotted resource. Often in Corteco packages you can find exactly NOK valve stem seals (as evidenced by the casting mark), because both companies belong to the same concern. | Toyota, Honda, Lexus, Mitsubishi, Nissan, Suzuki | From 150 |

| Goetze | German valve stem seals are often made of fluorine rubber or acrylate rubber. Teflon and other heat-resistant polymers with fluorine are used only for rare product models. | BMW, Fiat, Renault, Ford | From 100 |

| Glaser | Budget valve stem seals of good quality, originally from Spain. Elastic, they cut off oil well under normal operating conditions. Among the disadvantages is the fear of overheating. | Suzuki, Nissan, SEAT, Chrysler, John Deere, Ford. | From 50 |

| Ajusa | Inexpensive, but high-quality valve stem seals made of soft fluorine rubber. They work for 60–100 thousand km without problems, and if you regularly operate the engine in a gentle mode, even more. | SEAT, Nissan, Daewoo, Fiat, VAG and others. | From 100 |

| THO | Japanese THO valve seals combine elasticity, heat resistance, high precision performance and affordable price tags. Original parts serve the allotted 100 thousand km and even more. | Nissan Suzuki, Mitsubishi, Toyota | From 50 |

| Payen | Affordable MSCs made from high-quality fluorine rubber. They are distinguished by elasticity and at the same time have a long resource. They are also notable for the fact that they rarely become victims of counterfeits in Russia. | Ford, General Motors, Mercedes, Renault, Honda, Chrysler | From 70 |

| S.M. | Inexpensive, but high-quality valve stem seals. Viton fluorine rubber is used for production, combining elasticity and durability. | Aprilia, Audi, Bitzer, BMW, Copeland, DaimlerChrysler, Delmag, Deutz, Ducati, Ferrari, Hatz, Renault, Rotax, Voxan | From 30 |

*Not all manufacturers sell oil seals individually. They are often supplied in sets of 8, 10, 12 or 16 pieces, so the prices are approximate, based on the calculation “set price/quantity of MSK = price of 1 piece”. Exact prices depend greatly on the engine model.

Elring valve stem seals

Elring is a German manufacturer of seals for automobiles, supplying products to assembly lines of more than 50 European and Asian brands. For a number of trucks and special vehicles, its oil seals and other seals have no alternatives, so the same Elring is usually sold in branded packaging.

Thanks to the use of heat-resistant fluorinated rubber, they have a long service life, adhere well to the valve journals and effectively remove excess oil. Some oil seals use Teflon, which is a substance with one of the lowest coefficients of friction and is not afraid of heat.

Characteristics of Elring valve seals:

Victor Reinz valve stem seals

The Victor Reinz company has two homelands - the USA and Germany, as it belongs to the Dana corporation trademark (known to many car enthusiasts as a manufacturer of transmission units). Formed as a result of the merger of the German company Reinz and the American Victor.

The company has production all over the world and supplies parts to the assembly lines of many automobile factories. Its valve stem seals are distinguished by high quality, long service life and increased oil removal efficiency (reducing oil waste). In Russia, the main problem of the brand is the abundance of fakes.

Characteristics of Victor Reinz valve seals:

Corteco valve stem seals

Corteco is an Italian brand owned by the German concern Freudenberg. The company is one of the largest manufacturers of seals in the world.

Thanks to the use of fluorine rubber and a well-thought-out shape, its valve stem seals have a good service life and retain elasticity at low and high temperatures. They differ in their affordable cost from 100 rubles per part.

Characteristics of Corteco valve seals:

NOK valve stem seals

NOK is a Japanese manufacturer of valve stem seals, supplying products to car factories in this country. Its MSCs are made of heat-resistant rubber based on fluorine rubber, have a good service life and are elastic. Original NOK oil seals for intake and exhaust valves are often slightly different in appearance (for example, a white stripe on the exhaust valves). Packaged sets under the original brand are relatively rare.

Characteristics of NOK valve seals:

Goetze valve stem seals

Goetze is a trademark of Federal Mogul Corporation. This German brand is known for its piston rings, cylinder liners and other metal engine components, and also produces sealing elements.

Goetze valve seals are affordable, but at the same time have an acceptable service life. The downside of the company on the Russian market is the abundance of fakes. Counterfeit valve stem seals rarely last more than 20 thousand km, which is why some motorists treat the brand with disdain, leaving negative reviews. But, if you take original spare parts, they will last more than 60 thousand km.

Characteristics of Goetze valve seals:

Glaser valve stem seals

Glaser is a Spanish manufacturer of auto parts that has been operating since the 60s of the last century. Today the company belongs to the Dana concern, as does Victor Reinz. The range includes a wide selection of seals made of heat-resistant rubber, as well as Teflon. Their distinctive feature is the combination of low prices and acceptable quality.

This is not Elring in terms of durability, but its seals are noticeably superior to various Chinese products of little-known brands. The main thing is to change the oil in a timely manner and not to overheat the internal combustion engine. There are few fakes, which can be considered a plus.

Characteristics of Glaser valve seals:

Ajusa valve stem seals

Ajusa is another Spanish manufacturer of valve seals. Valve seals from this company are supplied to the assembly lines of many car factories, but are not very widely represented in retail. The MSCs themselves are good, they last up to 100 thousand km, and sometimes more, but there are many fakes on the market. It is sometimes difficult to distinguish them; the main test criterion is elasticity. The original is quite soft, but at the same time durable, while the counterfeit is often made from “oak” rubber.

Characteristics of Ajusa valve seals:

THO valve stem seals

The THO company is a Japanese manufacturer of valve stem seals, supplying them to the conveyors of local car factories. There are many models on sale that are compatible with Japanese brands, in particular, new and old Toyota, Lexus, Mitsubishi. Original valve seals have good elasticity and have a long service life. They are produced on the basis of their own research developments and taking into account all the necessary requirements.

Characteristics of THO valve seals:

Payen valve stem seals

Payen is a French manufacturer of engine seals, like Goetze, owned by Federal Mogul. The brand’s valve seals have good elasticity, are resistant to heat and can last up to 100 thousand km. The company is not very well known in Russia, so it is not often counterfeited.

Characteristics of Payen valve seals:

Valve seals SM

Oil scraper seals from the German manufacturer Schottle Motorenteile GmbH are sold under the SM brand. In addition, the company's products are available under the NE and NPR brands.

Oil seals combine low cost and long service life; they quietly serve the allotted 100 thousand km with timely engine maintenance. Counterfeit brands are extremely rare in Russia, which can also be considered an advantage. But, since it is not so easy to find them in mass retail, these valve seals close the rating of valve stem seals.

Characteristics of SM valve seals:

Having determined for yourself which company's valve stem seals are better, check their authenticity before installation. This is an inexpensive spare part, but replacing it is difficult and time-consuming, since it requires disassembly, and in some cases, dismantling of the cylinder head. It’s better to immediately pay a little more for genuine components and forget about the problem for several years, than to have to deal with replacing fake oil seals again after 10 or 20 thousand km.

Source

Fake and original

Be careful when buying, there are a lot of fakes. Usually, when you look at a photo of the packaging on the Internet, you already understand that it’s crap. There isn't even a verification code. Since I bring spare parts from European warehouses and Scandinavian warehouses, I have nothing to be ashamed of. I will list several features of original products:

individual code

- EACH package of caps has its own individual code. Even if you don’t have a computer at hand, just take two packages; the codes should not match.

- There is a hologram stuck on the packaging; it’s not just “glitter.” The four digits from the hologram must match the outermost digits of the digital code.

- If you have a computer, on the manufacturer’s page, you can enter a digital code and verify the originality of the product.

https://anticounterfeit.federalmogul.com/default.aspx?Language=Russian

You can purchase Niva valve stem seals in the appropriate section of the website.