The VAZ car is a vehicle produced by the famous Russian company. The released models became a real legend of the domestic automobile industry, and they gained great popularity not only because of the company’s big name, but also due to the high-quality production at that time.

One of the features of the VAZ-2105 car was the use of an engine with a timing belt. Among the main technical characteristics, one can note the accelerated operation of the motor. The engine quickly gained trust among car enthusiasts, and the design was improved more than once, making it possible to improve the existing characteristics.

This article will take a closer look at what a timing belt is, how much it can be purchased for, and also how to change the belt if it wears out.

Model features

If we turn to history, then for the first time the belt drive of the gas distribution mechanism in cars of the Volzhsky Automobile Plant began to be used on the VAZ 2105 model: an engine with such a drive was an experiment, and was not installed on all cars (some of them used a motor from the VAZ 2101 and 2103 models, having a timing chain drive).

And also, this version was the first in the Soviet era to drive the gas distribution mechanism using a belt instead of a chain, like other models. This experience can hardly be called a success, because the engine became known for its unstable operation and frequent leaks of engine oil.

VAZ 2105

But, thanks to the efforts of Soviet engineers, the mechanism is absolutely safe to use. A broken belt on a VAZ 2105 does not lead to a collision of pistons with valves, since the former have special rounded recesses on top, and this will not require engine repair.

During standard use, belt replacement in 2105 is necessary in the following cases:

- The mileage is around 60 thousand km.

- Damage appears on the rubber (tears, cracks).

- Major engine repairs are being carried out.

Engine parameters and features

The VAZ 2105 engine is used on the VAZ 2104, 2105 and 21072 models. It has a camshaft belt drive and the following main parameters:

- engine capacity 1.3 l,

- power 64 horsepower,

- maximum luggage compartment volume – up to 385 liters,

- fuel consumption in the city – 10 liters per 100 km,

- in the combined cycle - 8 liters per 100 km.

Cars based on this engine use 5W-30-15W40 oil and AI 93 fuel. The engine life, according to the factory, is 125, in practice - about 200, 4 cylinders and 2 valves, power system - carburetor, type - in-line. Torque is approximately 94 Nm at 3400 rpm. The piston stroke and cylinder diameter are 66 and 79 mm, respectively.

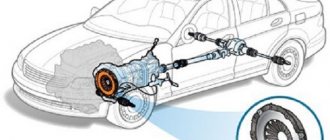

And also, when repairing the timing belt on the 2105, do not forget about the features of this engine. The use of a toothed belt in the gas distribution mechanism drive instead of a classic metal chain made it possible to achieve quieter operation of the machine. In addition, the belt tension has become automatic, removing an extra lubrication point, which has significantly reduced engine oil losses.

Do-it-yourself: Replaced sprockets and timing chain after 220 thousand km

Hi all! As you know, the car has already covered 200 thousand km, so I decided to do a mini-overhaul, almost completely replacing the timing mechanism myself. I decided not to touch the rocker with the camshaft for now and work on the chain with sprockets that have been there since the factory. Various sources write that the life of the chain is somewhere around 100-150 thousand, although even at 220 thousand it was tensioned well by the tensioner, and I didn’t notice much noise, perhaps due to timely maintenance and good oil. However, during diagnostics at the service center, the technician said that the valve timing angles had already dropped a little, so it was better to replace it. I decided to play it safe and replace it along with the stars, as is done wisely.

I bought a set of sprockets, a chain, a new stabilizer and shoe, a front cover gasket, a front crankshaft oil seal, nuts, sealant, etc. from a trusted store.

First, let's provide access to the front cover - remove the cooling fan, radiator, drain the antifreeze from it, and decorative grille.

Then the engine protection and mudguard to provide access to the three cover mounting bolts from below. We will be replacing the mudguard, as it was rotten through and through and the generator was flooding in the puddles.

Now we unscrew the crankshaft pulley nut (ratchet), we need a 36 wrench, or better yet a head, but we couldn’t find one, and the standard stamped wrench was bent and did not want to unscrew the nut.

I also had to weld pipes from it for a 40 key, long enough to rest against the right side member.

It was not possible to unscrew it manually; I had to tear it off with the starter, resting it on the spar.

Next, remove the PCV sensor, alternator belt, valve cover and set the timing marks on the crankshaft pulley and camshaft sprocket at TDC of the 4th cylinder. Oddly enough, they completely coincided.

Then we remove the crankshaft pulley and the front cover, dismantle the shoe, damper, limiter and gears with the chain. We make sure that the marks do not go astray.

When comparing the old and new parts on the stars, I didn’t see any special workmanship, except for polishing on the sides.

The chain is also intact on the outside. The shoe and damper have minimal wear, as they have already been replaced relatively recently.

However, the old chain turned out to be 4-5 mm longer than the new one, which, according to the same data from the Internet, is already above the tolerance of 4 mm and requires its replacement.

Before installing new parts on the new camshaft sprocket and crankshaft pulley, I used a center punch to make additional marks at 90 and 180 degrees for convenience during subsequent valve adjustments.

We put them in reverse order according to the marks and keys: first the shoe with the damper, then the upper sprocket with the chain, then the small sprocket and the middle one, check the marks again and tighten the chain.

We carefully double-check everything and lock the retaining rings.

During assembly, due to inattention, I placed the small crankshaft gear with the “skirt” outward instead of inward, which is why the crankshaft was blocked when tightening the ratchet nut - I had to remove the cover again and rearrange it.

The marks coincided exactly again, as if nothing had changed, hmm..

Seal the front cover seal and gasket with sealant.

Also, instead of the usual nuts with engravers, I tightened the front cover with nuts with a nylon ring, which means they have the ability to unscrew and leak oil).

Well, at the end I installed a new engine splash guard.

- Set of stars – 680 rub.

- Chain – 630r

- Calmizer – 70 rub.

- Shoe – 90 rub.

- Oil seal – 110 rub.

- Nuts, washers, gasket – 200 RUR

- Engine splash guard – 400 RUR

- Ratchet key – 150 RUR

It took a couple of days to do everything, although it could have been done in one. After replacing, I did not notice any major changes in the operation of the motor. After a couple of thousand, after grinding in the parts, you will need to tighten the chain again. But then you can sleep peacefully with another couple of hundred thousand mileage).

Replacement procedure

- Remove the alternator belt.

- Remove the top belt cover.

- Turn the crankshaft clockwise until the marks on the camshaft gear coincide with the marks on its housing, on the crankshaft pulley and the drive cover.

- Remove the middle and bottom belt covers (out of a total of 3 pieces, the first was removed in step 1)

- Remove spring 7, loosen bolts 3, move the bracket to the left as far as it will go and remove the belt.

- Put on a new belt, press out the bracket and install spring 7.

The main condition when repairing or installing a timing belt on a VAZ 2105 will be that the installation marks match; Care should be taken to ensure that the shafts do not rotate.

Preparation for service operations

Control of the tension of the chain drive of the gas distribution mechanism begins on an engine with a power system such as an injector or carburetor, similar to each other. The operation is performed in the sequence established by the manufacturer:

- We place the car on a flat area with a hard surface and fix its spontaneous movement by installing chocks under the wheels and applying the parking brake. Set the gear shift lever to the neutral position.

- Remove the cover from the cylinder head by unscrewing all the nuts along its contour using a tubular wrench. It is recommended to replace the old gasket; the use of sealants is not allowed.

- Using a key set to “38”, we turn the crankshaft of the VAZ 2107 engine in order to align the marks on the moving parts and the stationary ones. Care must be taken when performing this action, and the locations of the control points should be illuminated with a flashlight or carrying device.

- We combine two marks: the first is on the generator drive belt pulley with a special protrusion on the cover body, the second is on the upper sprocket of the gas distribution mechanism of the VAZ 2107 power unit with an injector power system.

With this relative arrangement of parts, the piston of the fourth cylinder is at the dead center at the top. Now you can begin performing service work on engine systems, in particular, timing belt and some others.

Tension adjustment

According to the regulations, it is required every 15 thousand km. Check the timing belt tension on this engine and adjust the tension if necessary.

To adjust the tension you need to:

- Remove the timing belt cover.

- Loosen bolts No. 3.

- Turn the crankshaft by the hexagon of the ratchet several turns. It must be turned clockwise.

- When performing the previous step, spring No. 6 will provide optimal tension automatically.

- Tighten No. 3 bolts.

- Put on the timing belt guard.

Frequency of replacing the timing belt on a VAZ 2105

Replacing the timing belt on a VAZ 2105 is necessary approximately every 60 thousand km during standard use, but in case of some damage it becomes necessary to replace the timing belt earlier than the standard period. Despite a certain motor resource set at the factory (in our case - 125), malfunctions occur quite often and their elimination is critical for continued use of the machine.

If folds, cracks, or fraying of the belt appear, it must be replaced, since when using a timing belt on a VAZ 2105 in this condition, there is a danger of rupture when the engine is running. When oiling, you should carefully wipe the belt with a cloth, after dipping it in gasoline.

Refinement of the power system

It is best to use Weber modifications; in this case, adjusting fuel consumption for each VAZ 2105 carburetor is not so difficult. And Weber’s reliability is better. To install it, you will need a set of plumbing tools, tees, hoses and manifolds from Oka, the markings of which are in the catalog. It is worth remembering that it can be very difficult to achieve synchronous operation of carburetors. And why this happens is difficult to say. Most likely, each VAZ 2105 carburetor is unique, and therefore the fuel consumption adjustment is not ideal. So two carburetors are quite a risk. Although if everything can be set up synchronously, then the VAZ’s internal combustion engine will begin to operate very smoothly. And fuel consumption on a VAZ will increase, but by no more than 1 liter.

Considering the problematic carburetor of the VAZ 2105, the adjustment of fuel consumption of which takes a lot of time, it makes sense to switch to an injector. To do this, it is better to buy all spare parts at the official VAZ center. There is a special diagram for installation; all the work can be done in a couple of days in the garage. After this, you can forever forget about the VAZ 2105 carburetor, the adjustment of fuel consumption of which was so exhausting. However, the injector may also require initial setup.