June 22, 2021 Lada.Online 379 466 72

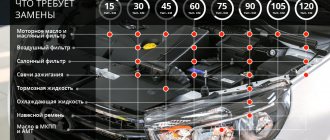

AVTOVAZ recommends performing maintenance (MOT) for cars of the Lada Granta and Lada Kalina family every 15,000 km or every year (whichever comes first). It is also recommended that during the warranty period, maintenance be performed only at an official LADA dealer, with a mandatory note about the work being carried out in the service book coupons. It is worth noting that the maintenance regulations differ depending on the year of manufacture of the car.

Maintenance schedule for Lada Granta and Kalina 2

AVTOVAZ recommends performing maintenance (MOT) for cars of the Lada Granta and Lada Kalina family every 15,000 km or every year (whichever comes first). It is also recommended that during the warranty period, maintenance be performed only at an official LADA dealer, with a mandatory note about the work being carried out in the service book coupons. It is worth noting that the maintenance regulations differ depending on the year of manufacture of the car.

Features of design solutions in the front suspension

The front suspension in the LADA Granta is based on the following aspects:

- independent design with hydraulic shock absorbers;

- a pair of wishbones;

- anti-roll bar;

- the levers are equipped with auxiliary braces;

- the spring, combined with the shock absorber into a single strut, has a conical profile and coils of variable cross-section.

The shock absorber strut is connected to the steering knuckle by a lower bracket. The design feature is that during a turn with a fist, the shock absorber and spring rotate. The scheme is very simple. This solution made it possible to preserve the technological hole in the shock absorber body, which helps to increase its service life.

The pillar supports have undergone some modifications, which made it possible to get rid of unpleasant squeaks and increase the strength characteristics of the structure.

The transverse stabilizer is based on spring steel. Its middle part is fixed to the body, both end sections are fixed to the mounting points of the transverse arms.

The modernized front suspension of the domestic Lada Granta differs from its counterpart in other representatives of the model range due to the increased steering angle of the wheels. The value of the so-called cluster reached 2° 45`. The undeniable advantage of this solution is the improvement of directional stability, especially when driving at high speeds. The other side of the coin is the slightly increased required force that should be applied to the steering wheel during a turn. If you believe the reviews of the owners, this moment is almost imperceptible.

This is due to the modernization of the steering control unit, namely:

- integration into the unit of an amplifier with an increased compensating effect;

- use of a short-throw steering rack.

This approach resulted in improved handling and resulted in a reduction in the number of steering wheel rotations. And the steering wheel itself now has more information and sensitivity.

Based on reviews from LADA Granta owners, one can judge that the designers have adopted a design solution that is strange for the modern era of automotive manufacturing - this is when a standard suspension is used and there is no power steering in the steering mechanism. Can this solution be interpreted as a way to reduce the cost of the design?

Chassis

| Item or system being serviced | Vehicle mileage, thousand km. | Description of work and repairs on the website | ||||||

| 3 | 15 | 30 | 45 | 60 | 75 | 90 | ||

| Engine oil and oil filter (replacement) | P | Z | Z | Z | Z | Z | Z | Changing the engine oil and oil filter |

| Cooling system hoses and connections | P | P | P | P | P | P | P | Checking the tightness of hoses and connections of the cooling system |

| Cooling system (coolant replacement) | P | P | P | P | P | P | Z | Coolant replacement |

| Fuel filter (replacement) | P | P | Z | P | Z | P | Z | Replacing the fuel filter |

| Air filter element | P | P | Z | P | Z | P | Z | Replacing the air filter element |

| Spark plugs (which ones to choose) | P | P | Z | P | Z | P | Z | Replacement and maintenance of spark plugs |

| High voltage wires | P | P | P | P | P | P | Z | (for 8-valve internal combustion engine) |

| Thermal clearances in valve actuators | — | P | — | P | — | P | — | Adjusting the clearances in the valve drive of VAZ 11183, VAZ 21116 and VAZ 11186 engines |

| Valve cover gasket, valve shims | + | + | — | + | — | + | — | for 8-valve internal combustion engine |

| Manual transmission (replacement) | P | P | P | P | P | P | P | Checking the level and adding oil to the gearbox, changing the oil in the gearbox |

| Automatic transmission | P | P | P | P | P | P | P | |

| Boots (covers) of constant velocity joints | P | P | P | P | P | P | P | Front wheel drives |

| Front suspension | P | P | P | P | P | P | P | Checking the technical condition of the front suspension parts on the car |

| Rear suspension | P | P | P | P | P | P | P | Checking the technical condition of the rear suspension parts on the car |

| Wheels and tires | P | P | P | P | P | P | P | Wheel check |

| Wheel alignment angles | P | — | P | — | P | — | P | Checking and adjusting wheel alignment (wheel alignment angles) |

Switches and levers under the steering wheel

The right switch under the steering wheel is responsible for the window cleaner and washer. The switch turns on electrical circuits when the ignition is on. The switch lever can be moved to the following positions

0 - windshield wiper and washer off

1 — intermittent wiper operation mode is on (non-fixed position)

2 — intermittent wiper operation mode is turned on (fixed position). In intermittent operating mode, the windshield wiper blades make one stroke at regular intervals of several seconds, regardless of the presence of drops on the windshield (in a variant, an automatic wiper control system is installed

3 - low speed windshield wiper enabled

4 - high speed windshield wiper enabled

5 — by moving the lever toward you, the windshield washer is turned on (not a fixed position)

Brake system

Hydraulic drive of the brake system (replacing the brake fluid) PPPPPPReplacing the brake fluid in the hydraulic brake Brake mechanisms (replacing the front, rear pads) PPPPPPChecking the degree of wear of brake pads, discs and drumsParking brakePPPPPPChecking the parking brakePipes of the hydraulic brakesPPPPPPChecking the tightness of the hydraulic brakesCooling

Parameters and technical characteristics of the Lada Granta.

Lada Granta VAZ 219010. Lada Granta model 219010 To cool the air in the cabin, do the following:

- Switch switch 1 (see Fig. 2) of the electric fan operating modes to one of the positions “1”, “2”, “3” or “4”.

- Place the regulator handle 4 opposite the pictogram.

- In the 3 pushbutton switch block, press the air conditioner switch key. The indicator located on the switch button will light green all the time the air conditioner is operating.

When the air passing through the evaporator cools, the water vapor contained in it condenses. The condensate is drained through a drain pipe under the bottom of the car. If the ambient air humidity is high, a puddle of water may form under the car, which is an indirect sign that the air conditioning system is working properly.

Turning on the air conditioner while the engine is running under difficult conditions (long climbs, heavy city traffic, etc.) can lead to engine overheating. Monitor the coolant temperature gauge: if the temperature exceeds the permissible value, turn off the air conditioner. During long trips in city traffic, the efficiency of the air conditioner may decrease due to the intense thermal conditions of the engine. This is not a sign of malfunction; the air conditioner will operate effectively when driving under normal road conditions.

- climate block grants

- air duct grants

- air conditioning grants

- stove grants

Lada Granta has become a really popular car. And, in many ways, this happened thanks to the affordable price and good components. For example, the stove installed on the Lada Granta is quite good, as it warms up the interior to the required level very quickly. AvtoVAZ engineers did a very good job on this issue, since for our harsh winters the issue of high-quality heating of the interior is very relevant.

Electrical equipment

Headlights (adjustment)PPPPPPChecking and adjusting headlightsBattery (check)PPPPPPPABattery External lighting devicesPPPPPPChecking external lighting devicesLada Granta instruction manual: features

Firmware for mms grant 2190: instructions with step-by-step description

It’s not enough to say that the book is very useful; it is vital for young drivers who are just starting to learn how to drive a new car. It helps you save valuable time and money on maintaining your iron horse.

The Grant operating manual will also be useful for experienced drivers and service station workers, as it will help maintain the car in good condition.

The manual contains, as educational material, more than 3 thousand original color photographs, which depict in sufficient detail and step-by-step sequence all stages of repair of the Lada Grant.

Such an operation as engine repair is especially considered and detailed, almost all technical characteristics of the model range are indicated, a detailed list of possible faults and methods for eliminating them from experienced professionals is given.

The peculiarity of the book “Operating Manual for Lada Granta with Automatic Transmission” is that, in comparison with the usual manual for Lada Granta, this manual covers in detail the issue of operating a car with an automatic transmission, focusing on possible malfunctions and ways to eliminate them

Body

Air filter for heating (conditioning) and interior ventilation systems (replacement)ZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZ holesDesignations in the table: P - check (if necessary, replacement/topping up/adjustment/lubrication); 3 - replacement.

The table is compiled according to data from the official LADA website.

How to adjust the front seats

Before driving, adjust your seat position so that you feel comfortable behind the wheel. An uncomfortable seating position increases fatigue, which can negatively affect driving safety. The front seats are adjustable in the longitudinal direction (back and forth), by the angle of the backrest and the height of the headrests. The seat adjustment is considered correct when the straightened left leg rests with the entire foot on the floor under the clutch pedal, and the arms, slightly bent at the elbows, lie on the steering wheel wheel in the “10 minutes to 2 o’clock” position. Sit on the seat and check how comfortable it is to drive.

If you need to adjust the seatback angle, turn the hinge handle. The backrest rises or falls when the handle is rotated in the appropriate direction.

If you need to move the seat forward or backward, lift the handle located under the seat and move it with the seat in the desired direction, then release the handle. Move back and forth slightly until the seat locks into place.

To adjust the height of the headrest, move it up or down. Spring clips will hold the headrest in the selected position.

Maintenance regulations from 06.2021

Around June 2022, AVTOVAZ has changed the LADA maintenance regulations. The changes affected the replacement of the timing belt, replacement of brake fluid, coolant, etc. The table was provided to the Lada.Online website by one of the official LADA dealer centers:

Body condition (visual inspection)

The condition of the front and rear suspension elements, their rubber-metal hinges, bushings and covers.

Condition of the front suspension ball pins and their protective rubber covers.

Condition of telescopic shock absorber struts.

Condition of the upper support of the telescopic strut of the front suspension.

Tightness of seals of components and assemblies (inspection from below the car)

Tightness of cooling systems, power supply, condition of hoses and tubes.

The tightness of the hydraulic brake drive system, the condition of hoses and tubes

Inspect and check without hanging the vehicle

Body condition (visual inspection)

Adjust the operation of the locks of the front doors, rear doors, hood, trunk lid, tailgate, if necessary.

The operation of the fuel tank hatch cover and the reliability of fixing the fuel tank filler cap.

Locking operation of side door locks, trunk lid (tailgate), adjust if necessary

Operation of the rear door lock rotary latch (“child lock”).

Tightness of seals of components and assemblies (in the engine compartment)

Tightness of cooling systems, power supply, condition of hoses and tubes (in the engine compartment).

The tightness of the hydraulic brake drive system, the condition of the hoses and tubes in the engine compartment).

Brake fluid level, if necessary, bring to normal.

Operation of the emergency brake fluid level sensor in the reservoir.

Coolant level.

No traces of short circuits or visible damage to the wire insulation.

The operability of electrical equipment components: generator, lighting, light and sound alarms, control devices, heater, glass cleaner, washer, heated rear window and front seats, electric windows and exterior mirrors.

Performance of the headlight range control

Absence of extraneous knocks and noises from the engine, clutch, gearbox, front wheel drive and steering mechanism. Clean and complete engagement of the clutch.

Presence and correct location of warning labels in the vehicle interior.

Place the vehicle at the service station and perform the following work:

Check the condition and tension of the generator drive belt (or auxiliary drive belt), if necessary, adjust the tension (if there is an adjustment mechanism)

Replace the generator belt (or accessory drive belt) and adjust the belt tension (if there is an adjustment mechanism)

On cars with engine 11186: adjust the clearances in the gas distribution mechanism.

On cars with engine 11182: adjust the clearances in the gas distribution mechanism.

Organoleptically check the reliability of fastening the battery and terminals.

The normal voltage at the battery terminals is not lower than 12.6 V.

The normal density of battery electrolyte is 1.24-1.27 g/cm3.

Remove the battery clamps and if there is a white coating on the terminals and clamps, remove it with sandpaper and apply a thin layer of lubricant.

Replace the filter element of the interior ventilation and heating system.

Clean the drainage hole in the front panel.

Replace the engine air filter element.

Replace the high-voltage wires of the ignition system (for an 8-valve engine).

- rubbing areas of door stops and axles, hinges and springs of the fuel tank hatch

-keyholes for side doors, tailgate, trunk lid

Place the vehicle on a two-post lift and perform the following work:

Clean the drainage holes in the thresholds and doors.

Check the condition of the front brake pads and brake discs.

The minimum permissible brake lining thickness is 1.5 mm.

Check the condition of the rear brake pads, parking brake cables, protective caps, and the tightness of the brake wheel cylinders.

Replace the brake fluid and check the tightness of the brake system in accordance with the requirements of TI 3100.21100.08020.

or after 5 years, whichever comes first

Replace the fine fuel filter.

Replace the coolant and check the cooling system for leaks.

or after 5 years, whichever comes first

Replace the oil filter and oil in the engine crankcase, checking the level and tightness of the lubrication system.

Check the condition of the wheels and tires.

min permissible residual tread height 1.6 mm.

Check the air pressure in the tires and adjust them to normal if necessary.

Check the braking efficiency of the service and parking brakes.

Check total steering play

Place the vehicle on a level surface, check compliance with the established standards for the boundaries of the light beams of the headlights and, if necessary, adjust the direction of the light beams.

Check the proper operation of the electromechanical power steering (EMS).

Check the functionality of the electronic engine control system (ECM) and the absence of ECM fault codes in the controller memory.

Check the functionality of the vehicle's electronic systems using the indicators of the instrument cluster and other indicators on the instrument panel and the absence of fault codes in the controller's memory.

Replace the timing belt, tensioner and support roller (if equipped)

Replace the crankshaft and camshaft sprockets

Change the oil in the gearbox

After 180 thousand km or after 5 years

Control and inspection work to identify defects in paintwork and anti-corrosion coating of the body

Check for chips, cracks and points of corrosion, as well as other damage to the paintwork of the body, damage to the underbody mastic.

Check for chips, cracks and points of corrosion, as well as other damage to the paintwork of the body, damage to the mastic of the wheel arches and the bottom.

Present the vehicle to the Quality Control Department.

Download

service book Lada Granta/Kalina 2: To download files you need to log in to the website

Articles

You will find spare parts for maintenance here.

Buy

Everything you need to undergo maintenance can be found in our online store.

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Discounts from the help desk

When you mention ACC you can get discounts on parts and services

Automotive Help Desk: auto news, spare parts in Krasnoyarsk for foreign and domestic cars, disassembled cars, car repairs, addresses and phone numbers of companies, bulletin boards, spare parts catalogues, service and repair manuals.

All information presented on the site is for informational purposes only and under no circumstances constitutes a public offer.

Source

What is the rear suspension like?

Unlike the front suspension, the rear suspension of the Lada Granta chassis is practically devoid of innovations. As before, its basic element is a rigid torsion beam, as the diagram shows. It is attached to the body by means of hinges, and its swinging arms are equipped with support posts. The last components are shock-absorbing struts with spring elements.

If you believe the reviews, then this rear suspension allowed the car to acquire serious advantages over its competitors:

- high energy intensity (it is noted that the degree of loading is not capable of having a significant negative impact on the behavior of the car);

- increased reliability (due to the simplicity of the design aspects of the suspension, its elements may need repairs no more than every 100 thousand km);

- a simple design solution, which makes it possible to carry out repairs with the simplest tools and the owner’s basic experience.

Among the minor changes that affected this model and distinguish it from the Priora, there is a negative camber of the stern wheels (-1°). A slight positive toe-in (0.1°) should also be highlighted. These solutions are aimed at ensuring increased directional stability.