The production of the popular domestic Lada Granta started in 2011. It was this car that became the next after the Lada Kalina, meeting the new needs of modern drivers. However, the value of the parameter on which the vehicle’s efficiency depends—the Lada Grant’s fuel consumption—remains always relevant. The design features of the engine and fuel system of a car determine the dependence of gasoline consumption on many factors, such as fuel quality, wear of engine parts, quality of lubricants, etc.

A competitive car in an affordable price category is available in several trim levels: Luxury, Standard and Normal. AvtoVAZ often installs an automatic transmission on Grant cars, and some modifications are equipped with a 16-valve engine instead of the standard 8-valve.

Types of system

The fuel injection system gets its name from the device that is responsible for spraying gasoline - the injector (from the English Injection - injection, injector - nozzle). A power system of this type was installed on aircraft back in the 20s of the last century. What is noteworthy is that even then it was direct fuel injection into the engine cylinders. We will focus on the development of variations of the Motronic system, in which the engine control unit (hereinafter referred to as the ECU or ECU) is responsible for supplying fuel and adjusting the ignition angle.

The main reasons causing excessive fuel consumption of Lada Granta

Among the reasons why the fuel consumption of a Lada Granta car is unreasonably high are:

- subjective, depending on driving style;

- objective, related to the features and technical condition of the machine.

In the first case, excessive consumption of gasoline is caused by:

- sudden braking and acceleration;

- poorly warmed up engine;

- ill-conceived tuning that worsens the aerodynamics of the car;

- machine overload;

- operating a vehicle in mountainous areas;

- driving too fast.

Engine LADA GRANTA

Among the objective reasons are:

- wear of engine parts;

- breakdowns or failure of elements of the vehicle’s power system;

- insufficient tire pressure;

- Brake failure, creating excessive friction and resistance.

- air conditioning operation;

- damage to the wheel bearing, causing increased resistance when driving.

Single Point fuel injection

Single-point injection, better known as mono-injection, is a transition technology that has allowed many automakers to cheaply switch from a carbureted power system to fuel injection.

In other words, instead of a carburetor, a central fuel injection unit began to be installed above the intake manifold. The system had a number of advantages, since the ECU made it possible to dose gasoline more accurately.

The operating principle of the injector is based on the following elements:

- – a fuel tank with a fuel pump located in it;

- – filter element for fuel purification;

- – central injection unit. 3a – throttle position sensor (TPS); 3b – regulator responsible for fuel pressure; 3с – injector nozzle; 3d – sensor of air temperature entering the intake manifold; 3e – throttle position regulator (in the simplest design options, the damper drive was connected to the accelerator pedal by a cable drive);

- – coolant temperature sensor (DTOZH);

- – lambda probe (oxygen sensor);

- – electronic engine control unit.

Principle of operation

The diagram does not show one element, without which the operation of the mechanism would be impossible - the crankshaft position sensor. It is the DPKV that allows the ECU to calculate the amount of air entering the engine. Let us recall that the amount of fuel supplied depends entirely on the mass of air entering the cylinders, otherwise it is impossible to regulate the composition of the air-fuel mixture (AFM) for normal operation of a gasoline engine. At the stage of engine creation, designers calculate how much air flows at a certain load, that is, the degree of throttle opening, and at certain engine speeds. The data is entered into the engine fuel map, which will be recorded in the ECU. Subsequently, when the engine is running, the control unit records the speed using the DPKV, the load is determined by the throttle potentiometer, which allows you to take the value corresponding to the required amount of fuel from the fuel map. But the system can ideally work only in laboratory conditions, since in practice atmospheric pressure depends not only on the position above sea level, but also on temperature; the air filter becomes clogged over time, allowing less air to pass through it, and the throttle assembly itself becomes clogged. An air temperature sensor is used for correction, but its role is small. The composition of the mixture is truly influenced by the lambda probe, which measures the amount of oxygen in the exhaust gases. If there is too much oxygen, the ECU understands that the mixture needs to be enriched, and vice versa.

Characteristic

The main advantage of single-point injection is its low cost of implementation. Flaws:

- uneven filling of the cylinders, which is due to the location of the nozzle;

- "wet" collector. When the injector opens, gasoline travels a long way to the combustion chamber. When the collector is cold, the fuel does not evaporate, but settles on the walls, as a result of which the mixture must be very rich;

- Although the lambda probe makes it possible to adjust the air pressure control system, the method of measuring air mass is generally ineffective.

Real fuel consumption of Lada Granta: reviews from owners

No matter how the manufacturer declares the parameters of the optimal fuel consumption of the Lada Grant, the real picture can always be found out from those who have been using this car for many years. Depending on the type of engine, the car’s fuel consumption per 100 km has the following values (combined cycle/highway/city):

Engines LADA GRANTA

According to reviews from Lada Granta owners, the average fuel consumption per 100 km in the highway/city/combined cycle ratio is:

- on the highway from 5.5 to 6.5 liters;

- in the city from 9 to 11.8 l;

- mixed cycle from 7.5 to 8.1 l.

These indicators are relative, since in practice each car is operated in certain climatic conditions and has its own technical characteristics.

Multi-Point fuel injection

Multipoint injection was a significant step forward compared to single point injection, as it allowed cars to meet EURO 3 emission standards.

Single-point injection, due to incurable diseases caused by design features, could only meet the requirements of EURO-2.

The history of the evolution of automobile injection systems is extremely interesting, but it is not the main topic of this article. That is why we will not pay attention to the intricacies of the operation of such engine control systems with distributed injection as D-Jetronic, KE-Jetronic, K-Jetronic and L-Jetronic. They stopped installing the listed variations on cars back in the early 90s, and therefore it is extremely difficult to find a car with a “live” distribution injection system of this type.

The main difference between a full-fledged injector and a single injection is the presence of 4 nozzles located near the intake valves. Injection engine components:

- – fuel pump, which in the vast majority of cases is located in the tank;

- – fuel coarse filter;

- – a fuel pressure regulator, from which a return line goes to the tank to drain excess fuel. In some cars there is no return line as such, and the fuel regulator is located next to the pump in the tank;

- – nozzle. The picture above shows how all the injectors are connected by the fuel rail;

- – air flow meter;

- – coolant temperature sensor;

- – idle speed controller (IAC);

- – a potentiometer that records the actual position of the throttle valve (TPV);

- – crankshaft speed sensor (DPKV);

- - oxygen sensor;

- – ECU;

- – ignition distributor.

Air mass calculation

In addition to the nozzles, a special feature of the system is the method for calculating the air mass. There are only 5 ways to measure the amount of air passing through the throttle valve:

- rpm/load. Used on single point injection systems and as a backup option for distributor injection if the air flow meter fails;

- vane type flow meter. Used on Jetronic engine management systems;

- MAF – mass air flow sensor. The operating principle is based on maintaining a constant temperature of the heating element by electric current. The air passing through the mass air flow sensor cools the element, which requires an increase in current. Using a converter, the heating current of the element is converted into an output voltage. There is a relationship between the voltage and the mass of incoming air, which allows the ECU to calculate the amount of fuel required to supply;

- MAP sensor – pressure sensor in the intake manifold. The ECU, having information about the absolute pressure in the intake manifold and additionally using the readings of the air temperature sensor, calculates the cyclic fuel supply;

- air volume sensor. It is the volume that is measured, which is subsequently converted into mass; At the moment, this method of calculating air is not used.

Characteristic

Advantages of distributor valve injection:

- uniform filling of cylinders;

- the use of a mass air flow sensor or MAP sensor allows you to accurately calculate air flow, which provides more opportunities for adjusting the air flow valve in all engine operating modes.

That is why cars with a full-fledged injector are always more powerful and economical than cars with single-point injection.

Fuel pipe Lada Granta

We remove the fuel tank to wash or replace it. We carry out the work on an inspection ditch or overpass. We perform operations when the tank is empty or when there is no more than 5 liters of fuel left in it. Fuel can be removed from the tank by removing the fuel module (see “Removing and disassembling the fuel module”) and pumping gasoline into a canister with a hose through the hole in the tank. If we do not dismantle the fuel module, then disconnect the wiring harness block from the connector of its cover (see “Removing and disassembling the fuel module”).

Use the tallest head to turn it “10” away...

...four nuts securing the tank heat shield...

...and remove the screen.

Squeezing the clamps (greenish) of the tip of the plastic tube and inserting the lips of the pliers between the shoulder of the ventilation tube and the end of the tip...

...move the tip from the ventilation tube.

Use a Phillips screwdriver or an 8-mm socket to loosen the clamp securing the inlet pipe hose.

To make removing the hose easier, inject a universal lubricant between the hose and the pipe...

...and pull the hose off the pipe.

Using a 10mm socket, unscrew the three nuts securing the heat shield of the tubes...

...and remove the screen. Squeezing the clamps (greenish) of the tip of the fuel supply tube to the ramp...

...remove the tip from the fuel pipe.

Similarly, we disconnect the tip (yellowish fasteners) of the vapor removal tube from the adsorber from the tube connecting to the adsorber purge valve. We install an adjustable stop under the fuel tank, placing a block of wood between the tank and the stop.

Using a 13mm socket, unscrew the bolts of the two clamps securing the tank to the body.

We move the ends of the tank mounting clamps through the rear suspension support.

We transfer the fuel pipe and the vapor removal pipe from the adsorber through the additional muffler pipe. Slightly lower the fuel tank on the stop and move it to the right side of the car.

We remove the fuel tank assembly with the adsorber, fuel module, fuel filter and tubes connecting them. Install the fuel tank in reverse order.

Source: sinref.ru

Direct injection

Direct injection, a type of distributor injection system, is the last word in gasoline engine power systems. The main feature of direct injection is the supply of fuel directly into the combustion chamber.

GDI, FSI, D4 are abbreviations used by Mitsubishi, Volkswagen and Toyota, respectively, to designate direct injection engines. The power system of such internal combustion engines is more similar to diesel engines than to the Otto cycle internal combustion engines familiar to all. Device:

What determines the effectiveness

The high cost and complexity of production, which are the main disadvantages of direct injection, are more than compensated by extreme efficiency and power characteristics. This is achieved due to the fact that the engine can operate on 3 main fuel mixture options (the GDI system was chosen as an example):

- superbread mixture. The fuel is injected at the end of the compression stroke and burns in close proximity to the spark plug, while around the combustion zone in the combustion chamber there is predominantly clean air or a mixture of air and exhaust gases, which is supplied by the EGR;

- stoichiometric. Fuel is supplied during the intake stroke and mixes well with air, forming a mixture close to the ideal proportional ratio (14.7/1) throughout the combustion chamber;

- power mode, in which TPVA is prepared in two stages. A small amount of fuel is supplied during the intake stroke, but the main portion is injected at the end of the compression stroke.

By supplying liquid fuel directly into the combustion chamber, direct injection engines are less prone to detonation, which allows for higher compression ratios and increased engine efficiency.

All modern cars with gasoline engines use a fuel injection system, since it is more advanced than a carburetor, despite the fact that it is structurally more complex.

The injection engine is not new, but it became widespread only after the development of electronic technologies. This is because it was very difficult to mechanically organize control of a system with high operating accuracy. But with the advent of microprocessors this became quite possible.

The injection system differs in that gasoline is supplied in strictly specified portions forcibly into the manifold (cylinder).

The main advantage of the injection power system is compliance with the optimal proportions of the constituent elements of the combustible mixture at different operating modes of the power plant. Thanks to this, better power output and economical gasoline consumption are achieved.

Fuel pipe VAZ-2190 Granta front fuel line (steam outlet) 21900-1104040-00

Out of stock, check availability in other towns

| Vendor code: | 21900-1104040-00 |

| Catalog: | 2190-1104040 |

| Title: | Fuel pipe VAZ-2190 Granta front fuel line (steam outlet) 21900-1104040-00 |

| Product from the group: In categories: | VAZ power system spare parts |

| Availability: |

Pickup from a warehouse in Yekaterinburg

Payment (issue of money for some obligation)

upon receipt:

- Cash

- Transfer to card

- By bank card

- By invoice (for organizations with VAT)

Fundamentally. Before receiving the product, please check its availability by phone or place an order on our website.

Delivery by courier in Yekaterinburg and nearby towns

- Payment (issue of money for any obligation)

in cash upon receipt of the product - The cost of delivery within the city and nearby towns is 100-250 rubles

- Free delivery throughout Yekaterinburg for orders over 10,000 rubles.

- Please check with the RusAvto manager for delivery times and costs.

For small orders and delivery costs, see the Delivery section.

| Small order | Cost of delivery | Free delivery from | |

| Ekaterinburg | 1000 | 150 | 6000 |

| Upper Pyshma | 3000 | 200 | 10000 |

| Berezovsky | 3000 | 200 | 10000 |

| Aramil | 3000 | 200 | 10000 |

| Revda | 5000 | 400 | 17000 |

| Pervouralsk | 5000 | 400 | 17000 |

| Polevskoy | 7000 | 500 | 26000 |

| Sysert | 7000 | 500 | 26000 |

| Novouralsk | 10000 | 600 | 34000 |

| Nevyansk | 12000 | 700 | 37000 |

| *does not apply to large spare parts and special products. cost | |||

Delivery by Russian Post

- Prepayment 30% of the product price (Cashless payment on invoice)

- The balance of the amount is cash on delivery upon receipt of your product at the post office.

- Delivery services are paid by the recipient according to the current tariffs of Russian Post.

Why do we ask for partial payment in advance before shipping? In our practice, there have been cases when a product sent by cash on delivery remained for a long time in the recipient’s post office and was not picked up. We were required to pay for storage and bear additional costs for the return shipment of the unclaimed product to our warehouse.

Source: rusautoopt.ru

System design

The fuel injection system consists of electronic and mechanical components. The first controls the operating parameters of the power unit and, based on them, sends signals to activate the executive (mechanical) part.

The electronic component includes a microcontroller (electronic control unit) and a large number of tracking sensors:

- Lambda probe;

- crankshaft position;

- mass air flow;

- throttle position;

- detonation;

- coolant temperature;

- air pressure in the intake manifold.

Injector system sensors

Some cars may have several additional sensors. They all have one task - to determine the operating parameters of the power unit and transmit them to the ECU

As for the mechanical part, it includes the following elements:

- tank;

- electric fuel pump;

- fuel lines;

- filter;

- pressure regulator;

- fuel rail;

- injectors.

Simple fuel injection system

What to do if hoses/tubes fray under the hood of a LADA car

During driving, vibrations are transmitted to the body. They not only make the car less convenient to operate (creaks and rattles of plastic appear in the cabin), but can also shorten the service life of certain parts and the body. In connection with this, it is recommended to periodically inspect the engine compartment to check the condition of hoses, tubes, pipes and paintwork.

Moving elements (hoses, tubes, cables, casings, etc.) that are poorly secured in the engine compartment can become chafed during use of the vehicle. To eliminate friction of rubber and plastic parts and extend their service life:

- the system is firmly fixed with clamps;

- wrapped with protective material (for example, electrical tape);

- install additional fastenings;

- Reworking the fastenings.

For owners of Lada cars, it is recommended to pay attention to the following places:

How it all works

Now let’s look at the principle of operation of an injection engine separately for each component. With the electronic part, in general, everything is simple. The sensors collect information about the speed of rotation of the crankshaft, air (entered into the cylinders, as well as its residual part in the exhaust gases), throttle position (connected to the accelerator pedal), and coolant temperature. The sensors constantly transmit this data to the electronic unit, due to which high accuracy of gasoline dosage is achieved.

The ECU compares the information received from the sensors with the data entered in the maps, and based on this comparison and a series of calculations, it controls the executive part. The electronic unit contains so-called maps with optimal operating parameters of the power plant (for example, for such conditions it is necessary to submit as many - so much gasoline, for others - so much).

Toyota's first fuel-injected engine in 1973

To make it clearer, let us consider in more detail the algorithm of operation of the electronic unit, but according to a simplified scheme, since in reality a very large amount of data is used in the calculation. In general, all this is aimed at calculating the time length of the electrical pulse that is supplied to the injectors.

Since the diagram is simplified, we assume that the electronic unit carries out calculations only on several parameters, namely the base time pulse length and two coefficients - coolant temperature and oxygen level in the exhaust gases. To obtain the result, the ECU uses a formula in which all available data is multiplied.

To obtain the basic pulse length, the microcontroller takes two parameters - the crankshaft rotation speed and the load, which can be calculated from the pressure in the manifold.

For example, the engine speed is 3000, and the load is 4. The microcontroller takes this data and compares it with the table included in the card. In this case, we get a basic pulse length of 12 milliseconds.

But for calculations it is also necessary to take into account the coefficients, for which readings are taken from the coolant temperature sensors and the lambda probe. For example, the temperature is 100 degrees, and the oxygen level in the exhaust gases is 3. The ECU takes this data and compares it with several more tables. Let's assume that the temperature coefficient is 0.8 and the oxygen coefficient is 1.0.

Having received all the necessary data, the electronic unit carries out the calculation. In our case, 12 is multiplied by 0.8 and 1.0. As a result, we find that the pulse should be 9.6 milliseconds.

The described algorithm is very simplified, but in reality, more than a dozen parameters and indicators can be taken into account in the calculations.

Since data is constantly supplied to the electronic unit, the system almost instantly reacts to changes in engine operating parameters and adapts to them, ensuring optimal mixture formation.

It is worth noting that the electronic unit controls not only the fuel supply, its task is also to adjust the ignition angle to ensure optimal engine operation.

Now about the mechanical part. Everything is very simple here: a pump installed in the tank pumps gasoline into the system, under pressure, to ensure forced supply. The pressure must be certain, so a regulator is included in the circuit.

Gasoline is supplied through the highways to a ramp, which connects all the injectors. An electrical impulse supplied from the ECU causes the injectors to open, and since gasoline is under pressure, it is simply injected through the opened channel.

Quick-release fitting for fuel pipe Lada Granta, Kalina 2, Priora, Datsun corner

Dear customers, in order to avoid errors when sending a fuel pipe fitting, in the “Comment” line indicate the model of your car, year of manufacture, and the shape of the fitting (straight, angle, tee, Y-shaped).

Flexible fuel hoses are placed at a distance of at least 100 mm from parts of the exhaust system and 250 mm from the catalytic converter.

On some models, nylon fuel hoses with quick-release connectors are installed. As it becomes necessary to replace the 1st hose, the hoses complete with quick-release connectors are replaced.

The fuel pipe fitting (Quick Release Adapter) is used to ensure the best seal between the quick release and a pipe of the same or different internal diameter. Using straight, elbow, tees, Y-shaped fittings.

– The unique fitting connection ensures a hermetically sealed quick release;

– For pipes with an internal diameter from 7 mm to 10 mm;

– Quick release is resistant to extreme temperatures from -65°C to +250°C and additives to cooling water, gasoline, diesel fuel, and oil.

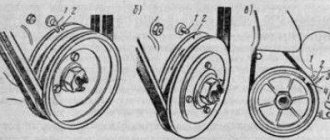

Replacing fuel pipes and hoses is done as follows:

– The pressure in the fuel system is relieved;

– All clamps securing the tube/hose to the car body are released;

– The clamp is opened and removed,

Opening the clamp (1) of the quick connector.

– Then with one hand they press the clamps on both sides, and with the other hand they remove the tube from the connector.

Pressing the latches and removing the tube from the quick connector

When connecting tubes and hoses, be sure to install the latest O-rings (as specified by design).

On quick-release connectors, align the tube with the connector and insert the tube into the connector until it snaps into place with the clamps.

At the usual connections of a metal fuel pipe and hose, the clamp is loosened, then the tube of their hose is pulled out. Rotating the tube and hose in different directions makes the disconnection process easier.

Other articles of the product and its analogues in the catalogs: 316310110441000.

VAZ 2170, VAZ 2190, Kalina 2, Largus, Datsun, Vesta.

No matter what the breakdown is, it’s not the end of the world, but a completely solvable problem!

How to independently change the corner fitting of the fuel pipe on a Lada car.

AvtoAzbuka Discounter Web Store, repair costs will be minimal.

Just COMPARE and BE SURE.

Don’t forget to share the information you found with your friends and acquaintances, as it may also be useful to them - just press one of the social network buttons located above.

Source: avtoazbuka.net

Types and types of injectors

There are two types of injectors:

- With single point injection. This system is outdated and is no longer used on cars. Its essence is that there is only one nozzle, installed in the intake manifold. This design did not ensure uniform distribution of fuel throughout the cylinders, so its operation was similar to a carburetor system.

- Multipoint injection. Modern cars use this type. Here, each cylinder has its own nozzle, so this system is characterized by high dosage accuracy. Injectors can be installed both in the intake manifold and in the cylinder itself (direct injection system).

A multipoint fuel injection system can use several types of injection:

- Simultaneous. In this type, an impulse from the ECU is sent to all injectors at once, and they open together. This type of injection is not currently used.

- Paired, also known as pairwise-parallel. In this type, the injectors work in pairs. It is interesting that only one of them supplies fuel directly during the intake stroke, while the second does not have the same stroke. But since the engine is a 4-stroke, with a valve timing system, the mismatch of injection on the stroke does not affect the performance of the engine.

- Phased. In this type, the ECU sends signals to open for each injector separately, so injection occurs with a coincident timing.

It is noteworthy that a modern fuel injection system can use several types of injection. So, in normal mode, phased injection is used, but in the event of a transition to emergency operation (for example, one of the sensors has failed), the injection engine switches to twin injection.

conclusions

You should only drain gasoline in the most extreme cases, since you are interfering with the operation of the mechanism. This may be regarded by the manufacturer as a violation of warranty requirements, especially if the work was performed poorly, resulting in damage to some parts. Therefore, try to refuel only at proven gas stations, and constantly monitor the amount of fuel along the way.

Yes, I completely agree, sometimes when they fill up with gasoline, you drive 1 km away from the gas station and begin to sneeze, the traction disappears and there is practically no speed, sometimes it helps that you can fill in twice as much good gasoline at another gas station and stir it, you can go, in general, for everyone I have favorite dressings, as I noticed)

I didn’t think there would be so many problems if I had to drain all the gasoline from the tank. Although no one is insured, with our tankers.

Draining gasoline from a gas tank is an event that is faced not only by lovers of easy money.

The quality of fuel in Russia is such that even a trustworthy and honest motorist may encounter such a need.

A drop in engine power, erratic operation, extraneous sounds, an unpleasant odor, a changed color of exhaust gases - many symptoms indicate that low-quality fuel was poured into the gas tank.

Operating a vehicle in such a situation is not recommended, in fact, it is even prohibited, as the risk of deposits in the fuel lines and carbon deposits forming on the valves and inside the cylinders increases.

All this is fraught with serious damage, the elimination of which will require considerable financial investments. There is only one correct solution - stopping and draining the low-quality product. How to do it? Let's find out in our article.

Read more: Jump in the wrong place