In general, the problem is known. I've been hearing a knock on the right side for a long time now, and on top of that, the car jerks when shifting or releasing the gas. There is a hundred percent assumption that the right engine mount is to blame. Here's what I found on the Internet:

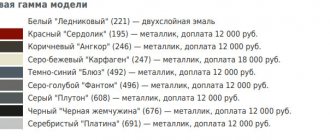

Depending on the batch, different engine mounts are installed on Vesta (VAZ 21129). In some cases, it may cause extraneous noise (knocking, clicking, rattling). Let's figure out how to eliminate this drawback with your own hands. Currently, there are no AvtoVAZ regulations on this problem. Therefore, when contacting an official dealer with such a defect, there cannot be an unambiguous solution. According to the owners' reviews, in some cases the dealer sent data on this malfunction to AvtoVAZ (you need to wait for a response), in other cases they replaced the upper engine mount with an alternative, more rigid one. Solution No. 1.

You can also get rid of the knocking with a simple modification.

It is necessary to lubricate the engine mount with silicone grease (WD-40 will not work) in the places where the rubber comes into contact with the metal housing. Solution No. 2.

Install 1-2 mm thick plates into the engine support. A similar solution is found among Renault owners. Despite the fact that the VAZ 21129 engine (1.6 l, 106 hp) is also installed on the Lada XRAY, the upper right mount of the power unit has a different part number (on Vesta - 8450030109, on XRAY - 112107286R), accordingly, this problem is not observed on the crossover.

It all looks like this, the video is not mine:

I lubricated it with silicone, made gaskets - there is no point, it doesn’t last long, the car still knocks and jerks. The unit jumps under the hood quite well, this, by the way, may be the reason for the failure of the corrugations on the exhaust pipe. Has anyone encountered a real solution to this question, which pillow to buy? I'm interested in the desk number, just to be sure.

The pillow, also known as the Lada Vesta engine support, is a kind of stabilizer against detonation. Vesta car parts come in three types: left, right, rear additional - price from 1,400 rubles. The parts have a separate article number. Malfunctions: the main malfunction is a knocking sound from the support, usually knocking on the left. The left pillow is reinforced. It is important to adjust the engine mount correctly. During engine operation, useful energy is generated, which is used to set the Lada Vesta car in motion. The movement of the “insides” of the motor causes it to begin to create vibration. To “dampen” engine vibration, they place them on supports, which perform several more functions:

- increase sound insulation of the engine compartment;

- protect other parts and assemblies from damage;

- stabilize the position of the motor as much as possible (if the amplitude of movement of the motor constantly increases, this will lead to wear of the connections);

- protect the engine from the negative influence of the external environment (when the car passes obstacles, the suspension does not completely dampen rolling, and the struts act as additional shock absorbers).

This way, not only the engine is secured, but also the gearbox. His pillow on the Lada Vesta consists of three supports. On the sports model, an additional support enhances stabilization when accelerating and braking; its design is mechanical rubber-metal. Each pillow is a mechanism of two metal plates, between which there is elastic rubber.

At the most unexpected moment, strange sounds may be heard from under the hood - knocking, grinding, clanging, unusual for the normal operation of the car - perhaps this is just the knock of the Lada Vesta engine support. To recognize it and “cure” it correctly, let’s look at everything in order.

For what reasons do hydraulic compensators knock on Lada Vesta: fault diagnosis

Sounds and background

Poor maintenance of the engine oil system can cause knocking of hydraulic compensators in Lada West even at low mileage. Unsuitable oil viscosity or untimely replacement of it are direct preconditions for the appearance of clattering noise from “hydrikis” in the near future.

Not all owners correctly recognize a specific engine knock when they hear it for the first time. Meanwhile, the hydraulic modules rattle identically to a running diesel engine. To be more precise, the sound is similar to the acoustic design of a functioning injection pump of a diesel or gasoline engine with direct injection.

Simply recording the presence of a knock will not help identify the cause of the problem. It is necessary to find out how hydraulic modules behave:

- Hot.

- To the cold.

- At different speeds.

It will become clear later that these circumstances are important in determining a strategy for eliminating tapping.

Knocks when cold

A sudden clattering noise should not always be regarded as a breakdown. This fully applies to the case when the sound appears briefly when starting a cold engine - literally for 1-2 seconds. Such a reaction only indicates the bleeding of oil from the hydraulic tappets due to long-term parking, but does not in any way indicate problems with the oil supply to the hydraulic compensator unit during operation of the power plant.

Longer tapping when cold is unacceptable. The prerequisites for violation of the operating mode are identical to the reasons for the clattering of hydraulic compensators on the Lada Priora, of which there are several:

- Insufficient pressure in the oil system (oil pressure lamp is on).

- Excessive contamination with wear products or mediocre quality of the oil composition.

- Oil of inappropriate viscosity: it is impossible either to push the fluid through small channels or to maintain the specified pressure.

- Coked holes in the oil system lead to knocking from the hydraulic compensators of the Lada Vesta engine due to a decrease in pressure inside them.

- Hydraulic pusher wedge due to carbon deposits.

- Wear of the plunger pair, leading to oil emulsion leaks.

Tapping on hot

Vest owners sometimes notice that when the engine is cold, it whispers, and as it warms up, a clattering sound occurs from the hydraulics. Such a symptom can appear for any of the above “cold” reasons. However, more often the knocking of hydraulic compensators on a hot engine has its own prerequisites:

- Incorrect oil level. Engines equipped with hydraulic compensator devices are quite sensitive to foaming of the oil composition, which occurs when the lubricant is overfilled. Underfilling is also fraught - the oil pump will pick up air.

- The increase in landing areas for hydraulic pushers is the result of overheating of the cylinder head.

Detailed diagnostics: structural component of knocking

Guided only by a thermal sign, it will not be possible to find out exactly why the hydraulic compensators are knocking. An additional set of tests is required. Its essence is to analyze changes in the acoustic design of the Vesta engine, changing the speed and taking into account the temperature of the coolant.

Operating with revolutions

The testing stages boil down to analyzing the operation of the motor in various modes:

- A knocking sound when cold or hot, which disappears at high speeds, indicates wear of the ball valve of the hydraulic module or its clogging with wear products. Option No. 1 - change the oil and oil filter to ones known to be suitable for the 129 engine. As a last resort, replace substandard hydraulic compensators.

- A clattering sound exclusively on a hot engine, which goes away with increasing speed, indicates a critical condition of the plunger pair. It can only be eliminated by replacing the compensator assembly.

- Tapping noises are heard only at high speeds, regardless of engine temperature, and at idle the engine operates smoothly - check the oil level. It is advisable to fill slightly above the average dipstick level, without exceeding the MAX mark. A damaged oil pickup has a similar effect.

Consequences of ignoring a fault

The main prerequisite for troubleshooting is intrusive extraneous noise. Few people know what the real danger of tapping is. Excessive clearances in the timing belt affect the operating mode of the cams: the resulting shock loads significantly reduce the service life of the crankshaft.

Knock of the engine mount on cars of the Lada Vesta family

Some owners of Lada Vesta family cars began to notice noise and knocking coming from the engine compartment of their car.

After long disputes with official dealers and between the owners themselves, the hero of the occasion was identified. It turned out to be a car engine support (pillow). In most of these cases, the noise came precisely from the right engine mount, after the owners went en masse to official centers with this problem, and also began writing appeals directly to AvtoVAZ, the manufacturer confirmed the possibility of this problem occurring on some cars, as well as sent an information letter to the showrooms of official dealers. This letter contains information about identifying a problem with the engine mount, as well as methods of elimination, mainly replacing the defective spare part. So if your car is under warranty and you suspect the engine mount is not functioning properly, feel free to go for diagnostics to an official dealer, where this defect will be corrected for you. Solving the problem becomes more expensive if the car’s warranty has expired or it is not possible to visit an official dealer. First, you need to establish whether the engine mount is exactly to blame for the extraneous noise from the engine compartment; to do this, we follow the instructions taken from the AvtoVAZ information letter.

The knocking sound of a faulty engine mount can be heard from the driver's and front passenger's seats; the sound itself emitted by the mount is muffled and occurs when the engine oscillates transversely. To reproduce a knock, do the following:

- We accelerate to 30 kilometers per hour and brake, repeat several times, make turns and hit a small curb (actions that can cause engine vibrations)

- Sharp acceleration from a stop and subsequent braking.

When performing the above steps, a dull knock should be heard, if this does not happen, most likely the cause of the extraneous noise in your car is not related to the engine mount.

If, after carrying out diagnostics, you are also sure that the engine mount is faulty, you need to inspect it for defects. Defects can be both obvious (cracks in rubber, metal wear) and hidden (large gaps).

By the way, AvtoVAZ sentences the cushion to be replaced if the gap is more than 2 millimeters; in all other cases, silicone grease is applied to the right and upper contact surfaces of the bump stop. Lubrication occurs at the will of the owner and is paid according to the price list.

Also, to solve the problem on their own, the owners lubricate the engine mount themselves; this is done only with the help of silicone grease; WD-40 and similar chemistry are powerless here. It is worth noting that this solution is temporary and you will still have to replace the pillow in the future.

AVTOVAZ recommendations for determining the causes of engine knocking

One of the reasons why customers contact the LADA dealership is the appearance of knocking noises in the engine. To determine the causes of extraneous noise, recommendations were sent to PSSS specialists (since there are relatively frequent complaints about piston knocking, further emphasis is placed on the pistons).

1.

Open the hood of the car, ask the client to demonstrate a non-functional knock. If there is engine knocking, go to step 2.

2.

Using a stethoscope, localize the location of the knock by sequentially listening to the lower and upper parts of the cylinder block in the area of all cylinders. Ideally, this is how you can identify a “knocking” cylinder. Regardless of the success of localizing the knock, proceed to step 3.

3.

Make a high-quality video recording with the sound of knocking, for example, on a smartphone. In the video, first remove the car (so that the model is clear), then its registration plate, then remove the running engine (the mode in which it knocks) with the hood raised. Video duration is from 15 to 30 seconds.

4.

Assess how the knocking noise changes when the “knocking” cylinder is turned off (by turning off the spark plug of a given cylinder). If it was not possible to localize the knocking in step 2, then turn off all cylinders one by one.

5.

Describe the diagnostic work and send a video file with a recording of the non-functional knock to the factory. Wait for further instructions from the specialists of PJSC AVTOVAZ.

6

. After receiving instructions from the specialists of PJSC AVTOVAZ to disassemble the engine, remove it from the car and disassemble it, remove the pistons.

7.

Take photos of the pistons and cylinders using the procedure below:

A)

Gently wipe the surface of the cylinders and pistons from liquid oil, DO NOT TOUCH hard carbon deposits and varnish.

b)

Using a dark colored marker (or felt-tip pen), mark the piston/cylinder number, front/rear part of the cylinder, loaded/unloaded side of the piston/cylinder. Examples of markings are shown in all photos below. Mark the cylinder number on the top of the piston with a sharp metal object. The loaded side is the release side, indicated by stripes. The unloaded side is the inlet side for 16 cells. ICE and spark plug side for 8 cells. ICE is indicated by dots. The points between the cylinders indicate the direction towards the front of the engine. An example of a marked cylinder block is shown below.

V

) Clean (if necessary) the lens of your camera or smartphone.

G)

Focus the camera and take a photo according to the sample photo. If necessary, take as many photos as required for a sharp shot.

In the photo below, the pistons are separated from the connecting rods and are standing on a table.

If the pistons are assembled with connecting rods, then place them on the table surface and photograph from above.

An example of correct cylinder block markings

: stripes – loaded side; dots – unloaded side; arrows or ticks indicate the direction to the front of the engine; number of stripes and dots – cylinder number.

Photo of the 2nd cylinder, loaded side.

The two red stripes at the top of the photo mark the loaded side (black arrow).

The two red dots at the bottom of the photo mark the unloaded side (yellow arrow).

The red tick on the right marks the rear of the engine (blue arrow).

The red tick on the left marks the front of the engine (green arrow).

Photo of the 2nd cylinder, unloaded side.

Photo of the 2nd cylinder, front side.

Photo of 2nd cylinder, rear side

Photo of the 2nd piston, loaded side (two black stripes on the skirt at the top right)

Photo of the 2nd piston, unloaded side (two black dots on the skirt at the top right)

Photo of the 2nd piston, back side (two black dots on the skirt at the top left)

Photo of the 2nd piston, front side (two black stripes on the skirt at the top left)

Photo of the 2nd piston, top view (the number “2” means the second cylinder)

Photo of the 2nd piston, bottom view.

8

. Measure the diameters of each cylinder in a section perpendicular to the axis of the crankshaft, in zones 40, 50, 60, 70, 80 and 100 mm from the mating plane of the block with the cylinder head (see photo below) with an accuracy of 0.001÷0.005 mm (the specified measurements are for installed piston groups from Federal Mogul).

9

. Measure the diameters of the skirts of each piston at a distance of 10 mm from the lower edge of the skirt (see photo below) with an accuracy of 0.001÷0.002 mm. Record it in the protocol. The pistons of the VAZ-21179 1.8 l engine - 16 cl (only these) have a special window on a graphite coating at a distance of 10 mm from the lower edge of the skirt. If the measuring instrument allows you to take measurements in a window without affecting the graphite, then be sure to indicate “measurement for metal” in the protocol.

10

. Send photographs and measurement reports of pistons and cylinders to the factory. Wait for further instructions from the specialists of PJSC AVTOVAZ.

Let us remind you that we previously published a collection of Technological Instructions (for Lada Vesta, XRAY, Granta/Kalina, Largus), which will help you service your car with your own hands.

Source

How to eliminate the knocking of hydraulic compensators on Lada Vesta using auxiliary means

The manufacturer sets the service life of hydraulic compensator mechanisms for the entire period of operation of the motor. There are no routine maintenance activities for these units. By filling in high-quality lubricating fluid and knowing how often to change the engine oil, problems with hydraulic tappets can be avoided.

Use proven lubricant

At the first appearance of knocking, attempts are often made to change the oil composition. Well, the action is justified both when recording the fact immediately after replacing the emulsion, and as an early prevention of coking of hydraulic pushers

It is important not to deviate from the factory viscosity standards:

But this is not enough. A good product will be one that, according to reviews, is problem-free for the VAZ 21129. Since the development is still young and little technical information has been collected on oils, you can use the database for 126 and 127 sixteen valves. For example, Shell Helix Ultra 5W-40 was not suitable for them. Among the optimal lubricants were the following:

- Liqui Moly Optimal Synth.

- Mobile Ultra.

- Total Quartz Energy 9000.

- Wagner Windigo.

Additives

Additional auto chemicals are not used as the main solution to the problem. Its task is to delay repairs by several thousand km. Accordingly, it is advisable to use this method only in case of wear or damage to the expansion joints. Liqui Moly Hydro-Stossel-Additiv and XADO products can be considered as additives.

Flushing

It is appropriate to carry out flushing activities when it is detected that the hydraulic compensators are coked or clogged. Only a local wash, not a general one, will help remove the knocking noise of contaminated hydraulic compensators on the Lada Vesta. The oil emulsion is poorly pumped through hydraulic pushers, hence the low efficiency of complex flushing.

Removing the valve cover on the 129th engine is not easy, and for local washing, access to the hydraulic modules is a necessary condition. A defective compensator either has a constant gap, or is pressed much easier than others with a wooden wedge resting on the non-working surface of the cam.

The following liquids can be used to wash away carbon deposits and remove foreign products:

- Dimexide.

- Acetone + kerosene (2:1).

- Solvent.

- Any washing takes five minutes.

Problem

As sad as it is to realize, West owners are not spared this problem either. Many owners notice knocking noises under the hood of the Lada Vesta, and they come from the right side.

As a rule, you don’t have to search for long, since the situation is well known. It appears on sedans that were equipped with engine mounts from the VAZ 21129. As a result, a whole cacophony of sounds began to be heard from the engine compartment, including knocks, clicks, squeaks, etc. Moreover, these sounds are so loud that they can be heard even in the cabin.

The knock from the support is quite loud

And the best confirmation of this is numerous videos in which owners of the domestic model demonstrate trouble.

And in this video you can hear knocks directly inside the car.

In addition, some owners began to “dig deeper” and found out that a similar situation occurs not only on Vesta, but also on other models of the Renault-Nissan Alliance. In particular, on the Nissan Qashqai. This is also confirmed in the video.

As for the Lada X-Ray, the hatchback has not noticed such a problem, even though its engines are the same as those on the sedan. The whole point is that X-Ray is equipped with different supports for the power unit.

How to check engine mounts

The first sign of a strut malfunction is a knocking sound coming from the engine compartment. To pre-confirm this “diagnosis”, check for the following signs:

- A hum is heard in the cabin when driving at high speeds.

- When starting the Lada Vesta engine when cold, metallic tapping is heard in the cabin and strong vibration is felt.

- When accelerating sharply or braking sharply, knocking noises are heard from under the hood.

- A knocking sound from the left engine mount of the Lada Vesta is less common, but the final conclusion can be made by visually inspecting the cushions. A good rubber-metal part should be completely free of damage, so that the rubber does not make a knock when it comes into contact with metal - this way it does not absorb shocks.

- Rock the engine and then press on each corner to identify the worn pad that needs to be replaced. Wait until it cools down before touching the motor.

The knocking sound of the upper engine mount on Vesta is common

It is important to point out the knocking of the Lada Vesta engine mount, which carries a greater load than the other two - this is the upper (or lower) cushion. It is located in the center and does not dampen the vibrations that come to the left or right edge of it, which is why it quickly becomes loose. The design can be modernized by adding a special pillow for the sports version.

Hydromount from BMW

1. First version Stage 1

Engine mount 2495601 from BMW 3 (E46) was taken as a basis. The price is about 2800 rubles.

The peculiarity of the support is that it is hydraulic (the design uses not only metal and rubber, but also oil).

a) at idle, soft support: b) in motion, hard support: 1 – lower (expansion) chamber; 2 – throttling channel; 3 – upper (working) chamber; 4 – movable membrane; 5 – hydraulic support housing; 6 – damping fluid channel.

The difference between a hydraulic and standard support is demonstrated in the video:

The weight of the pillow is 1.76 kg.

Price:

5300 rub. (the LEMFORDER 2495601 support itself costs about 2800 rubles).

2. Modified version of Stage 2.

The hydraulic mount itself is essentially the same thing with the addition of a guitar of the same manufacturer. Due to this, we managed to save some money, so the price increased only for the silent block itself.

Silent block from jikiu be21058, there are no analogues.

Buy

: withdrawn from sale.

Review of Manufacturer Prices

| Catalog number / Size / Diameter | Price in rubles |

| Original | |

| 17012680 (inner diameter 21.5 mm.) | From 400 |

| 8450006748 | From 400 |

| Analogs | |

| Polyurethane from Chevrolet Niva 2123 (17012680) | From 350 |

| Polyurethane for Lada Vesta from Kia Rio (548132K100, 548141G000) | From 550 |

| 54813-2K100 (diameter 21.5 mm.) | From 550 – 600 |

| KSBSOULF (diameter 21.5mm) – new sample | From 550 – 600 |

| Vesta front left / right (8450006750), stabilizer struts length 275 mm | From 700 |

| RENAULT Logan suspension mount (30768) | From 130 |

| Nut RENAULT 7703034221 | From 300 |

| Bracket 8450006747 | From 350 |

| Rod 8450006748 | From 450 |

| Toyota Rav4 (48820-42020), length 285 mm | From 2500 |

| CTR (CLT50) | From 650 / piece |

| Renault, SASIC, SIDEM, LEMFORDER, length 275 mm | From 400 |

| Alfa – Fiat – Lancia 46413122 | From 370 |

| MONROE: L15600 | From 380 |

| Multipla, Lybra | From 350 |

| Kia Rio (548132K100) | From 370 |

| Bracket (548141G000) | From 250 |

*prices are as of April 2, 2019.

Conclusion

If you notice a third-party creaking, knocking, or rattling noise in the suspension, don’t panic. Malfunctions are a natural process

At the initial stage, it is important to correctly identify the source of the breakdown and its location

If you do not have a special tool, such as mounting tools or TORX keys, contact a service station. It is extremely difficult to repair a car with your bare hands. Regarding the manufacturer of spare parts, the final decision rests with the owner of the technical equipment. The domestic manufacturer is not inferior in quality to foreign analogues. In this case, it is not advisable to overpay for the brand.

How to change airbags on a Vesta car

In order to correctly adjust the engine mount, it is not at all necessary to go to an official dealer - contacting him will still result in the installation of exactly the same part.

Replacing the left engine mount

Before work, prepare and “clear” your way to the part: remove the battery, battery shelf, air filter mount and crankcase protection from under the hood; all components will have to be put aside and then reinstalled. The Lada Vesta cushion itself is attached to the side member on the body with four bolts, and to the gearbox bracket with two bolts. In order not to worry about the reliability of the structure, make sure for yourself that this bracket is attached to the gearbox housing with three bolts.

The replacement procedure is as follows:

- Jack up the gearbox - this will reduce the load on the cushion, because the jack will “take” it.

- Using keys 16 and 18, unscrew all the bolts that are responsible for fastening the pillow. When retightening the mounting bolts to the side member, stop at a torque of 53-71 Nm.

- As for the mounting bolts to the bracket, their tightening torque is 90-120 Nm.

- Remove the right engine mount.

- Place the new part in place of the old one and tighten the bolts until you are sure that the structure is stable.

Replacing the right engine mount

Depending on the engine model: HR16 or 21129, the design of the right airbag of the Lada Vesta is different. In the VAZ 21129 engine, the right support is located next to the spar, to which it is attached with two bolts, and the engine itself, to which it is attached with three bolts.

The HR16 engine has a slightly different design, and the part can be found next to the fuel pipe and the gasoline vapor recovery system pipe. Three bolts secure its body to the motor, two more hold the bracket. This power unit support in the Lada Vesta is located on the right.

To replace, unscrew all the fastening bolts (depending on what kind of “engine” is in your car) with a 16mm wrench and a TORX E12 wrench and remove the pillow itself.

When you assemble the structure, tighten the bolts to a force of 53-71 Nm.

Replacing the rear additional engine mount

This part is installed below, on the rear side of the motor. The mounts are different on the two types of motors. On the 21129 engine of the Lada Vesta, it is “tied” into a large network of fasteners. So, on one side it is held in place by a bracket that is firmly supported by two bolts. On the other hand, it is attached to the subframe with a bolt and nut. On the HR16 engine, the fastening is simpler: on one side, one bolt secures the part to the subframe, on the other, two bolts secure it to the gearbox.

To replace, unscrew all bolts and remove the rear cushion. On motor 21129, be careful with the bracket fastening bolt - loosen it last and “catch” the pillow.

When putting the structure back together, tighten the bolts to 90-120 Nm.

You can do the work of replacing the power unit supports yourself. After tightening the bolts, check the strength and stability of all racks - they should not wobble excessively and should not stand “tight” - they should have a small amplitude of movement. Proper bolt torque will keep the motor in place and reduce vibration. To ensure the reliability of new parts, you can modify them by lubricating them (wd-40 will not work here).

Source

Right pillow

Replacing the engine mount of the Lada Vesta and X-Ray begins with dismantling the mudguard of the power unit, after which the engine must be jacked up on the right side. The support itself is fixed to the spar using 3 bolts.

For dismantling you will need:

- Using a 16mm wrench, unscrew the 2 bolts that secure the cushion to the body.

- Remove the 2 bolts that secure the cushion to the power unit bracket. A TORX E12 bit is used for this.

When everything is done, you can remove the support.

Installation proceeds in the reverse order, and the bolts should be tightened in the range from 53 Nm to 71 Nm.

As for the right motor mount of the HR16 series, it has a slightly different layout.

Solving the problem yourself

Method No. 1

. You can also get rid of the knocking with a simple modification. It is necessary to lubricate the engine mount with silicone grease (WD-40 will not work) in the places where the rubber comes into contact with the metal housing. Photo of the upper right mount of the Vesta engine: Read more: Nissan Terrano engine where it is assembled After this, the knocking should go away:

Method No. 2

. Install 1-2 mm thick plates into the engine support (author of the photo). A similar solution is found among Renault owners.

Despite the fact that the VAZ 21129 engine (1.6 l, 106 hp) is also installed on the Lada XRAY, the upper right mount of the power unit has a different part number (on Vesta - 8450030109, on XRAY - 112107286R), accordingly, this problem is not observed on the crossover.

Let us remind you that knocking noises in the front part of Vesta can come from the brake caliper or suspension, for example, from anti-roll bars.

The pillow, also known as the Lada Vesta engine support, is a kind of stabilizer against detonation. Vesta car parts come in three types: left, right, rear additional - price from 1,400 rubles. The parts have a separate article number. Malfunctions: the main malfunction is a knocking sound from the support, usually knocking on the left. The left pillow is reinforced

It is important to adjust the engine mount correctly. During engine operation, useful energy is generated, which is used to set the Lada Vesta in motion.

The movement of the “insides” of the motor causes it to begin to create vibration. To “dampen” engine vibration, they place them on supports, which perform several more functions:

- increase sound insulation of the engine compartment;

- protect other parts and assemblies from damage;

- stabilize the position of the motor as much as possible (if the amplitude of movement of the motor constantly increases, this will lead to wear of the connections);

- protect the engine from the negative influence of the external environment (when the car passes obstacles, the suspension does not completely dampen rolling, and the struts act as additional shock absorbers).

This way, not only the engine is secured, but also the gearbox. His pillow on the Lada Vesta consists of three supports. On the sports model, an additional support enhances stabilization when accelerating and braking; its design is mechanical rubber-metal. Each pillow is a mechanism of two metal plates, between which there is elastic rubber.

At the most unexpected moment, strange sounds may be heard from under the hood - knocking, grinding, clanging, unusual for the normal operation of the car - perhaps this is just the knock of the Lada Vesta engine support. To recognize it and “cure” it correctly, let’s look at everything in order.

Solution options

In fact, there are several of them.

Contacting the dealership

In the event of a visit to the dealer, there is, as a rule, no clear solution to the issue of knocking from under the hood of the Lada Vesta. It all depends on the specific salon. Some centers simply refuse to replace them, citing the fact that this is not a warranty case. Others sent information about the defect directly to AvtoVAZ, but this is a rather lengthy procedure, and therefore not everyone agrees to wait that long. And the answer is not always positive.

Many dealers refuse to replace the airbag under warranty.

But even if the dealer agrees to make a replacement, things don’t always go smoothly. The fact is that often a part is replaced with a similar one, although managers in the salon assure that it is already from a different batch. The result is the same - literally after a few thousand kilometers the sound returns.

However, some owners note that they had reinforced supports installed, after which the problem disappeared.

Independent actions

Do-it-yourself Lada Vesta engine mount replacement

Some car owners who have encountered a knocking noise from under the hood of their Lada Vesta decide to replace the support themselves, so as not to waste time traveling to the dealer and waiting for AvtoVAZ’s decision.

Sometimes you have to change the support yourself

The process itself is not too complicated and we will look at it in a separate article. However, in this case it all depends on the part purchased.

Bolt

Sometimes the source of knocking under the hood of a Lada Vesta is not the support itself, but the bolt that secures it. Moreover, according to some owners, if you simply tighten it, the knock will soon be heard again. In this case, you have to add a grower.

Using Lubricant

As practice and numerous attempts to solve the problem have shown, getting rid of the knocking noise under the hood of the Lada Vesta is quite simple. It is necessary to lubricate the support itself with silicone grease - directly in those areas where the rubber of the support comes into contact with the metal. Some people use WD-40 liquid for this, but it is not recommended to use it, as it washes out too quickly - it lasts literally for a day.

After this manipulation, the knocking stops, which is recorded on video.

Wear of stabilizer bushings

The first sign of “fatigue” of the stabilizer sealing bushings is a dull knock when overcoming a speed bump. Even in Lada Vesta, the manufacturer saves on materials and uses the cheapest ones. As a result, the service life of the bushings is short; creaking of the Lada Vesta suspension appears after several tens of thousands of mileage.

Other signs of bushing wear:

- knocking in the area of the front axle when the car rolls;

- beating in the steering wheel at speeds over 60 km/h;

- play in the steering wheel when maneuvering;

- arbitrary deviation of the machine from a given course. Car enthusiasts say that it “takes away” to the side.

The final conclusion will be given by a mechanic after conducting a comprehensive diagnosis.

Knocks in the rear suspension of Lada Vesta

In the process of identifying a malfunction, distinguish between knocking (dull) and squeaking, rubber friction. One of the weak points of the rear suspension is the upper shock absorber mount. There is a gap between the mount and the body, as a result of which on uneven surfaces the rod hits the metal surface. The defect is typical for all Lada Vesta models, this is the factory design.

To eliminate knocking, place a rubber or asbestos gasket between the upper support and the body mount.

The following can also produce crunching noise:

- poorly tightened discs that rattle at speed;

- equipment, cargo, suitcase with tools in the trunk;

- metal cable of the parking brake lever;

- trunk lid dampers;

- locks of the rear sofa, seat backs.

Things in the trunk

Many people remember that in the first year of sales, the plant provided a personal manager for 6 months. You could call him, complain, say whatever you wanted. After the purchase, when I started driving, there was a creaking of the bushings, and some kind of knocking from the rear. During the reception, together with the manager, we looked for the cause of the noise. They told me that there might be a bucket in the trunk. To this I thought that the bucket was just the machine itself.

Of course, there may be some truth in this. Foreign objects may dangle and rattle in the trunk. You also need to check the security of the spare wheel. The trunk lid itself can also knock.

In some cars, its lock does not press tightly onto the bracket. I first wrapped the area shown in the photo with electrical tape. But then I was able to lower the lock by adjusting the bolts. You can also adjust the trunk lid of the Lada Vesta using rubber stops. They have a threaded slot.

The front and rear license plates are secured with soft spacers. They also rattled on the bumps. There are no complaints about the rack and beam itself, everything is simple and reliable. There were knocking noises from the support; a paronite gasket was inserted there. The lower spring cushion may dry out.

The door guide also creaks - I spray penetrating lubricant all the time.

Loose wheel bolts

For various reasons, personal carelessness, including insufficient tightening of bolts, contributes to the appearance of extraneous sound. If you detect an uncharacteristic sound, check the tightening of the bolts yourself. If you do not have a wheel wrench, contact a service station for help.

After tightening, be sure to check that the wheel does not knock and make sure that the cause has been eliminated.

We do not recommend doing your own repairs while the machine is under warranty. Otherwise, it may be classified as a breach of contract by the consumer. It is not uncommon for a factory warranty to be voided prematurely.

Replacing the rear additional engine mount

This part is installed below, on the rear side of the motor. The mounts are different on the two types of motors. On the 21129 engine of the Lada Vesta, it is “tied” into a large network of fasteners. So, on one side it is held in place by a bracket that is firmly supported by two bolts. On the other hand, it is attached to the subframe with a bolt and nut. On the HR16 engine, the fastening is simpler: on one side, one bolt secures the part to the subframe, on the other, two bolts secure it to the gearbox. To replace, unscrew all bolts and remove the rear cushion. On motor 21129, be careful with the bracket fastening bolt - loosen it last and “catch” the pillow.

When putting the structure back together, tighten the bolts to 90-120 Nm.

You can do the work of replacing the power unit supports yourself. After tightening the bolts, check the strength and stability of all racks - they should not wobble excessively and should not stand “tight” - they should have a small amplitude of movement. Proper bolt torque will keep the motor in place and reduce vibration. To ensure the reliability of new parts, you can modify them by lubricating them (wd-40 will not work here).

Left pillow

The left engine mount of Lada Vesta and X-Ray is fixed to the body with 4 bolts. Also, the cushion is attached to the gearbox bracket with 2 bolts. In turn, the bracket is fixed to the gearbox housing using 3 bolts.

Replacing the part is complicated by the fact that access to it is blocked by several components at once - the crankcase protection, the filter (air) mount, and the battery shelf. Therefore, to get to the support, all this will have to be dismantled.

First you need to unload the cushion, for which you slightly raise the gearbox using a jack.

Next, using a 16mm wrench, unscrew the 4 bolts that secure the left engine mount to the body.

Then, using an 18mm wrench, you need to unscrew 2 more bolts that secure the cushion to the transmission bracket. Once this is done, the part can be removed.

Assembly is carried out in reverse order.

Support bearing knock

Often, car enthusiasts perceive the shock of the shock absorber rod as the knock of the wheel bearing. This can be explained by the design of the rack: two cylinders and a metal rod.

During systematic use, the bypass valves wear out and the strut does not dampen vibrations. With a sharp push, a blow occurs, which is perceived as a knock of the support bearing.

To guarantee that the latter is faulty, it is necessary to conduct a comprehensive diagnosis. It’s not difficult to do this yourself; in the transport position of the car, it’s enough to bleed the strut with a few presses on the car’s fender. After sharp pressure, the car must stabilize on its own, otherwise the shock absorber strut is faulty.

If there are no complaints about the shock absorber, then you are guaranteed to replace the support joint. The process is quite complex and requires minimal knowledge in servicing equipment. Unprofessional intervention does not guarantee full functionality of the mechanisms.

In order to carry out comprehensive diagnostics and replace worn-out equipment, contact a certified service station for help.

Review of reinforced right engine mounts for Lada Vesta

One of the reasons for the appearance of extraneous knocks from the front right on the Lada Vesta family is a “tired” right engine mount. To solve the problem, the engine mount is lubricated, modified, or replaced under warranty. There are cases where the engine mount was replaced four times in a short period of time. In such a situation, there is reason to think about installing an alternative, reinforced right engine mount. Are there any analogues?

Currently, there are several analogues of this part.

- Reinforced cushions are installed without modifications in the standard mounting points.

- According to the manufacturer, reinforced supports are more reliable and durable, which eliminates the appearance of extraneous sounds over a long period of operation.

Reinforced upper right engine mount

Guarantee

: 6 months per bracket. (there is no warranty on the rubber product, it is replaceable)

The right airbag of the new model was tested over a mileage of 5 thousand kilometers; according to the test results, the following were discovered:

- Some extraneous engine sounds are gone

- Starting off and shifting gears is smoother

- More precise installation holes in the pillow ebbs:

- Low cost of the rubber cushion (IT IS REPLACEABLE, the support becomes repairable, and repairs are inexpensive)

- Easy pillow installation

- More reliable design, unlike the factory one

- The quality of the rubber component in the cushion leaves much to be desired (but since it is replaceable and costs 300-700 rubles depending on the manufacturer, you can always replace it, which is cheaper than buying a new support assembly, article number 21080-1001031)

- The support lacks any additional anti-corrosion coating

Standard support left, right, rear – article number and price

The entire engine support system, called the suspension of the Lada Vesta car, consists of 14 parts, for each of which it is worth giving brief information:

- Right engine mount assembly. Article: 8450030109. Price: from 1800 rubles.

- Engine mounting rod with cushion and silent block assembly. Catalog number: 112381035R. Cost: from 700 rubles.

- Rear engine mount bracket. Article: 8450006293. Price: from 3,900 rubles.

- Reinforcement bracket for rear engine mount. Article: 8450030214. Price: from 70 rubles.

- Left engine mount cushion assembly. Article number: 8450006299. Cost: from 1000 rubles.

- Left rear eye for lifting the engine. Serial number: 8450008699. Price: from 600 rubles.

- Bolt M10-1.5-35 10-9 SA3GS. Article: 7703602240. Cost: from 300 rubles.

- Nut M10x1.25. Article: 8450001014. Cost: from 30 rubles.

- Lower right engine mount bolt. Catalog number: 8450007980. Cost: from 60 rubles.

- Upper right engine mount bolt. Catalog number: 8450008999. Cost: from 70 rubles.

- Bolt M12-1.75-90 10-9 SA3GS (for bracket amplifier). Article: 7703602269. Price: from 600 rubles.

- Hex nut with flange M12x175. Article: 7703033210. Price: from 350 rubles.

- Rear engine mount bracket mounting bolt. Catalog number: 8450007985 (the lower bolt is numbered 8450007986). Cost: from 300 rubles.

- Bolt M10X1, 25X53 TORX E Article: 8450008989. Price: from 30 rubles.

- An additional engine mount for the Lada Vesta is sold under number 8450031975 and costs from 1,400 rubles.

Manufacturers and prices of analogues

The cushions for Lada Vesta engines are considered by owners to be not particularly reliable and are even being modified to increase the effect of vibration absorption.

Otherwise, there are no special attempts to create analogues, because the “craftsmen” have already drawn the attention of Vest owners to two modification options:

- Came from Renault owners. It is necessary to create for each problematic pillow a metal plate 80 mm long, 38 mm wide and two grooves on the sides measuring 23 mm wide and 38 mm deep. The funny thing is that the X-Ray, which is in many ways similar to the Vesta, has the same engine (21129), but there are no problems with the upper right support - it’s just different.

- If the part itself is still intact, it can be lubricated with silicone grease where the rubber hits the metal body.

Wear

The wear of the engine mounts is determined by the “crampedness” of those points of the metal body that take the blow, damage and the thickness of the layer itself - rubber will not dampen vibrations if its thickness is very small.

Under the hood

The main problems: chafing pipes, rattling engine lining, have already been fixed in new batches. In mine, I filed down the notch so that the breather would not rub. The engine mount is also knocking. The treatment is simple - spray with silicone grease, and temporarily listen to silence or change the pillow. The manual transmission is not quiet, and the robot's actuator dries out lubricant, and it begins to creak when the gas is pressed, especially in the heat.

The canister valve still clicks loudly - it’s better not to touch it, it won’t get any quieter. The lion's share of knocks on my Lada Vesta comes from the resonator and plastic pipe.

What broke on the Lada Vesta in a month.

For the test, a piece of material was inserted for gluing sound insulation. You cannot completely remove the resonator - it is needed to dampen the sound. Although some people throw it away. It knocks because of the metal mounting bracket or pipe. It is frayed or installed loosely. The dealer contacted the factory - this is not a warranty issue. A new resonator with a pipe assembly in the cabin costs 1,500 rubles. They advised to wrap it with electrical tape. Draw your own conclusions about AvtoVAZ’s attitude towards consumers.

What happened to Lada Vesta after 3 years.

Lubricant, package - no noise: How to remove noise in the right engine mount on a LADA Vesta

The knocking noise will disappear and wear of the support rubber will stop.

Lubricant and the package are the best friends of the right engine mount of the Vesta. Image: Driver-News

After 10 thousand km on Russian roads, the engine mount begins to make noise and rattle, like a compressor on an old refrigerator. This is bad for engine performance, so “newsman” Gagarinec from the Drive2 portal shares his method.

The metal simply “eats” the rubber. Photo: Drive2

Replacing the support on the Vesta did not eliminate the noise, so the man decided to fight the noise with lubricants. I used thick silicone grease as a basis (we will indicate the names of those suitable for LADA Vesta at the end). I generously lubricated the right support and began to monitor the knocking noises.

All steps are simple. Photo: Drive2

Then the experiment began: at three and ten thousand km the rubber band did not move away from the support, although the motorist did not change his driving style. While driving, the rubber bands of the LADA Vesta get a lot of wear and tear on the metal, but the thick silicone lubricant absorbs shocks and saves from noise. At the same time, the bag holds back dirt and dust.

What lubricants do drivers recommend for Vesta:

- Loctite 8104 is the lubricant used by the author of the experiment;

- Molykote DC-33 medium - AvtoVAZ lubricant at the factory;

- Silicot gel, Liqui moly Silicon-Fett, Huskey HVS-100 - advice from other Vesta drivers.

Knocks and noises in the front suspension of Lada Vesta

- Many car enthusiasts note the appearance of a squeaking sound in the front axle area immediately after purchasing a car from a dealership. Driving through speed bumps turns into real hard labor. The culprit is the rubber bushings on the stabilizer bar.

Service station technicians do not recommend lubricating sealing products with grease or transmission oil. The creaking will go away, but for a short time, then it will resume again. To get rid of annoying squeaking, use polyurethane stabilizer bushings from Chevrolet Niva. (Cat. Art. 17012680).

- The play of the tip in the ball joint can also cause knocking. According to the regulations, replacement is carried out complete with suspension arms.

- Often inexperienced drivers confuse the creaking of suspension elements with a dull knock in the exhaust system area. The muffler mount is another defect from AvtoVAZ. The rubber retainer must be lubricated with silicone grease. The unpleasant sound will go away for a long time.

- The front suspension is knocking or rattling - contact a service station for help. Specialists identify the source of the breakdown with high accuracy. Self-diagnosis does not always bring the desired result due to the lack of special equipment.

- Do not forget that play in the chassis of the car can also be perceived as a malfunction in the suspension. Carry out diagnostics carefully and take a comprehensive approach to identifying the breakdown.