Every car has an electronic control unit. It controls the operation of the engine actuators based on readings from sensors associated with the motor.

The comfort of travel and the dynamic performance of the car depend on the software of the control unit and its operation. Both aspects can be improved by chip tuning the car.

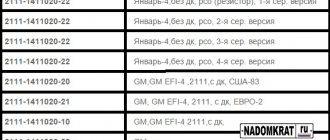

The Lada Granta is equipped with ECU M74.5, ECU M74 and M74M. Which unit is included depends on the year of manufacture and the engine. The software for different types of blocks is different, the firmware is not interchangeable.

“Itelma 11186-1411020-222”: from stock firmware to chip tuning?

The dilemma associated with the rationality of performing firmware on the “native” software in the ECU excites the minds of many owners.

Here it is worth highlighting the optimized dynamic firmware version for the 1.6-liter 8-valve Lada Granta, which has the “M74” module and meets the toxicity standard according to “E2”.

What preferences does this firmware have? After performing a certain list of manipulations and returning the ECU to its rightful place, optimization of the parameters of fuel supply and ignition distribution is observed. Also, one of the purposes of the firmware is to ensure that the settings of the throttle assembly are adjusted.

Chip tuning allows you to physically disable the 2nd DC (“lambda”) in combination with the catalyst. The implementation of such firmware leads to an increase in the dynamic capabilities of LADA Granta.

The role of the stock firmware is to form the parameters characteristic of normal driving conditions. Let us remind you that the “native” version of the firmware is included in the warranty package. Self-correction of the firmware version without any alternative leads to the cancellation of warranty coverage.

Today, so-called commercial versions of firmware software are available to the mass consumer, including the following:

Lada Granta repair and operation department (VAZ 2190)

(ECU, Lada Granta controller) is connected by electrical wires to all sensors of the system. The ECU receives information from the sensors, the unit performs calculations in accordance with the parameters and control algorithm stored in the memory of the programmable read-only memory (PROM), and controls the system actuators. The program version recorded in the PROM memory is indicated by the number assigned to this modification of the ECU (controller, computer).

The control unit detects a fault, identifies and stores its code, even if the fault is unstable and disappears (the fault does not appear constantly).

After repair, the fault code stored in the control unit's memory must be erased.

The Lada Granta control unit (controller) supplies 5 and 12 V DC to various sensors and switches of the control system. Since the electrical resistance of the power circuits is high, the test lamp connected to the system terminals does not light up. To determine the supply voltage at the ECU terminals, use a voltmeter with high impedance (10 MΩ). The electronic unit is installed in the cabin at the feet of the front passenger.

Electrical connection diagrams for the front wiring harness of Lada Granta

List of elements of the electrical connection diagram of the front Lada Granta wiring harness

Electrical connection diagram of the harnesses of the LADA GRANTA VAZ-2190 car

If you have a circuit diagram of a VAZ-2190 (GRANTA) and a multimeter or voltmeter (up to 15V), or even (you can assemble this simplified avometer yourself), and also having a little knowledge in electrical engineering, you can figure out the breakdown of the electrical part of your car.

Color schemes. All wire colors correspond to their color markings.

Wiring harnesses for LADA GRANTA 21900

- Instrument panel wiring harness - 21900-3724030-00

- Ignition system wiring harness - 21900-3724026-40

- Injector wiring harness - 2111-3724036-00

- Rear wiring harness - 21900-3724210-00

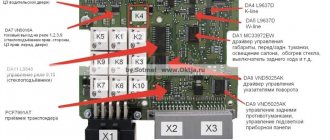

Below is a schematic electrical diagram of the instrument panel harness for LADA GRANTA VAZ-2190.

- — wiring harness block of the wiring panel to the front wiring harness block;

- — wiring harness block of the wiring panel to the front wiring harness block;

- — wiring harness block of the wiring panel to the rear wiring harness block;

- — wiring harness block of the wiring panel to the rear wiring harness block;

- — lighting control module;

- - egnition lock;

- — on-board computer mode switch;

- — windshield wiper switch;

- — instrument cluster;

- — light alarm switch;

- — trunk lock drive switch;

- — diagnostic block;

- — block of the wiring harness of the instrument panel to the block of the wiring harness of the air supply box;

- — rear window heating switch;

- - hazard warning switch;

- — brake signal switch;

- — block of the instrument panel wiring harness to the radio;

- — block of the instrument panel wiring harness to the radio;

- — rotating device;

- — driver airbag module;

- — — —

- — mounting block;

- — electric power steering;

- - cigarette lighter;

- — backlight lamp for the heater control panel;

- — illuminator;

- — block of the instrument panel wiring harness to the block of the ignition system wiring harness;

- — controller;

- — clutch pedal position signal switch;

- — electronic accelerator pedal;

- — additional resistor;

- — heater electric motor;

- — heater motor switch;

- — control unit for the door locking system.

Purpose of the RELAY of the car "GRANT"

K1 - relay for the electric fan of the engine cooling system;

K2 - door lock relay;

K3 - additional starter relay;

What to expect from ECU tuning

Reflashing allows you to correct errors and optimize vehicle performance

Companies offering chip tuning services develop and offer various software that allows you to optimize the basic performance of cars.

This process allows you to correct all sorts of errors, create a backup copy of the initial settings, study and adjust characteristics, as well as make changes and test new firmware of electronic components.

If you need to return to default settings, this is done almost instantly. But those who have already reflashed Granta will never return to the standard factory settings. After flashing you can get:

- reduction in fuel consumption by 5%;

- high speed characteristics;

- 10% increase in power;

- smooth operation of the automatic transmission;

- improved traction.

And that's not all. In this case, not a single intervention is made in the mechanics. This is one of the cheapest ways to make Granta better. There is one caveat. If the car is currently under warranty, after flashing the ECU, the warranty is invalid.

Modern chip tuning specialists offer 3 different firmware options for the Lada Granta controller. Of course, there are more of them, but not all are ideal. Particularly popular systems are “Paulus”, “Icebreaker” and “Adakt”. They are the most tested and tested.

Some experts suggest installing one of the control programs, or all three. Sometimes they offer to try each one and then choose the one you like best. The actual firmware installation takes about 30 minutes on average.

Reasons for flashing the computer

Incorrect operation of the system can be eliminated by flashing it

Granta is equipped with an M74 controller 11186-1411020-12. Its functionality is significantly different from what was installed on cars previously. Firmware methods that could be used on other ECUs do not work here.

The car, configured at the factory, meets the requirements of car enthusiasts and Grant owners. However, some still flash the system. And there are several reasons for this:

- The 8-valve Granta does not hold speed when the air conditioning is on;

- there are difficulties in starting a cold engine;

- temperature conditions are incorrectly determined;

- stopping the engine;

- lack of dynamics;

- increased fuel consumption.

A Lada Granta with an automatic transmission may experience various kinds of difficulties when choosing the required gear already at medium speeds. Granta constantly wants to drive at lower speeds. In city mode with small traffic flows this is not critical, but when driving on the highway and in a dense flow of cars there may be problems when maneuvering.

Some motorists complain about the impossibility of smooth transitions and weak traction if the engine operates at low speeds. There is an opinion here that the controller was initially flawed, namely, the parametric characteristics were not calculated at the factory. Only firmware will help solve this situation.

Main controlled parameters.

To ensure the functioning of vehicle components and assemblies, the control unit collects and processes signals from the following sensors:

- Temperatures - engine, fluid in the cooling system, environment;

- Air flow and fuel supply;

- Idle mode;

- Vehicle position on the lane, anti-wear, ABS and other safety systems;

- Speed, engine speed, position of the crankshaft and camshafts;

- Throttle valve tilt and gas pedal position;

- Fluid pressure in the brake system;

- Interior climate and air conditioning sensors;

- Power steering or electric power steering;

- Voltage in the vehicle's on-board network.

The set of signals processed depends on the model and modification of the car (for example, for SUVs with air suspension, monitoring of its condition is required). In the most prestigious brands and configurations, the number of interrogated sensors is several dozen.

Devices controlled by the ECU:

- throttle valve and air supply system elements (for example, turbochargers);

- fuel supply system devices (injectors, nozzles, when fuel injection is carried out under electronic control);

- valve timing control system;

- electronic distributors of the ignition system;

- cooling system fan;

- solenoids and valves for gear shifting in automatic and robotic transmissions;

- differential locking clutches;

- stove, air conditioner and other climate control devices;

- head light, interior lighting;

- window regulators;

- elements of electrical equipment of a car.

Like the number of sensors, the set of controlled actuators depends on the make, model, configuration, and options of the vehicle. In business or premium class cars, the number of control commands can exceed the set typical for budget cars by an order of magnitude.

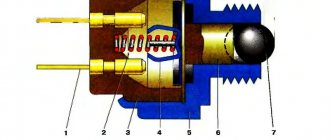

Example of a device diagram:

ECU of the Lada Granta car - software guarding safety

The control unit, or controller, is a kind of “brain center” of any car equipped with various electronics. It receives signals from sensors that are equipped with all important parts of the car, from the fuel system to the wheels. Data processing then occurs to allow the ECU to effectively control the engine and ensure safe operation. It is in controller malfunctions that the greatest danger for the driver lies, because an error in quantitative indicators, a malfunction in the fuel supply system, or even a violation of climate control can lead to a threat to life and health.

What types of ECUs are available to Granta and what is the principle of their operation?

Sometimes the Lada Granta model is identified with an exclusive car. Why is she given such status? It's simple. "Lada" has a unique control unit, which is called "Itelma 11186-1411020-22" and cannot be combined with previous modifications of "VAZ". The primary difference of this module is the integrated “CAN bus”. Previously produced models used the “K-channel” to ensure the transmission of pulses. If you set out to experiment and replace the Itelma with a similar device with functionality in the K-channel, then in the end the devices on the panel will certainly “fall asleep”.

Where is the ECU located and what is its operating principle? It is based on a special type of algorithm, the formation of which occurs on the basis of software pre-integrated into memory. This allows the module to process signals from all sensors present in the ECM in real time.

The process associated with processing streaming information allows the control unit to subsequently carry out corrective actions regarding the functioning of such systems:

- nozzles;

- ignition system coils;

- throttle mechanism;

- sensor-regulator of idle modes, etc.

To be able to identify the type of device in a LADA Granta car and the firmware version of its software, a special marking code is applied to the body, which allows for the correct selection of an analogue if there is a need for replacement, and in some cases pinout of the ECU is required.

What ECU is on the Grant? Operating principle

Lada Granta is a truly exclusive car from a domestic manufacturer. What exactly is exclusive? This car received an electronic control unit, namely Itelma 11186-1411020-22, which is not compatible with previous VAZ models.

The main difference is the integration of the CAN bus. In previous versions of cars, for example, Lada Kalina, a K-channel is installed to transmit data to the instrument cluster.

Based on the main difference between the Itelma 11186-1411020-22 ECU and the ECU of previous models, we can draw a conclusion regarding the installation of an ECU with a K-channel on the Lada Granta. As a result of such an experiment, both in practice and in theory, the car’s instruments will “fall asleep.”

What about the operating principle? This principle is based on an algorithm of a certain type, which, in turn, is formed on the basis of software previously added to the device. Granta ECU receives and processes information from almost all ECM sensors.

Data processing according to the conditions of the above algorithm makes it possible for the Grant 11186-1411020-22 ECU to control the following devices, namely:

Location of the Lada Granta ECU

We can talk for a long time about how important the correct operation of the electronic control unit (ECU) is. The functioning of the heart of your car depends on it: from increased fuel consumption to the fact that the car may stall as a result of incorrect operation of the controller.

The ECU is located under the glove compartment under the passenger's feet and hidden under the upholstery. The upholstery is attached to the body on the right with a self-tapping screw.

I would like to immediately convey a special greeting to the designer of AvtoVAZ, who came up with this arrangement of this block. In my opinion, I can't think of a worse place. See for yourself.

- If your interior heater (radiator) leaks, the antifreeze will go straight to the control unit, causing almost 100% failure. Even though the Lada Granta is initially equipped with a good quality imported Visteon radiator.

- As you correctly noted, water can get in from under the hood. The rubber plugs on the Lada Granta are not of very good quality, so when they dry out, water will flow onto the controller. To prevent this from happening, check the condition of the rubber plug.

Water enters the controller through this plug.

There are two ways out of the situation, or rather three.

- Leave everything as it is and hope for chance.

- Place the plug tightly onto the sealant.

- The most labor-intensive is moving the controller higher, closer to the passenger airbag, with the contacts facing down.

Can be attached to the air duct

Video about how the ECU is flooded on a Lada Granta

The hose that receives water goes directly into the car interior. In my photos there is an alarm bell, so it's hard to see.

The ECU has become an integral part of a modern car. The domestic Lada Granta model is equipped with such a device, labeled as “M74 CAN”. The module allows you to automate most processes occurring in nodes and systems. The control function of the ECU is achieved due to the presence in the units of various types of sensors that send signals to the “brain center” of the car.

Over the long period of operation of the Lada Grant, an annoying drawback of the ECU was identified - its insufficient sealing and sometimes the ECU pinout is required. Penetration of moisture inside the unit casing provokes burnout of the microcircuit, which subsequently ends in the need to replace the device.

The ECU is located at the bottom of the front panel (under the glove compartment) opposite the front passenger seat and is hidden from view by layers of sound-insulating material and upholstery on the inner surface of the bottom. Now you know where the ECU is located, all that remains is to find out other details.

We flash the Itelma M74 (Lada Granta) ECU with our own hands

The M7.4 ECU is very easy to program; the contacts to enable programming “B2 and A4” are placed in the first connector; it does not need to be disassembled. You can even change it without removing it from the manina via the OVD-2 connector, but before that you need to apply +12v to these two contacts “B2 and A4” and turn on the ignition.

In order to independently flash the Itelma M74 ECU, which, as we already know, is installed on the Lada Grant, you need to perform the following procedure:

- Disconnect the battery mass.

- Remove the ECU block. The connectors are disconnected like this:

- Let’s make a “spider” like this (I recommend signing the wires)

- We connect the connectors: Connector 1 (large) J1 - switchable voltage (K15) (12V) - second switch B2 - programming permission (12V) - first switch A4 - programming permission (12V) - first switch Connector 2 (Small) G2;G3; G4 - Ground (can be connected to any) H1; H2 - non-switchable voltage (K30) F2 - switchable voltage (K15) (12V) - second switch D2 - K-Line

- here's EL. diagram (many people write that they are flashing, but there is no diagram anywhere)

6. It is not recommended to apply voltage to all wires at the same time! It is necessary step by step through a double switch.

7. 4-And so the whole circuit is assembled and the KKL VAG-COM cord is inserted into the USB PC. Here is the voltage supply sequence

- Apply voltage (+12 V) to H1; H2 (throw the hooks onto the battery)

- Turn on the first switch (programming permission) B2 A4

- We launch the WinFlashECU program (-Select M74, -select the port number on which KKL VAG-COM hangs -it’s better to set the speed to the minimum)

- Next, turn on the second switch (which is on the “switch-off voltage”) F2 J1

- Communication with the ECU should appear (this is an indicator that the circuit is assembled correctly)

- Then we save copies of your “firmware and immo” on your computer, click

- Reading EEPROM and Reading ECU just in case (at the same time we check how everything works)

- code copying finished

- click ECU programming, look for the required firmware on your computer and download

Attention ! A window may pop up stating that this software is not for this ECU, but click “OK” anyway

- We are waiting for the download to finish (it took me 4 minutes to load) when the window pops up: the operation has been completed successfully.

- Close WinFlashECU.

- Turn off the power.

- And only then disconnect the wires.

How to dismantle the ECU?

It’s easy to remove the controller with your own hands:

- Operations are performed to provide access to the device, for example, partial dismantling of the center console or disassembling the instrument panel.

- The negative terminal of the battery must be removed to avoid emergency situations with the connected unit.

- The fixing latches or clamps on the sensors, actuators and power cables are removed.

- The connectors are disconnected.

- The fixing bolts are unscrewed and the ECU is removed.

The decision to repair or replace is made based on diagnostics. In any case, failure entails significant costs - the cost of units for domestic cars is in the range of 10-20 thousand rubles, for foreign cars 14-50 thousand rubles. (depending on the class of car). Repairs will cost 40 - 50% of the indicated amounts.

Video with instructions for replacing the ECU unit on VAZ models.

Deciphering codes for self-diagnosis

Checking instrument panel sensors before diagnostics

| Code | Description |

| 1 | This code indicates an excessively high voltage detected by the bk in the on-board circuit of the Lada Grant. |

| 2 | If there is a break in the gasoline level sensor circuit for twenty seconds, then this code indicates the need to check the network. |

| 3 | This code indicates the need to replace the refrigerant temperature control device in the refrigeration system. |

| 4 | Something has happened in the operation of the air temperature control device; the circuit needs to be checked or the sensor replaced. |

| 5 | Code 5 indicates overheating of the internal combustion engine. In this case, the problem may be a broken thermostat. In addition, this code may indicate more complex failures. For example, if the cylinder head gasket is broken, the engine will also overheat from time to time. |

| 6 | This indicates an emergency pressure of the engine fluid in the injection system. |

| 7 | Indicates a malfunction in the brake system. |

| 8 | Battery malfunction. Code 8 tells the owner of the Lada Grant that the battery needs to be replaced due to the charge being too low. |

How to check mass with a multimeter

Disconnect the negative terminal of the battery

We take a multimeter and switch it to resistance measurement mode up to 200 Ohms. We check the resistance of the probes themselves by connecting them together

The resistance of the probes themselves is 2.1 Ohms.

Now we connect one probe to the engine. At least here

And the second probe is to the engine control unit, which, in turn, is screwed to the body

We look at the multimeter readings. So what do we see? But we usually see the same 2.1 Ohm

What happens - the mass resistance of the engine - the body has practically no resistance? Is everything perfect? Is the engine and body weight OK? What is the problem then? Is the starter defective or are otherworldly forces overcoming you?

The whole thing is much simpler. What is a mass chain in the understanding of an ordinary person? This is just a piece of wire that connects the engine to the body. Just a piece of wire! If we connect ohmmeter probes to the ends of this wire, then we will find out its resistance. It will be minimal - it’s just a piece of copper wire. Right? Right.

If we connect the voltmeter probes to the ends of this wire, we will see zero voltage. After all, where will the potential difference come from on a single piece of wire? Right? Right.

Now let's connect our voltmeter to this ground wire on the car. That is, as when measuring resistance, one probe is to the engine, and the second to the body. They are connected by this piece of wire. Right? Right.

We switch the multimeter to the mode for measuring constant voltage up to 2 Volts. We start the engine and look at the device display.

Oops. And we have tension!

How can this be - we are connected to the ends of one wire, and we have voltage.

So I showed off my artistic creativity and painted a picture of what was happening

These values on the multimeter display are nothing more than the voltage drop on our ground wire! Even though it looks great and has minimal resistance, it still drops voltage. Moreover, the greater the consumer current in the circuit, the greater the voltage drop on this wire will be, which can reach several volts!

This is the situation. And the mass of the engine and body is not as good as it seemed at first, and problems from it are inevitable.

How to come out of such a situation as a winner?

First, it is necessary to periodically service this section of the chain.

Unscrew the mass on the body

Do the same with the mass on the engine.

But this doesn't always help. The fact is that this chain still has weak points - crimps.

Crimping lugs, crimping on battery terminal

All this oxidizes over time and cannot fully perform its function.

It is necessary to either re-crimp these connections, or it is better to change these wires sometimes.

Here is a video on the topic of engine mass - body

Well, ideally you can lay additional ground wires: Generator - body

Decoding codes after diagnostics with a scanner

As stated above, if the measured characteristics do not differ from the standard ones by more than 20%, then everything is in order with the car. What are the standard parameters?

| Parameter | Meaning |

| UACC | Shows battery voltage. To understand whether there is an error in this case, it is necessary to activate all devices that consume the most voltage. Allowable voltage is from 13.9 to 14.5V. If it is less, then it is necessary to check individual circuits of the network. |

| THR | Throttle position parameter. As a rule, if it is faulty, the driver will know about it without diagnostics, since the car will move jerkily and the engine power will constantly drop. Press the gas pedal without starting the engine, but turning on the ignition. The TPS readings should gradually increase to 90% (or slightly less). If everything is so, then the sensor is working; if not, it needs to be replaced. |

| FREQ | Crank pulley rotation speed parameter. The rotation speed is up to 840 rpm. If this sensor fails, the operation of the motor will be impossible. |

| AIR | Mass air flow parameter. It should not exceed 12 kg/hour. Start the engine and press the gas pedal so that the number of revolutions increases to 5 thousand per minute. In this case, the parameter should increase to approximately 250 kg/hour. Naturally, if the device is working properly, then the indicator will be like this. |

| UOZ | Represents the ignition timing angle. It should change in the range from 6 to 15 degrees. |

| INJ | This parameter bk represents the duration of the injection pulse (the time required to open each injector so that gasoline enters the cylinder). Ideally, this parameter should be between 3 and 5 milliseconds when driving at neutral speed. If the readings obtained during diagnostics are much higher, then, most likely, the injectors are already clogged and need to be cleaned. Or this indicates low gasoline pressure as a result of a clogged gasoline filter or pump. Press down the gas pedal sharply. The injection time should increase to 20 ms. Ideally, accurate diagnosis of injectors is only possible using a test bench. |

| FSM | Idle speed sensor performance indicator. Ideally, this parameter should not exceed 50-60. If you press the gas pedal sharply, it can increase to 160-180. |

| ALAM 1 | Indicates the voltage level recorded on the oxygen level monitoring device. When the car engine is warmed up, this indicator should increase from 0.007 to 0.7 V. If this indicator differs, then something is wrong with the circuit. |

| LUMS_W | This coefficient indicates the rotation of the crank pulley. Ideally, it should vary around 4 revolutions per second. If it is slightly larger, then this already indicates a misfire in the engine cylinders. This means that you should pay attention to checking the spark plugs (whether they are working, filled or not), as well as the condition of the high-voltage wires. |

| QT | Gasoline consumption coefficient. With the engine running and idling, it should not exceed 0.9 liters per hour. |

Where is the ECU located?

In the cabin, the unit can be found under the panel. In models from AvtoVAZ it is located near the heater radiator. On business-level foreign cars, the ECU can be found under the rear seat. Some manufacturers try to install the controller in the trunk. Placing the ECU under the hood is not the best solution.

After all, the block is affected by rain, snow and other factors. Often in the engine compartment this device can be found near the battery or under the safety block. It’s not difficult to find – even an ordinary car owner without special skills can find it. You just need to disassemble the dashboard a little or find the unit under the hood. Externally, it is a box from which two wire harnesses extend. But you shouldn’t repair the ECU yourself without special knowledge. It is better to entrust this work to professionals.

Where is the grant ecu located?

Tell me the location of the ECU on the Lada Grant.

The ECU on the Grant is located under the glove compartment , directly opposite the passenger seat. It hides under the upholstery and soundproofing of the floor. To get to it you need to peel back the upholstery and sound insulation.

In short, the ECU serves to control the engine, coordinating its operation based on data received from various sensors. Accordingly, if the ECU is damaged, the engine will not work as expected.

And it can be covered quite easily - from moisture. Water penetrates through the ring inserted into the body. They say that this problem was corrected at the factory (and even the cars were recalled), but in order to avoid getting into trouble, it won’t hurt to apply sealant.

Car : Lada Granta. Asks : Kirill K. Question : Where is the Lada Granta ECU located and are there any pitfalls of such a location?

On the first Kalinas there were many cases of ECU failure due to the fact that it was filled with coolant. The great and mighty AvtoVAZ did not recognize this as a warranty case and the owners ended up losing money. The ECU is not that cheap, plus troubleshooting and replacement.

So the question arose. Where is the ECU located on the Lada Granta and is this model protected from the shortcomings of its predecessor? I read that as a result of clogged drainage outlets under the hood, water pours into the cabin and the ECU fails.

Engine control modules [ edit | edit code]

">Company controllers

- Bosch M1.5.4 (55 Pin) (1.45/1.5l., 8kl.) (Russia-83) Simultaneous injection.

- Bosch M1.5.4N (55 Pin) (1.5 l., 16 kl.) (Euro-2) In pairs - parallel injection / Phased injection.

- Bosch MP7.0HFM (55 Pin) (1.5/1.7l.,8/16kl.) (Euro-2/3) In pairs - parallel injection./Phased injection.

- Bosch M7.9.7 (81 Pin) (1.5/1.7l.,8/16kl.) (2003 – 2007) (Euro-2/3) In pairs – parallel injection./Phased injection.

- Bosch M7.9.7+ (81 Pin) (1.5/1.7l.,8/16kl.) (2005 – 2011) (Euro-3) Phased injection.

- Bosch ME7.9.7 (Euro-3) Phased injection.

- Bosch ME17.9.7 (Euro-3) Phased injection.

">Controllers

- Delphi MT20 (Euro 3)

- Delphi MT80 (Euro 3/4/5/6)

- Delphi MT92 (Euro 3/4/4/6) – Gasoline Direct injection (GDi).

- Delphi AC Delco E39/E39A (Euro 2)

- Delphi AC Delco E73

- Delphi AC Delco E78

- Delphi AC Delco E83

- Delphi MR140

">Controllers

- GM EFI-4 (24/32/32 Pin) (USA-83) – Single injection.

- GM ISFI-2S (24/32/32 Pin) (1.5 l. 8/16 cells) (USA-83/Euro-2) – 8 cells. in pairs - parallel injection, 16kl. phased injection

- GM ITMS-6F (Euro-2) – In pairs – parallel injection.

">Controllers

- Simtec 70 (Euro 2) Phased injection.

- Simtec 71 (Euro 3) Phased injection.

- Simtec 75.1 (Euro 4) Phased injection.

- Simtec 75.5 (Euro 4) Phased injection.

- Simtec 76 (Euro 2/3)

- Simtec 81 (Euro 5) Direct injection.

">Controllers

The January xxx and Mxx controllers were produced at two different factories - Itelma (The first element in the firmware designation is the letter “I” in the ECU marking) and Avtel (The first element in the firmware designation is the letter “A”.

- January 4 (24/32/32 Pin) (1.6l., 8kl.) (Russia-83) In pairs - parallel injection. (The label contains the designation of the debug version “Kvant”.)

- January 4.1 (24/32/32 Pin) (1.5l., 8/16kl.) (Russia-83) (1998) Phased injection. (The label contains the designation “Quantum”.)

- January 5.1 (55 Pin) On the label: NPP AVTEL LLC, TU 4573-004-45886863-99, .

- January 5.1.1 (55 Pin) On the label: NPP AVTEL LLC, TU 4573-004-45886863-99, . (1.5 l., 8 cells) (Euro 0) Simultaneous injection.

- January 5.1.2 (55 Pin) On the label: NPP AVTEL LLC

">Controllers

- VS 5.1 1411020-02 (1.45l, 8kl.) (Russia-83) Simultaneous injection.

- VS 5.1 1411020-72 (1.5l, 8kl.) (2003- ) (Russia-83) Simultaneous injection.

- VS 5.1 1411020-62 (1.5l, 8kl.) (2003-) (Euro 2) Pair-parallel injection.

- VS 5.1 1411020-42 (1.5l, 16kl.) (2003-) (Euro 2) Phased injection.

- VS 9.2 (Euro 4) Used diesel engine UAZ 3151 (Hunter).

- T11183 (Euro 2/4) (1.6l, 8kl.)) Pair-parallel injection.

- T11186 (Euro 4) (1.6l, 8kl.)

- T11194 (Euro 3) (1.6l, 16kl.)

- T21067 (Euro 3) (1.6l, 8kl.)

- T21114 (Euro 2/3) (1.6l, 8kl.)

- T21116 (Euro 4) (1.6l, 8kl.)

- T21124 (Euro 2/3) (1.6l, 16kl.)

- T21126 (Euro 3/4) (1.6l, 16kl.)

">Controllers

In the designation of the firmware January 7.2 and Mikas 10 there are the following designations: (I – Itelma) (A – Avtel).

- January 5.1 (55 Pin) (1.5 l., 8/16 cells) (Euro 2) On the label: , TU 4573-004-45886863-99. (1999 -) Simultaneous injection.

- January 5.1.1 (55 Pin) (1.5 l., 8 cells) (Russia-83) Simultaneous injection.

- January 5.1.2 (16 grades) (Russia-83) Simultaneous injection.

- January 5.1.3 (1.5 l., 8 cells) (Euro 2) In pairs - parallel injection.

- I 7.2 (81 Pin) (1.5/1.6l., 8/16kl.) (Euro 2) (2004 – 2007) Pairs - parallel injection. / Phased injection.

- I 7.2M (81 Pin) (1.6l., 8/16kl.) (Euro 2) (2007 – ) Pairs - parallel injection. / Phased injection.

- M10.3 (Euro 2/3).

- M73 (1.4/1.6l., 8/16kl.) (Euro 3) (2007 –) Phased injection, works without a camshaft position sensor (phase sensor).

- M74 (1.6l, 8/16kl.) (Euro 3/4) Phased injection.

- M75 (1.6l, 16kl.) (Euro 4) Phased injection.

A modern car is more than just four wheels and an engine. This is a smartphone on wheels. The operation of all systems of a modern car is controlled by a huge number of different sensors. This information is then analyzed by a special computer and other electronic components. The more expensive the car, the more different electronic options it has. All this “orchestra” is controlled by one small box - this is the ECU. What it is? This is an electronic control unit. We'll talk about it today.

What can be optimized in the power units of the Lada Granta

The plant sometimes releases new firmware and makes adjustments to the operation of the Unified Control System at warranty stations. But not everyone's car is under warranty, and not everyone who is under warranty receives this adjustment.

Many people continue to drive unfinished cars, not even suspecting that all their problems can be easily solved. You just need to make small changes that will optimize the operation of the engine and transmission components.

The Granta firmware allows you to solve the problem with the ignition timing, change the injection time, modify the exhaust gas toxicity control system, make changes to the algorithms that allow you to determine the octane number of gasoline, and optimize the operation of the automatic transmission.

Itelma ECU 11186-1411020-22: stock firmware or chip tuning?

The dilemma regarding the need to flash a manufacturer-installed or a new ECU installed by the car owner depends on many factors. Among the main points is the “thoughtfulness” of the car at the time of overtaking or moving in a dense stream of cars.

It is worth noting the optimized dynamic firmware for Lada Granta 1.6L, 8V with an M74 controller and an established E2 toxicity standard. What does the practical implementation of such firmware provide?

As a result of the manipulations carried out and the return of the controller to its rightful place, fuel supply and ignition were significantly optimized. The firmware provides for changing the throttle settings.

Carrying out modern chip tuning on a domestic Lada Granta car provides the opportunity to physically disable the 2nd DC and the catalyst. As a result of such firmware, the dynamic characteristics of the car significantly increase while maintaining a moderate driving style.

The stock firmware of the Lada Granta ECU is designed for ordinary daily use of the car, while the manufacturer's firmware version is included in the warranty package. Unauthorized changes to the firmware version will void the manufacturer's warranty.

At the moment, the end user is provided with commercial firmware for M74 controllers, namely:

• AY_I484GG30 – Lada Granta 1.6l, 8V with pre-installed M74 controller 11186-1411020-22;

• I484GI06-STR – Lada Granta 1.6L, 8V; controller – 11186-1411020-22 and Euro-2 standard;

• AY_484GP12 – with preinstalled M74 controller 11186-1411020-22 and E3/E2 standards.

How to reset an error on a grant

In the Lada Granta, the check error “pops up” relatively often. This is caused by the presence of a large number of auxiliary equipment and electronic modules in the engine compartment.

Partial error reset on a car can be done mechanically:

- warm up the engine to normal temperature;

- disconnect the battery from the on-board network for 15-20 minutes;

- reconnect the battery;

- turn the key in the ignition lock cylinder to position No. 2 and leave it alone for 1-2 minutes;

- return the key to position “0”.

If everything is done correctly, the errors will be cleared. The method is not suitable for complex failures - some errors cannot be canceled this way.

To completely remove codes from the on-board computer’s memory, it is performed using special diagnostic equipment. Devices must be purchased separately in case of constant need. Purchasing a scanner to service one car is not economically feasible.

Having diagnostic equipment and the required knowledge about the system in hand, you can read and decipher Lada Granta errors yourself. If the user does not have enough experience to perform the operation, it is recommended to contact a specialized service.

Basic functions of the device

On-board vehicles for the Lada Granta have high information memory and a small monitor, except for the “State” model, which only has a digital display. This makes it easier for people with poor eyesight and those who are unfamiliar with the nuances of engine operation to monitor all the processes that accompany its stable operation. BC will help the car owner by pointing out the following parameters:

- total travel time;

- detailed fuel consumption at different speeds;

- average speed indicators and excessive fuel consumption;

- remaining fuel in the gas tank;

- speed of start of movement;

- engine temperature;

- malfunctions of components and mechanisms;

- temperature inside and outside the car;

- on-board network voltage;

- crankshaft rotation speed (engine speed).

The on-board computer has a volatile memory and the ability to control the anti-theft system - the Lada Granta immobilizer. The on-board vehicle has a built-in supervisor, a fault indicator, and a “afterburner” function - the ability to reset the memory after starting the engine.

Some on-board drivers can additionally control lighting, stove operation, clock, calendar and alarm clock, and automatic window closers. You can plan your trip route based on the BC readings. It also allows you to use various navigation installation options and can warn you about low fuel levels or exceeding the permissible speed limit.

Most devices allow you to independently diagnose the operation of different car systems. The device can read ECU error codes without using any equipment. The explanation is presented in the accompanying documentation for each device. Such functionality will allow you not only to save on a trip to a specialized center, but also to identify problems, preventing serious malfunctions from occurring.

Instructions for diagnosing the Lada Granta via OBD2 connector with your own hands via a laptop or smartphone

Determine where the OBD2 connector is located

You can study this issue in the article: “Location of the diagnostic connector on the Lada Granta”

Determine which scanner is suitable for your car

The selection of a scanner (adapter) for LADA GRANTA depends on the ECU model, as well as the needs of the diagnostician / car owner.

To select diagnostic equipment, use the calculator: “Selecting a scanner for the Lada Granta”

Read the detailed material “Car scanners for diagnosing VAZ and LADA cars“

Download the diagnostic program for the scanner

The diagnostic adapter requires software that can be installed on a laptop or smartphone/tablet. Auto scanners with their own software shell and display do not require software.

To select a program for the adapter, go to the section: “Programs“

Use the instructions and carry out diagnostics

When you purchase an adapter, instructions are included with the adapter. More detailed instructions on diagnostic car scanners and descriptions of their operation are available in the section: “OBD2 car scanner reviews“

Read the guide article “Car scanners for diagnosing VAZ-LADA cars with instructions”

Identify errors and decipher them

Error codes and their interpretation are displayed in the scanner program interface. You can also study the complete database of errors for your car in the section: “OBD2 error codes for Lada Granta“

Make repairs according to the error code

The unit is repaired according to the decoding of the error (problem) or contact a car service to eliminate a particular malfunction.

Check errors again

After auto repair, you need to re-check the car for errors using an adapter (scanner). Erase errors if necessary.

Scan Tool Pro – budget multiscanner for LADA GRANTA

A good choice for a novice diagnostician

Nowadays there are scanner models with different versions of firmware and chips on sale. Scan Tool Pro with firmware 2022 is the most stable version so far, and also has maximum compatibility with cars manufactured since 2001, including LADA and VAZ.

By following the link on the right you can get acquainted with the scanner for autodiagnosis “Scan Tool Pro”. This is an official dealer website that provides a 12 month warranty.

Engine diagnostics

The capabilities of engine diagnostics via the OBD2 connector depend on the scanner and software. For example, a simple amateur adapter ELM327, together with the OpenDiag application on a smartphone, allows you to read engine errors and decipher them, as well as view temperature sensors and engine speed, both at idle and while driving in real time.

We provide documentation for engines with electronically controlled throttle valves that meet toxicity standards. Read the files by running engine diagnostics.

EURO-4 (controller M74) (.PDF)

EURO-4 (controller M74 16 VALVE) (.PDF)

Instructions and diagnostics of EMUR

Instructions and diagnostics of ABS

ABS diagnostics via OBD2 connector

If problems arise with the ABS, before changing or manually diagnosing the problem, read the errors according to the instructions provided. Checking for errors will show you not only the condition of the sensors, but also the wires and connectors.

Diagnostics of mass air flow sensor

Using the Open Diag program, we record the voltage at the mass air flow sensor. The permissible voltage values are:

Important: If it exceeds 1.05 V, the mass air flow sensor requires replacement!

Diagnostics of the oxygen sensor (lambda probe)

The oxygen sensor is checked using the Open Diag program and an adapter connected to the OBDII connector. We analyze the voltage values at the sensor.

When the engine is running, the voltage should change from 0.008 to 0.7V and back. There should be no smooth declines or freezes on the oscilloscope.

Automatic transmission diagnostics

Diagnostics of the gearbox is also possible, but limited by the Granta ECU itself. Yes, you can use professional, expensive car scanners, but we are talking about self-checking.

Using an adapter and an application on a smartphone, you can see errors in the transmission; if there are any, their decoding will indicate one or another malfunction of the box. Also, in real time, data from temperature sensors is taken from the box.

Automatic transmission errors:

P0720 “Output shaft speed sensor is faulty” P0717 “Turbine speed sensor” P0706 “Automatic transmission selector. No signal “P0705” Automatic transmission selector. Several signals at the same time" P0974 "On-off solenoid. Open circuit" P0973 "On-off solenoid. Circuit shorted to ground" P0963 "Pressure control solenoid. Open circuit" P0962 "Pressure control solenoid. Circuit shorted to ground” P0740 “LOCK UP SOL(Open)” P0743 “LOCK UP SOL(GND short)” P17AB “L/C SOL(Open)” P17AA “L/C SOL(GND short)” P17AE “2-4 /B SOL(Open)” P17AD “2-4/B SOL(GND short)” P17B1 “H/C&L&R/B SOL(Open)” P17B0 “H/C&L&R/B SOL(GND short)” P1735 “INTER LOCK FUNCTION (1st)” P1736 “INTER LOCK FUNCTION(2nd)” P1737 “INTER LOCK FUNCTION(3rd)” P1738 “INTER LOCK FUNCTION(4th)” P0744 “LU CLUTCH(Lock-up)” P1744 “LU CLUTCH(Slip Lock-up) )” P0731 “Incorrect automatic transmission ratio in 1st gear” P0732 “Incorrect automatic transmission ratio in 2nd gear” P0733 “Incorrect automatic transmission ratio in 3rd gear” P0734 “Incorrect automatic transmission ratio in 4th gear” P17A1 “NEUTRAL FUNCTION(1st)” P17A2 “NEUTRAL FUNCTION(2nd)” P17A3 “NEUTRAL FUNCTION(3rd)” P17A4 “NEUTRAL FUNCTION(4th)” P17A0 “NEUTRAL FUNCTION(Rev)” P0712 “Oil temperature sensor low reading” P0713 “Oil temperature sensor high reading” P0711 “Oil temperature sensor, frozen” P0863 “CAN bus connection (initialization)” P062F “BACKUP MEMORY” P1701 “Controller supply voltage”

ECU characteristics

We suggest that you familiarize yourself with all the necessary information regarding the operation of the unit below.

Where is the block located?

The engine control unit of a Lada Kalina, Kalina 2 or Granta car is located near the center console of the cabin. To get to it, you only need to remove the panel. As you know, domestic engineers have always been famous for their senseless and “merciless” decisions in terms of assembling cars, so the location of the ECM unit was chosen thoughtlessly. In practice, such a device often fails as a result of moisture getting on it, so many car owners decide to move the unit so that it can stand in a safer place.

ECU location

Mass air flow sensor (MAF)

This important sensor is located behind the engine air filter. It is also called an air flow meter. Its purpose is to estimate the amount of air entering the car engine. Based on the information received from the sensor, the electronic control unit (ECU) calculates the required amount of fuel to maintain the stoichiometric fuel-to-air ratio for the given engine operating conditions.