During the entire warranty period, all routine maintenance work on a new car must be performed at an authorized dealer. Each such visit should be accompanied by a corresponding entry in the service book - this information will be useful to you in the future, when the time comes to sell your car. But this is not why maintenance is carried out - every part of the car has a service life, after which it must be checked for functionality and replaced.

Features of the Lada XRAY maintenance regulations

Regardless of the brand model, the service interval is 15,000 kilometers, recorded by the speedometer. If, after a year has passed since the last maintenance, this distance has not been covered, then this time stamp should be considered as a guide.

As for zero maintenance, this procedure is optional for Lada XRAY. However, on Kalina. Priora, Grant and Niva 4x4 require zero maintenance after running in (2-3 thousand kilometers).

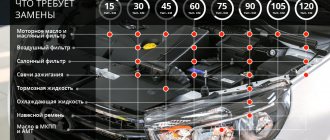

We bring to your attention a table with a list of work carried out in relation to certain systems and components of the model:

| Name of works | Frequency, km. |

| Engine check: | |

| Absence/presence of extraneous knocks and noises | 10000 |

| No leaks in the cooling system or fuel line | 10000 |

| Replacing the fuel filter | 30000 |

| Cleaning and washing the crankcase ventilation system parts | 60000 |

| Checking the coolant level | 10000 |

| Checking the functionality of the thermostat | 20000 |

| Replacing the air filter | 30000 |

| Changing engine oil and oil filter | 10000 |

| Replacing spark plugs | 30000 |

| Replacing antifreeze | 60,000 or after 3 years |

| Checking the degree of exhaust toxicity | 10000 |

| Checking for errors in the ECM and eliminating them | 10000 |

| Transmission check: | |

| Checking the condition of the front wheel boots | 10000 |

| Checking the presence/absence of extraneous sounds in the operation of the gearbox, clutch, both axles and transfer case (humming, knocking, howling) | 10000 |

| Checking for oil leaks in the gearbox, axles, and transfer case | 10000 |

| Checking the fluid level in the clutch hydraulic drive | 10000 |

| Measuring the free travel length of the clutch pedal | 20000 |

| Checking the oil level in the gearbox, gearboxes, transfer case | 45000 |

| Changing oil in gearboxes, gearboxes, transfer case | 40000 |

| Replacing the hydraulic fluid in the clutch hydraulic drive | 30000 |

| Lubrication of bearings and splined joints of universal joints | 10000 |

| Checking the chassis | |

| Diagnostics of suspension bars and arms, rubber-to-metal joints, front wheel joints, condition of ball joints, shock absorbing bushings, rubber caps/covers | 10000 |

| Diagnostics of anti-roll bar cushions | 30000 |

| Shock absorber inspection | 30000 |

| Checking and tightening the fastenings of suspension parts | 20000 |

| Adjusting the front wheel wheel bearing clearances | 45000 |

| Replacing wheel bearing grease | 40000 |

| Checking tires/rims, balancing, rearranging tires according to the diagram | 10000 |

| Camber/Toe Adjustment | 20000 |

| Steering check | |

| Checking the oil level in the power steering reservoir | 10000 |

| Checking the tightness of power steering parts, the condition of connections, hoses, pipes | 10000 |

| Checking the steering wheel play | 10000 |

| Checking the power steering pump drive belt | 10000 |

| Checking the brake system | |

| Checking the front pads | 10000 |

| Checking the rear brakes | 30000 |

| Checking the parking brake | 20000 |

| Checking braking performance | 10000 |

| Checking the fuel fluid level in the hydraulic drive reservoir and the functionality of the warning lamp | 10000 |

| Checking the functioning of the vacuum booster and brake system pressure regulator | 30000 |

| Replacement of TZ | 30000 |

| Checking electrical equipment | |

| Checking the condition of the electrolyte in the battery | 10000 |

| Checking belt tension | 10000 |

| Inspection of the starter, checking the degree of brush wear, cleaning the commutator, lubrication of drive parts | 40000 |

| Inspection of the generator, lighting, control devices and alarms, wipers, head optics light direction controls, washers | 10000 |

| Cleaning battery terminals and lubricating them | 20000 |

| Inspection of the generator - slip rings and brushes | 30000 |

| Headlight adjustment | 20000 |

| Checking body elements | |

| Checking the paintwork for defects, including pockets of corrosion, inspecting the bottom and wheel arches for damage to the mastic layer | 10000 |

| Cleaning drain holes | 10000 |

| Lubricating door hinges, hood release cables, seat hinges, door stops, keyholes, fuel tank cover components | 10000 |

Replacing brake fluid

Prevention measures

No one needs to be convinced that it is easier to prevent any malfunction than to eliminate it when it unexpectedly appears.

But it’s one thing if the breakdown is minor and concerns, for example, the smoke of the engine exhaust, and quite another thing when the malfunction affects the safety of the Niva Travel. Or, sub-optimal tire pressure can cause a road accident, in the worst case scenario, and in the best scenario - premature wear of the treads and imbalance of the wheels.

The manufacturer does not list many preventive measures in the service books, but this does not mean that they do not need to be carried out.

Let's take, for example, regular washing of throttle valves, which largely ensure the economical operation of engines. But this is not all of their functional responsibilities. The most important thing is that these chokes ensure reliable starting of engines in any frost; they increase throttle response and smooth operation of engines.

Timely lubricated door locks, as well as hinges, will not freeze in cold weather, and timely cleaned drains of body cavities will protect against corrosion.

The reality is that those owners who understand the components and assemblies of Niva Travel can independently carry out certain, both routine and preventive measures in their own garages. Namely:

- replace the lubricant

- fuel or air filters,

- check the current condition of the tubes,

- tightness of hoses of the same hydraulic drive,

- assess the condition of the pads and other brake components,

- tighten the rims and check the tire pressure, etc.

However, all those who, in terms of technology, consider an oak to be a coniferous tree, in other words, have absolutely no idea what is inside this or that unit or system, then to carry out maintenance, their Niv Travel is a direct route to the service station.

However, as well as for those who understand the insides of components and assemblies, because they must understand that it is impossible to predict the failure of a particular part even if it is removed from the inside of the machine.

But with the help of diagnostic bench equipment, you can easily detect “painful” or “pre-infarction” states of certain components, systems and even individual parts.

List of works TO-1

The Lada XRAY first maintenance schedule provides for the following work after driving 15,000 kilometers or within a year after the start of the vehicle's running-in:

- replacing the oil filter and engine oil;

- diagnostics of the presence of extraneous noise in clutch operation (for modifications with a manual transmission);

- checking for extraneous sounds during operation of the power unit;

- diagnostics of the presence of extraneous noise coming from the area of the front wheels when cornering at low speeds and when driving in a straight line;

- checking for extraneous sounds in the gearbox;

- diagnostics of the presence of knocks in the area of the rear wheels when driving over uneven road surfaces;

- checking the correct functioning of the electric power steering;

- measuring camber/toe angles;

- diagnostics of engine mount fastenings;

- inspection of the condition of engine oil seals and gaskets for engine oil leaks;

- checking the fuel fluid level;

- when the on-board computer issues error codes, check the functioning of the power unit control system;

- tightening the parking brake;

- inspection of the brake system line for the presence of brake fluid leaks, checking the condition of pipes, hoses and connecting elements;

- checking braking efficiency;

- measuring the tension of the generator belt;

- checking the functioning of the vacuum brake booster;

- revision of the electrical corrector for head optics;

- checking the serviceability of the horn, light alarm, lighting devices;

- adjusting headlights in case of non-compliance with regulatory requirements;

- replacing the alternator belt;

- replacing the cabin filter;

- lubrication of door hinges and stops;

- timing belt inspection;

- inspection of the suspension of muffler elements, checking the tightness of the exhaust tract of the exhaust system;

- checking the presence of coolant leaks, the condition of the main radiator and hoses of the Lada X Rey cooling system;

- checking the condition of the fuel line for leaks;

- antifreeze level measurement;

- checking the condition of the anthers;

- measuring the amount of steering play;

- checking the condition of the rear/front brake pads;

- diagnostics of suspension parts;

- checking the transmission oil level;

- revision of protective covers of front wheel joints, gear shift drive;

- diagnostics of the electrolyte condition in the battery;

- checking the functioning of the wipers;

- generator inspection;

- checking the functioning of the heated glass, seats, exterior mirrors;

- diagnostics of the functioning of electric windows;

- checking the serviceability of door locks;

- cleaning drainage holes in thresholds and doors;

- Checking the correct functioning of the air conditioner.

Replacing the oil filter

Replacements according to service life

The automaker recommends replacing consumables every 15 thousand kilometers, as well as vehicle parts subject to increased wear or the greatest impact. If the car is operated in difficult conditions, this interval is reduced to 7,500-10,000 kilometers.

The following factors are considered particularly unfavorable:

- operating a car in a metropolis, associated with short distance travel;

- frequent and prolonged standing in traffic jams, driving at extremely low speeds;

- frequent travel on dusty dirt roads;

- Frequent driving fully loaded or with a trailer.

Diagnostics and repair of Lada XRAY chassis

During the first maintenance, the oil filter and engine oil, cabin filter, and alternator belt will be replaced. During TO-2, consumables are replaced, including four mandatory items and three that are performed as necessary.

The first includes: changing the engine oil, cabin filter, air and oil filters, spark plugs. If the condition is unsatisfactory, the brake pads at the front and rear, as well as technical fluids, are changed.

Scope of work related to replacing consumables during maintenance-3:

- oil filter;

- cabin filter;

- oil for power unit.

If required, the brake system pads are changed, freon and other technical fluids are added.

At the fourth maintenance, replacement of spark plugs is added to the previous mandatory work; technical fluids are added as necessary and brake pads are replaced.

The scope of work with consumables at the fifth maintenance does not differ from the scope of work during maintenance-3.

During the sixth maintenance, antifreeze, engine oil, brake fluid, spark plugs, alternator belt, both air filters, and the alternator drive belt tension roller must be changed.

If required, freon is added and the brake system pads are changed.

At all subsequent maintenance, up to the twelfth, the scope of work with consumables is identical to TO-6. On TO-12, replacement of the timing belt is added.

Replacing the alternator belt

Diagnostics, monitoring and checking the current status of Niva Travel

These service works consist of:

- in checking both systems and units of Niva Travel;

- in monitoring the external condition of units, for example, whether there are leaks of oil and other technical fluids;

- in carrying out diagnostic procedures to identify problems and defects that cannot be detected by external inspection;

- in compiling a list of all faults and problems of equipment to eliminate them.

It should be taken into account that one should not ignore diagnostics, which are carried out using special equipment at service Auto Centers because not every unit will announce its malfunction by knocking.

And not every knock will appear immediately before long trips, but, according to the rule of a sandwich falling butter-side down, hidden defects appear precisely during these trips.

Routine SUV maintenance work

As for these maintenance procedures, they are of two types, namely work to replace consumables, as well as preventive measures to maintain Niva Travel in good condition.