The performance of key components and mechanisms in your car is the basis for its safe operation. Such important devices installed on board domestic vehicles include a sound signal.

The Volzhsky auto industry, releasing new models of its cars, equips them with standard signaling devices of type 20.3721. Similar signals are also installed on the Lada Granta. But due to its low sound quality and frequent breakdowns (especially after moisture), many car enthusiasts strive to install a higher quality and “melodic” signal on the Grant.

As an alternative, Volga signals on Granta are especially popular, tested by time and the experience of many drivers. The signal from the Volga actually sounds louder and is more reliable in operation, but replacing the standard signal with a Volga signal requires the driver to have some knowledge of electrical equipment. If you follow the rules for installing electrical wiring, the installation of signals from the Volga to Grant will be done quickly and as correctly as possible.

How to fix a car horn, instructions for use

According to the Russian Federation Traffic Regulations and the list of faults presented therein, it is prohibited to operate a vehicle with a non-functioning sound signal.

An ordinary situation, let's say. Early morning, you are driving your car to work and suddenly, unexpectedly and shamelessly, you are “cut off” by a neighbor in the flow of traffic, wedging into your lane. Your further actions are naturally predictable, you immediately hit the brakes and hit the horn with your palm as hard as you can. But bad luck, instead of a powerful signal escaping from the depths of the car’s hood, there is deathly silence. Of course, you managed to avoid an accident, but you failed to warn the boor or just a sleepy, unwary driver. The morning didn't start out well as you had planned.

Of course, there are options and situations that are much worse, when a non-working sound signal led to truly tragic consequences. An inattentive pedestrian running onto the road, or a cyclist running out onto the road, or worse, any teenager or a very small child... A terrible situation, what is there to hide, which might not have happened if the car’s sound signal were working at that moment.

In this article, dear readers, we will figure out how to fix the signal yourself. Let's get started.

As a rule, the circuit of such a sound signal consists of the following elements: - the signal itself, the switch, the fuse and the relay. Battery voltage is supplied through the fuse to the relay coil and contacts. When you press the sound signal, the relay is activated and the electrical circuit is closed, and then the sound signal is activated. Some vehicles do not use such a relay, which means the voltage is supplied directly through the horn switch directly to the horn. In this article, dear friends, we will look at the possibilities of how you can check and repair each of the components of this simple system yourself.

Symptoms of problems

How can you even determine that the horn is not working or has some kind of malfunction? It's actually extremely simple.

There are 2 main signs of problems with a car horn:

- The signal doesn't work at all. When you press the button, the driver, like other road users, hear absolutely nothing. This is a clear indication that the system has failed;

- The signal appears periodically. There is also a slightly different situation when the horn does not go off with every press. That is, they pressed it once, everything works, but when you try to honk again, the horn goes silent, there is no reaction to the press. Then the situation repeats itself.

How to fix a broken horn

1. Purchase the necessary tools. To fix the signal on your car you will need the following: - a digital multimeter or a regular multimeter, protective gloves, a quick-release connection, a repair manual for your car, safety glasses, crimping pliers and wire strippers (can be replaced with a regular knife), and of course spare ones wires.

2. Locate the fuse box. First of all, you need to check whether the fuse or the relay itself has failed. The location of the fuses and their diagram can be found in the user manual. Typically, one fuse box is located in the dashboard on the driver's side and another one is located under the hood of the car.

Tip: -if you don’t have a car manual at hand, you can enter the model and year of your car in an online search, and then find circuit diagrams and manuals for fixing the signal on the Internet. There is a high probability that you will find what you are looking for there.

3. Finding the right fuse. Examine the diagram on the back of the fuse box and find the fuse number that matches the horn circuit.

Tip: -this information is duplicated in the manual for your car, in it you can look and find a diagram for each of the fuse blocks.

4. Remove the fuse. Once you have identified the fuse in the circuit you are interested in, pull it out with the special plastic pliers you will find in the fuse box. If they are not in their rightful place, then call on your ingenuity to help you. But be very careful not to break the connectors.

5. Check the fuse. In order to identify a breakdown, whether the problem is really in the fuse, you will need to check that it is working; perhaps it has simply blown. This can be done in two ways, for example, if a break is visible inside the U-shaped wire, then the fuse itself needs to be replaced, it naturally burned out. If the wiring inside it is intact, this is not a guarantee that everything is in order with the fuse. Thus, we move on to the second stage of verification.

6. Check the fuse using a multimeter. Test the fuse with a multimeter.

When using a digital multimeter, you must use the device’s adjustment knob to select the position for measuring the minimum resistance value with a sound signal (if your multimeter has such a setting).

When measuring with an analog (arrow) tester, it is necessary to select the starting position for measuring the minimum resistance value in Ohms. Then you need to calibrate the device by connecting the probes to each other and then, using the adjustment knob, move the arrow to the zero position, that is, set it to zero.

We press the probes to the fuse contacts. For a working fuse, the tester should show zero ohms. Conversely, if the needle or DMM readings do not change, the resistance is excessively high, then the fuse has blown.

7. Install a new fuse. If the fuse fails, then install a new one of the same current rating (10, 20, 25, 30 Amperes, etc.). To do this, simply insert the new fuse back into the appropriate slot.

Note: -Keep in mind that fuses do not blow out for no reason, they fail at the moment and in order to protect the circuit itself from excessive current. Watch the newly installed fuse for a moment. If it burns out again, you will need to check the circuit for faults.

8. Locate the relay box. If the fuse is good, the next part of the test we move on to is the horn relay. The location of this relay can also be found in the owner's manual. Typically, the relays are installed in the fuse box under the hood.

9. Check the relay. The simplest and at the same time effective way to check the correct operation of the relay is to take and swap the horn relay with another identical relay in the car. As a rule, “relays” of the same design can be used on a couple of other circuits, which, if necessary, allows you to replace them in the machine. If, after replacing the relay, the horn (sound signal) starts working, we can state the fact that the problem was in the relay and it should simply be replaced.

Common causes of malfunctions

All that remains is to talk about why such situations arise and what the motorist himself needs to do in order to restore the functionality of the horn.

Since a car signal consists of a fairly large number of components, the reasons must be looked for in them. To do this, it is good to understand the device, design and principle of operation of the warning system.

- Blown fuse. A trivial but common problem. The fuse is located in a special block. Look for information in the instruction manual. Sometimes simply replacing the fuse is enough;

- Burnt out relay. Since the horn is powered through a fuse and a relay, the latter is also necessarily checked in the mounting block, and changed if the problem is with it;

- Broken horn. If everything is fine with the relay and fuse, the problem may be in the device itself. To check, you can take the element and directly supply power through the battery. When the horn is working, the signal appears;

- Short circuit. The place to start your search is with the safety socket. And then move along the chain;

- The contact ring on the steering wheel is worn out. It will need to be replaced if necessary;

- The clamping contacts on the column are worn out. A characteristic feature of domestic cars;

- The contacts have oxidized. Check the contact group for rust or signs of oxidation;

- The winding on the horn has burned out. The problem is solved by replacement;

- Violation of electrical contact;

- The cable on the steering wheel where there is an airbag is broken.

In the vast majority of cases, and if desired, most of the possible problems can be solved on your own.

But for this you need to know how to use a tester or multimeter. These are truly integral tools that help determine the source of problems, check the condition of the electrical circuit, the power supply to the horn and other points.

In the worst case scenario, you will have to carry out a comprehensive replacement, or even install a new horn or a new steering wheel. But this happens quite rarely.

Most often, motorists are faced with banal oxidation and contact failure due to rust. The problem is resolved by stripping the contacts and then reconnecting them.

If for some reason you cannot find the problem yourself, or do not dare to take on the task of correcting the current situation yourself, contact experienced specialists. They will quickly carry out diagnostics, find the source of trouble, and fix the breakdown. But directly for your money.

Have you ever encountered a failure of the steering wheel signal? How did you troubleshoot the problem and what was the cause of the problem? Did you manage to do it yourself?

Thank you all for your activity and comments! Be sure to subscribe, leave reviews, ask questions on the topic and invite your friends to join us!

(

2 ratings, average: 5.00 out of 5)

Very useful article. I was just looking for information on this issue. The car's horn stopped working.

Replacing the signal on Grant - from simple to complex

There can be a great many reasons why the signal on Grant does not work:

– a break in the current-carrying signal wiring harness; – poor contact with the vehicle ground; – malfunction of the signal itself or its unstable operation; – failure of the signal activation button.

Every car enthusiast can find out why the signal on Grant disappeared on his own. To do this, you only need attentiveness and the correct sequence of actions.

Despite the ease of installation of signaling devices, many car enthusiasts have a reasonable question - how to install signals on the Grant without damaging the electrical equipment of the car?

Everything is very simple. To replace a faulty or poorly functioning signal on a Lada Granta, first of all, you will need to disconnect the minus terminal from the power source. Although they say that replacing the sound signal on a Grant without removing the bumper is possible, it is better to remove the bumper itself to avoid damage.

Next, you need to gain access to the left radiator mounting post, because it is where the signal to the Grant is normally installed. Using your hand, squeeze the latch of the signal contact connector and disconnect the supply wires.

Features of the placement of fuses in the Lada Granta Liftback

The Grant Liftback fuses are located near the driver’s left hand.

To gain access, simply remove the decorative plug by pulling it down.

To make it convenient to work, the plug can be removed completely, for which you pull it out of the grooves, on one of which the trunk opening button is fixed (this can also be removed; it applies to the “luxury” and “norm” modifications).

Signal pair: installation features

When the question arises about what signal to put on the Grant, you should proceed from the experience of advanced car owners. On forums dedicated to automotive topics, you will find a lot of advice regarding choosing a signal for Grants.

Some advise installing only Volga signals, others like signaling devices from Hella, and still others are happy with the standard signal. There are the same disagreements regarding the number of signals, but the overwhelming majority recommend using a two-tone signal.

Installation of a two-tone signal on Grant is carried out in the same order as installation of a standard signal. Two wires are connected to the positive wire, which will power both signals, and the mount works great as a ground. In this case, it is extremely important to ensure reliable contact at the terminals of both signals and at the junction of the vehicle ground and the signal itself.

Installation of sound signals S308/S309 in Grant

I installed beeps from classics, each 7.5A. Unlike “Volgov” signals, these are smaller, and their current consumption is higher. Initially I thought of wiring through a relay and a fuse, let’s say to protect the wiring from overheating, but after looking through a sufficient amount of information on the forums I came to the conclusion that this was stupid. We have a standard relay for the signal, it is rated at 15A. This is quite enough.

And so, we acquire sound signals C308 and C309.

Sound signals S308/S309 manufactured by: JSC Lyskovsky Electrotechnical Plant

Now let's look at the location of our beeps. On Granta, unlike Kalina, they stopped installing a plastic protective beam under the front bumper (catalog number for Kalina: 11180280313200), but they left the studs for fastening. There are 2 of them on each side. with a thread for an M8 nut, so we will attach our future brackets to them. We will make the bracket from a PS 40×110 connecting plate, bought at Megastroy for 15 rubles*. each. (Vector also has it, but is more expensive)

Connection plate PS 40×110 or 40×120

We also need a wire with a cross section of at least 0.75 mm2. I took one, took it with a margin of 4m. I used the following terminals:

RP-M Flat connector without insulation “MAMA” - 2 pcs. We use it on the “+” of the sound signal.

NK Ring tip without insulation - 4 pcs. We use 2 wires, 10 cm each, crimp on both sides. This will be our “-” from the horn to the standard “-” under the headlight on each side.

To prevent the standard plug from “damaging” the “MAMA” (which fed the standard audio signal), we cut off the connector (“DAD”) from the Grant signal; we only need “+” from it.

Also, when preparing the wires, you will need heat-shrinkable tubing, electrical tape, automotive corrugated tubing and 10 nylon ties.

Don’t forget to purchase M8 self-locking nuts - 4 pcs; M6 - 2 pcs. and under them the corresponding lock washers.

And so, we mark and drill the purchased connecting plates according to the drawing. We get one hole for 6mm and two for 10mm. Ask why 10mm and not 8mm? Yes, because the studs for fastening the protective beam are not riveted quite evenly, one can look a little up, the other a little down, and so as not to catch the holes, we drill them 10mm. Drill the second plate in the same way. From an old bicycle inner tube we cut out pads for each resulting bracket so that there is no friction with the radiator frame panel.

The length of the lower part is not particularly important to us, the main thing is to measure the upper part correctly

Ready-made brackets and pads

The brackets are ready. Now let's do the wiring. Measure the “positive” wire as you wish, I pulled the wiring behind the panel of the radiator frame. This is for safety reasons, because if we lay it in front of the radiator, where the temperature sensor is installed, our wiring may flood. But everyone decides this for themselves.

Do not take wires below 0.75 mm2

When the “positive” wire is ready, we make 2 “negative” ones, each

10 cm. We crimp on both sides with ring tips. As I said earlier, this is our minus from the sound signal to the standard minus under the headlight.

Afterwards, we assemble everything, check it, put the wires in a corrugated tube and fasten it with zip ties to the factory wiring, the one under the generator and radiator.

The finished result. There is a gap of about 2 cm between the signal and the headlight.

To achieve clear sound, you need to turn the adjusting screw in the appropriate direction. I didn't have to adjust anything, the buzz is clear and loud.

Sound signal from Volga in Lada Granta

Good day, as they say. At this point in the evening, I'm a little tipsy from the champagne. Once we were at a wholesale food store that had recently opened, I grabbed some for myself, but it was just for the holiday of Russian champagne. Today my wife and I opened this bottle, an unexpected surge or a sudden desire, an impulse, etc. My wife had enough of 1% of the bubbles, 99% took over, like a gentleman and a gentleman, all in one. I thought about the advisability of installing a mesh in the bumper, but I will write about this a little later. I’ll start in order of installation, and these are sound signals from the Volga. Many Grant Guides combine grid installation and signal installation, and this is advisable (in any sequence or combination). Let me back up a bit: in practice, I liked (was happy with) the native signal, because fortunately you rarely use it. But as a former Volgovod with a stereo signal (specifically on Gaz 31105 the signals were located at a distance from each other, on the sides) I was familiar with it firsthand. On Grant this is a native signal, of course - everyone is aware.

So, I purchased these signals, although many have single contacts, mine have two. I don’t presume to speak for the original, I didn’t “punch” this topic. As long as they don’t break and “squeak” acceptable, these are the two main criteria. Price tag on the package.

Reviews

Delivery of goods is carried out throughout Russia and the CIS:

1. Russian Post (from 350 rubles and above)

Delivery to all regions of the Russian Federation and CIS countries

2. Transport Companies (from 350 rubles and above)

Delivery throughout Russia and the Republic of Kazakhstan

- TK Energy (nrg-tk.ru)

- TC Business Lines (dellin.ru)

- TC SDEK (www.cdek.ru)

- TK PEK (pecom.ru)

- TK KIT (tk-kit.ru)

3. Pickup

The order can be picked up at the office at Tolyatti, 40 Let Pobedy 38, TD “Malachite”, 1st floor.

The waiting time for sending an order in our online store is approximately 2-7 working days, large orders 7-14 working days. days; color of bumpers, mirrors, body parts, spoilers, etc. 7-14 work. days; sewing covers, upholstery, steering wheels, gear knobs, EVA mats, etc. 7-14 work. days.

During this period, we will send you a tracking number by email. email to track the parcel en route.

Payment can be made in the following ways:

1. Payment to a Sberbank card

You can pay using the SBERBANK-Online application and other Bank applications.

After placing an order, making payment, do not indicate comments , we ourselves will understand by the amount of the order and the name of the sender. After receiving the funds, the status of your order will be changed to paid until 17.00 of the current day, or from 9.00 of the next Moscow time.

2. By bank card

Automatic acceptance of payments using MIR Bank cards, VISA International, Mastercard.

You can also pay with credit cards with a grace period.

To select payment for goods using a bank card, on the corresponding page you must click the “Pay for order by bank card” button.

2. Payment to QIWI wallet 89272115207

3. Payment on Yandex.Money 410013993950891

5. Payment to a bank account for legal entities and individual entrepreneurs (commission 6%)

Send your organization's details to [email protected] for invoicing. After paying the bill, be sure to send a payment order.

4. Cash on delivery of Russian Post (commission from 4%)

IMPORTANT! When sending by cash on delivery, RUSSIAN POST will take a commission for providing the cash on delivery service of 150-300 rubles, and the delivery cost also increases due to the evaluation of the goods.

Cash on delivery delivery is possible only within Russia.

Product description

Air signal for passenger cars, trucks, motorcycles. Made of components: ABS plastic body and aluminum alloy pneumatic compressor. Accessory from the global brand: BOOMBLOCK.

Fixation location:

- car engine compartment;

- front fork of motorcycle and scooter;

- truck roof.

Fixation type: mounting bolt “17”. Thanks to the combination of ABS plastic and aluminum, the manufacturer managed to balance the weight of the product as much as possible and reduce weight.

Type of packaging:

- multilayer cardboard;

- cellophane wrapper;

- impact-resistant foam around the perimeter.

Equipment:

- accessory in red;

- metal mounting bolt “17” with nut.

Advantages and disadvantages

| № | Advantages |

| 1. | Weight less than a kilogram. |

| 2. | Using impact-resistant ABS plastic for manufacturing. |

| 3. | Budget cost. |

| 4. | Versatility in application: various classes of automobile brands. |

| 5. | Flaws |

| 6. | Susceptibility to deformation due to mechanical impact, impact, collision. |

What to do with worn seat belts?

The seat belt squib often deploys along with the airbag. There are two options here - turn to specialists or do the work yourself.

In the second case, the sequence is as follows:

- Move the front seat forward as far as possible;

- Unscrew the blind edge of the belt from the body part;

- Disassemble the lower edge of the rack trim (the mechanism is located there);

- Pick out the plug on the adjustment mechanism;

- Remove the rack trim to check the level of wear;

- Carefully unscrew the belt and push it away from the adjuster;

- Remove the device and discard the system connectors;

- Remove the cover and locking assembly;

- Under the steel plate there is a mechanism with a return spring. The latter, when the squib operates, is triggered, jumps out of its place and fixes the belt;

- Compress the springs and put everything back in place.

Results

If the airbag has deployed, operating the car or doing it yourself often leads to tragedy on the road.

To eliminate problems, you should contact an authorized dealer, who, after a complete diagnosis, will replace the failed elements.

Otherwise, there is no guarantee that the airbag will work in an accident and save lives.

The SNPB control unit is secured with three nuts on a bracket on the floor tunnel and is located under the instrument panel console, under the floor mat.

The control unit carries out diagnostics of the air intake system, displaying the system status on the diagnostic indicator, and has software for storing fault codes and supporting a diagnostic data exchange channel via the CAN bus.

Removal and installation of the SNPB block

We prepare the car for the job. Disconnect the negative terminal of the battery.

Removing the front interior heating duct - How to remove the floor tunnel lining of a Lada Granta

Disconnect block 1, Figure 1, from control unit 2 of the airbag system.

Using a 10mm socket, unscrew nuts 3 and remove block 2.

Installation of the SNPB block

Install the block in reverse order.

When installing the block, the arrow on the block cover should be directed in the direction of travel of the vehicle.

The tightening torque of the block mounting nuts is 7 – 8 Nm (0.7 – 0.8 kgf.m).

The SNPB control unit is sold in a locked state. After installing the block, you need to unlock it.

Activation of the electronic control unit

We connect the diagnostic tester to the car diagnostic block

After establishing communication with the car, turn on the ignition.

When the ignition is turned on, the ECU performs a self-diagnosis for 5 seconds, and the airbag system warning light in the instrument cluster turns on for 3 seconds and turns off for 2 seconds.

Next, the SNPB indicator will flash at a frequency of 1 Hz if there is no active fault or remain on continuously if there is an active fault.

To unlock the ECU, you must enter the vehicle's VIN number into it and then activate it using the corresponding functions in the diagnostic tester menu.

After activation of the SNBP, the indicator in the instrument cluster will be turned off in the absence of active faults (not counting 3 seconds in self-diagnosis mode).

The electrical connection diagram of the single-channel airbag system of the LADA 2190 car is shown in Figure 2

Assignment of the terminals of the single-channel SNPB control unit in Table 1

Other section materials

| Technical description |

| Vehicle specifications |

| Vehicle registration details |

| Location of controls and instruments |

| Car keys |

| Ignition switch (lock) |

| Front and rear doors |

| Hood |

| trunk lid |

| Fuel filler plug |

| Seats |

| Rear view mirrors |

| Interior lighting |

| Instrument cluster |

| Granta steering wheel adjustment knob |

| Steering column switches |

| Granta headlight beam direction control unit |

| Granta heating and ventilation system control unit |

| Safety precautions during maintenance and repair of Granta |

| Location of the main components and assemblies of Granta |

| Vehicle check |

| Maintenance schedule |

| Checking the condition of wheels and tires |

| Replacing windshield wiper blades |

| Checking the fluid level in the windshield washer reservoir |

| Checking the engine oil level |

| Changing the engine oil and oil filter |

| Checking the level and topping up Granta coolant |

| Coolant replacement |

| Checking the condition and replacing Granta spark plugs |

| Removing the Granta air filter replacement element |

| Replacing the fuel filter |

| Adjusting thermal clearances in the valve drive of the Lada gas distribution mechanism |

| Checking the condition and replacing the generator drive belt |

| Checking the condition and replacing the Lada timing belt |

| Checking the condition of the exhaust system |

| Checking the gearbox oil level |

| Changing the gearbox oil |

| Checking the fluid level in the hydraulic brake reservoir |

| Bleeding the hydraulic brakes Granta (VAZ-11183, |

| Checking the condition of the chassis and transmission |

| Checking the steering condition |

| Checking the condition of the brake system |

| Adjusting the parking brake |

| Replacing the heating and ventilation system filter |

| Adjusting the direction of headlight beams |

| The crankshaft does not turn with the starter |

| Loud noise when the starter is running |

| The crankshaft is turned by the starter, but the engine does not start |

| The engine is running erratically |

This is interesting: Cigarette lighter wiring diagram Lada Largus

Airbag device

An airbag cushion is an elastic base that fills with gas in the event of an accident.

The complex of components also includes a control system and a gas generator. Starch or talc acts as a lubricant for the material, guaranteeing clear opening.

The gas generator's job is to fill the airbag with gas during a collision. Together, the gas generator and the shell form an airbag.

Airbag designs are classified:

- By the nature of the action - with one and two-stage operation;

- In shape - in the form of a tube or dome;

- According to the type of gas formation - hybrid or solid fuel.

A solid fuel generator is based on a fuel charge, a squib and a housing. The airbag is charged with a special composition based on silicon dioxide, potassium nitrate and sodium azide.

The fuel is ignited by the action of the squib, after which gas is formed.

Why do you need a relay?

The seller persistently sold me a relay for 40 rubles, saying that I couldn’t live without it. But in the end, it worked out without him.

What is the point of a relay?

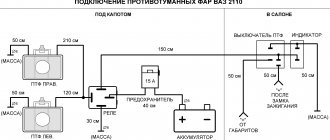

First version (MYTH) The point is that the VAZ and Volgov circuits for connecting sound signals are not the same. Volgov's horns take ground from the body, while VAZ's horns take ground from the connected wire. According to the sellers, when we press the beep, we close the ground (-) and not (+). Therefore, if you connect without a relay, the horn will work constantly. But in reality, everything turned out quite the opposite, which made the work easier. Therefore, we proceed as follows.

Second Version (more real). Volgovsky buzzers consume a current of 14A, and a standard buzzer 5.5A. Due to excessive load, the fuse may melt, and if you set its rating higher, the tracks on the board will melt.

If you want to install a relay, install it, but I didn’t install it, because... The loads applied to the beep are not constant and short-term.