Purpose

The damper position sensor takes an active part in the formation of the fuel mixture, and therefore, if certain problems arise with its condition, fuel consumption increases significantly. To be more precise, it determines the opening angle of the damper, as a result of which it will be possible to draw certain conclusions about the volume of air in the system.

Opening data is sent to the control unit, after which it is transmitted to the main indicator panel. The readings obtained play an important role in the operation of the fuel mixture formation system.

Device

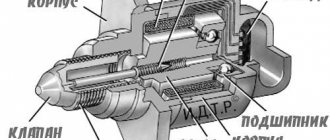

This component of the system is a fairly simple electrical resistor, which changes the resistance when the axis is rotated.

The sensor is located on the damper shaft and, when it opens, performs the function of turning together with the damper. Due to the fact that the design is quite primitive and unreliable, the sensor often fails, resulting in certain problems with the formation of the fuel mixture. So, in most cases, the problem is the rubbing of the tracks, but the possibility of other problems with the condition of the resistor cannot be ruled out.

Location

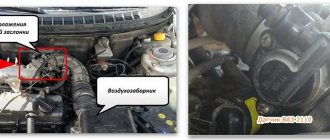

The location of the sensor is quite accessible - on the base of the throttle body, which is located above the cold speed sensor. It is worth noting that in most cases this resistor is fixed with two screws that can be unscrewed with a Phillips screwdriver, and there is also a certain foam washer and boot.

Symptoms of a problem

When the first signs of a malfunction appear, you should contact the service to fix the problem. The most obvious of them are:

- When starting the vehicle at speeds from 500 to 2.5 thousand per minute, a certain knocking sound appears

- The idle speed seems to float and does not have a constant value

- The internal combustion engine stalls on its own, which can result in dangerous emergency situations on the road.

If such problems are detected in the operation of the vehicle, it is recommended to contact the service as soon as possible to check the condition of the sensors. It is worth noting that replacement takes a minimum amount of time.

Brand tour

Based on the above, we advise you to take the original sensor. Structurally, it fully corresponds to the specific vehicle model. And, by the way, it is better to install it at a service station. Craftsmen will cope better with this work, although even a car enthusiast can do it.

The choice of non-originals is very wide, however, in the secondary spare parts market there are only a few manufacturers of sensors of decent quality:

- Hella (Germany). As many drivers say, the sensors from this manufacturer are practically not inferior to the originals;

- Bosch (Germany). Another German manufacturer that has already proven itself. And not just anywhere, but all over the world. The price may unpleasantly surprise the buyer. However, German sensors are the best among all other analogues;

- Era (Italy). Widely known manufacturer in Europe. Its products meet all quality standards. But what the driver would like to know is that Italian sensors are not particularly inferior to the originals. Since 2010, the quality of products, as well as their range, began to reach a fundamentally new level;

- Dello (Germany). Products are manufactured under the brand name AutoMega. It is also important to remember that some Dello spare parts are produced in China and are much inferior in quality to German-made products. It is worth buying German sensors;

- Hotaru (China). This is a brand known only in Eastern European countries. The range of products is not very wide, but the quality is always high.

Here are the brands that offer analogues at the most affordable prices:

- JP Group (Denmark). A well-known manufacturer in Europe, less so in Eastern countries. Solid “average”, but at a very good price;

- Topran (Germany). German quality at a price that is favorable to the car owner. There are other German manufacturers of affordable analogues, but Topran is still the clear leader among them;

- Luca s (UK). The products of this company are located somewhere on the periphery between premium and budget analogues. The quality and fault tolerance of English sensors are high, and the range is also good.

Whatever sensor you choose, it must comply with the parameters set out by the automaker. Otherwise, you will not feel either fuel economy or improved dynamics. Choosing the right cheap analogue, the driver, however, will not get the desired result either. It makes sense to overpay here.

Examination

Checking the operation of the resistor can be carried out exclusively using a multimeter or a special device like ELM-327, however, the first option is the simplest and most common.

Checking the power circuit condition

First of all, it is recommended to check the condition of the power circuit, since this is where breakdowns and malfunctions are most often observed.

To do this, it will be necessary to put the device into a state of changing the constant voltage with a limit of 20 Volts, then remove the connector from the sensor and turn on the ignition on the car. After this, all that remains is to connect the tongs to the device and obtain certain information on the voltage status (it must be at least 5 Volts).

Checking the functionality of the sensors

Here it is already assumed that data is obtained by rotating the central part of the sensor. To do this, you will need to put the device into a state of resistance change, and then connect it to the sensor terminals.

When rotating the internal part, it will be possible to obtain certain readings, which should change quite smoothly, without any jumps. If so, then the performance status is good.

Mechanism of action of the equipment

The TPS works like a potentiometer.

- Each output of the mechanism has its own channel - a 5V electrical signal goes to one contact, the other is connected to ground, the third is connected to the controller. When the gate is turned, the voltage from the current collector slider to a specific output changes.

- With the ignition on, you can check it with a special device by installing probes on the input contacts of the unit. When the throttle shield is closed, the readings will be in the range of 0.5 - 0.7 V. When open - up to 4V.

- The VAZ 2114 throttle valve is in contact with the idle air control mechanism. When the shutter is closed, the IAC comes into operation, and the engine is filled with additional air, bypassing the TPS.

You can check the performance of the valve sensor by measuring the resistance - with an ohmmeter. If the mechanism is working properly, the indicators should be zero.

Throttle sensor malfunctions

Malfunctions of the throttle sensor lead to unstable operation of the car engine. That the TPS is not working correctly can be understood by the following signs: unstable idle, decreased car dynamics, increased fuel consumption and other similar troubles. The main sign that the throttle position sensor is faulty is jumping speed. And the main reason for this is wear on the contact tracks of the throttle valve sensor. However, there are a number of others.

Checking the throttle position sensor is quite simple, and even a novice car enthusiast can do it. To do this, you only need an electronic multimeter capable of measuring DC voltage. If a sensor fails, repairing it is most often impossible, and the device is simply replaced with a new one.

Signs and causes of TPS failure

First, let's define the symptoms. Sensor failure manifests itself in the following behavioral changes on the part of your vehicle:

- When idling, increased (sometimes excessive) revolutions are observed;

- When the transmission is shifted into neutral, the engine immediately stalls;

- Idle speed is unstable (drivers call it floating);

- When accelerating (either from a standstill or already in motion), jerking is observed;

- The dynamics are noticeably worsening.

Finding out why the sensor is covered only makes sense if you intend to revive it. There are 3 possible reasons:

- Oxidation of contacts

. In principle, this cannot be considered a breakdown - just a temporary hindrance. The sensor is removed, a cotton swab is soaked in WD-40, all terminals are wiped, the device is put in place; - The next option is that when moving the slider, the track (spraying) was erased. For this reason, the TPS did not increase the voltage at the output;

- The design of the said slider includes a moving core. When one tip is damaged, burrs are scratched on the substrate, which damage the remaining ones. The track layer with the slider loses contact, which leads to engine malfunctions.

It is probably possible to restore the sensor, but it is quite troublesome and unreliable. In the last two options, people prefer to install a new TPS - it is not that expensive. So, after checking the contacts, if you are convinced that the throttle sensor is to blame for the abnormal functioning of the car, do not bother with its restoration, buy another one.

Signs of a malfunctioning throttle position sensor

Before moving on to describing the symptoms of a TPS failure, it makes sense to briefly dwell on the question of what the throttle position sensor affects. It is necessary to understand that the main function of this sensor is to determine the angle at which the damper is rotated. The ignition timing, fuel consumption, engine power, and dynamic characteristics of the car depend on this. Information from the sensor enters the electronic engine control unit, and based on it, the computer sends commands about the amount of fuel supplied and the ignition timing, which contributes to the formation of an optimal air-fuel mixture.

Accordingly, malfunctions of the throttle position sensor are expressed in the following external signs:

- Unstable, “floating” idle speed.

- The engine stalls while changing gears, or after changing from any gear to neutral speed.

- The engine may stall randomly when idling.

- While driving there are “dips” and jerks, in particular during acceleration.

- The engine power is noticeably reduced, and the dynamic characteristics of the car drop. This is very noticeable in terms of acceleration dynamics, problems when driving the car uphill, and/or when it is heavily loaded or towing a trailer.

- The Check Engine light on the dashboard activates (lights up). When scanning errors from the ECU memory, the diagnostic tool shows error p0120 or another related to the throttle position sensor and its malfunction.

- In some cases, there is increased fuel consumption by the car.

Sensor ringing

You should not count on the Check Engine light to warn you in a timely manner: it does not light up in all cases. And the symptoms described can be caused by other breakdowns in the complex modern automotive organism. So in order to determine which component requires your attention, you must first eliminate the throttle position sensor from the list of suspects.

- To facilitate access to the desired unit, the air ducts from the air filter are removed from the branch pipe related to the throttle assembly;

- The crankcase ventilation hoses are also removed from the pipe leading to the cylinder head cover;

- Directly from the sensor itself, by pressing the lock, the block with the wiring harness is disconnected;

- Testing is transferred to a voltmeter. Its negative terminal is connected to the minus of the engine, the positive terminal is connected to the block at the output indicated by the number 1 and also by the letter A (depending on the model);

- The engine starts, and measurements are taken while it is running. They should fall in the range from 4.8 to 5.2 V. The absence of voltage or its very low value indicates that there is an open somewhere in the circuit - in this case, the contacts are checked. A more unpleasant option is a malfunction of the ECU. At a minimum, you will have to reflash the computer brains; in a very bad case, they will have to be replaced;

- The ignition is turned off; the device is switched to ohmmeter mode;

- The terminals of the device are connected to the two remaining unconnected outputs of the block;

- With the damper closed, the resistance level is measured. When the TPS is in working condition, the optimal indicators are 0.9-12 kOhm;

- Similar measurements are carried out after opening the damper. This data should fit into the range up to 2.7 kOhm.

If the ohmmeter readings do not change when the damper position is changed, then the device will need to be replaced. Once you learn how to check the throttle position sensor, you can easily replace it yourself: you've already done most of the work. Installation of a new TPS proceeds in the opposite direction to removal. The main thing is that during installation the damper is in the closed position, and the axial shank fits into the corresponding groove.

We're sorry, but the requests coming from your IP address appear to be automated. For this reason, we are forced to temporarily block access to the site.

To continue, please enter the characters from the image in the input field and click "Submit".

Cookies are disabled in your browser

. We will not be able to remember you and correctly identify you in the future. To enable cookies, follow the tips on this page.

Causes of TPS malfunction

There are two types of throttle position sensors - contact (film-resistive) and non-contact (magnetoresistive). Most often, it is the contact sensors that fail. Their work is based on the movement of a special slider along resistive tracks. Over time, they wear out, which is why the sensor begins to provide incorrect information to the ECU. So, the reasons for the failure of a film-resistive sensor may be:

- Loss of contact on the slider. This can be caused either simply by physical wear or by a broken tip. The resistive layer may simply wear out, causing the electrical contact to also disappear.

- The linear voltage at the sensor output does not increase. This situation may be caused by the fact that the base coating has worn off almost to the base in the place where the slider begins to move.

- Wear of the slider drive gears.

- Broken sensor wires. These can be both power and signal wires.

- A short circuit has occurred in the electrical and/or signal circuit of the throttle position sensor.

As for magnetoresistive sensors , they do not have a coating of resistive tracks, so their breakdowns are mainly reduced to broken wires or a short circuit in their circuit . And the testing methods for one and the other type of sensor are similar.

In any case, repairing a failed sensor is hardly possible, so after performing the diagnostics, you simply need to replace it with a new one. In this case, it is advisable to use a non-contact throttle position sensor, since such a unit has a much longer service life, although it is more expensive.

How to check TPS yourself

The work is done in several stages:

- Turn on the ignition;

- Using a measuring device (we recommend getting an inexpensive multimeter), measure the voltage that acts between the slider contact and the instrument negative. Norm: no more than 0.7 V ;

- Achieve full opening of the throttle valve, again monitor the instrument readings. The voltage should be 4 V , no more;

- Turn off the ignition, then pull out the connector, then set the device to measure electricity. resistance. We are interested in the resistance between any of the pins and the slider;

- Now turn the sector and watch the readings of the device - they should change smoothly. If they change abruptly, there is a serious problem with the TPS.

Like many other sensors, the subject of this article is not a repairable part. And what’s more, finely tuned “rheostat” sensor should be changed at the slightest flaws in its operation - over time they will become more and more obvious. Of course, some car enthusiasts solder fillings from resistors, but even after such repairs, the sensor functions properly for a long time in very rare cases. It's easier and more reliable to buy a new one.

How to Determine a Malfunctioning Throttle Sensor

Checking the TPS itself is simple, and all you need is an electronic multimeter capable of measuring DC voltage. So, to check the TPS malfunction, you need to follow the algorithm below:

- Turn on the car's ignition.

- Disconnect the chip from the sensor contacts and use a multimeter to make sure that the sensor is receiving power. If there is power, continue checking. Otherwise, it is necessary to “ring” the supply wires in order to find the break point or another reason why the voltage to the sensor is not suitable.

- Set the negative probe of the multimeter to ground, and the positive probe to the output contact of the sensor, from which information goes to the electronic control unit.

- When the throttle is closed (corresponds to the accelerator pedal being fully depressed), the voltage at the sensor output contact should not exceed 0.7 Volts. If you open the throttle completely (fully depress the accelerator pedal), then the corresponding value should be at least 4 Volts.

- Next, you need to manually open the damper (rotate the sector) and at the same time monitor the multimeter readings. They should rise smoothly. If the corresponding value rises abruptly, this indicates that there are worn spots in the resistive tracks, and such a sensor must be replaced with a new one.

Owners of domestic VAZs are often faced with the problem of TPS malfunction due to the poor quality of the wires (in particular, their insulation) with which these cars are standardly equipped from the factory. Therefore, it is recommended to replace them with higher quality ones, for example, produced by PES/SKK CJSC.

And, of course, it is necessary to perform a check using the OBDII diagnostic tool. A popular scanner that works with most cars is Scan Tool Pro Black Edition . It will help you find out exactly the error number and see the operating parameters of the throttle valve, and will also determine whether the car still has problems, possibly in other systems.

The most common error associated with the throttle position sensor is code P0120 and stands for “Throttle position/pedal position sensor/switch “A” circuit malfunction.” Another possible error p2135 is called “Mismatch of readings from sensors No. 1 and No. 2 of the throttle position.” The following codes may also indicate incorrect operation of the remote control or its sensor: P0120, P0122, P0123, P0220, P0223, P0222. After replacing the sensor with a new one, it is necessary to erase the error information from the ECU memory.

In the diagnostic application, the scanner will make it possible to see the data coming from the sensor in real time. When moving the damper, you need to look at the readings in volts and the percentage of its opening. If the damper is in good condition, the sensor should produce smooth values (without any jumps) from 03 to 4.7V or 0 - 100% with the damper fully closed or open. It is most convenient to view the operation of the TPS in graphical form. Sharp dips will indicate wear of the resistive layer on the sensor tracks.

Conclusion

A malfunctioning throttle position sensor is not a critical failure, but it needs to be diagnosed and corrected as quickly as possible. Otherwise, the engine will operate under significant loads, which will lead to a reduction in its overall service life. Most often, the TPS fails simply due to simple wear and tear and cannot be restored. Therefore, you just need to replace it with a new one.

Source

Cleaning methods

There are two ways to clean the throttle valve for a VAZ 2114 car:

- Superficial;

- Deep.

Each of them deserves separate consideration.

Surface cleaning

The easiest way that does not require virtually any knowledge in the field of car repair and disassembly. There is no need to disassemble the damper itself, because this option is preferred by almost all beginners who are just beginning to learn the joys of self-repair.

Unfortunately, this method does not give the desired effect, since cleaning consists of removing dirt from surfaces. We recommend that you arm yourself with the almighty WD40. If it is not available, an alternative is regular gasoline, alcohol or carburetor cleaner. Plus you will need dry rags and a brush.

The procedure for superficial cleaning of the throttle valve is as follows:

- Remove the corrugation from the throttle valve;

- Treat interior surfaces with your chosen cleaning product. Better than WD40;

- Go over the knot with a brush. Just don’t use metal ones;

- Wipe off any accumulated dirt with a dry cloth;

- Carry out similar activities on the reverse side of the damper;

- Reinstall all removed items.

Let’s say right away that this method cannot be called effective. It’s not called superficial for nothing. This tells us that all the internal components of the unit will still remain dirty. Therefore, the symptoms are unlikely to disappear.

Deep flushing

In most cases, you will not be able to fix the problem without deep cleaning. Plus, it is still recommended to check the throttle position sensor on the VAZ 2114, since the reason for the violation of the proportions of the air-fuel mixture may lie in it.

From a set of materials and tools you will need:

- The almighty WD40;

- Crosshead screwdriver;

- Dry rags;

- Throttle valve gasket (for 1.5 liter engine);

- Receiver O-ring (for a 1.6-liter engine);

- Spanners;

- Two M13 bolts;

- Ear cotton swabs.

A fairly inexpensive set, each item from which will be useful to you. Therefore, it is better to immediately collect everything you need and get to work.

- Remove the entire throttle assembly. To do this, remove the corrugation from the filter, turn off the antifreeze pipe (here you will need M13 bolts to close the pipes). There is no need to drain the antifreeze, as many recommend. Just try to disconnect the pipes as quickly as possible and plug the holes with bolts.

- Now the adsorber pipe is removed.

- You have completed the most difficult stage, so it will be easier further. Remove the assembly fasteners, disconnect the cable from the gas pedal. This will allow you to remove the throttle body.

- After removing the unit, disassemble it into parts. The first are two sensors - TPS and IAC. They must be thoroughly cleaned using the products indicated in the previous section. If you don't have WD40, use alternative solutions.

- Rinse the damper thoroughly from all sides, blow out the holes, which will allow all internal components to dry properly.

- Now all you have to do is assemble the assembly in reverse order. This is not difficult to do if there are no problems with disassembly.

- Don't forget the gaskets or rings. There is no point in cleaning them from dirt, so immediately replace the old ones with new ones. Do not confuse which element is suitable for which VAZ 2114 engine size. Many people manage to put the ring where the gasket should be, or vice versa.

Throttle valve malfunctions

Malfunctions of the throttle valve can be externally determined by the following signs of engine operation - problems with starting, decreased power, deterioration of dynamic characteristics, unstable idling, increased fuel consumption. The causes of malfunctions may be contamination of the damper, air leaks in the system, incorrect operation of the throttle position sensor, and others. As a rule, repairing the damper is not difficult, and even a novice car enthusiast can do it. To do this, it is cleaned, the TPS is replaced, or the leakage of external air is eliminated.

Signs of a bad throttle valve

The throttle assembly regulates the air supply to the intake manifold, which subsequently creates an air-fuel mixture with parameters that are optimal for the engines. Accordingly, if the throttle valve is faulty, the technology for creating this mixture changes, which negatively affects the behavior of the car. Specifically, signs of a bad throttle position include:

- problematic engine starting, especially “cold”, that is, on an unheated engine, as well as its unstable operation;

- the engine speed value constantly fluctuates, and in a variety of modes - at idle, under load, in the average range of values;

- loss of dynamic characteristics of the car, poor acceleration, loss of power when driving uphill and/or with a load;

- “dips” when pressing the accelerator pedal, periodic loss of power;

- increased fuel consumption;

- a “garland” on the dashboard, that is, the Check Engine indicator light comes on and then goes out, and this repeats periodically;

- the engine suddenly stalls, after restarting it works normally, but the situation soon repeats;

- frequent occurrence of engine detonation;

- a specific gasoline smell appears in the exhaust system, associated with incomplete combustion of fuel;

- in some cases, self-ignition of the air-fuel mixture occurs;

- You can sometimes hear soft popping noises in the intake manifold and/or muffler.

Causes of throttle valve malfunction

There are a number of typical reasons that lead to malfunctions of the throttle assembly and the problems described above. Let us list in order what malfunctions of the throttle valve can occur.

Idle speed control

The idle air control valve (or IAC for short) is designed to supply air to the intake manifold of the engine when it is idling, that is, when the throttle valve is closed. If the regulator fails partially or completely, the engine will experience unstable operation at idle until it stops completely. Since it and the throttle assembly work in tandem.

Throttle sensor malfunctions

Another common cause of throttle failure is problems with the throttle position sensor (TPS). The function of the sensor is to fix the position of the throttle valve in its seat and transmit the corresponding information to the ECU. The control unit, in turn, selects a certain operating mode, the amount of supplied air, fuel and adjusts the ignition timing.

If the throttle position sensor malfunctions, this unit transmits incorrect information to the computer or does not transmit it at all. Accordingly, the electronic unit, based on incorrect information, selects incorrect engine operating modes or switches it to operation in emergency mode. Typically, when a sensor fails, the Check Engine light on the dashboard lights up.

Throttle Actuator

There are two types of throttle valve actuator - mechanical (using a cable) and electronic (based on information from a sensor). A mechanical drive was installed on cars of older models, and is now becoming less common. Its operation is based on the use of a steel cable connecting the accelerator pedal and the lever on the throttle rotation axis. The cable can stretch or break, although this is quite rare.

Electronic throttle control is widely used in modern cars Commands for the throttle position are received by the electronic control unit based on information received from the damper actuator sensor and the throttle sensor. If one or another sensor fails, the control unit is forced into emergency mode. In this case, the damper drive is turned off, an error is generated in the ECU memory, and the Check Engine warning lamp lights up on the dashboard. The problems described above arise in the behavior of the machine:

- the car reacts poorly to pressing the accelerator pedal (or does not react at all);

- engine speed does not rise above 1500 rpm;

- the dynamic characteristics of the machine are reduced;

- Unstable idle speed, until the engine stops completely.

In rare cases, the damper drive motor fails. In this case, the damper is located in one position, which fixes the control unit, putting the machine in emergency mode.

System depressurization

Often the cause of unstable operation of a car engine is depressurization in the intake tract. In particular, air can be sucked in in the following places:

- the places where the damper is pressed against the body, as well as its axis;

- cold start jet;

- connecting corrugated tube behind the throttle position sensor;

- joint (inlet) of the crankcase gas cleaner pipe and the corrugation;

- injector seals;

- conclusions for gasoline fumes;

- vacuum brake booster tube;

- throttle body seals.

Air leaks lead to incorrect formation of the air-fuel mixture and errors in the operation of the intake tract. In addition, the air leaking in this way is not cleaned in the air filter, so it may contain a lot of dust or other harmful small elements.

Damper contaminated

The throttle body in a car engine has a direct connection with the crankcase ventilation system. For this reason, tar and oil deposits and other debris accumulate on its body and axle over time. Typical signs of throttle valve contamination occur. This is reflected in the fact that the valve does not move smoothly; it often sticks and jams. As a result, the engine is unstable and corresponding errors are generated in the electronic control unit.

To get rid of such troubles, you need to regularly check the condition of the throttle valve, and if necessary, clean it with special means, for example, carburetor cleaners or their equivalents.

How to clean the throttle body

Before cleaning the throttle valve, it is worth studying the five main mistakes that car owners make in this procedure. Recommendations on how to properly clean carbon deposits from the electronics. More details

The damper adaptation has failed

In rare cases, throttle adaptation may be reset. This may also lead to the above problems. The reasons for failed adaptation may be:

- disconnecting and further connecting the battery on the car;

- dismantling (disconnection) and subsequent installation (connection) of the electronic control unit;

- the throttle valve has been removed, for example for cleaning;

- The accelerator pedal has been removed and reinstalled.

Also, the cause of a failed adaptation may be moisture getting into the chip, a break or damage to the signal and/or power wire. You need to understand that there is an electronic potentiometer inside the throttle valve. Inside it there are tracks coated with graphite. Over time, during the operation of the unit, they wear out and can wear out to such an extent that they will not transmit correct information about the position of the damper.

The main symptoms of a malfunction of the VAZ-2110 TPS: how to check them

Owners of VAZ-2110 cars often have to repair their vehicle. And the consequence of repair work can be both significant breakdowns and minor malfunctions. What type of failure is a malfunction of the throttle position sensor? What is this part responsible for in a car? How can we determine that this particular part is no longer functioning correctly? Read about it in our article.

What is TPS in a VAZ-2110 car?

The throttle position sensor is abbreviated as TPS among motorists. This part is used in several types of engines:

- Gasoline injection type.

- Single injection type.

- Diesel engines.

TPS is also known as a throttle valve potentiometer. This is due to the fact that the sensor is designed to function as a variable resistor. The sensor itself is installed in the engine compartment - the place of fixation is the throttle pipe. The mechanism of operation of the sensor is as follows: depending on the position and degree of opening of the throttle valve, the resistance also changes. That is, the level of the value of such resistance depends on the pressing of the gas pedal. If the pedal is not pressed, the throttle valve will be closed and the resistance will be minimal. The opposite is true when the damper is open. Accordingly, the voltage across the TPS, which is directly proportional to the resistance, will also change.

The control of such changes is carried out by the electronic control system; it is the one that receives all signals from the TPS and supplies fuel using the fuel system.

So, at the maximum voltage of the signal contact of the throttle position sensor, the fuel system of the VAZ-2110 car will supply the largest portion of fuel.

Thus, the more accurate the TPS indicators, the better the VAZ-2110 electronic system adjusts the engine to the correct operating mode.

Communication of the throttle valve with other automotive systems of the VAZ-2110

The throttle valve of a VAZ-2110 car is a component of the engine intake system and is directly connected to a large number of other vehicle systems. These include the following systems:

- directional stability;

- anti-blocking;

- anti-slip;

- anti-slip;

- cruise control.

In addition, there are those systems that are controlled by the electronics of the gearbox. After all, it is this throttle valve that regulates the flow of air into the car system and is responsible for the quality composition of the fuel-air mixture.

TPS design

The throttle position sensor can be of two types:

- film;

- magnetic or contactless.

In its design, it resembles an air valve - in the open position the pressure corresponds to atmospheric pressure, in the closed position it drops to a vacuum state. The TPS includes DC and AC resistors (each resistance is 8 ohms). The process of opening and closing the damper is monitored by the controller, with subsequent adjustment of the fuel supply.

If at least one symptom of a malfunction occurs in the functioning system of this sensor, then fuel may be supplied to the engine either in excess or in deficiency. Such malfunctions in engine operation are reflected in the engine of the VAZ-2110 car and on its gearbox.

Characteristic symptoms of a malfunctioning TPS condition

Thanks to the correct functioning of the throttle position sensor, the fuel system of the VAZ-2110 car engine works with a smoothing effect. That is, the vehicle moves smoothly, and the gas pedal responds well to pressure. Therefore, a malfunction of the TPS can be noticed almost immediately by the following signs:

- Poor engine starting.

- Noticeable increase in fuel consumption.

- The car's movements are intermittent.

- The idle speed of the engine is noticeable when running.

- The Check e light comes on on the dashboard

- The car accelerates poorly due to delays in acceleration.

- Popping sounds are heard in the intake manifold.

Of course, these signs of a faulty sensor may not all be observed at once. But even if you notice only one of the above symptoms, it is worth carrying out computer diagnostics of the vehicle at a service center.

TPS problems and their diagnosis

As you know, eternal parts for cars have not yet been invented. And the breakdown of the TPS can be foreseen; for this you need to inquire about the possible reasons for the failure of this part. Here are the main ones:

- Abrasion of the sprayed base layer, which serves to move the slider (the result is incorrect TPS readings).

- Failure of the movable type core (the result is deterioration of the contacts between the slider and the resistive layer).

How can you figure out problems with this sensor yourself? To do this, you can independently diagnose the operation of your diagnostics:

- Listen to the VAZ-2110 engine idling:

- the breakdown is obvious if you notice that its speed is in a “floating” state;

- Quickly release the gas pedal:

- a malfunction is present if the engine stops after this action.

- Pick up speed:

- There is a problem with the TPS if the car starts to move jerkily, which indicates an incorrect supply of fuel to the system.

Experts say that most often the sensor fails when the resistive track is heavily contaminated or is completely broken. To verify the opposite, you need to check the working condition of the TPS.

Checking the operation of the throttle position sensor

To check the TPS yourself, it is not necessary to call an auto electrician for consultation. To do this you need a multimeter or voltmeter. Next, experts offer step-by-step instructions for checking the sensor.

The first step is to turn the key in the ignition switch, take the voltage readings between the sensor slider contact and the minus. In normal condition, the indicator will be up to 0.7 V.

The second step is to turn the plastic sector and open the damper, and then take measurements again. In the normal state of the sensor, the device will show a result of 4 V.

The third step is to turn on the ignition completely (as a result of this the connector will stretch out), measure the resistance between the slider and any terminal. When rotating the sector, you must monitor the measuring device:

- when the multimeter or voltmeter needle moves smoothly, the sensor is working;

- when the needle on the meter shows sudden changes, the DPPZ is faulty.

Once the sensor is faulty, it can be adjusted or replaced. The VAZ-2110 car repair service center will tell you how to do the right thing.

Throttle valve repair

Repair measures for the throttle assembly depend on the reasons why the problems arose. Most often, the scope of repair work consists of all or part of the following measures:

- in case of complete or partial failure of the throttle sensors, they must be replaced, since they are not repairable;

- cleaning and flushing the idle speed regulator, as well as the throttle valve itself, from oil and tar deposits;

- restoring the tightness by eliminating air leaks (usually the corresponding gaskets and/or connecting corrugated tube are replaced).

Adaptation of the throttle valve “Vasya the diagnostician”

On VAG cars, the damper adaptation process can be performed using the popular diagnostic program “Vag-Com” or “Vasya Diagnostician”. However, before proceeding directly to adaptation, you need to perform the following preliminary steps:

- first remove (preferably several times) all errors from the engine ECU BEFORE starting the basic settings in the “Vasya Diagnostic” program;

- the car battery voltage should not be less than 11.5 Volts;

- the throttle valve should be in the idle position, that is, it does not need to be pressed with your foot;

- the throttle must be pre-cleaned (using cleaning products);

- The coolant temperature must be at least 80 degrees Celsius (in some cases it can be lower, but not much).

The adaptation process itself is performed according to the following algorithm:

- Connect the computer with the “Vasya Diagnost” program installed using the appropriate cable to the service connector of the car’s electronic unit.

- Turn on the car ignition.

- Go to section 1 “Engine” in the program, then 8 “Basic settings”, select channel 060, select and press the “Start adaptation” button.

As a result of the described actions, two options are possible: the adaptation process will begin, as a result of which the corresponding message “Adaptation OK” will be displayed. After this, you need to go to the error block and, if there are any, programmatically delete information about them.

But if, as a result of launching adaptation, the program displays an error message, then you need to proceed according to the following algorithm:

- Exit “Basic settings” and go to the error block in the program. Remove errors twice in a row, even if there are none.

- Turn off the car ignition and remove the key from the lock.

- Wait 5...10 seconds, then reinsert the key into the lock and turn on the ignition.

- Repeat the adaptation steps above.

If, even after the described actions, the program displays an error message, this indicates a malfunction of the nodes involved in the operation. In particular, the throttle valve itself or its individual elements may be faulty, problems with the connected cable, or an inappropriate adaptation program (you can often find hacked versions of Vasya that do not work correctly).

If you need to train the Nissan throttle valve, then there is a slightly different adaptation algorithm that does not require the use of any program. Accordingly, other cars, such as Opel, Subaru, Renault, have their own throttle learning principles.

In some cases, after cleaning the throttle valve, fuel consumption may increase, and engine operation at idle speed will be accompanied by a change in speed. This is due to the fact that the electronic control unit will continue to give commands in accordance with the parameters that were before cleaning the throttle. To avoid such a situation, it is necessary to calibrate the damper. This is done using a special device that resets past operating parameters.

Mechanical adaptation

Using the specified “Vag-Com” program, you can programmatically adapt only cars produced by the German concern VAG. Other cars have their own algorithms for adapting the throttle valve. Let's consider an example of adaptation on the popular Chevrolet Lacetti car. So, the adaptation algorithm will be as follows:

- turn on the ignition for 5 seconds;

- turn off the ignition for 10 seconds;

- turn on the ignition for 5 seconds;

- start the engine in neutral (manual transmission) or Park (automatic transmission);

- warm up to 85 degrees Celsius (without accelerating);

- turn on the air conditioner for 10 seconds (if available);

- turn off the air conditioner for 10 seconds (if equipped);

- for automatic transmission: use the parking brake, press the brake pedal and move the automatic transmission to position D (drive);

- turn on the air conditioner for 10 seconds (if equipped);

- turn off the air conditioner for 10 seconds (if equipped);

- turn off the ignition.

On other machines, the manipulations will be similar and will not take much time and effort.

How to determine air leaks

Depressurization of the system, that is, the occurrence of air leaks, can lead to incorrect operation of the engine. In order to find the locations of the indicated leaks, you must perform the following steps:

- Use diesel fuel to flush the injector installation areas.

- With the engine running, disconnect the mass air flow sensor (MAF) from the air filter housing and cover it with your hand or other object. After this, the corrugation should shrink a little in volume. If there is no choke, the engine will begin to “sneeze” and eventually stall. If this does not happen, there is an air leak in the system, and additional diagnostics are needed.

- You can try closing the throttle valve by hand. If there is no suction, the engine will begin to choke and stall. If it continues to work normally, there is an air leak.

Some car owners pump excess air pressure into the intake tract with a value of up to 1.5 atmospheres. Next, using a soap solution, you can find places where the system is depressurized.

How to buy a new TPS

The driver has a limited choice of techniques:

- Search for a new part by VIN code . This way he is guaranteed to buy the sensor that fits his car. We advise you to search for similar spare parts by vehicle code due to the high accuracy of the search. In addition, this way the driver will find the original faster. Original sensors, although expensive, are worth the money;

- According to transport data . If you are purchasing a throttle sensor, this method is good, but not good enough. The problem lies in the analogues. Most likely, the driver will be able to find many non-original sensors that, at first glance, are in no way inferior to the factory part. The purchased non-original will not last that long, and it is not a fact that it will fully correspond to the original. We will now talk about this in more detail.

Prevention of use

The throttle valve itself is designed for the entire life of the vehicle, that is, it does not have a replacement frequency. Therefore, it is replaced when the unit fails due to mechanical failure, failure of the entire engine, or other critical reasons. More often than not, the throttle position sensor mentioned above fails. Accordingly, it must be replaced.

For normal engine operation, the throttle valve must be periodically cleaned and reconfigured. This can be done either when the above signs of breakdown appear, or simply periodically so as not to bring it to such a state. Depending on the quality of the fuel used and the operating conditions of the vehicle, it is recommended to clean the throttle valve when changing the engine oil, that is, every 15...20 thousand kilometers.

Source

Conclusion

Choosing a TPS cannot be called something difficult. The driver only needs to know the vehicle code or the characteristics of his vehicle. But brand knowledge is really important. Above we have indicated the “winners” of the Audience Choice Award. What's really not worth your attention are the cheapest parts on the market. And the market is not the best place to buy sensors - we advise you to give preference to large stores with a good reputation. When purchasing, do not forget to inspect the packaging, check the spare part according to the security code and identify physical damage - perhaps this is a fake. Only branded spare parts will serve you for a long time.