Construction and repair of the VAZ 2121 Niva car

Our additional

services and sites:

S Aratov

Statistics

| e-mail: | [email protected] [email protected] |

| icq: | 613603564 |

| skype: | matrixplus2012 |

| telephone | +79173107414 +79173107418 |

The VAZ-2121 Niva (Fig. 1) began production at the Volzhsky Automobile Plant in 1977. This is a small-class passenger car, combining the comfort and speed of a passenger car with the high cross-country ability of an all-terrain vehicle. It can transport passengers and cargo on roads with all types of surfaces, including unpaved ones. This car is intended mainly for the rural population and, in addition, is indispensable for fishermen, hunters and tourists.

When developing the design of the VAZ-2121 car, the peculiarities of its operation were taken into account. It was necessary to ensure high cross-country ability in off-road conditions, stability and ease of control, as well as make the car reliable and easy to maintain. At the same time, it was envisaged to unify as much as possible the parts and components of the car used from other VAZ car models in order to organize mass production of new cars in parallel with the production of Zhiguli cars at minimal cost and to facilitate the provision of spare parts. Therefore, the engine, gearbox, clutch, electrical equipment, rear suspension, and steering of the VAZ-2121 are not much different from those used on the BA3-2103 and -2106.

For the first time, permanent all-wheel drive was used on VAZ-2121 cars, which made the car more stable on the road and increased its maneuverability. Torque from the engine and gearbox is transmitted to the front and rear axles through a two-stage transfer case with a center differential. When driving in particularly difficult road conditions, the center differential can be locked to improve the vehicle's maneuverability. The front axle is located under the engine crankcase and is attached to brackets on the engine.

The front wheel suspension is independent, on wishbones, with coil springs, telescopic, hydraulic shock absorbers and anti-roll bar. The rear wheel suspension is dependent, spring.

The brake drive is hydraulic with a vacuum booster, dual-circuit, and in case of failure of one circuit, sufficient braking efficiency is ensured. Front brakes are disc with movable caliper. The rear brakes are drums with self-aligning pads.

The steering is safety-resistant and has a shaft with cardan joints.

The body is all-metal, monocoque, three-door. The rear door opens upward and provides easy access to the rear. The rear seat can recline forward. This creates a spacious trunk for transporting goods.

Over the years since the production of cars began, a number of changes have been made to their design, aimed mainly at reducing fuel consumption and reducing the toxicity of exhaust gases, and increasing the durability of components and parts. For example, a new carburetor (model 2107-1107010-20) and an ignition distributor with a vacuum regulator began to be installed. The design of the cardan transmission has been changed. Some cars began to use a five-speed gearbox.

In 2009, production began of a restyled version of the injection version of the Lada 4x4 3-door, which was called Lada 4x4M or VAZ-21214m. Now only this model, as well as the Urban model, is produced from the Niva family. Visually, the car is not too different from its predecessors, but most of the changes are found inside.

Transmission

The transmission has been modernized much more seriously. First of all, a new clutch from Valeo was installed - the same one that is installed on the NIVA-Chevrolet. As a result of this, the resource of this unit almost doubled, and the Niva 21214m car itself became less susceptible to vibration due to a reinforced damper spring and an enlarged disk.

A more efficient crankcase ventilation system was installed on the transfer case, the cardboard seals were replaced with silicone ones, and they began to be equipped with new seals.

Anti-corrosion protection

One of the important issues of the body of any car is corrosion resistance. On the classic three-door Niva, which is now called Niva Legend, there is not a single zinc-coated body element. These compared models are much better.

Here, the front parts of the body, except for the hood and roof, are galvanized on one side. But the elements of the bottom and thresholds, which are most susceptible to aggressive environmental influences, are double-sided galvanized.

Suspension and chassis

The most significant changes affected the suspension - it was optimized and almost completely unified with the well-proven NIVA-Chevrolet suspension:

- New front suspension steering knuckles;

- The front suspension has lower control arms with modern silent blocks;

- Front wheel alignment angles have been changed;

- Front axle of increased diameter;

- Reinforced brackets;

- New ball joints with an increased swing angle, forged body and liner made of polymer materials;

- Modern gas-oil shock absorbers with increased travel and service life;

- Optimized layout of the lower rods and arms in the rear suspension.

Engine compartment

Everything in the engine compartment remains unchanged. Whether this is good or bad, everyone will decide for themselves. There are pros and cons here. The advantages are that everything has been well studied for a long time, has been debugged in terms of defects and malfunctions, and is inexpensive to maintain and maintain.

The disadvantages are that this engine does not provide this car with decent acceleration dynamics and consumes a lot of fuel. In terms of technical characteristics, it does not deserve special praise. But we won't see another powertrain. Technical changes to a car are always a huge investment. In addition, the new all-wheel drive Niva is now in full swing preparing for production launch. This is where most of the money goes.

What are your thoughts on this issue, write in the comments.

Price policy

Despite the high unification with NIVA-Chevrolet, the VAZ-21214M costs much less. So, for the Niva 21214m the price, depending on the showroom and dealer, is about 370-380 thousand rubles - this is the “Standard” package. When ordering additional options, it may increase slightly.

“Winter test drive Niva LADA 4×4 M (NIVA VAZ-21214), winter test-drive.”

Candidate of Technical Sciences D. ZYKOV

Among the models produced over 30 years, Volzhsky Automobile stands somewhat apart. First of all, this is the first independent VAZ development to reach the production line. The car has been in mass production since 1977. It is still very popular, not only in Russia and other CIS countries, but also on the world market. Among cars of its class, the Russian SUV has become one of the most successful models. The car was well received abroad, especially in France, Canada, Spain and Portugal. Niva cars with the French Peugeot diesel engine are in great demand there. However, cars with a domestic engine with a displacement of 1.6 liters are also selling well.

For its time, the Niva was quite a comfortable car. A comfortable ride was achieved mainly through the use of an independent front suspension. On models created earlier, such a scheme was practically not used; it was believed that independent suspension was not suitable for an all-terrain vehicle. Operating experience of the Niva has shown that this is far from true. Nowadays, independent suspension is widely used on SUVs all over the world, not only the front, but often the rear as well.

The design of the VAZ-2121 Niva was originally based on the principle of using permanent all-wheel drive with torque distribution between the front and rear axles in a ratio of 50:50 and the ability to block the center differential located in the transfer case. It also houses a pair of downshift gears. This combination of structural elements coupled with high ground clearance (22 cm) makes it possible to overcome difficult sections of the road, such as heavy sand, deep snow, and mud.

Compared to ordinary Zhiguli, the Niva has several features in its maintenance, primarily related to the operating conditions of the car as an SUV. Let's look at them in more detail.

Having driven around through mud and gullies to your heart's content, the car needs to be thoroughly washed. It is especially important to flush the front wheel brakes. The Niva's calipers and working brake cylinders are designed in such a way that the dirt stuck to them does not fall off on its own, but, having dried, can significantly disrupt the operation of the mechanism. To clean the brakes, you have to jack up the car and remove the wheels.

Along with the brakes, you need to clean all visible “rubber bands” from dirt. The closest attention should be paid to the condition of the ball joint covers, steering pins and constant velocity joints in the drive and intermediate shafts. (On modern Nivas, a much more durable constant velocity joint is installed in the intermediate shaft between the gearbox and transfer case instead of a relatively unreliable universal joint.) If cracks or, even worse, ruptures are found on the covers, they should be replaced immediately. Driving with torn anthers is truly dangerous.

Getting rid of the factory sound insulation of the Niva VAZ-2121

Hello everyone! For more than two years now I have been going digging on the good old Soviet Niva made in 1984, but there is not a single article on the blog dedicated to this white all-wheel drive car. And so, I correct the jamb - I create a new section and write the first publication in it. Let's talk today about the sound insulation of the VAZ-2121 and body rot.

I have been doing this for a long time and did not take photographs specifically for the article, for which I apologize to the readers. The photographs are not particularly beautiful, but they still carry some useful load. So, let's begin!

When the sky was bluer and the trees were taller, the Tolyatti Automobile Plant equipped its products with noise and vibration insulation. Bitumen protected the driver and passengers from vibrations, and cotton wool protected them from the sounds of the engine, transmission and bad roads. Since my Niva is many years old, I decided to see what condition the “Shumka” and “vibra” are in. In addition, on the Internet I saw enough horror films about how the bottom rots due to water absorbed into the cotton wool.

Still, we have driven this little car everywhere, including through puddles as deep as doors, the alarm should have been sounded earlier. And the autopsy showed this. To get to the necessary parts that are required to provide comfort while driving, you need to partially disassemble the interior. Unscrew and remove the front seats and remove the rubber carpets.

Having done all of the above, a natural swamp appears! The water stands right on the film covering the cotton wool. It’s really not in vain that I climbed in! What's next? Maybe everything there has already rotted.

I pick at the sound insulation, bend it back and continue to be horrified, tearing off pieces of cotton wool and squeezing water out of them onto the ground. And at this moment the car’s interior is filled with the swampy smell of stale water.

Under the guise of bitumen vibration insulation. Since the car was released from the AvtoVAZ assembly line, it has been covered with cracks. I picked it up with a screwdriver and it easily came off the metal. That's the number! And underneath, as I expected, the red beast, rust, was already living and thriving with all its might. Armed with a wide and sharp tool, I tore off all the bitumen. It is noteworthy that in some places he was still sitting tightly and did not want to rip off in any way.

When I cleared the bottom of the Niva from cotton wool and bitumen, the full scale of the disaster appeared in full. Although... I wouldn’t say that everything was so bad here. There was rust, but not in such large quantities as I imagined during disassembly of the interior.

Fortunately, it was summer, so I pulled out an extension cord, armed myself with an angle grinder with a brush attachment, and began to scrape off the rust. As soon as I turned on the tool, bristles and pieces of loose iron oxide flew into my eyes. You should take a mask! And using personal protective equipment, I stripped the rust down to bare metal. Fortunately, the metal was practically not rotten through. Only two barely noticeable holes were visible under the pedals.

It's the anticorrosive's turn. First, I treated the entire bottom with a rust converter. This caustic mixture is capable of penetrating into places where I could not reach with an angle grinder. For example, in the seams. When the chemistry reacted, I mixed Cordon bitumen mastic and Movil anticorrosive agent in an approximate proportion of 50/50. He heated the whole thing, mixed it and boiled it. After that, I applied the anti-corrosion compound to the bottom with a brush. Although I don’t have photos of this process with the Niva, I’ll show you using the example of my second car-puzzler.

The last step is to assemble the interior of the SUV in reverse order. The only downside to all this is the pungent smell in the car. Especially in the heat it becomes unbearable. But in hot weather we opened the windows and hardly smelled petroleum products. But thanks to such a simple operation, we increased the service life of the car body!

Other tuning options

One of the improvement options is to improve the cylinders for more efficient operation of the updated piston. Reformation involves boring these elements to a width of 84 mm. Properly performed work in this direction will allow the owner to increase the engine capacity of the 2123 Chevrolet Niva to 1.9 liters. In this case, it will be necessary to additionally change some parts associated with the assembly. Replacing the old carburetor with a new version, as well as installing lightweight connecting rods, will also make it possible to slightly increase the power of the car.

The engine stalls when idling or while driving

In this case, problems with the 2123 engine may be as follows:

- There is no required level of pressure in the fuel supply system (the same applies to diesel modifications). Check the serviceability of the pump and, if necessary, repair it or replace it with a new version.

- Violation of adjustment of the functioning of the power unit at idle speed. The regulator needs to be replaced, since repairing it yourself is very troublesome and time-consuming.

- Unstable operation of the crankcase ventilation is observed, air gets into the brake boosters or fuel supply hoses. It is necessary to check the integrity of all hoses and connections, and also tighten the existing clamps.

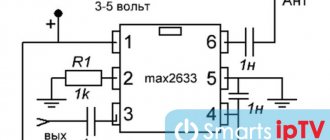

Engine control system fuse box

Scheme

p, blockquote 8,0,0,0,0 —>

p, blockquote 9,0,0,0,0 —>

Designation

p, blockquote 10,0,0,0,0 —>

| 1 | 15A 1* ECM sensors Starter relay Canister purge valve |

| 1 | 7.5A 2* Controller |

| 1 | 3: Electric fuel pump relay (contacts) Electric fuel pump |

| 1 | 30A 4.5* Cooling fan |

| 2 | 15A 1* Injectors Ignition coils ECM controller Right electric fan relay Left electric fan relay |

| 2 | 15A 2* Electric fuel pump relay (contacts) Electric fuel pump |

| 2 | 30A 3* Reserve |

| 2 | 30A 4.5* Cooling fan |

| 3,4 | 30A 1* Electric fans (right, left) Right electric fan relay Left electric fan relay |

| 3 | 15A 2* Main relay |

| 3 | 15A 3* Controller |

| 3 | 15A 4* Ignition coil, power supply for fan relay control, controller, injectors |

| 3 | 15A 5* Ignition relay |

| 4 | 15A 3* Main relay Electric fan relay (winding) Electric fuel pump relay (winding) Vehicle speed sensor Canister solenoid valve Oxygen sensor Mass air flow sensor Controller |

| 4,5 | 30A 2* Electric fan relay (winding) (right, left) Electric fan motor (right, left) |

| 4 | 15A 4* Mass air flow sensor, phase sensor, heating oxygen sensor (two), canister purge valve, DS |

| 4 | 15A 5* Electric fuel pump |

| 5 | 15A 1* Electric fuel pump Electric fuel pump relay |

1* - 2014-2016, 2* - 2010-2012, 3* - 2007-2008, 4* - Cars with Bosch ME17.9.7/M74 controllers, 5* - Cars with 7.9.7+ controllers.

p, blockquote 11,0,0,0,0 —>

Description of the fuse box in Niva 21214

Every car has a fuse box that is responsible for the operation of certain components of the vehicle. If certain fuses fail, the operation of some elements becomes impossible, but if the unit itself breaks down, the vehicle simply will not be able to continue moving. Today we will tell you what role the VAZ 21214 Niva injector fuses play, what the diagram looks like, where the block is located and how to replace it.

Modernization

There are several methods to improve the design of the VAZ-2123 engine. Tuning will make it possible to slightly increase the power parameter and improve overall performance. One should not expect too high results from modernization; nevertheless, certain progress will take place. Before carrying out work, you should think about: is the game worth the candle?

To begin with, you can try to increase the movement of the piston, which will increase the volume by 0.2 liters. Boring is carried out to increase the inner diameter of the liner, after which pistons with rings are selected for the updated sizes.

In addition, the engine is equipped with a crankshaft with shortened connecting rods and longer arms. Only replacing the CPG and the crankshaft will not be entirely sufficient. As the volume of liners increases, it will be necessary to increase the supply of the fuel-air mixture with improved ventilation of the cylinders. To do this, you will need to bore the cylinder head inlet and outlet sockets, replace the valves with larger analogues, expand or remake the seats.

Some users completely change the exhaust assembly, simultaneously increasing the diameter of the outlet pipes and replacing the catalysts with flame arresters. It is worth considering that such transformations in the 2123 engine block require reconfiguring the functioning of the fuel supply, since the standard portion will no longer be enough. It follows from this that chip tuning will be needed. The increase in power is on average about 15%, however, fuel consumption also increases.

Air intake

The new Chevrolet Niva (2018) is equipped with a completely redesigned air intake system. The main difference is a significant increase in the dimensions of the air filter. This is visually noticeable by the impressively grown body. In addition, the design of the intake pipes, receiver, and throttle element has been modified.

The electronic system of the vehicle has also been transformed. The main control of the “engine” is carried out by the controller. In other variations, an analogue of “January 7.2” was mounted. This feature affects the comfortable interface for the consumer, and also allows you to control fuel consumption thanks to an improved injection control system with a parallel pair configuration. As a result, the new Chevrolet Niva (2018) began to comply with Euro-2 standards in its standard version. To reduce the emission of harmful substances, it is possible to additionally install phased fuel supply. This approach raises the environmental bar to Euro 3 levels while simultaneously optimizing its more accurate delivery.

Replacing fuses

If any electrical circuit in the vehicle fails, the condition of the fuse must be checked.

If it is necessary to replace parts, it should be taken into account that the VAZ 21214 fuses on the Niva injector belong to two different types:

- in the main block there are cylindrical inserts (inherited from the Zhiguli);

- and in the injection system blocks - modern, knife type.

Therefore, when you go on a trip, you need to take with you spare inserts of different types.

If, for example, a cigarette lighter fails on the road, you must:

- Turn off the ignition.

- Open the cover of the additional unit.

- Visually check the condition of the PR14 16 ampere fuse, which is responsible for the cigarette lighter circuit.

- Remove the burnt insert with your fingers and replace it with a spare one taken from the reserve socket PR15. It is prohibited to use homemade inserts, as they are not able to protect the circuit from overloads. The consequence of this may be overheating of the elements and fire.

- Check the functionality of the circuit. If the insert immediately burns out again, then the reason lies in damage to the wiring, which must be carefully checked.

The remaining fuses and relays on the VAZ 21214 are changed using a similar scheme.

Replacing the block

In case of burnout or mechanical damage, it is necessary to repair the unit by replacing its components or the entire assembly.

To replace the main unit, follow these steps:

- Disconnect the battery from the on-board network.

- Remove the box cover and unscrew the two 8 mm nuts securing the block. Then you need to pull the box towards you and remove it from the fastening studs.

- Write down the markings and position of the wires on the old unit.

- Disconnect the cables from the plugs of the old unit and connect them in the same sequence on the new one.

- Check fuse ratings and wire installation.

- Secure the replaced block with nuts.

- Connect power to the on-board network and check the functionality of the circuits.