TPDZ

This sensor is designed to transmit readings to the computer about the position in which the throttle valve is located. This is necessary for the control unit to calculate the required amount of fuel to form the air-fuel mixture.

When you press the gas pedal, driven by a cable, the damper changes its position and opens the way for more air into the system. The TPS, transmitting information that the damper has increased the amount of air, the control unit raises the amount of fuel supplied through the injectors, thereby increasing the quality of the air-fuel mixture and the car begins to accelerate or increase speed.

How to clean the throttle valve on a VAZ 2170-VAZ 2172

For the entire period of their production, Lada Priora cars have used two types of unit, the first is a cable-driven unit (somewhere before 2010-2011, all cars were equipped with this unit, and after 2010-2011 the second unit began to be installed), and the second - This is a unit from the e-gas system that no longer has a cable drive, and if you have it and you decide to clean it, then you need to be more careful and by the way, when you install this unit on the car, you still need to wait until the controller adapts to it, otherwise If you start the car, it will work in emergency mode (the speed will increase greatly and the consumption will increase), we will describe how to make the controller adapt to the newly installed unit on the car and you will learn all this as you read this article!

1) First, let's start talking about the unit with a cable drive and along the way we will move a little to the unit with an electronic gas pedal, first you will need to remove it, both units are removed almost identically (I partially drained the coolant, unscrewed the bolts securing them, disconnected all the pads wires and all the hoses and then removed it from the car), but there will be a little more hassle with the cable unit, for more details on how to remove this unit from the car, read the article: “Replacing a cable-driven throttle unit on a VAZ”, if you you e-gas, then also study this article in order to at least have some idea of how the unit is removed from the car.

Before removing the minus terminal from the battery, be sure to remove it; read about how to do this in the article: “Replacing the battery on a VAZ”, in point 1 everything is described in detail!

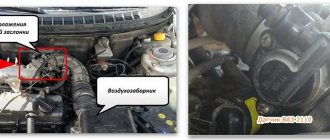

2) After removal, proceed to cleaning; during this procedure, do everything as smoothly and softly as possible, because if, for example, you move the damper on e-gas, it can be very easily damaged (By the way, it is generally not recommended to touch the damper on e-gas, that is, open it with your hand and close it, so if you can without this, clean it anyway, or at least open it, but just do it very carefully without damaging anything), although this does not apply to the cable-driven unit at least , on the side of such a unit there is a sector (Indicated below in the photo by an arrow) by rotating which you can completely open and completely close the damper itself, and when you open it, spray the inside with carburetor cleaner and until then clean the unit in this way. until all the dirt is removed from it.

When you clean the unit, be careful and be sure to remove all the sensors that are on it (This applies to a cable-driven unit, there are two sensors on it, we described how to remove them in the article, the link to which is given just above, it also calls it: “Replacing the throttle assembly on a VAZ”), in addition, there is a control unit on the electronic damper, you don’t need to spray liquid on it either, it will only be enough if you remove all the dirt from the inside of the unit (Where else is the damper itself located) , and you shouldn’t even spray it on the outer part!

3) As soon as the unit is cleaned, you can safely install it in the reverse order on the car and connect all the sensors to it, but just don’t rush to install it right away, put it in the sun and let it dry all the moisture, otherwise all the moisture will after you start the engine of the car, dirt will fly inside, in addition, if your car is equipped with an e-gas system, then you will also need to adapt the controller to the throttle unit after installing it, for this in positive weather (Over +7 the factory recommends , otherwise adaptation may not work) turn the key in the ignition of the car to a level when all the instruments light up, then wait about 30 seconds (more is possible) and then start the car, if the speed is normal (not too high), that means the adaptation was successful, otherwise you will have to repeat it; we wrote in more detail about this adaptation in the article: “Cleaning the throttle on a viburnum,” so be sure to read it.

You can see in more detail how the throttle assembly can be removed from the car and then cleaned, in the video posted just below, but in that video a VAZ 2110 car is used, but it has almost the same 16 valve engine that was installed on the Priora, so there won’t be much difference with the ten and the Priora.

I recently cleaned the throttle assembly using an electronic pedal and there’s nothing wrong with it, I opened the valve with my finger and closed it the same way, so do everything carefully and you will be happy))

Symptoms of a problem

There are a huge number of symptoms of TPS malfunction and they are all different. Each problem can have its own impact on engine behavior. Below are the most common symptoms of a TPS failure.

- Floating speed at start-up and recovering after warming up;

- Jerks and jerks when accelerating;

- Reduced dynamics and loss of power;

- Spontaneous increase in speed;

- Increased fuel consumption;

- Unstable operation of the internal combustion engine at idle;

If you find any of the signs from this list on your car, the first thing you need to check is the throttle position sensor.

Sensor check

In most cases, if the TPS is completely inoperable, a “check engine” indicator lights up on the car’s dashboard, signaling a malfunction of this sensor. By connecting diagnostic equipment, you can accurately determine the culprit of the problem.

How to independently diagnose a car using the Chinese ELM327 scanner, read our article.

But if there is none, then the test can be carried out using a conventional multimeter.

Verification Process

The check must be carried out with the ignition on!

The first thing you need to do is check the integrity of the sensor's power supply circuit. To do this, remove the connector from the TPS and measure the voltage between contacts “A” and “B”. The voltage should be around 5V. If everything is normal, we come to the next point.

Reconnect the sensor connector. For this test you will need two needles. We insert them between contacts “B” and “C” and measure the voltage. When the damper is closed, the voltage should be 0.4-0.7V, and when fully open, 4-4.7V. If the readings do not match, then the sensor is most likely faulty.

Operating principle of the regulator

The controller is located in the throttle assembly, not far from the idle air control. The device has three outputs.

One of them is a signal signal, which is connected to the control unit, the second is power from the on-board network, and the third is a ground connected to the vehicle body.

The greatest resistance of the device is recorded when the damper is closed. When the driver presses the gas pedal, the damper begins to open, causing the resistance value to change.

The car's ECU is equipped with an operating system where all the necessary information is marked. In accordance with the level of opening of the damper, the ECU changes the ignition angle, as well as the time at which the injectors should open.

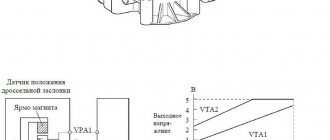

When you press the gas, the permanent magnet of the device begins to rotate. At the same moment, the resistance parameter of the sensitive component of the device changes; this occurs as a result of a change in the magnetic field around it.

But in this case, the car control unit does not record the voltage, but the change in the ignition angle.

Signs and causes of TPS malfunctions

Since the design of the TPS is quite simple, there may be several reasons for its malfunction:

- the coating layer on the device has worn off;

- the movable core has failed;

- wear of the regulator substrate, which can be either complete or partial.

As for the signs of malfunction, you can determine the breakdown of the TPS by the following symptoms:

- The speed of the power unit has become unstable, especially when driving uphill.

- While driving, there are dips - the driver presses on the gas, but at this moment the car refuses to accelerate.

- Sharp jerks during acceleration, which are caused by dips. When you press on the gas, you first feel a dip, then the car begins to sharply gain momentum.

- Poor idle speed, the engine may stall when shifting into neutral.

- The power of the power unit as a whole decreases.

- Increased engine speed, as a result of which the driver can no longer brake with the engine.

- Another symptom is the appearance of an indicator on the dashboard (the author of the video about the symptoms of a malfunction and replacing the TPS is Ivan Vasilyevich).

If the TPS fails, an error will appear on the instrument panel.

Sensor repair manual

How to replace and repair the throttle sensor? Before starting the process, it is necessary to de-energize the vehicle's on-board network; to do this, disconnect the battery.

When braking there is vibration in the steering wheel

Further actions are carried out in the following sequence:

- Open the hood and find the regulator, as we already reported, it is located on the throttle assembly. You need to disconnect the connector from it. To do this, the mount itself must be moved up, as shown in the photo.

- Next, using a Phillips-head screwdriver, you need to unscrew the two bolts that secure the controller to the assembly. Be careful not to lose these bolts.

- After the bolts are unscrewed, the sensor must be removed.

- When the regulator is removed, pay attention to where it fits. Here you can see a special foam pad; it must be left intact. Carefully inspect the gasket - if it shows signs of damage, it is better to replace it.

- If you decide to repair the device yourself, then you need to carefully inspect the part for damage. Measure the width of the shaft, this figure should be 5 mm. If this indicator is different, then it will not be possible to change the gap; it will need to be completely replaced. It is quite possible that to ensure normal operation of the power unit, you will also have to clean the throttle itself. After all, if dirt has accumulated on the axis of the unit, the controller will have difficulty moving.

- As for further installation, there is nothing complicated in this matter either. Installation is carried out in the reverse order; this task should not cause difficulties.

Video “Self-diagnosis and sensor replacement at home”

How to check the functionality of the throttle position sensor and how to replace a non-working device - more detailed instructions are presented in the video (author - Alexander Skripchenko).

A surprisingly unreliable throttle position sensor (TPS) on a Lada Priora car. Every year at least (at least) once it necessarily fails at the most inopportune moment. Therefore, you must have a throttle position sensor (TPS) in your glove compartment. Otherwise there will be problems. It costs about three hundred rubles.

In general, it was clever or deliberately poorly done. ATTENTION.

When going on a long road, be sure to have a spare throttle position sensor (TPS) on your Lada Priora car. And you will not have unnecessary problems on the road. Forewarned is forearmed. Don't ignore this remark.

Connecting DRL Lada Kalina

The throttle position sensor (TPS) is installed on the side of the throttle assembly and is connected to the throttle axis to adjust the fuel supply to the Lada Piriolra engine.

It is a potentiometer, one end of which is supplied with a “plus” supply voltage (+5 V), the other end is connected to “ground”. From the third terminal of the potentiometer (from the slider) the output signal goes to the ECU.

When the throttle valve is turned (by operating the control pedal), the voltage at the sensor output changes. When the throttle valve is closed, it is below 0.6 V. When the throttle valve opens, the voltage at the sensor output increases and should be more than 4.4 V when the throttle valve is fully open.

By monitoring the sensor output voltage, the ECU adjusts the fuel supply depending on the throttle valve opening angle (i.e., at the driver’s request). TPS does not require adjustment, since the electronic unit perceives idle speed (i.e. completely closing the throttle valve) as the zero mark.

If the throttle sensor fails, the ECU stores the sensor fault code, turns on the CHECK ENGINE warning light, and calculates the expected value of the throttle opening angle based on the crankshaft speed and the mass air flow sensor signal. To replace the sensor, do the following:

The most important. For removal and installation you will need a very short Phillips head screwdriver (or a flathead screwdriver depending on which screws were tightened first) approximately 8-12 cm in length.

Without such a screwdriver, it is problematic to replace the throttle position sensor (TPS) on the road.

And always carry with you a short screwdriver no more than 8 cm long, otherwise there will be a problem replacing the throttle position sensor.

Dear drivers, do not forget not only about yourself. Be attentive and polite to others on the roads of the country.

Operating instructions for VAZ 21074 injector

The throttle position sensor on a Lada Priora car is necessary to determine the required amount of fuel depending on how open the throttle is. A signal is sent to the ECU and at this moment it determines how much fuel to supply to the injectors.

The TPS on the Priora is located in the same place as in all similar cars of the front-wheel drive VAZ family - on the throttle assembly in close proximity to the idle air control.

Cost and articles

There are many different sensors on the market. They all depend on the manufacturer; the more famous the manufacturer, the more expensive the sensor itself is, accordingly. Below is a table with articles and prices for TPS for Lada Priora.

| Manufacturer | vendor code | Price, (rubles) |

| RICOR | 2112-1148200 | 400 |

| StarVolt | 21120114820000 | 390 |

| ERA | 550485 | 200 |

Replacement

Replacing the throttle position sensor will not take even 5 minutes using these instructions.

- Remove the negative terminal from the battery.

- Remove the connector from the sensor;

- Unscrew the 2 screws securing the TPS;

- We remove the sensor and install a new one.

The replacement process is complete. We start the engine and check its performance.

We hope our article was useful to you.

Throttle valve at rest

If within 15 seconds from the moment the ignition is turned on, the engine is not started and the accelerator pedal remains at rest, the controller will stop the supply of power to the electric throttle drive, as a result of which the damper will move to an almost closed position (no more than 7% opening). In this state, the output signal power of the first sensor will be 0.5-0.6V , and the second - 2.7-2.8V .

If the engine and accelerator remain at rest for the next 15 seconds, the throttle will automatically enter test mode. This means that it will move to the zero position until it is completely closed and then moved to the pre-start position, after which the electric throttle drive will be completely de-energized until the next ignition is turned on.

If a problem is detected in the sensor circuit, the controller completely stops supplying voltage to the throttle actuator, while simultaneously storing the error code in memory and displaying it on the dashboard. In this case, the throttle valve is always set to 6-7% opening

.

Regardless of what position the throttle valve is in, the output signals from both sensors should add up to 3.3V . The maximum permissible deviation is 0.1V .