Print this article Font size 16

As you know, the VAZ 2110 was produced with injection and carburetor engines. The injectors are equipped with an impressive number of sensors, the performance of which determines the functionality of important units. Therefore, if they break down, problems may arise in moving, power decreases, fuel consumption increases, and much more.

A prime example of an important sensor is the throttle position sensor. Today we’ll talk about it in more detail.

Evidence of pollution

Let's look at the signs that indicate a malfunctioning throttle valve:

- Revolutions. You sharply release the gas pedal, but the engine is in no hurry to switch to idle speeds from high speeds. Instead of a smooth reset and acceleration, the engine begins to shake, it either stalls completely, or with great difficulty restores the required speed;

- Launch. Your VAZ has difficulty starting cold, and sometimes you cannot quickly start even a hot engine. There may be other reasons for this phenomenon, but the fact that the throttle valve is to blame may be indicated by the fact that after several throttle applications (short-term presses on the gas), the engine usually starts;

- The starter spins for a long time before starting, and the smell of gasoline is heard from the exhaust pipe;

- The engine may run for a couple of minutes after starting.

Dirty throttle valve VAZ 2110

This is interesting: How to remove the steering rack sense

Cleaning Rules

Before removing and cleaning the throttle valve, you need to buy a special cleaner for it. There are many manufacturers, there is enough choice. Among the inexpensive ones, Abro is effective.

Disassembly:

- You need to remove the engine cover (decorative plastic);

- Reduce the pressure in the cooling system by unscrewing the expansion tank cap;

- Loosen the clamps and remove the hose from the forced ventilation air pipe;

- Use a screwdriver to remove the heating hoses for the remote control (it is advisable to plug them for now);

- Disconnect the cable and unscrew the fastening nuts. Now removal of the throttle assembly is possible;

- Use a cleaner to wash everything very thoroughly. Most often, it is necessary to use a needle to check whether the forced ventilation channel is coked, and also to clean it;

- Cleaning is necessary for the idle air regulator, for which it must be removed and inspected. If you find that it is jamming and adjustment is impossible, then it needs replacement;

- After washing, reassemble everything as it was. Please make sure that the gasket is intact and in good condition, then you can leave it. If this is not the case, then only replacement.

Removing the throttle assembly

Dismantling the remote control will be necessary in any case. If there are malfunctions, the unit is replaced with a new one, but if there are no problems other than contamination, then the gasket on the damper is changed, and then a thorough cleaning is performed. For dismantling you will need a set of screwdrivers and a 13mm socket wrench. You also need to purchase a special cleaning fluid, which can be found at any car store. An excellent option would be a product for carburetors - Arbo. Dismantling is carried out only on a “cold” motor.

The work proceeds according to the following scheme:

- Raise the hood and remove the plastic engine cover.

- Next we need to reduce the pressure in the cooling system. To do this, you need to remove the expansion tank cap.

- Unscrew the clamps and loosen them.

If, during a visual inspection, deformation of parts was noticed, then the best solution would be to replace the unit. If only cleaning is required, then move on to the next section.

Symptoms of sensor malfunction

The main control unit contains a program: if one of the important meters stops working, the air-fuel mixture is prepared and supplied according to average indicators, and the Check Engine warning sign turns on on the dashboard. Emergency operation with increased fuel consumption is a clear sign of a breakdown of any sensor.

The insidiousness of the TPS is that it does not break in the usual sense. When the resistive film begins to wear away, the resistance of the device changes unpredictably. The controller either “sees” a working sensor in the circuit, or notes incorrect voltage surges and tries to switch to emergency mode. From here, the main sign of a malfunctioning throttle valve is determined - a periodically flashing Check Engine display.

The problem is accompanied by a change in the behavior of the engine, or more precisely:

- “shaking” and spontaneous stops of the engine idling;

- there is no acceleration dynamics; after pressing the gas pedal, jerks and dips are observed;

- increased idle speed of the power unit (1500–2500 rpm);

- the car “does not pull” due to loss of power;

- jerks are also felt while driving;

- Fuel consumption increases by 10–25%!

The listed symptoms can be caused by a dozen reasons, ranging from malfunctions of the ignition system to wear and tear of engine parts. That is why it is important to weed out problems that lie on the surface, including incorrect operation of the throttle position sensor.

Common signs of TPS malfunction

If the sensor malfunctions, the ECU will incorrectly decipher the throttle position data or not receive it at all, which may cause the “CHECK ENGINE” light to come on.

Among the likely signs of failure or incorrect operation of the TPS, the following points can be noted:

- jerking, stalling at idle;

- turning off the engine when switching to neutral gear;

- jerks and dips when accelerating;

- “floating” speed in various operating modes of the power unit.

How to choose the right TPS? Which sensor is better to buy?

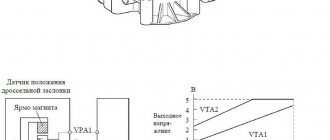

Film-resistive throttle position sensors are the most popular among motorists, this is explained by their low cost, but the service life of such sensors also leaves much to be desired. I recommend buying contactless TPD VAZ 2110, the price of such a device is higher, but thanks to the magnetoresistive operating principle it can boast an excellent service life.

Current:

- How to check the coolant temperature sensor (DTOZH) VAZ 2114

- How to check the VAZ 2109 starter at home

- Diagnostics of faults of the VAZ 2110 mass air flow sensor and its replacement

Communication of the throttle valve with other automotive systems of the VAZ-2110

The throttle valve of a VAZ-2110 car is a component of the engine intake system and is directly connected to a large number of other vehicle systems. These include the following systems:

- directional stability;

- anti-blocking;

- anti-slip;

- anti-slip;

- cruise control.

In addition, there are those systems that are controlled by the electronics of the gearbox. After all, it is this throttle valve that regulates the flow of air into the car system and is responsible for the quality composition of the fuel-air mixture.

This is interesting: How to remove a tie rod without a puller

What is TPS and where is it located?

The damper position sensor is a car potentiometer, one end of which is connected to ground, the other to the positive voltage. It also has a third contact; it sends signals about the throttle position to the vehicle's electronic control unit.

The throttle sensor on a VAZ 2110 car operates on a very simple principle: the throttle opens the throttle at the moment when the driver presses the accelerator pedal. This leads to increased tension. Based on this change in voltage, the TPS adjusts the quality and parameters of the combustible mixture. The relationship is similar when the driver releases the gas pedal.

The VAZ 2110 throttle position sensor is located in the throttle body.

It is not difficult to get to it, so if it is necessary to replace this device, a more or less competent driver can dismantle the TPS and install a new sensor independently, without going to a service station.

How to understand that the cause of problems is in the TPS

- This device is designed to read information about its position from the gas pedal, as well as determine at what angle the throttle valve is open.

- It is located on the same axis as the damper drive, on the throttle pipe. Its service life cannot be predicted; many factors can influence device malfunctions.

- One of the most common malfunctions is increased idle speed. This happens because in the event of a breakdown, the TPS mistakenly determines the position of the damper, and its functions are transferred to another controller - the mass air flow sensor (the sensor responsible for the mass air flow).

- The problem can manifest itself in different ways. For example: the car stalls while driving or, when accelerating and picking up speed, you feel jerking. Sometimes the “XX” (idle) speed is unstable, no matter what engine operating mode you turn on. The CHECK ENGINE indicator may light up, although this does not always happen.

- It is not difficult to check the operation of the sensor: with the ignition on, you need to measure the voltage between its winding and ground with a voltmeter. In this case, the voltmeter reading should not exceed 0.7 volts.

- Then you need to turn the plastic sector by hand, thereby opening the throttle valve. The new measurement should show a voltage value of 4 volts, or slightly more.

- Now you need to turn off the ignition and measure the resistance. Having opened the connector, connect an ohmmeter between it and the slider terminal. Smoothly turning the sector, monitor the readings of the ohmmeter needle - there should be no sharp jumps.

- In case of any deviations from the norm, the VAZ 2114 throttle position sensor will need to be replaced. Moreover, if the tip is broken, or the coating of the base along the slider is worn off. For all injection VAZ cars, starting from 2108, the sensor itself and the work to replace it are identical.

Buying a new sensor

The car manufacturer VAZ, when assembling injection cars, installs domestically produced resistive film sensors on them, which differ only in their very short service life. The price of such a device is small - within three hundred rubles, so there is no point in repairing it. Replacing the VAZ 2110 throttle sensor, in this case, will be the best solution.

The internal structure of a proximity sensor essentially consists of a rotor and a stator. The rotor itself is made of a material that cannot be affected by a magnetic field, and a magnet is located on its base. The stator, on the contrary, is an element that ideally senses the magnetic field (the so-called Hall element). It is located at a distance from the magnet, which has a constant value, and during the assembly of the device itself is programmed in a certain way. This invention is used in the automotive industry for installation in an electronic control system. For the VAZ 2110, replacing the throttle position sensor with a non-contact version will be the best solution. Despite the fact that such devices are twice as expensive as film-resistive devices, they are much more reliable in operation and last much longer.

Characteristic symptoms of a malfunctioning TPS condition

Thanks to the correct functioning of the throttle position sensor, the fuel system of the VAZ-2110 car engine works with a smoothing effect. That is, the vehicle moves smoothly, and the gas pedal responds well to pressure. Therefore, a malfunction of the TPS can be noticed almost immediately by the following signs:

- Poor engine starting.

- Noticeable increase in fuel consumption.

- The car's movements are intermittent.

- The idle speed of the engine is noticeable when running.

- The Check e light comes on on the dashboard

- The car accelerates poorly due to delays in acceleration.

- Popping sounds are heard in the intake manifold.

Of course, these signs of a faulty sensor may not all be observed at once. But even if you notice only one of the above symptoms, it is worth carrying out computer diagnostics of the vehicle at a service center.

TPS problems and their diagnosis

As you know, eternal parts for cars have not yet been invented. And the breakdown of the TPS can be foreseen; for this you need to inquire about the possible reasons for the failure of this part. Here are the main ones:

- Abrasion of the sprayed base layer, which serves to move the slider (the result is incorrect TPS readings).

- Failure of the movable type core (the result is deterioration of the contacts between the slider and the resistive layer).

How can you figure out problems with this sensor yourself? To do this, you can independently diagnose the operation of your diagnostics:

- Listen to the VAZ-2110 engine idling: the breakdown is obvious if you notice that its speed is in a “floating” state;

- a malfunction is present if the engine stops after this action.

- There is a problem with the TPS if the car starts to move jerkily, which indicates an incorrect supply of fuel to the system.

Experts say that most often the sensor fails when the resistive track is heavily contaminated or is completely broken. To verify the opposite, you need to check the working condition of the TPS.

Checking the operation of the throttle position sensor

To check the TPS yourself, it is not necessary to call an auto electrician for consultation. To do this you need a multimeter or voltmeter. Next, experts offer step-by-step instructions for checking the sensor.

The first step is to turn the key in the ignition switch, take the voltage readings between the sensor slider contact and the minus. In normal condition, the indicator will be up to 0.7 V.

The second step is to turn the plastic sector and open the damper, and then take measurements again. In the normal state of the sensor, the device will show a result of 4 V.

Replacement

In fact, changing this sensor is insanely easy. So don't rush to send your car to a service station. Everything can be done with your own hands, the quality will not suffer from this.

- To remove the throttle position sensor, you first need to find it.

- As we have already noted, the desired unit is located on the side of the throttle pipe on the throttle valve axis.

- Having found the element, pick up a shaped screwdriver.

- Using this simple tool, unscrew a couple of bolts that hold the device.

- Pay special attention to the gasket that is available under the old regulator. We do not recommend using it again; it is better to immediately buy a new one. Often the gasket is already included with the throttle sensor itself.

- After removing the old sensor, you can slightly clean the place where it is installed if there is dirt there.

- Next, a new sensor is installed along with a new foam gasket and the bolts are tightened.

- Try to tighten the fasteners as far as possible, otherwise the new throttle sensor will quickly lose its effectiveness. The work will have to be done again.

- There is no need to make any adjustments after replacement.

- The zero mark on the controller will determine that the throttle is completely closed.

Foam pad

What to choose?

When replacing, many more or less experienced car owners have a question about which regulator is better to install. After all, there are two types.

| Sensor type | Peculiarities |

| Film-resistive | These sensors are usually factory installed. The service life of such a throttle position sensor is stated to be about 55 thousand kilometers, but in practice it has to be changed more often |

| Contactless | The operation of such a device is based on the magnetic-resistive phenomenon; a Hall element is used. The cost is noticeably higher than the first option, but it is unlikely to have to be changed. Huge resource, high reliability |

In pursuit of savings, many forget about the importance of quality. But it should be in the first place when choosing spare parts when repairing a car.

TPS is an important, but easy to replace device. The repair operation will take you no more than an hour, even if you are just beginning to learn the joys of repairing your car yourself.

But under no circumstances delay repairing the sensor, otherwise this may negatively affect the operation of the engine, its service life and the cost of fuel, which you will overuse due to incorrect data from the sensor to the ECU.

Diagnostics

Signs of a malfunctioning throttle sensor on the VAZ 2110 are not too different from other models. But there are some features that are worth paying attention to. The following signs may indicate a malfunction of the TPS:

- Floating idle speed until the engine stops in neutral;

- Jerks during acceleration, the car jerks and accelerates extremely difficult;

- Check Engine

light is on .

These signs can usually indicate more than just problems with the throttle sensor. That's why drivers rush to check everything except TPS. Many people are also afraid of getting into electronic systems.

The ideal option is diagnostics using a special scanner. This allows you to recognize the cause of the phenomena without any problems. The error code can be 0122 or 0123. When the signal is low, the first code is issued, and when the signal is high, the second. Such computer readings indicate a clear problem with the sensor. Code 0122 may indicate problems with the wiring supplying the TPS.

Be sure to check all wiring for damage. If you don’t have a scanner at hand, then when checking all the elements, you should first check the throttle and its sensor.

Principle of operation

. To properly check the TPS, you need to know the features of its operation. This sensor is a potentiometer that transmits all information about the position of the throttle valve to the controller. It works as follows. By pressing the gas, you change the position of the damper, and the sensor reacts to this. There is a constant voltage at its outputs, which can vary.

The controller reads the readings from it and, based on this data, doses the fuel supply. If the TPS malfunctions, incorrect readings are given, and as a result, the fuel supply begins to be unstable. And you may notice malfunctions in the engine.

Location

. To check the device in detail, you need to find it. This is quite easy to do. In the VAZ 2110, the throttle sensor is located on the throttle pipe. It connects to the throttle shaft. This directly ensures the operation of the device. The sensor is secured with two screws.

Procedure for replacing TPS

We turn off the “ground” using the corresponding button or simply remove the negative terminal from the battery. Very carefully press the plastic latch on the sensor, and then disconnect the wiring connected to the TPS. Now we need a shaped screwdriver, with which we need to unscrew the fastening screws (there are two of them). Installing a new sensor is carried out, as you yourself understand, in the reverse order.

Here I would like to add that two types of sensors are currently sold - film-resistive and non-contact. Film ones are characterized by an operational life of about 50 thousand kilometers; they are, as a rule, installed on cars initially (at the factory). Contactless devices equipped with a Hall element are considered by experts to be of higher quality. The resource of their use is almost unlimited due to the fact that they operate on the magnetoresistive principle.

But be prepared to pay quite a lot of money for a contactless sensor. Compared to film elements, they are really expensive. When installing a new sensor, tighten the mounting bolts very carefully. If the tightening is not sufficient, the device will break quite quickly. In addition, do not forget to install a new foam rubber gasket instead of the one that was previously available on the TPS.

(1 vote, average: 5 out of 5)

Home →

Device →

Fuel and exhaust systems →

Fuel injection system →

Location and principle of operation of the meter

The sensor is installed on the throttle valve block and is mechanically connected to its axis. Thanks to this, the device is able to solve 3 problems:

- inform the controller at what angle the throttle is currently open;

- signal that the air supply is completely closed (the driver has released the accelerator pedal);

- monitor the speed at which the damper opens.

Based on this information, the electronic powertrain control unit (ECU) makes a decision to increase or decrease the fuel supply and fuel injection for intense acceleration when the gas pedal is sharply pressed.

Reference. Two types of TPS are installed on cars: resistive and non-contact. The first ones are cheaper and therefore are found on all budget cars. The latter are more reliable and more expensive, and are installed on cars of medium and high price categories.

The operating algorithm of the resistive sensor is as follows:

- At idle, the damper is closed and air flows into the engine through a separate channel. The voltage at the output of the device does not exceed 0.5 volts; the controller supplies fuel to maintain engine idle speed.

- When the driver presses the gas pedal, the sensor slider moves along the resistive film. The resistance of the electrical circuit into which the device is connected in series decreases.

- The ECU “sees” the increase in voltage in the meter circuit, makes a calculation, prepares the air-fuel mixture in the required quantity and supplies it to the cylinders. The maximum voltage at wide open throttle is about 4.5 V.

- When the driver sharply presses the accelerator pedal, the controller notes a similar voltage surge and delivers a portion of the enriched mixture for dynamic acceleration.

Note. The operating voltage values are indicated for a common Russian car - VAZ 2110.

The non-contact throttle position sensor functions identically. The difference lies in the method of influencing the electrical circuit. A resistive device changes resistance using a slider moving across the film, while a non-contact device changes resistance due to the magnetic-resistive effect. Thanks to this principle of operation, the TPS lasts much longer and does not create problems for the owner of the car.

Examination

The sensor can be checked using a multimeter or a diagnostic scanner. Since not all car enthusiasts have a scanner, and almost everyone has a multimeter, we will give an example of diagnostics using a multimeter.

The check must be carried out with the ignition on. To carry out diagnostics, you will need two sewing needles or pins.

- Insert the needles into the connector contacts

- We set the DC voltage measurement limit on the multimeter to 20V.

- We connect the multimeter probes to the needles.

- The readings on the device should be within almost 6 Volts. If the readings are lower or absent at all, then the sensor is faulty.

- Next you need to check the integrity of the resistor. To do this, turn the throttle valve by hand, the readings on the multimeter should decrease and, with the throttle fully open, should be approximately 4.5 Volts.

If the readings fluctuate or disappear, it means the sensor is faulty and requires replacement.

Why is it needed?

The throttle position sensor is responsible for determining the current throttle position. Depending on this, the fuel supply system changes the amount of fuel supplied under one or another operating mode of the power unit.

If problems arise with it, you can contact a service station so as not to waste your energy and nerves. But in practice, changing the TPS yourself is quite simple, plus you will save a decent amount of money.

The desired regulator is located on the side of the throttle pipe on the throttle valve axis.

Regulator location