Electric power steering (EPS) is a more modern alternative to the traditional power steering system. On the one hand, the electric amplifier does have a number of certain advantages, but the system is still not without its drawbacks. Moreover, on budget cars (including Lada Priora), ESD malfunctions can appear even at low mileage.

In such a situation, it is important to know what signs indicate that the Priora electric booster needs diagnostics, as well as what malfunctions may occur, and how to identify and repair the breakdown. Next, we will look at what breakdowns are typical for the Priora ESD, as well as how the Lada Priora electric power steering is repaired.

Electric power steering Lada Priora: power steering device and operating principle

So, electric power steering provides the necessary ease when turning the steering wheel at a standstill or in motion. The mechanism creates a force that is transmitted to the steering system.

At the same time, unlike the power steering, the power steering amplifier does not take away engine power, does not require a complex system for pumping hydraulic fluid under high pressure, is less noisy, does not leak, and theoretically should be more reliable.

For this reason, at first VAZ installed power steering on some models, but then they began installing electric power steering on Priora, Kalina, etc. However, in fact, the power steering is also not without its drawbacks; this unit breaks down, and in some cases more often and earlier than the power steering.

Let's start with the EUR device. The main components of electric power steering can be divided into three groups:

- Mechanics;

- electrician;

- control electronics;

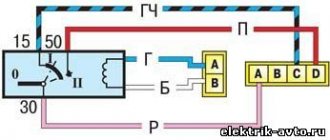

The mechanics actually represent the steering elements (for example, input and output shaft, etc.). Electrics involves an electric amplifier motor, leads, terminals, contacts. The electronics includes an EUR control unit (EUR ECU), a group of EUR sensors, and connectors. Taken together, the Priora steering rack with electric power steering is designed so that the electric motor can create force. At the same time, the “weakest” part is considered to be the electronics, and not the mechanical part.

As for the operating principle of the EUR, it is quite simple. When the driver turns the steering wheel, sensors record the rotation of the steering shaft, after which the electric motor is connected, which creates the necessary additional force. It would seem that the solution is simple and reliable, but this is not entirely true.

Diagnosis of EUR malfunction

First of all, the main symptom of a malfunction appears in the form of a steering wheel icon with an exclamation mark on the Priora’s instrument panel. In this way, the ECU notifies the driver of problems with the power steering.

Normally, when the ignition is turned on, this icon lights up for a while and then goes out. However, if the system is faulty, the icon indicating that the Priora's electric booster is faulty will be constantly on.

The fact is that the electric booster unit is connected to the computer, that is, an error is recorded in the memory. This means that computer diagnostics can be performed. In this case, even a simple individual ELM 327 scanner will do. The main thing is to read the error codes and decipher them. Priora ESD errors usually begin with the letter “C” (for example, C1013, low voltage).

As for the most common problems, the EUR power wires (red and black) may become loose or burnt. The power steering fuse also often fails. By the way, voltage drops may not be related to the amplifier. In this case, you need to check the condition of the battery and the functionality of the generator.

Let's move on. It also happens that the steering wheel icon on the panel does not light up, but the driver still notices that the EUR on the Priora does not work as it should. To quickly check, you need to turn the steering wheel with the ignition off, remembering the force. Next, start the engine, and then check the force. If the force is the same both when the engine is turned off and when the engine is running, then there is reason to believe that there are problems with the electric booster.

Kalina/Priora on-board computer errors

0102 Low level of mass air flow sensor signal 0103 High level of mass air flow sensor signal 0112 Low level of intake air temperature sensor 0113 High level of intake air temperature sensor 0115 Incorrect signal of coolant temperature sensor 0116 Incorrect signal of coolant temperature sensor 0117 Low level of temperature sensor coolant 0118 Coolant temperature sensor signal high 0122 Throttle position sensor signal low 0123 Throttle position sensor signal high 0130 Oxygen sensor signal 1 incorrect 0131 Oxygen sensor signal low 1 0132 Crankshaft sensor signal high 1 0133 Slow response oxygen sensor 1 0134 No signal from oxygen sensor 1 0135 Malfunction of oxygen sensor 1 heater 0136 Short circuit to ground of oxygen sensor 2 0137 Low level of oxygen sensor 2 0138 High level of high signal of oxygen sensor 2 0140 Open circuit of oxygen sensor 2 0141 Malfunction of oxygen sensor 2 heater 0171 Too lean mixture 0172 Mixture too rich 0201 Injector 1 control circuit open 0202 Injector 2 control circuit open 0203 Injector 3 control circuit open 0204 Injector 4 control circuit open 0261 Injector 1 circuit short to ground 0264 Injector 2 circuit short to ground 0267 Injector circuit short to ground sunki 3 0270 Short to ground in the injector 4 circuit 0262 Short to 12V in the injector 1 circuit 0265 Short to 12V in the injector 2 circuit 0268 Short to 12V in the injector 3 circuit 0271 Short to 12V in the injector 4 circuit 0300 Many misfires 0301 Misfires in cylinder 1 0302 Misfire in cylinder 2 cylinder 0303 Misfire in cylinder 3 0304 Misfire in cylinder 4 0325 Open circuit of knock sensor 0327 Low level of knock sensor signal 0328 High level of knock sensor signal 0335 Incorrect crankshaft position sensor signal 0336 Crankshaft position sensor signal error 0340 Phase sensor error 0342 Neither low signal level phase sensor 0343 High signal level of the phase sensor 0422 Low efficiency of the converter 0443 Malfunction of the canister purge valve circuit 0444 Short circuit or break in the canister purge valve 0445 Short to ground of the canister purge valve 0480 Malfunction of the cooling fan circuit 1 0500 Incorrect speed sensor signal 0501 Not correct speed sensor signal 0503 Interrupt speed sensor signal 0505 Idle speed control error 0506 Low idle speed 0507 High idle speed 0560 Incorrect on-board power supply voltage 0562 Low on-board power supply voltage 0563 High on-board power supply voltage 0601 ROM error 0603 External RAM error 0604 Internal RAM error 0607 Knock Channel Malfunction 1102 Low Oxygen Sensor Heater Resistance 1115 Faulty Oxygen Sensor Heater Circuit 1123 Rich Idle 1124 Lean Idle 1127 Rich Partial Load 1128 Lean Partial Load 1135 Oxygen Sensor Heater Circuit 1 open, short circuit 1136 Rich mixture in Light Load mode 1137 Lean mixture in Light Load mode 1140 Measured load differs from calculation 1171 CO potentiometer low level 1172 Potentiometer CO level high 1386 Knock channel test error 1410 Canister purge valve control circuit short circuit to 12V 1425 AD purge valve control circuit sorber short short to ground 1426 Control circuit of the canister purge valve open 1500 Open circuit of the control circuit of the fuel pump relay 1501 Short to ground of the control circuit of the fuel pump relay 1502 Short circuit to 12V of the control circuit of the fuel pump relay 1509 Overload of the control circuit of the idle speed regulator 1513 Circuit of the idle speed regulator short circuit to ground 1514 Idle air control circuit short circuit to 12V, open 1541 Fuel pump relay control circuit open 1570 Incorrect APS signal 1600 No communication with APS 1602 Loss of on-board voltage to the ECU 1603 EEPROM error 1606 Rough road sensor incorrect signal 1616 Rough road sensor low signal 1612 Reset error ECU 1617 Rough road sensor high signal 1620 EPROM error 1621 RAM error 1622 EPROM error 1640 EEPROM Test error 1689 Incorrect error codes 0337 Crankshaft position sensor, short to ground 0338 Crankshaft position sensor, open circuit 0441 Air flow through the valve is incorrect 0 481 Cooling fan circuit malfunction 2 0615 Starter relay circuit open 0616 Starter relay circuit short circuit to ground 0617 Starter relay circuit short circuit to 12V 1141 Malfunction of the oxygen sensor 1 heater after the converter 230 Malfunction of the fuel pump relay circuit 263 Malfunction of the injector driver 1 266 Malfunction of the force driver nki 2 269 Malfunction of injector driver 3 272 Injector driver fault 4 650 CheckEngine lamp circuit fault

New Lada: Lada Kalina error codes with decoding

Frequent electric power steering malfunctions and repairs

Once you are convinced that the ESD does not work fully or partially, you must stop using the vehicle. Next, you should check and try to more accurately determine and localize the fault. There are many possible reasons for this.

The total cost of repairs will also depend on the nature of the damage. In some cases, a new steering rack on a Priora is needed, while in others it is enough to inspect the connectors or contacts.

Please note that it happens that on the Priora model the steering rack is out of order (for example, it bites). At the same time, the electric power steering in this case is not a problem, since the Priora rack relates not to the amplifier, but to the steering. In fact, when turning the steering wheel, malfunctions may occur, the force increases, but the EUR itself works normally and the problem is in the mechanical parts of the rack itself.

Let us also add that usually in terms of mechanics, failure of shafts, connections and other elements may occur. Electrically, cases of failure of the Priora power steering servomotor are not uncommon. In this case, it is better to abandon attempts to repair it and immediately buy a new EUR.

There is also a situation when the EUR unit cannot communicate with the vehicle's ECU. In this case, connector 2 with a cable of wires often fails. Also, the signal may not reach the unit from external sensors DPKV and DPRV, and this problem has a direct impact on the EUR.

In parallel, in the list of problems it is worth highlighting problems with the electric booster unit itself, as well as shaft position sensors. It is better to change the sensors immediately; it is also recommended to replace the control unit. If you have the tools, you can change many components of the electric power steering with your own hands in a regular garage.

How to replace electric power steering on a Priora

Often, owners buy an EUR for a Priora and change the faulty elements of the amplifier themselves. At the same time, the Priora steering rack with electric steering is not in the most accessible place, however, all the work can be done with your own hands, since, unlike the power steering, you do not have to work with the rack itself.

- To replace the EUR on a Priora, you must have a socket wrench 8, a head with a wrench, or a socket wrench 13. You will also need a cross-head screwdriver. You will also need separate tools to remove the steering wheel itself. It is advisable to have a puller or separately study the material on how to remove the steering wheel on a Priora.

- So, when the steering wheel is removed, you need to disconnect the battery (if this was not done while removing the steering wheel).

It is enough to remove the “+” terminal from the battery. Next, remove the plastic covers from the steering column (unscrew a couple of screws and unclip a couple of clips). We also recommend reading the article about what kind of oil to fill in the power steering. From this article you will learn how to select power steering oil, what oil should be poured into the power steering, and also how to select power steering fluid. - Then use a screwdriver to unscrew the 4 bolts and remove the lower part of the trim.

Then you will need to remove the lock, as well as the wiper and turn signal switches. First you need to disconnect the wiring from these elements, then you will need to loosen the fixing clamp with a size 8 key and remove the elements from the shaft casing. The next step is to disconnect the connectors from the ESD ECU and remove the plastic cover from the stud. The lower nuts should not be completely unscrewed (it is enough to loosen them with wrench 13). As for the coupling bolt of the intermediate shaft hinges, its nut should be completely unscrewed with a 13mm wrench and the bolt should be pulled out. - Having removed all the fasteners, the EUR can be removed by disconnecting the lower shaft from the splined joint using a 13mm wrench. Then you can remove the EUR, perform repair work or replace individual components. Once completed, assembly is carried out in reverse order.

Summary topic about EMUR for VAZ [Kalina, Priora] operation, diagnostics, repair.

Welcome to ChipTuner Forum.

Theme Options

GARRICK

GARRICK

GARRICK

Sergey_karb

GARRICK

GARRICK

valerik

Hello everyone! I want to share my experience of dealing with EMUR errors on Kalina.. Since recently, SOMETIMES!! The EMUR began to turn off spontaneously. After reading a little on the internet, I identified the error as follows:

* turn off the ignition; * close contacts 6 and 7 of the 8-pin connector of the EMUR control unit (CU), located next to the power supply unit; * turn on the ignition and read the codes through the flashing diagnostic lamp.

If you look at the ECU connector from the wire side (8-pin black connector, 1st pin on the top right near the latch), then from right to left the count goes like this:

* 1-blue (ignition switch +12V); * 2-brown-red (tachometer); * 3-gray (vehicle speed); * 4-pink-white (EMUR control lamp); * 5-yellow-black (K-Line); * 6-blank (L-line) * 7-brown (mass) * 8-blank.

Light code timing parameters:

* duration of the initial pause – 2 seconds; * long signal duration – 2 seconds; * short signal duration – 0.5 seconds; * pause duration between signals – 0.5 seconds; * pause duration between codes – 2 seconds

* 11 The system is working * 12 No engine speed signal * 13 Malfunction of the torque sensor * 14 Malfunction of the EMUR engine * 15 Malfunction of the steering shaft position sensor * 16 Malfunction of the EMUR engine rotor position sensor * 17 Malfunction of the vehicle's on-board network (below 10V or more than 18V) * 18 Malfunction control unit EMUR * 19 Malfunction of the vehicle speed sensor in my case it was error 16 Malfunction of the engine rotor position sensor EMUR I boldly soldered all three optocouplers and everything magically worked immediately!

Source

Let's sum it up

As you can see, the Priora EUR itself is not a complex design, which somewhat simplifies the process of replacing individual system components. However, the active use of electronics reduces the reliability of such a system as a whole. In practice, more often than not, malfunctions of the electric power steering occur not due to mechanical breakdowns, but as a result of problems with connectors, sensors, contacts, wiring, control modules, etc.

We also recommend reading the article on how to replace power steering fluid in a hydraulic booster with your own hands. From this article you will learn about the features of changing power steering oil, when to change power steering oil and how the replacement is performed.

In any case, with regard to ESD, it is necessary to start with computer diagnostics, and only then move on to an in-depth check of all system components individually.

Finally, we note that the problem with the electric booster cannot be ignored. Some owners try to reset ESD errors without identifying and eliminating the causes. In fact, you need to understand that the good condition and full functionality of the power steering is the key to a comfortable and safe ride.

For this reason, the power steering, regardless of type, must be periodically checked and serviced (in the case of power steering, you need to monitor the tightness and change the power steering oil; in the case of power steering, at least in-depth diagnostics should be performed). This approach makes it possible to increase the service life of the system and also avoid unexpected breakdowns of the vehicle's power steering.