Owners of a VAZ 2110 very often encounter a problem - the starter spins, but the car does not start. In today’s article I would like to tell you about all the reasons for this malfunction, what to pay attention to first and how to fix this breakdown yourself.

In general, there are many reasons why the engine may not start and it is impossible to consider them all in one article. However, there are “basic” conditions that are necessary for a successful launch. We will discuss them now.

Why does the starter spin but the car won't start?

For a successful start, a fuel supply with operating pressure, air and a timely spark are required. It is also extremely important to prepare the correct fuel-air mixture. These conditions need to be checked first when the engine refuses to start.

Burnt contact of the starter solenoid relay VAZ 2110

Difficulties with starting or its impossibility can arise for a variety of reasons. The culprits should be looked for in the following devices:

- Fuel system malfunctions for all types of engines;

- Problems in the electrical equipment of the machine.

It should also be taken into account that starting the engine in cold weather is significantly different from carrying out this operation at above-zero temperatures. We will not touch upon problems with the battery and starter; we will assume that everything is in order with them, so we will focus only on the problems of the power unit.

Fuse

It would be a good idea to check details such as fuses. VAZ 2110 injector 8 valves may not start due to burnt elements. Open the fuse box and check their integrity. There is a thin wire running through the center - if the current is above a certain value (5, 15, 20 Amperes), it burns out.

In our case, it could be the fuel pump fuse. If it doesn't hum, that's definitely the problem. Often replacing the fuse will make it work again.

Battery problems

First of all, if the VAZ 2110 does not start, but the starter turns, you should check the operation of the battery. The voltage at the terminals of a fully charged battery will correspond to a value of 12.6 V. When completely discharged, it drops to a level of 10.5 V. But even a high value of battery voltage at idle does not guarantee its stable operation, which will be discussed in more detail shortly below.

Good battery

It is worth understanding that lead batteries cannot be completely discharged. In addition, their capacity may decrease significantly depending on the number of operating cycles and the total service life. Thus, a battery with a high no-load voltage level, with electrical receivers disconnected, may be unable to produce the necessary power for the starter to operate. How can I check this?

You can determine the fact that the battery does not have the required capacity (Ampere hours) left using the same multimeter, which reads the voltage level at the battery terminals at the moment the engine starts. If the voltage drops below 10.5 V, it means the battery is completely discharged or has failed and is unable to start the VAZ-2110 starter.

Checking battery density replacement

Among the main reasons for battery self-discharge are the following:

- the generator has failed or the voltage regulator is not working;

- the ignition key is left on for a long time;

- improper operation of the battery, failure due to physical wear and exhaustion of its working life;

- electrical wiring faults.

In order to prevent problems with the battery and generator operation, there is a special indication on the VAZ dashboard. It reports possible problems with the generator, a broken belt drive from the drive shaft to the generator, or a faulty battery. If you don’t want to buy a new battery prematurely, problems with the generator should be resolved in the next 50-100 km. mileage after the corresponding indication appears on the dashboard.

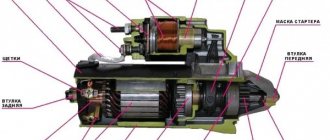

We diagnose the starter

To remove the starter and inspect it for faults at home, you can use a step-by-step algorithm:

Step 1: put the VAZ-2114 in a repair pit.

Step 2: remove the car engine protection.

Step 3: Open the hood.

Step 4: Remove the battery "-" terminal.

Step 5: Disconnect the wiring harness.

Step 6: Remove the crankcase protection.

Step 7: Unscrew the fastening nut to remove the wires from the traction relay.

Step 8: You should also unscrew the two starter mountings from the bottom of the car.

Step 9: Remove the last top fastener.

Step 10: remove the starter (this is done from the bottom of the car).

After removing this VAZ-2114 part, it is visually inspected for the presence of external damage and malfunctions. If everything is in perfect order, then the removed part should be disassembled element by element and a thorough inspection of each element should be carried out:

- unscrew the retaining nut;

- release the solenoid relay from the wire;

- unscrew the bolts securing this relay from the back cover;

- remove the retaining ring, which is located on the back of the rotor;

- Unscrew the nuts from the studs and the bolts securing the wires from the windings to the brush holder;

- remove the brush assembly;

- remove the pin that secures the Bendix fork;

- remove the rotor and stator separately;

- Remove the retaining ring from the rotor.

After all the described operations, you can begin to inspect the overrunning clutch and gearbox, namely the gears that are part of them. It’s worth immediately inspecting other elements of the starter that affect the functioning of the vehicle as a whole. Experts include irreparable breakdowns of the main elements of this part:

- rotor failure;

- stator failure;

- destruction of the rotor and/or stator windings;

- broken bushing.

In these cases, it is better to replace the old starter with a new one than to repair it.

Checking spark plugs and sparks

If the engine does not start within five seconds, there is no use turning the starter. You can try to start it again, but it’s unlikely to help. Moreover, operating the starter for too long can lead to overheating and even fire.

If you try to start a carburetor engine for a long time, gasoline will flood the spark plugs and make further starting attempts impossible in principle. The injectors have a purge mode, so the spark plugs can be dried without removing them from the car - you just need to press the gas pedal to the floor and turn the starter.

Clean working spark plugs VAZ 2110

But these are half measures. First of all, you should unscrew at least one spark plug, put the wire back on it and position the spark plug on the engine so that there is a distance of about three millimeters between the metal part of the spark plug and the metal of the engine. Turn on the starter and make sure that there is a uniform spark between the spark plug contacts.

Checking the spark in the spark plugs of the VAZ 2110

Do this check for each candle. If there is no spark on any spark plug, then there are global problems in the ignition system.

VAZ fuel pump

Once you are convinced that, despite the serviceability of the battery, it still does not want to, find out how the fuel pump works. Its failure leads to the fact that fuel does not enter the VAZ-2110 injector, therefore, the engine cannot be started. This problem often occurs when the engine is still hot.

Try starting it and listen. If the pump motor is humming, then the problem is not there. On a noisy street they use a different method. Make sure the spark plugs produce a spark. Do this: unscrew one and attach it to the power plant housing, and then activate the ignition.

Checking the fuel pump and fuel supply

The principles of fuel supply in carburetor and injection engine models are different, but periodically occurring malfunctions are largely similar. Fuel supply in both systems is carried out by a fuel pump. In the carburetor model it has a mechanical drive; in injection models it is an electric pump that creates high pressure in the fuel rail. Both types of pumps have built-in fuel filters, the clogging of which leads to failures when trying to start the engine.

You can indirectly determine the supply of gasoline to the cylinders by the appearance of the spark plug. If the spark plug removed from the cylinder is wet and smells of gasoline, then everything is fine with the fuel supply. However, it is better to make sure of this more reliably.

An electrically driven fuel pump may not work due to the lack of supply voltage at its terminals. The culprit for this situation may be a blown fuse or broken wires. Problems may arise due to the fault of the carburetor; clogged jets will prevent the engine from starting. But most of the problems in the fuel system are inherent in the injectors. In such systems there are several sensors that monitor and regulate the operation of the power unit. Failure of the DPKV will make starting the engine impossible. Such problems can occur due to the fault of the pressure regulator in the fuel system. Poor starting of the engine injectors cannot be excluded from the organizers.

Fuel pump VAZ 2110

On injection engines, this requires relieving pressure in the fuel system using a special valve at the end of the fuel rail. Unscrew the cap and press the valve with a screwdriver. Gasoline should squirt out from under the valve. After this, release the valve and turn on the ignition. At this time, the fuel pump must start, restoring the released pressure in the system. If the pump is silent, turn on the starter. When the pump does not operate even when the starter is turned on, there is most likely a malfunction in its power supply system.

If the pump starts working, then we check the pressure in the fuel system again, releasing it through the same valve in the ramp. Splashing gasoline again indicates that everything is in order with the fuel supply system. When gasoline does not splash and does not appear from under the valve at all, we can talk about a faulty fuel pressure regulator in the rail (constantly bleeds gasoline through the return line into the tank) or some kind of plug in the main fuel line (for example, due to freezing of water in low-quality fuel ).

Fuel pump VAZ 2110 disassembled

On carburetor engines, checking the fuel supply is much easier. It is enough to remove the air filter cover, move the throttle lever of the first chamber of the carburetor, simulating pressing the gas pedal, and see if gasoline sprays from the spray nozzle. You can pump gasoline into the carburetor using the manual pumping lever, which is found on all mechanical gasoline pumps.

Poor starting of the VAZ 2107 engine in the cold season

Almost all the problems with the VAZ 2106 engine listed above are typical for the warm season. Poor starting of the “six” engine in winter should be discussed separately. The main reason for this phenomenon is obvious: frost. Due to the low temperature, the engine oil thickens, as a result, the starter simply cannot crank the crankshaft at a high enough speed. In addition, the oil in the gearbox also thickens. Yes, when the engine starts, the car is usually in neutral gear. But on it, the shafts in the gearbox are also rotated by the engine. And if the oil thickens, these shafts create a load on the starter. To prevent this from happening, you need to fully depress the clutch when the engine starts. Even if the car is in neutral gear. This will take the load off the starter and speed up the start of a cold engine. There are a number of other typical problems due to which the engine cannot start in cold weather. Let's list them:

- poor compression in the engine. This problem is very often observed in old “sixes” with high mileage: compression in the cylinders in the cold becomes very low. Not only can compression be low, but it can also be different. For example, in two cylinders it is normal, in the other two it is low. If the driver has found out that the reason for poor engine starting is low compression, and the car needs to be started urgently, then you should unscrew all the spark plugs and add a little engine oil to the combustion chambers (it is better to do this using a syringe - five “cubes” of oil in each cylinder will be sufficient). After this, you should crank the starter of the car several times without screwing in the spark plugs. The spark plugs are then screwed into place and the engine starts as the engine oil significantly increases compression in the cylinders (albeit only briefly). And to completely eliminate the problem, a major overhaul of the engine should be carried out. And in particular - replacing the piston rings. Without this, normal compression in the cylinders cannot be restored. There is another way to start a hopelessly frozen car: use the so-called starting fluid. It is sold in auto parts stores. It is injected directly into the carburetor (to do this, you will have to unscrew the air filter cover). And if you don’t want to tinker with the filter cover in the cold, you can unscrew the spark plugs and inject liquid into the combustion chambers. This is also an option, although not as effective;

Starting fluid helps start even a completely frozen car - bad spark. If in summer this moment in the “six” does not prevent the driver from starting the engine, then in winter the situation can change dramatically. Most often, the problem occurs due to poor contact in various plugs, especially those located on the ignition coil and on the distributor. The fact is that the plugs on these parts very often oxidize, and this causes a decrease in spark strength. Understanding how strong a spark is is very simple. The main wire is removed from the distributor and brought to the valve cover at a distance of one centimeter. Having secured the wire in this position, turn the starter several times. If a spark reaches the valve cover at a distance of one centimeter, then everything is fine with it. If not, you should carefully check all plugs and contacts for oxidation.

It is best to hold the spark plug when checking the spark strength using pliers with insulated handles.

Timing belt broke

VAZ 2110 does not start, the starter turns - perhaps the reason lies in a broken timing belt?

The engine gas distribution mechanism is driven by the crankshaft gear. Initially, chains were used for this purpose, and timing belts, which began to be widely used about twenty years ago, aroused mistrust among car owners.

The undoubted advantages of a belt drive over a chain drive are its simple design, low weight and low noise. However, it is not without its drawbacks, the main one of which is the relatively short resource of the timing belt.

Of course, a faulty, torn or misaligned timing belt also causes the VAZ 2110 to fail to start. By the way, on stock, non-deformed models of the 21120 engine, a torn timing belt also causes valve deformation and requires additional repairs. In this case, driving even after replacing the belt without restoring the valves is impossible.

New timing belt VAZ 2110

Check for the presence of a spark in the spark plugs visually by turning on the ignition and pressing the outer metal part of the spark plug against the unpainted metal body of the car or against structural elements. Do not forget that all electrical parts of the product are under high voltage, so it is better to carry out work with insulating gloves. If there is no spark on only one spark plug, be sure to check the others and draw the appropriate conclusions.

The consequences of a broken timing belt depend entirely on the design of the power unit. To imagine what will happen at this moment, you need to turn to the mechanics of the internal combustion engine.

In a running engine, the pistons continuously move from one dead center to another. During the intake stroke, the piston moves down and the intake valve opens; during the exhaust stroke, the exhaust valve opens and the piston moves up. At the moment when the piston is at top dead center, all valves must be closed. If the timing belt breaks, the camshaft stops rotating and the valves stop in one position. At the same time, the crankshaft continues to rotate by inertia, and the pistons rush towards the open valves.

Timing belt VAZ 2110 OPEN

In some engines, for example, the 8-valve VAZ-2111, the pistons have special recesses to avoid contact with the valves in the event of a break. In this case, there will be no consequences, except that the car will not be able to get to the garage or workshop under its own power.

Doesn't start well and boils

In this case, the reason lies in the coolant. Check its level. If necessary, dilute with distilled water. However, there is no need to mix different brands of antifreeze. It may foam, which will further accelerate overheating.

The thermostat may also break. The VAZ 2110 8-valve injector is equipped with a two-piston element. It's very easy to check. To do this, you need a burner and a pan of water. Place the thermostat in the container and wait for the water to boil. If bubbles appear and the piston does not move, it means the element is faulty. The temperature at which it should operate is indicated on the metal body of the thermostat. The element cannot be repaired - it must only be replaced. As a result, the system is unable to regulate the operating temperature of the antifreeze. The coolant moves only in a small circle. But the car may start poorly (every once in a while) due to an incorrectly adjusted ignition. Most "ten" cars have a distributor ignition. Here you need to set the correct lead angle.

How to check the fuel - air system of a VAZ 2110

Another reason why the VAZ 2110 will not start may be a faulty supply of the fuel-air mixture to the car’s engine. In the air supply system, malfunctions occur extremely rarely and boil down to either a tightly clogged air filter or a blockage of the air channel by a foreign object. Such malfunctions are unlikely to occur on a well-maintained personal vehicle. But if the car is, for example, a service car or recently purchased, it would be a good idea to make sure that the filter is intact and that there is no rag stuck in the channel after a recent repair.

The engine fuel supply system is controlled by an electronic control unit, which, in turn, regulates the fuel-to-air ratio based on readings from the mass air flow sensor (MAF) and the throttle position sensor. If both of them are faulty, it is not surprising that the VAZ 2110 does not start.

Diagram of the fuel air system of the VAZ 2110

Next, it’s worth checking the condition of the air filter, since this is the easiest thing to do. And, if none of the above steps help, you need to check the pressure in the system created when the fuel pump operates. Connect a pressure gauge to the diagnostic fitting of the fuel rail and measure the pressure. Its low level indicates a clogged pump filter, and its high level indicates a gearbox malfunction.

The normal pressure level directly depends on the type of engine installed in the VAZ 2110 car:

- the limit from 284 to 325 kPa is normal for engines of type 2111, 2112;

- the limit from 364 to 400 kPa is normal for engines type 21114, 21124.

By the way, the serviceability of the fuel pump can also be determined by disconnecting the main gas supply hose to the ramp and pumping gasoline through it into a clean container. A working pump will pump at least 1.5 liters in a minute. fuel.

Also listen to the starter. Does the main electromagnetic relay turn on with a characteristic click and does the electromechanical drive of the unit work at all? Despite the fact that the design of the starter is extremely simple, the electrical contact on it can easily be lost or the gearbox can fail. In the latter case, a characteristic creaking or whistling sound will be heard.

If the starter does not rotate, you should remove it from under the hood of the car. This process will not take much time, just like disassembling the block itself. It is worth checking the serviceability of the electrical part using a multimeter, “ringing” the windings, and disassembling the gearbox. A large amount of lubricant in it in the cold season does not allow the starter to rotate.

Engine overheating

If the car stalls and refuses to start, the engine may be too overheated . This happens for many reasons:

- temperature sensor failure;

- reduction of compression;

- water pump failure;

- decrease in coolant level.

In the first two options, you cannot do without a specialist, because you will not be able to check the sensors and compression yourself.

You can check the pump by connecting it to the battery. As for the coolant level, you should constantly ensure that it is not critically low, otherwise the liquid will simply boil.

Tips and tricks

Many experts recommend that you be sure to take into account and note what preceded the startup problems and what signs might have appeared before more serious failures began.

In other words, if the car was recently filled with gasoline of questionable quality, then there is a high probability of problems with the fuel system. If there was a recent wash under the hood or the engine stopped starting in wet weather, then maximum attention should be paid to electrical equipment and wiring.

It also happens that at first the car begins to consume more fuel, the engine smokes, the car jerks when accelerating, dips are noted when pressing the gas pedal, etc., and only then the unit does not start. In such a case, the filters and fuel pump may well be to blame. By the way, a heavily contaminated air filter can also lead to the internal combustion engine simply being left without air and not starting.

In any case, often before the engine completely refuses to start, certain signs first appear. These signs should be recorded so that in the future it will be easier to determine the nature of the breakdown and quickly localize the fault.

If the problem catches the driver on the road, then during the initial diagnosis you need to turn on the headlights and low/high beam headlights. In the case when weak light is noted, the headlights come on and go out when the starter is cranked, then problems with the electrical circuits or battery are obvious.

The most common reasons: what is the problem?

It is worth noting that a malfunction can be determined by indirect signs without even opening the hood of the car. For example, if the starter turns, but the engine does not catch on or immediately stalls, the problem lies in the fuel system. Without exception, all the reasons for the inability to start the engine can be divided into two main groups:

- malfunction of one of the fuel system components;

- lack of contact of the electronic ignition system.

It is also necessary to include the following in a separate category of faults: the engine “knocked”, the timing belt broke. In this case, expensive repairs will be required. In other cases, you can get by with a little bloodshed.