One of the most common reasons causing the inability to start a gasoline engine is the banal lack of spark at the spark plugs. Under such circumstances, there is nothing to ignite the combustible mixture on the compression stroke, and as a result, the engine refuses to work. Depending on what kind of power system the car is equipped with, it is determined exactly how to proceed to determine the exact cause of the lack of a spark and measures to return it. We’ll talk in more detail about this problem on injection engines today. Interesting? Then be sure to read the material below to the end.

No spark, VAZ injector

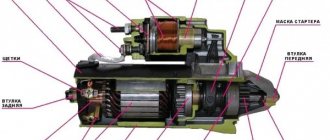

Using the 2111 injection engine of VAZ 21083, 21093, 21099 cars as an example, we will understand the causes of the “no spark, injector” malfunction.

Symptoms of a “no spark, injector” malfunction

There are only three signs of a “no spark, injector” malfunction in relation to the ignition system of the 2111 engine.

— The car engine starts and stalls

— The engine “troits” or “doubles” at idle

Causes of the malfunction “no spark, VAZ injector”

— Spark plugs are faulty

In rare cases, all spark plugs may fail at once. But most often one or two of them fail. The engine begins to run unsteadily at idle. The cause of spark plug malfunction is a breakdown of the insulator to ground (the spark goes not to the spark plug electrodes, but to the engine), carbon deposits on the electrodes due to the engine running on a rich fuel mixture, a malfunction of the spark plug itself (does not pass current), etc. See "Spark plug malfunctions" and "Checking the spark plugs of an injection engine."

In addition, the reasons for the disappearance of the spark on the spark plugs may be faulty high-voltage wires and the ignition module.

— The ignition module (“coil”) is faulty

The ignition system of the 2111 engine uses an ignition module consisting of four coils. Most often, two of them fail, and the engine, at best, begins to “doubly” - only two cylinders work, but most likely it will not start at all. Under certain conditions, difficult starting and ghosting of a cold engine may occur; when the engine is warm, the problems disappear.

Checking the module (ignition coil) VAZ 21083, 21093, 21099

And in case of malfunction, replace it.

— High-voltage wires are faulty

The high voltage wires are designed to carry high voltage current from the ignition module to the spark plugs (the so-called high voltage circuit). If a “break” occurs in this circuit, then there can be no talk of any spark. The cause of the “break” may be burnout of the central core of the armored wire, oxidation, or burnout of the contacts (tips). Or a violation of the integrity of the wire insulator (“breakdown”) due to which the spark goes to the “ground” and not to the spark plug.

The signs of malfunction of high-voltage wires are the same as those of spark plugs (“triples”, “doubles”, does not start, stalls).

— The ECM crankshaft position sensor is faulty

In the event of a complete failure of the DPKV sensor or a “break” in its circuit, the ECU does not receive an impulse when the pistons pass the top dead center. Accordingly, there will be no command to ignite the fuel mixture in the combustion chambers, and there will also be no spark on the spark plugs. When the DPKV fails, the “Check Engine” warning lamp (CHEK ENGINE) lights up in the instrument panel.

You can check the crankshaft position sensor yourself using the "Checking the Crankshaft Position Sensor" section.

Checking the DPKV engine crankshaft position sensor

— The low voltage electrical circuit of the ignition module is faulty

The diagram at the beginning of the article shows the electrical circuit of the 2111 engine ignition system. If there is a break in any of the system wires, the ignition system will not work.

Using the diagram, check the reliability of fastening of the wire blocks (chips) and the oxidation of the contacts in them.

— The control unit (ECU) is faulty

If the test establishes that all elements of the ignition system are in working order, then the controller (ECU) of the electronic engine control system (ECM) is most likely faulty, since the ignition system of an injection engine operates on its command.

Or the main relay (position 1 in the picture) and the ignition system fuse (6) in the relay and fuse box under the instrument panel have failed.

Relays and fuses of the ECM for injection VAZ 21083, 21093, 21099

A faulty controller will have to be replaced or sent for repair. You can check the relay and fuse yourself.

Notes and additions

Similar symptoms (the engine does not start, the engine stalls) can occur not only due to a malfunction of the ignition system, but also the power system, control system, or the engine itself. For example, “Signs of a clogged fuel filter, injector.”

Stage one

Usually the symptoms of difficulty are the following: the starter rotates regularly in its own standard mode, but the engine does not want to start. One of the most possible circumstances is a fuel pump that does not start. When on injection “tens” it is submersible and is located directly in the tank.

There is an option to check the element by the presence of operating sound. Turn on the ignition - there should be a rumble in the area of the rear seats. He is absent from time to time. In our version, you should check the fuses. The VAZ-2110 is a fuel-injected car, and the fuse box is located on the side of the center console of the unfamiliar front passenger. You need to unscrew the fasteners, then remove the cover, check the fuses for functionality and change them as necessary. In this case, the elements are 100% serviceable, then you need to check whether the relay will turn on, both the main one and the fuel pump. Of course, you can feel the moment of switching on with your finger. A corresponding click will also be heard.

If the fuel pump is operational, use a pressure gauge to check the presence of fuel there. If there is no pressure gauge, then press on the spool at the bottom of the fuel rail. myth element may be in a protective cap. The pressure will be completely tangible, although its power cannot be found. A running pump and no pressure indicates an obstruction in the fuel line. This is caused by a clogged fuel filter.

No spark VAZ 2109

What to do if the spark is lost on the VAZ 2109? Naturally, the engine will not start without a spark, so every car owner should know the solution to this issue. So, the main reasons that there is no spark are the following: 1) The switch has failed 2) The Hall sensor has failed 3) The timing belt has broken 4) The ignition coil has failed 5) The ignition switch contact group 6) The ignition distributor cover contacts 7) Fault in the wiring (any of the wires of the electrical circuit ignition switch-switch-ignition coil-Hall sensor is torn off or rotted). Above are the most basic faults due to which there is no spark on the ninth Zhiguli model. Let's look at each of them in order. Let's immediately make a reservation that the car must have a charged battery that rotates the engine crankshaft. If your starter does not turn the crankshaft of the VAZ 2109 engine, then first get it to turn it, and then look for a spark. 1) To check that the switch is working, it must be replaced with a known good one.

Switch

Experienced VAZ owners know that the switch is not the most reliable part, so it is always necessary to have a spare switch in the glove compartment. We remove the switch under suspicion and install a known good one. We try to start it - if it starts, then the problem is in the switch. If it doesn’t start, we put the old switch back and look further. 2) To check the Hall sensor, it is also better to replace it with a known good one, although there is a method for checking the Hall sensor directly on the car.

Hall Sensor

We replaced the Hall sensor and tried to start it again. If a spark appears, then the problem was in the Hall sensor. If a spark does not appear on the VAZ 2109, move on. 3) To make sure that your timing belt is not broken, remove the cover from the ignition distributor and turn the crankshaft with the starter.

Ignition distributor slider

The ignition distributor slider should turn. If it doesn't turn, change the timing belt. 4) The ignition coil fails quite rarely, so it is better to check it as indicated here. If the check indicates a malfunction of the ignition coil, change it and look: a spark appears, which means the problem is in the coil, if it does not appear, move on. 5) The ignition switch contact group may also be the reason why there is no spark. I had this thing: after two days in the cold, for some reason the spark on the VAZ 2109 disappeared. The starter turns briskly, but there is no spark. I noticed that when you turn on the ignition, there is power to the ignition system at pin B of the ignition coil. When you turn the starter, the power from contact B of the ignition coil disappears. The thing is incomprehensible and difficult to diagnose; you need to measure the voltage between ground and contact B of the ignition coil with a multimeter or a light bulb. To crank the starter, you need to turn the ignition key and somewhere in the contact group of the ignition switch there is no contact, so when the starter rotates, power is removed from the ignition system. It can be treated by replacing the contact group of the ignition switch, or as follows: Using a locking button, we connect +12V from the battery to contact B of the ignition coil.

We supply +12V to the coil bypassing the ignition switch

We pressed the button, +12V went to the coil and the ignition system will be powered even when the starter rotates.

Using a locking button, we power the ignition system

A spark will appear, start it, press the button again to break the direct circuit from the battery to the coil. If the button is left pressed, the car will not stall when the ignition is turned off. This method is quite acceptable, as in my case: the car is parked in -20 degrees cold, and it needs to be started. Changing the ignition contact group in this case is not the fastest and most convenient solution. You won’t do anything bad with a button from the battery to the coil. When you have time, you can safely make repairs somewhere in the garage, and put the jumper with the button in the trunk and save it just in case. 6) In general, when there are no sparks, this must be checked first. If there is no spark at the spark plug, then you need to check whether there is a spark from the ignition coil.

Other faults

If the starter does not spin, the spark disappears between the ignition switch and this element. This often happens when the battery is discharged or faulty. When tested, a regular battery indicates approximately 11.8 V. A faulty ignition cylinder will immediately appear just when the driver inserts and turns the key. If turning the key is very easy or difficult, you need to change the lock. The starter relay or the accounting ignition system is also one of the likely circumstances of the lack of a spark. But there is no way to check these nodes without the help of others. The “retractor” device may be stuck in the starter. In this case, the spark is lost along the way. Experienced car owners hit the starter with a key, or in other words, with a hammer, to return the spark. However, this is only relevant at the site of the breakdown.

What to do if there is no spark in a VAZ-2110 car? Check the starter in the garage using a battery. If you press the body of the device to the “minus” of the battery, and stretch the “plus” wire to the “retractor”, then the device comes to life. Often the spark may disappear where power is supplied to the starter. It is advisable to inspect this circuit with a multimeter. You can't do it alone - the assistant works with the key while taking measurements.

Bringing the car back to life

As for why a spark disappears, everything is probably very clear. Now, it would not be amiss to consider the order of her return. The reality is that in most cases, getting the spark back is a simple matter and just involves carefully checking the broken car. To be more precise, to normalize sparking it is required:

- Firstly, check the spark on the injector using the method described above, make sure that it has disappeared, and, at least indirectly, try to determine the cause of the malfunction;

- Next, it is enough to assess the current circumstances and act based on them. As typical situations, we suggest considering solutions to the following problems:

- the spark plug is wet, the presence and strength of the spark are unimportant, the carbon deposits are correct (brick color) - wipe the part and screw it back in;

- the spark plug is wet (not always) and the carbon deposits are incorrect (white or black) - clean, dry the part and try to start the engine, if there is no result, change the spark plug and deal with problems in the fuel system (cleaning the injector, checking the ECU, etc.);

- the spark plug is wet, there is no spark at all, the color of the soot is not important - we try to change the part, if there is no result, we check the ignition system and the operation of the injector.

In principle, in theory there are no particular difficulties in repairs of this kind. Despite this, it often causes difficulties in implementation for inexperienced motorists. To solve these, you need to act in the order described above, but if something doesn’t work out, it’s better to turn to professionals at a service station. This approach to repairs will not only save time, but also guarantee trouble-free operation of the car in the future.

Perhaps this concludes the most important information on today’s issue. We hope that the material presented was useful to you and provided answers to your questions. Good luck in operating and maintaining your car!

How to act in winter

There is a single algorithm with which you can start a VAZ-2107 without serious problems in the fuel supply, ignition or power supply systems. To successfully complete the procedure, you will need to have on hand dry, calcined spark plugs, a working and charged battery, and a special spray for the carburetor. Let's look at the launch procedure in more detail:

- Try to remove the battery at night to keep it warm. If you have not done this in the evening, then before you try to start your car, place the battery in a warm place for 20-30 minutes. Remember that when frost sets in, this battery loses its capacity by a quarter, so the inrush current also drops.

- If the temperature drop was not significant or heating the battery did not help, then turn on music in the car or flash the headlights a little in high beam mode. These simple steps will put a strain on the battery. If the quality of the battery is poor, you can charge it at low currents.

- Reinstall the prepared battery and try to start the engine. First, depress the clutch fully, and only then start cranking the starter.

- Warm up the power plant so that the oil becomes more liquid. Smoothly release the clutch to heat the lubricant in the gearbox.

- If the injector stalls during the gearbox warm-up stage, use cylinder blowing. This may not help, then remove the spark plugs and heat them. They may be flooded.

- For a cold start, a special spray is produced, which is injected into the carburetor behind the air vent. If you have an injector, then inject the spray into the corrugated hose, which is also located behind the air vent.

You should also know another popular starting method in winter - “lighting up”. It’s suitable if frost catches you on the road, and there is no way to bring the battery into a warm place. For this you will need a special starting battery or another car with a well-charged battery. Observe the following rules:

- park cars not close to each other;

- use only special cables with clamps;

- To avoid overloading the generator, do not give too much gas;

- connect the terminals observing polarity;

- the car must run for 3 minutes before you disconnect it from the “donor”.

Another common way to start an engine is by pushing. They rarely resort to it if nothing else has affected the car. In severe frost it may be ineffective, so initially all other methods are used.

Frost will not take you by surprise if you prepare your car for the cold in advance:

- change antifreeze;

- install a new set of spark plugs;

- pour anti-freeze liquid into the washer reservoir;

- install wheel arch liners;

- change the tires to studded ones;

- Spray WD-40 into the locks.

Such preparation will help maintain the car's driving performance even with a significant drop in temperature.

Possible errors in VAZ injectors

Codes, of course, indicate defects in all parts and components in the car. In most cases this is due to sensors. Temperature sensors suffer in particular - they overheat. Car owners also complain about the injectors. Problems arise due to breaks in the circuit. Once completed, they do not have the basis to work properly. This also includes the popular breakdown on the VAZ-2110 - no spark. The 8 valve injector cannot start normally due to this.

Now about errors related to the engine. The most common one is overheating. The spark plugs also overheat, causing the spark . And therefore the engine does not show any signs of life. Next it’s worth looking at the valves. These parts are usually very dirty, which in the process will lead to their complete closure. They do not allow the required mixture of air and fuel to pass through. And finally, the fans - if they don’t work, then the unit will constantly overheat.

Stage two

If there is no spark on a VAZ-2110 (injector, 8 valves), then spark plugs are often the cause. What, they are inspected if the fuel pump is working. It is best to use a spark gap for testing. If the current is distributed over two spark plugs, then there will certainly be a breakdown to ground.

You can find out why there is no spark on the VAZ-2110 (injector, 8 valves) using a faulty controller. It is also possible that the wires from the controller to the ignition coil will break. If spark on all coils, you should check the power supply. Typical specifications are up to 200 kΩ.

Low voltage circuit

Using a 12V lamp, you can check the low voltage circuit. The lamp must be connected with the first contact to the low voltage terminal, and the second to the car body. Next, you need to close the distributor contacts and start the ignition. If the circuit is OK, the lamp will light when the contacts open and go out when the contacts close.

If the lamp does not light up when the contacts are opened, this means that the problem is in the low voltage wiring or in the ignition coil, or rather, in its winding.

What are the reasons for the lack of ignition?

The reason is simple. It consists of a breakdown of any part of the system.

So, for example, a breakdown can occur in:

- Switch. As a result of such a breakdown, the required voltage ceases to flow to the coil.

- Sensor. A broken sensor will not be able to transmit current to the switch.

- Belt. If the belt breaks, the operation of the entire system is disrupted.

- Reel. A breakdown in the coil stops the process.

- Candlelight. Carbon deposits or moisture prevent a spark from forming.

- The distributor cover and its contacts. Such a malfunction does not allow voltage to be transferred to the spark plug.

Also, a malfunction can be detected in the ignition switch itself. Then the process stops before it even begins. Another reason may be a wiring fault, resulting in communication between elements being interrupted.

Diagnostics

To understand which part of the starter the breakdown occurred in, you should thoroughly clean it. First, the solenoid relay is checked. If it is working properly, a loud click will be heard. Another evidence of the serviceability of this mechanism is that the bendix moves slightly forward. The absence of a click indicates that the relay is broken and needs to be replaced with a new one.

If the problem is not in this part, then you need to make sure that all the insulation is in good condition. All damage can be restored with impregnating varnish and then checked with special electrical measuring instruments.

When, after a complete inspection, all parts are found to be in good condition, the rotor insulation must be checked. Traces of burning and soot on the anchor indicate that this device needs to be replaced. The collector must be clean, free of deposits, and if this defect is present, you can clean the element with sandpaper. After all procedures, the coupling is checked. It should spin freely in one direction and be locked in the other.

Coil

The VAZ 2109 ignition coil itself fails quite rarely, but it is necessary to check it. This can be done using a multimeter turned on in ohmmeter mode. We connect one of its probes to terminal “B”, and the second to terminal “K”. These are the ends of the primary winding. The resistance value should be 0.4-0.5 Ohm.

After this, we check the secondary coil by connecting the probes of the device to terminal “B” and the high-voltage terminal. Here the resistance should be about 4-5 kOhm. For any other indicators, the VAZ 2109 ignition coil must be replaced.

The VAZ 2109 ignition coil itself fails quite rarely, but it is necessary to check it. This can be done using a multimeter turned on in ohmmeter mode. We connect one of its probes to terminal “B”, and the second to terminal “K”. These are the ends of the primary winding. The resistance value should be 0.4-0.5 Ohm.

No need to guess too much - you need to use the following devices

The first device is A3-1 - emergency ignition . You can use it in the rain or when driving through puddles (to warm up or dry the spark plugs) to check the electronic switch or when the hall sensor fails. In other words, emergency ignition is a substitute for a hall sensor, but with a speed limit of up to 90 km/h.

The second device – MD-1 – instant diagnostics . Used to check the functionality of the hall sensor, ignition coil and ignition switch. To begin with, it is better to use MD-1. We connect it instead of the switch and turn on the ignition, but we don’t start the car!

- if the “P” LED is on, the ignition switch and ignition relay are operational

- LED “K” is on – the ignition coil is working

- turn on the starter: if the “D” LED blinks, it means the hall sensor is working