02/04/2022 3,050 VAZ 2112

Author: Ivan Baranov

Modern VAZ 2112 cars are equipped with various devices and sensors that ensure optimal engine performance. If one of the main components fails, this will negatively affect the functionality of the machine as a whole. For more information about what the VAZ 2112 mass air flow sensor is, where it is located and how to clean it if necessary, read this article.

[Hide]

Checking the serviceability of the mass air flow sensor with a multimeter

You can also check the air flow in the VAZ-2110 using a multimeter.

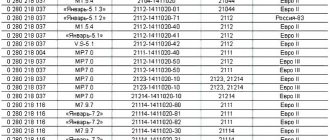

This method is well suited if the car has a Bosch sensor with numbers 0280218004, 0280218037, 0280218116. Each cable in the VAZ-2110 sensor device provides separate functions:

- yellow – indicates the signal input to the installation;

- gray-white – removes supply voltage from the mechanism;

- green – determines the grounding output;

- pink with black - approaches the main relay.

Note that the wire colors may change, but the pinouts remain the same. For a better understanding of the mass air flow sensor in the VAZ-2110, a diagram of the sensor is presented below.

Step-by-step instructions for checking the mass air flow sensor in a VAZ-2110 with a multimeter look like this:

- Turn on the ignition, but do not start the engine.

- Connect the multimeter with the red wire to the yellow, black to green, using a probe. This procedure allows you to determine the voltage that has arisen between the terminals.

- What’s good about the probe is that it is inserted through rubber seals along the wires without violating the integrity of the insulating material. The use of needles is considered incorrect; the error in measurements may be large.

- Next, take readings from the multimeter.

The output voltage of the new device varies from 0.996 to 1.01 Volts. During operation, the values may change, mostly increasing. A higher voltage indicator indicates a greater degree of wear on the mass air flow sensor:

- from 1.01 to 1.02 – the sensor is fully operational;

- from 1.02 to 1.03 – the condition is not bad;

- from 1.04 to 1.04 - soon the air meter will have to be changed;

- from 1.04 to 1.05 – the condition is critical, operation is possible if no negative symptoms are reported;

- more than 1.05 – it’s time to replace the sensor on the VAZ-2110 immediately.

Replacing the sensor - instructions

Using a screwdriver, unscrew the clamp of the air intake corrugation at the sensor outlet, pull it off and carefully inspect the internal surfaces of the sensor itself and the corrugation. These surfaces must be dry and clean; traces of condensation and oil are unacceptable. If the air filter is changed rarely, then dirt getting on the sensitive element of the sensor is the most common cause of its breakdown in VAZ cars.

There may be oil in the mass air flow sensor as a result of an increased oil level in the engine crankcase, or the oil sump of the crankcase ventilation system is clogged.

Next, unscrew the 2 screws of the sensor with a 10mm wrench and remove it from the air filter housing. There should be a rubber sealing ring on its front part (at the entrance edge). It prevents unfiltered air from being sucked into the intake tract through the sensor.

If the ring is out of place and stuck somewhere in the air filter housing, then there will be a thin layer of dust on the inlet mesh of the sensor itself. This is the second reason that destroys the mass air flow sensor ahead of time.

Correct assembly should take place in the following sequence: put a sealing rubber band on the sensor, check the sealing skirt, then insert everything together into the filter housing.

This concludes the visual check of the mass air flow sensor at home. You can check its operation 100% only with the help of special equipment in a car service center. For example, using a technique for assessing the oscillogram when the throttle is sharply opened to the cutoff mode (a motor tester is needed), or assessing the oscillogram when the ignition is turned on.

Resuscitation of a damaged air flow sensor is successful in no more than 5% of cases. In extreme cases, you can rinse with ethereal liquid to clean matrices and optics. It will evaporate without a trace. After making sure that there is no more dust or debris in the device, you can dry it thoroughly and put it back in place. Sometimes after such a simple procedure the device will work.

On most foreign cars, a mass air flow sensor was installed until 2000; subsequent generations of models began to be equipped with a pressure controller. Replacing a non-working sensor is simple and can be done on your own without any problems, you just need to buy a mass air flow sensor that matches the ECU firmware version. Its price is around 3,000 rubles, depending on the manufacturer.

Cleaning the sensor

Oxygen sensor on a 16-valve VAZ-2112 engine: signs of a malfunction

In some cases, it is possible not to flush the VAZ 2110 DMV, but to replace it. But many people don’t know how to clean the DMV VAZ.

These procedures are easy to do yourself:

- first you need to disconnect the pipe from the mass air flow sensor;

- then the sensor itself is removed, this is necessary for better flushing of the DMV VAZ2110;

- to remove the sensor, use a special key with asterisks;

- unscrew the fastening systems and remove the sensor from the pipe and inspect its appearance;

- in some cases, an oil deposit forms on the sensor, but after cleaning the sensor will be as good as new;

- to clean the sensor you need to purchase a special carburetor cleaner;

- There is a film inside the sensor, and there are thin wires on it, and in order not to damage them, you should carefully spray them with the product;

- leave for a while to allow the sensor to dry; it is best to use the product in cans;

- Some people use alcohol to clean the sensor; it will also clean it well;

- Also, when cleaning the sensor, do not forget about cleaning the pipe from accumulated dirt and dust;

- After cleaning, allow the parts to dry and then reassemble in the reverse order.

And after such measures are taken, the sensor can function and continue to work. But in some cases it is still worth replacing the sensor.

There are several price categories for the mass air flow sensor:

- Low cost, most often these are Chinese-made parts, and their cost does not exceed 1000 rubles, but experts do not recommend purchasing cheap sensor options.

- Average cost, most often these are AvtoVAZ parts, which can be of domestic or foreign production, their cost ranges from 1500-2500 rubles.

- It is best to purchase more expensive sensors, they are of high quality and reliable, but the cost here can be higher than 5,500 rubles, and they have a long service life.

When choosing, you should pay attention not only to the cost of the sensor, but you also need to take into account the manufacturer, and it is better to choose foreign manufacturers. They are usually of average cost and good quality

How to restore the mass air flow sensor?

Signs of a faulty air sensor on a VAZ, Niva Chevrolet and foreign cars; auto innovator

The optimal solution for problems with the mass air flow sensor is to replace the faulty sensor with a new one. But since the cost of the device is about 2500-3900 rubles, many owners are trying to “revive” the old part.

There are four recovery methods:

- installation of additional resistance;

- blocking part of the air supply channel to the thermistor with aluminum tape;

- updating the engine control unit firmware;

- washing the sensor body and housing from dirt.

Installing additional resistance

Additional resistances are installed in the circuit connecting the sensor to the control unit. When an electric current passes, the voltage decreases, which can be brought to the required limits. The resistance value is selected experimentally. Most often, a 1 kOhm resistor is soldered to the yellow wire and a 15 kOhm element to the green wire.

Blocking part of the air supply channel

The repair principle is based on partially cutting off the air supply to the thermistor. Due to this, less intensive cooling is ensured and it is possible to bring the voltage value to the state of a working device. The cross section is selected experimentally with voltage monitoring using a multimeter. In some cases, owners block the supply channel by 70-80%. Aluminum tape is used for gluing.

Correcting the firmware of the engine control unit

An adjustment means a change in the calibration or operating schedule of the mass air flow sensor stored in the unit’s memory. The dependence graph is constructed in such a way that at a sensor voltage of 0.996 volts, the flow rate is considered equal to zero. But if the sensor fails and the starting voltage is 1.055 volts, then the control unit considers the air supply to be 1.8 kg when the engine is not running. Changing the graph using the MAF Corrector utility will allow you to set the flow rate to 0, which will improve engine performance. This method can be recommended to owners who are well versed in the control unit software.

Do-it-yourself cleaning of the air flow sensor

The air volume sensor is cleaned after it is detected that it is not working correctly. The procedure is performed by partially disassembling and removing the device body with active elements. At the same time, the body is washed and cleaned from remaining leaves and dirt deposits. In many cases, washing the air flow sensor on a VAZ 2114 does not help restore the device’s parameters.

Mechanical methods 2114 are prohibited, as is blowing dust with compressed air.

What products should be used to clean the sensor?

To clean sensors, there are special liquids supplied in pressurized aerosol cans. An example of such a product is a special air flow sensor cleaner Luftmassensor-Reiniger from Liqui Moly. There are similar liquids from other manufacturers. You can wash the sensor with a mixture of 70% isopropyl alcohol and 30% distilled water, after warming the device to 60-70 ºС with a hair dryer.

When washing the mass flow sensor it is prohibited:

- try to clean the sensor with cotton balls, hard objects and brushes;

- use household cleaning products;

- Use carburetor cleaners based on acetone or ether.

Cleaners based on heavy petroleum products, for example, WD40, will remove plaque from working parts, but will leave a greasy film that must be washed off with isopropyl alcohol. The use of ether-containing substances is not recommended due to the destruction of the compound filling and electronic components.

Algorithm of actions

Sequence of steps when washing the mass air flow sensor:

- Remove the sensor together with the housing from the engine air duct. The device is attached with a clamp to the channel and two bolts to the air filter housing.

- Unscrew the two screws securing the sensor to the housing. The bolts have a star head, but many owners unscrew them with pliers.

- Wash the measuring thermistors and the air passage channels with a cleaning agent. If the cleaning method with alcohol is used, the removed sensor is heated with a stream of warm air and placed in a container. The alcohol-water mixture is also heated to 60-70 degrees.

- Dry the sensor.

- Wash the sensor housing with warm soapy water. Rinse under running water and dry.

- Assemble the sensor and install it in place.

How to check the air flow sensor (3 ways to check)

In some cases, to check the mass air flow sensor, it must be removed from the car. Dismantling procedure:

- Loosen the clamp

- Remove the air pipe,

- Unscrew the screws securing the sensor to the air filter housing.

- Before disconnecting the electrical connector, you must remove the negative terminal from the battery. This must be done so that the electronic engine control unit does not generate an error and the check lamp does not light up.

Method number 1. Visual control

To do this, you need to remove the sensor and carefully inspect it for mechanical damage or foreign objects or debris. It is also worth visually assessing the integrity of the heating filament sensors or heating film.

Such problems can arise due to a leaky air filter housing, or due to a poor-quality air filter.

If visible damage is detected, the sensor must be replaced. And if there is debris or dirt in it, the air flow sensor can be cleaned with special products or a carburetor cleaner (alcohol-based spray). Mass air flow sensors are very fragile, so be careful not to clean them mechanically. The sensor cannot be repaired!

Method number 2. Power off

The easiest way to check the mass air flow sensor is to disconnect power from it. With the engine not running, disconnect the electrical connector on the mass air flow sensor. Then we start the engine.

In this situation, the engine control unit switches to backup mode and replaces the readings of the disabled sensor with those programmed by the manufacturer.

In this case, engine operation should normalize and idle speed should increase. For additional checking, you can drive a car with the MAF connector disconnected - 100-200 meters. If all symptoms of a malfunction of the mass air flow sensor have disappeared, then the sensor is transmitting incorrect data - it is considered inoperative and requires replacement.

When checking the mass air flow sensor in this way, after disconnecting the electrical connector from the sensor, the “Check” engine error lamp will light up on the instrument panel. After completing the check or replacing it, you will need to reset the error! To do this, you can disconnect the negative terminal of the battery for a few minutes (carefully, absolutely all settings will be lost). In some car models, the error can only be reset at a service center using a special scanner connected to the car’s diagnostic connector.

Method number 3. Checking with a multimeter

To check the air flow sensor with a multimeter, you need to know which parameters to measure and from which contacts of the electrical connector. They may differ for each car brand. The location of the sensor wires and terminals can be found in the vehicle's electrical diagram.

For example, on Bosch sensors that are installed on VAZ and GAZ cars, you can check the voltage (V) between the incoming signal and ground at the mass air flow sensor connector. To do this you need:

- Turn on the car ignition, but do not start the engine,

- Connect the red (+) probe of the multimeter to the yellow wire,

- The black (-) probe goes to the green wire of the connector.

- We set the mode switch on the multimeter to measure the minimum direct current.

The voltage at the contacts should be between 1.00-1.04 Volts . If the readings are higher, the sensor requires replacement.

Additionally, you can remove the sensor without disconnecting the electrical connector and apply a stream of air to the sensor from the air filter side. The voltage should increase to 1.3 Volts , in which case the air flow sensor is considered working.

Depending on the sensor design, it is still possible to measure the resistance on the resistors. Moreover, the measurement results at different air temperatures will be different. Accurate data on the optimal values of resistance readings, measurement temperatures and the location of contacts on the connector are usually indicated either in special technical literature or in the car repair instructions.

How to replace the air flow sensor on a VAZ 2110

Crankshaft sensor for VAZ 2112 16 valves

Replacing the sensor yourself is not difficult. After the operation of the device has been checked and if there is no point in cleaning the sensor, you can begin to replace it.

- The car is placed on a flat surface, and the negative terminal must be removed from the battery.

- Then the sensor is turned off.

- To remove the clamping bolt of the clamp, use a screwdriver; it is located on the corrugation.

- We remove the corrugation.

- Then unscrew the bolts on the air filter.

- Now you can remove the old sensor and install a new one in its place.

- You can reassemble in reverse order.

If all the work is carried out correctly, the car will again regain power and dynamics, and the sign on the instrument panel will disappear. To check the correct operation of the MAF sensor, you should drive the car. If everything returned as it was before the breakdown, then the repair was carried out correctly, and the cause was the DMVR sensor.

If all else fails, buy a new air flow sensor

All testing methods showed the same result - “Sensor to be replaced.” The mass air flow sensor is quite expensive, and you should approach its purchase consciously.

Using the example of the same manufacturer Bosch for LADA and GAZ (article 0280218037) - according to the search results on the GisAuto portal as of September 18, 2022, 568 offers from different cities were found in Russia. The cost of this sensor varies from 2,490 rubles. up to 6,676 rub. Such a range in prices may depend on various reasons: availability, delivery time, purchase cost, etc.

You can select a mass air flow sensor for your car on the GisAuto portal - you can use the part number, make and model of your car, and also create a request using the VIN number of the car, and then the sellers themselves will send you their offers. All you have to do is choose the option that suits the price and time frame.

Cleaning the sensor

If you observe signs of a malfunction of the mass air flow sensor, then you can try cleaning the device.

By the way, this is the most expensive sensor of all in the line of front-wheel drive VAZ cars. But if yours is broken, don’t rush to change it. There is a small chance of restoring his “health”.

For the cleaning process you will need a special liquid that is used to clean the carburetor. Star keys are also useful. Unscrew the clamp, as well as the two “10” bolts.

Remove the pipe and take out the sensor. Spray the liquid onto the wire and tube. Work with extreme care, wait until this liquid has completely evaporated and leave the device to dry.

While the device is drying, remove the throttle assembly. You will see plaque inside the throttle assembly. It needs to be removed with liquid.

This dirt causes problems with the entire system. Because of it, problems with the mass air flow sensor appear, signs of a malfunction of the VAZ 2115, which bother beginners on automobile forums.

Do not remove the throttle cable. Place the knot on a cloth and treat particularly dirty areas with the liquid. Don't forget to clean the idle air control valve and the space underneath it.

After this, most likely, all signs of problems with the mass air flow sensor will go away, of course, provided that the sensor has no mechanical damage. Therefore, do not wait until you have the first signs of such problems, but take such prevention this coming weekend. It won't take you much time, and your car will truly breathe.

You won't recognize your engine. It will start much better, its traction will improve, and you will notice an increase in the power of your engine.

Carry out such preventive maintenance regularly, and your car will thank you.

The automotive market does not stand still; manufacturers are constantly improving car engine power, fuel consumption, aerodynamic values, and coming up with options for changing overall comfort. The main and obvious improvement was the transition from the use of a carburetor method of power supply to a more efficient injection system.

How does the latter work? Regulates the quantitative supply of fuel according to a single dosage for the operation of the power plant in different formats of activity. This allows you to reduce the amount of air consumption and ensure maximum power output from the power structure.

However, mechanics argue that the design of the carburetor system is technologically simpler, because the carburetor operates mechanically, which means that the mechanism can be assumed to be highly reliable. The VAZ-2110 is equipped with such a system. The advantage of the device is that the fuel-air mass is formed in the carburetor and in the cylinders through vacuum, which is created by the pistons.

- how is the crankshaft positioned?

- what is the rotation speed;

- how much air enters the cylinders;

- what volume is contained in the exhaust gas;

- where is the throttle valve located.

These data and the calculation of the required fuel are responsible for the sensors recorded in the individual components of the power product - mass air flow sensor, which we will look at in more detail right now.

Symptoms of a faulty air flow sensor

If the mass air flow sensor begins to produce incorrect data, then a failure occurs in the system for preparing the fuel-air mixture, and the proportions of fuel and air are disrupted. This results in the following symptoms of a malfunction:

- Unstable idle speed

- Violation of the smooth running of the car

- Difficulty or impossible to start the engine

- Noticeable deterioration in vehicle dynamics

- Increased fuel consumption

- The yellow "Check Engine" light on the instrument panel does not go out

Check engine light on the instrument panel

If the Check Engine light is constantly on on the instrument panel, the easiest way to check, if you have a diagnostic tool, is to read the error codes, which will allow you to pinpoint the problem. One of the most common DMRV errors is error p0100. Explanations of diagnostic codes can be found in the technical literature for a specific vehicle.

None of the above symptoms are a 100% guarantee that the mass air flow sensor has failed. Other vehicle systems may also be to blame. But all these symptoms together, or each one separately, give reason to check the flow meter for performance.

What is a DMRV?

This device is very necessary in order to determine the volume of air that fills the combustion chambers when the engine is running. The sensor is usually installed after the air filter in the power system.

When driving, the automobile power unit is supplied with 1 volume of fuel, as well as 14 equal parts of air. This prepares the correct fuel-air mixture. This is the key to proper operation of the motor in the most optimal modes for it.

For any violation of this ratio, the car owner will observe either increased fuel consumption, or a decrease in the power of the power unit, or both. If you know the signs of a malfunction of the mass air flow sensor, it is easy to identify a breakdown of the device.

The mass air flow sensor is necessary in order to accurately measure the required amount of air. This amount is calculated in the sensor itself and then sent to the ECU, where, based on these data, the required amount of fuel will be calculated.

The more the driver presses the accelerator pedal, the more air enters the combustion chambers. The sensor records the amount and sends a special command to the ECU to increase the volume of injected fuel. If the car is to run or drive more smoothly, then a small amount of air will be needed.

This is why you need a mass air flow sensor. It measures the required volumes of air for engine operation with maximum accuracy.

Checking the air flow meter

One way to check the air flow sensor

There are several ways to detect a malfunction of this sensor. The easiest way is to disconnect the power supply from the sensor while the engine is running. After the chip is turned off, the control unit goes into emergency mode, in which fuel dosage is carried out according to the readings of the throttle position sensor. In this case, the idle speed will begin to increase to over 1500 revolutions, although not always; some injection systems do not increase the speed.

With the flow meter turned off, you need to drive the car. If the performance of the power plant has improved, most likely there are problems with the mass air flow sensor.

Video: Demonstration of a faulty mass air flow sensor on Kalina, Priora, Grant, VAZ 2110-2112, 2114-2115

Some sensors can be checked using a voltmeter or multimeter with high precision settings. The measuring device is connected with a “positive” probe to the MAF signal wire (usually the far right wire), and with a “negative” probe - to the ground wire of the sensor. Then you need to turn on the ignition, but do not start the power plant. A working sensor should have a voltage between 0.9 and 1.4 V. The readings above indicate a sensor malfunction.

Very often the failure is caused by contamination of the working elements of the sensor. Therefore, a visual inspection can also indicate a malfunction.

If the working elements of the sensor are noticeably heavily soiled, this is most likely the cause of problems with the operation of the power plant. But restoration work can be done with sensors based on a pitot tube. They can be removed from dirt by washing with a carburetor cleaning spray.

Symptoms of a problem

The mass air flow sensor is located in the air duct near the air filter. It is designed to determine the amount of incoming air. Depending on its readings, the control unit will show how much fuel is needed to form a high-quality fuel mixture. The normal ratio is 1:14. Therefore, the quality of the fuel-air mixture depends on the correct readings of the flow meter.

The high-quality operation of the mass air flow sensor depends largely on the cleanliness of the air filter. Therefore, if symptoms of a malfunction of the mass air flow sensor appear, you should first check the air filter before making repairs. The flow meter is usually beyond repair. If it is faulty, it is replaced with a new device. But its cost is quite high, so you should first make sure that the causes of the problems are in the sensor and not in other malfunctions of the machine.

The signal for diagnosis is the following symptoms of a malfunction of the mass air flow sensor:

- Check Engine appears on the instrument panel;

- an error is displayed indicating a low level of the mass air flow sensor signal;

- the engine is bad, accelerates very slowly, stalls, its power drops;

- high level of fuel consumption;

- the engine is unstable at idle;

- the engine stalls when changing gears;

- The rpms are either high or low.

There are other symptoms of a “dying” sensor. For example, it may have cracks in the corrugated hose that connects the throttle body to the sensor. If the engine stalls, there may be a power problem or damaged wiring. This is a signal to check the electrical wiring. If malfunctions are detected, the machine's electrical system must be repaired.

In addition to the above possible signs of failure of the mass air flow sensor, you should diagnose the sensor signal level.

A low signal level may mean the following:

- Mass air flow sensor is not connected;

Disconnected sensor connector - open circuit in the sensor connection circuit;

- the mass in the chain breaks, oxidation appears;

- signal wires are broken or incorrectly connected;

- Engine control unit malfunction.

You should not draw conclusions about a malfunction of the mass air flow sensor, relying only on the symptoms listed above. A complete diagnosis of the engine and machine should be carried out, since signs of a flow meter failure may appear if other devices malfunction (for example, due to a clogged air filter). Then you need to repair these devices to restore the car's functionality.

DMRV error code

The following errors may indicate a malfunction in the operation of the mass air flow sensor:

- P0100 - damage to the electrical circuit connecting the sensor. To eliminate the breakdown, you need to check the wiring for integrity, since accidental disconnection of the connector or damage to the electrical contacts is possible.

- P0102 - the vehicle control unit began to receive a low signal, which was recorded at the input of the mass air flow sensor power line. To eliminate the cause of the breakdown, it is necessary to check the electrical wiring and the insulating layer of the cable; oxidation of the contacts of the wiring connector (the so-called chips) is possible.

- P0103 - critically high signal detected at the input of the mass air flow sensor power line. If the cause of the malfunction is not the wiring, then a visual inspection and cleaning of the flow meter will be required or it will have to be replaced with a new one.

When you need to change the DFID sensor 2110: symptoms of sensor malfunction and check

During the operation of a vehicle, the mass air flow sensor 2110 can fail for various reasons, one of which is the long period of use of the device. When a sensor fails, it is usually not repaired; it is simply replaced with a new one. The following symptoms may indicate that the sensor is not working properly:

- “Check Engine” lights up on the car’s dashboard (you need to check the engine);

- fuel consumption increased, acceleration dynamics decreased;

- the car engine does not start;

- at idle, the car’s internal combustion engine operates jerkily (change in idle speed down or up).

All of the listed signs of sensor malfunction indicate that air is not being supplied to the mixture in the volume required. Taking into account the fact that this problem may be associated not only with a malfunction of the mass air flow sensor, before proceeding with dismantling the sensor, it is necessary to make sure that it is faulty.

In fact, the VAZ 2110 mass air flow sensor can be checked for performance using three methods: in motion, with a multimeter, visually. Checking the mass air flow sensor 2110 experimentally (in motion) is the easiest and fastest way. It consists of analyzing the operation of the vehicle’s internal combustion engine when the sensor is forcibly turned off.

Algorithm of actions:

opening the hood, disconnect the mass air flow sensor connector; start the car engine; since the car will operate in emergency mode, the “Check Engine” light will come on and the amount of air in the fuel mixture will be determined depending on the throttle position; Having driven a car operating in emergency mode, you need to pay attention to its dynamics and compare them with the dynamics before the sensor was turned off; If the car accelerates faster with the sensor turned off, the air flow sensor is faulty.

The next stage of diagnosis may be checking the mass air flow sensor 2110 with a multimeter. This method of checking the sensor for functionality involves the use of a measuring device (multimeter).

Before checking, you need to understand the design of the device and find out its “pinout” (soldering of wires on the board). There are four wires coming out of the MAF. Typically these are the wire to the main relay (pink/black or pink), ground (green), power (gray), and signal input (yellow).

To check you need:

- set the multimeter to constant voltage measurement mode, setting the limit to 2 Volts;

- without starting the engine, turn on the ignition;

- connect the black multimeter probe to the ground wire, the red one to the signal input of the multimeter sensor, inserting the multimeter probes through the rubber seal of the connector;

- take measurements and use the results to determine the state of the sensor.

Based on multimeter readings:

- voltage 0.996-1.01 Volts (new sensor);

- voltage 1.01-1.02 Volts (working sensor in good condition);

- voltage 1.02-1.03 Volts (sensor working, with long-term operation);

- voltage 1.03-1.05 Volts (sensor is worn out and may fail);

- voltage from 1.05 Volts and above (the sensor is faulty and requires replacement).

If the device is not at hand, the faulty sensor can often be determined by its appearance, that is, by visual inspection. In this case, it is necessary to dismantle the device and carefully inspect it for mechanical damage or for the presence of liquid in the sensor and air pipe.

The reasons for liquid and dirt getting into the sensor can be different (for example, the oil level in the crankcase is increased, dust gets on the hot-wire anemometer due to untimely replacement of the air filter, the oil sump of the crankcase ventilation system is clogged, etc.).

External signs of a malfunction of the VAZ 2110 mass air flow sensor

This is the third way to diagnose the sensor. To determine its serviceability, carefully inspect the internal cavities of the air pipe where the mass air flow sensor is mounted. In order to do this, you will need a shaped screwdriver. Loosen the clamp and disconnect the corrugated pipe. The surface of the corrugation should be as dry as possible, without an oil film.

It should be noted that the main signs of a malfunction of the mass air flow sensor are dirt on the working surface. It is formed due to the fact that the air filter was not replaced in time. Oil deposits will tell the driver that the oil level in the lubrication system is high or that the oil cutter is not working properly. With these signs, the sensor may still work, but will soon fail.

Next you need to completely remove the mass air flow sensor. You will find signs of a malfunction after a visual inspection of the device. To carry out this operation you will need a 10 key.

Unscrew the two screws and remove the device from the air filter housing. A rubber seal will come out with the sensor. If the seal remains in the housing, this is the main sign of imminent failure.

System depressurization

If depressurization occurs in the intake tract system, then instability in engine operation occurs. Air leaks occur in the following parts of the car:

- In sealed areas of the nozzle;

- On exhaust systems for gasoline vapors;

- On the walls of the throttle frame;

- On idle jets;

- On the vacuum brake booster pipes;

- On the cleaning pipes.

Due to improper air removal, improper mixing of fuel masses occurs. Emergency symptoms are detected during the operation of the intake tract. The air leaving the system does not pass through the filtration system. It contains many harmful particles of dirt, metal, and plastic, which enter the engine and threaten to lead to poor performance of the latter.

What is the difference between sensors 037 and 116?

How can the regulators of these models differ from each other and is it possible to install 116 instead of 037? There are differences between these controllers, and the point is not in the MAF pinout. After all, if these models were the same, what would be the point of giving them different names?

So, how do the controllers differ from each other and is it possible to install model 116 instead of 037:

- The first difference that can be guessed based on the technical characteristics is that the 037 model can produce data with an error during operation. Of course, an error of 2.5% is not critical, but it does exist.

- Device 037 is intended for installation in VAZ 2111, 2112, 2123, 21214 cars, which are equipped with controllers M 1.5.4, January 5.1-5.1.3, etc.

- As for model 116, its use is relevant on Ladas 21114, 21124, 21214. Installation of this device is allowed on Kalina and Priora. Installation of the device is allowed on cars equipped with M 7.9.7 and January 7.2 controllers.

If you encounter a problem with the device not working, then when replacing it you need to install the same model that has already been installed. But it is worth considering that 037 is not a common option like 116, so it is more difficult to find. The latter, in turn, is more common, and its cost is lower.

Replacement is allowed, but experts do not recommend this. This is because these devices differ in their calibration, so in case of replacement, you will have to change the parameters of the control unit. And you can only get into the “brains” of a car if you understand what needs to be done and have minimal experience.

Loading …

Characteristic

On VAZ cars, the mass air flow sensor is mounted between the air filter element and the throttle hose. Today, products from the manufacturer Bosch are very popular among compatriots. Regardless of whether it is a universal Bosch sensor or, for example, spark plugs, quality from a German manufacturer can always give a head start to domestic products. Let's look at the main characteristics of regulators models 116 and 037.

116

DMRV 116 is designed to control and convert the air flow that enters the motor into voltage. The data transmitted by the regulator makes it possible to determine the operating mode of the power unit and calculate the cyclic filling of the cylinders with air flow. This filling is carried out in steady-state operating modes of the motor, which last no more than 0.1 seconds.

Let's look at the technical features that Bosch 0 280 218 116 has:

- the regulator operates on the principle of measuring air flow;

- the device provides accurate data, which ensures optimal fuel consumption;

- operating range varies from 8 to 550 kg/h;

- the output pulse level when measuring the range from 0 to 100% will be about 0.05-5 volts;

- As for power supply, the controller is powered from the vehicle’s electrical network, that is, 12 volts is enough for it;

- current consumption is about 0.5 ampere;

- the regulator can function normally in the operating range from 45 degrees below zero to 120 degrees;

- The service life of the Bosch 116 mass air flow sensor is about 3 thousand hours.

Bosch 116 device

037

As for the mass air flow sensor 037 from Bosch, the technical features will be similar. The controller consists of two main elements - working and control, as well as a heating resistor device. The air that enters the engine cools one of the controllers, while the electronic module converts the temperature differences between the controllers. In the event that sensor 280 218 037 fails, its options will be performed by TPS.

As mentioned above, the technical features of the models are the same:

- the operating range for normal operation varies in the region of 8-550 kg/h;

- when operating correctly, the controller will provide accurate data, making it possible to achieve optimal gas mileage (of course, if the engine is running in normal mode);

- since the element is used in a car, it is logical that it should be powered by 12 volts;

- the controller consumes about 0.5 ampere of current;

- the part can operate normally both at 45 degrees below zero and at 120 degrees of heat, this is its operating range;

- service life is at least 3 thousand hours;

- unlike model 116, the new mass air flow sensor 037 during calculations can produce an error of 2.5 percent (both downward and upward).

Regulator model 0280218037

Signs of a malfunction of the mass air flow sensor on a VAZ 2110: how to rinse and clean it yourself

When the first signs of a malfunction occur, you should definitely check the mass air flow sensor, and then, depending on the situation, clean or replace the device.

Now let's talk about how to check our sensor. Today, two main methods of checking the mass air flow sensor are used.

- The engine is tested in operation with the mass air flow sensor disconnected. Simply turn off the power from the regulator and start the motor. When the mass air flow sensor is not present during startup, the electronic control unit turns on the power unit in emergency mode. The speed is adjusted to 1500 rpm. After disconnecting the sensor, drive a few kilometers and evaluate the dynamics and power. If the engine is running normally, then the sensor is the cause of the symptoms.

- The second method will require the use of a car tester or voltmeter. After starting the ignition, do not start the engine. The voltage threshold is set on the tester to 2V. The positive probe connects to the yellow wire on the sensor connector, and the black probe connects to the green wire. Next, refer to the table.

Index

Air flow sensor condition

The sensor is functioning normally

Not ideal, but still acceptable voltage readings

Maximum permissible values that indicate imminent sensor failure

The air flow sensor has failed and needs to be replaced

Quite often you can avoid replacing the mass air flow sensor by simply cleaning this engine element.

You should do the cleaning yourself in this way:

- Remove the pipe from the mass air flow sensor;

- Now remove the sensor from the pipe. Otherwise, high-quality washing will not work;

- To remove the sensor, arm yourself with sprocket keys in advance. Finding such kits is not a problem;

- Unscrew all the fasteners, remove the sensor from the pipe and assess its external condition;

- Often there are traces of oil deposits on the sensor. The purpose of cleaning is to make the device as good as new;

- Carburetor cleaner is often used to clean the air flow sensor;

- Inside the film there are sensors, which are small wires attached to a special resin. These elements must be carefully sprayed with cleaner so as not to damage the devices;

- Wait a while for the surfaces to dry. To speed up the process, use a can of compressed air;

- It is not uncommon to use alcohol instead of carburetor cleaner, which also works quite effectively;

- Proper cleaning of the mass air flow sensor involves treating the pipes from accumulated debris, dirt and dust;

- Having carefully processed all the components of the removed mass air flow sensor, wait until it dries, and then reassemble it. Cleaning is complete.

Spray cleaning

Statistics show that in about 80% of cases, simple cleaning can return the mass air flow sensor to its previous functionality.

Price issue

80% is not 100. Therefore, sometimes you have to change the sensor. And to replace it, you need to buy it.

There are three price categories for air mass flow sensors:

- Cheap. These are predominantly Chinese products, the price of which is up to 1000 rubles. It is strongly not recommended to purchase such regulators;

- Average. These include sensors from AvtoVAZ, domestic and some foreign analogues. These cost from 1500 to 2500 rubles;

- Expensive. High-quality, reliable, imported air flow sensors, the price of which can reach 5.5 thousand rubles. It’s hard to say how rational it is to buy them. But they will definitely last a long time.

It is not difficult to replace the mass air flow sensor with your own hands, even if you do not have any special skills in car repair. Having checked the condition of the device and determined that cleaning will not help, all that remains is to replace it.

- Place the car on a level surface, lift the hood and remove the negative terminal from the battery.

- Disconnect the sensor connector. We have already talked about its location, so there will be no problems with the search.

- Using a screwdriver, remove the clamping bolt of the clamp that secures the corrugation to the mass air flow sensor.

- The corrugation is removed.

- Using a 10mm wrench, unscrew the two bolts that hold the sensor to the air filter housing.

- After removing the failed oxygen sensor, install a new regulator in its place.

- Screw back a couple of bolts, secure the corrugation and secure it with a clamp.

- Reconnect the connector and return the negative terminal to the battery.

If everything is done correctly and the breakdown is correctly identified, then the engine will return to its previous performance and the error signal on the dashboard will disappear.

Replacing the device

To finally check the result of the repair, go out onto the road, do a test drive and be sure to try to press the gas pedal sharply. If the dynamics and power become the same as before the problems arose, you did everything correctly, and it was the mass air flow sensor that was the culprit of the malfunction.

Characteristics and features of the mass air flow sensor on the VAZ twelfth model

A mass air flow sensor or mass air flow sensor is a device whose purpose is to estimate the volume of air flow entering the car’s engine. This controller is one of the main devices of the electronic powertrain control system. Failure of the mass air flow sensor will lead to unstable engine operation.

As for the location, this device is located behind the air filter element housing. To find the device, open the hood of the car and find the air filter housing, right behind it there is a mass air flow sensor. Operating a car with a faulty controller can be difficult or impossible (video author: Sergey Marunchenko).

How to check the DMRV on a VAZ 2110

Disconnect the sensor connector. Start the engine. Increase engine speed to 1500 rpm or more. Start moving. If you feel the car “swiftly”, this means that the mass air flow sensor is faulty and needs to be replaced with a new one. This is the first check option. If the mass air flow sensor is disabled, the controller goes into emergency mode, so the mixture is prepared only according to the throttle valve.

Turn the tester into DC voltage measurement mode, set the measurement limit to 2 V. The second option for checking the mass air flow sensor. Measure the voltage between the yellow “output” wire (closest to the windshield) and the green “ground” wire (3rd from the same edge), located in the sensor connector. Colors may vary depending on the year of production, but the layout remains the same. Turn on the ignition, but do not start the engine. Use the tester's probes to penetrate through the rubber seals of the connector, along these wires, and reach the contacts themselves without breaking the insulation. Connect the tester and take readings. These parameters can also be removed from the on-board computer display, if available. They are in the group of “voltage from sensors” values and are designated U dmrv.

Evaluate the results. At the output of a working sensor, the voltage should be 0.996-1.01 V. During operation, it gradually changes upward. Using this parameter, you can determine the degree of “wear” of the sensor. For example: 1.01-1.02 V – the sensor is working, 1.02-1.03 V – the sensor is working, but is already “planted”, 1.03-1.04 V – it will soon need to be replaced, 1.04-1.05 V – it’s time to change it, 1.05 V and above – operation is impossible, mandatory replacement.

Inspect the sensor when readings are abnormal. Take a shaped screwdriver and unscrew the clamp of the rubber corrugation of the air inlet, which is located at its outlet. Remove the corrugation and carefully inspect its internal surfaces and the sensor. They should be free of condensation and oil. This is the most common cause of damage to the air flow sensor. If they are, it means the oil level in the crankcase is too high and the crankcase ventilation oil trap is clogged. Before replacing the sensor with a new one. The problem must be corrected.

Checking the air sensor yourself

When a malfunction of the mass air flow sensor occurs, the air-fuel mixture becomes over-rich or lean, which immediately affects the operation of the engine and may ultimately result in engine failure.

Symptoms of a malfunctioning mass air flow sensor:

- Check Engine error appears;

- Increased fuel consumption;

- Doesn't start well when hot;

- The car began to accelerate slowly;

- Engine power lost.

The easiest way to check the mass air flow sensor on a VAZ 2114 is to disconnect the plug. If there is no signal, the engine control unit goes into emergency operation mode, determining the approximate air volume based on the throttle position. At the same time, fuel consumption increases slightly - for the VAZ 2114 it reaches 10-12 liters per 100 km. A characteristic feature is the increase in idle speed to 1500 rpm. But when using a January 7.2 or Bosch M7.9.7 controller, the idle speed does not increase due to the software features.

The normal voltage at the output of the new sensor is 0.996 - 1.01 Volts. During operation, it gradually changes and, as a rule, increases. The greater the value of this voltage, the greater the wear of the mass air flow sensor.

Here is the reference voltage in volts:

- 1.01 - 1.02 - good condition of the sensor.

- 1.02 - 1.03 - not a bad condition.

- 1.03 - 1.04 - the resource of the mass flow sensor is coming to an end.

- 1.04 - 1.05 - emergency condition.

- 1.05 and above - it’s time to replace the mass air flow sensor.

The measurement is made between the yellow and green wires. Voltage values can be displayed on the screen of some on-board computers (menu voltage from sensors, U Mass air flow sensor).

Important: the limits and fluctuations of the output voltage in at least 30% of cases for a faulty sensor will be NORMAL and will not cause the “Check” icon on the panel. That is, voltage measurements are not very informative, but the rate that it will produce in kilograms of air will correspond to the movement not where it actually is, and the ECU will interfere with the mixture based on it - hence the extra consumption!

You need to check the sensor at a service center, preferably with a proprietary scanner, which itself indicates by blinking if there is a imbalance in some parameter (in this case, air flow in kilograms), comparing it with the reference values stored in its memory.

Features, diagnostics and replacement of elements of injection systems on VAZ cars

Below we will look at the main controllers!

Hall

There are several options for how you can check the Hall sensor of a VAZ:

- Use a known working device for diagnostics and install it instead of the standard one. If after replacement the problems in engine operation cease, this indicates a malfunction of the regulator.

- Using a tester, diagnose the controller voltage at its terminals. During normal operation of the device, the voltage should be from 0.4 to 11 volts.

The replacement procedure is performed as follows (the process is described using the example of model 2107):

- First, the switchgear is dismantled and its cover is unscrewed.

- Then the slider is dismantled; to do this, you need to pull it up a little.

- Remove the cover and unscrew the bolt that secures the plug.

- You will also need to unscrew the bolts that secure the controller plate. After this, the screws that secure the vacuum corrector are unscrewed.

- Next, the retaining ring is dismantled and the rod is removed along with the corrector itself.

- To disconnect the wires, you will need to move the clamps apart.

- The support plate is pulled out, after which several bolts are unscrewed and the manufacturer dismantles the controller. A new controller is being installed, assembly is carried out in the reverse order (the author of the video is Andrey Gryaznov).

Speeds

The following symptoms may indicate a failure of this regulator:

- at idle, the speed of the power unit floats, if the driver does not press on the gas, this can lead to an arbitrary shutdown of the engine;

- the speedometer needle readings float, the device may not work as a whole;

- fuel consumption has increased;

- the power of the power unit has decreased.

The controller itself is located on the gearbox. To replace it, you only need to jack up the wheel, disconnect the power wires and remove the regulator.

Fuel level

The VAZ or FLS fuel level sensor is used to indicate the remaining volume of gasoline in the fuel tank. Moreover, the fuel level sensor itself is installed in the same housing with the fuel pump. If it malfunctions, the readings on the dashboard may be inaccurate.

The replacement is done like this (using the example of model 2110):

- The battery is disconnected and the rear seat of the car is removed. Using a Phillips screwdriver, unscrew the bolts that secure the fuel pump hatch and remove the cover.

- After this, all wires leading to it are disconnected from the connector. It is also necessary to disconnect all the pipes that are supplied to the fuel pump.

- Then the nuts securing the clamping ring are unscrewed. If the nuts are rusty, treat them with WD-40 before unscrewing.

- Having done this, unscrew the bolts that directly secure the fuel level sensor itself. The guides are pulled out from the pump casing, and the fasteners need to be bent with a screwdriver.

- At the final stage, the cover is dismantled, after which you will be able to gain access to the FLS. The controller is replaced, the pump and other elements are assembled in the reverse order of removal.

Idle move

If the idle speed sensor on a VAZ fails, this is fraught with the following problems:

- floating speed, in particular, when additional voltage consumers are turned on - optics, heater, audio system, etc.;

- the engine will start to stall;

- when the central gear is activated, the engine may stall;

- in some cases, failure of the IAC can lead to body vibrations;

- the appearance of a Check indicator on the dashboard, but it does not light up in all cases.