Preparing j7esa firmware for online configuration

In this article I will tell you how to roll back the firmware yourself, how and what to use.

First, let's think about what we need for this. Necessary equipment: 1. Laptop (I use a small Asus netbook) 2 K-line adapter. (I wrote about them in this article) Programs: 1. ChipTunerPro v3.21 You can find it on the Internet. Moreover, I draw your attention to the fact that it is version 3.21. You don’t even have to download any other versions. 2. Programs for reloading the firmware (I wrote about this here) 3. Logger I recommend my Atomic tune program, but in principle you can use the icd program (it’s not difficult to find on the Internet)

Requirements for the car: The car must be in working order and have an Oxygen Sensor (OS) or you must have an Oxygen Sensor. I wrote about him here

Article on the topic: How to install a car antenna

What exactly will we configure? By and large, we need to adjust the parameters that affect the composition of the mixture so that the composition is always optimal. This will allow you to efficiently and economically consume gasoline, creating effective power or efficiency when needed. You can also adjust parameters related to the ignition timing so that the mixture burns on time and efficiently. You can also adjust the injection phase, idle speed, etc. and so on. I want to focus on adjusting the composition of the mixture. For example, I use one of the old firmware j5ls n35 What needs to be prepared for rollback: 1. Composition of the mixture The firmware has such a table. It determines the composition of the mixture at operating conditions.

Considering that we will roll back according to the standard recreation center, the mixture composition must be set everywhere to 14.7 As we remember, this is the ratio in which the standard recreation center works. Those. when the mixture is richer, he simply tells his brain - Richer. when poorer - POORER. Those. Our task is to roll back the firmware on this composition so that the DC always says - 14.7 Therefore, we put all the points in this table at 14.7

By the way, some more nuances. The firmware is designed in such a way that the mixture will never be richer than indicated in the table Basic mixture composition

and poorer than the table Mixture composition depending on temperature

2. It is necessary to turn on a constant fuel supply to eliminate the IAC mode. This is done in the equipment section. Check the box “Sign of constant fuel supply”

Article on the topic: Detonation when pressing the gas sharply

3. Go to the section dedicated to lambda regulation and set the learning gradient to 255

In principle, it can be put into one. You can read about what a gradient is in the help for the CTP program. We also change the number of cycles for training to 3-4

Next, we must set the limit of the lambda regulation mode. Those. make sure that the DC always works and regulates the mixture. This is how it is done.

4. If the firmware is not standard, then we check the adequacy of the injector statics. If the injectors are not standard or there are doubts, then enter your data. You can calculate the statics here

5. Go to the operating modes section and set the Cycle Filling Correction to 1. This is done only once before the first rollback

All. Now you can roll back the firmware according to the mixture (Amendments and BCN tables). Save the firmware, upload it to the block, clean the firmware and start rolling back in the car. The next article will be devoted to exactly this

IMPORTANT INFORMATION (FAQ): 1. Why do you need a recreation center? The DC is a source of information on how correctly the mixture burns. This is what the firmware setup itself is based on. If there is no DC, then there is no feedback from this sensor and the mixture cannot be adjusted. 2. What is BCN? The BCN table stands for Basic Cycle Filling. During normal driving, air flow parameters are sent to the ECU from the mass air flow sensor. there they are analyzed, calculated and, in accordance with all this, the computer calculates the gasoline injection time. But in the sharp acceleration mode, when there is a sharp jump in the throttle, a sharp drop in air, the DMRv cannot evaluate it correctly and then, instead of the sensor, data on air flow is taken from this table. 3. What is the CN Amendment? The mass air flow sensor counts the air that passes through it. But it turns out that not all the air that passed through it gets into the engine. This is due to the peculiarity of the engine itself, the intake and exhaust manifold. This manifests itself differently in different modes. Therefore, we came up with a table so that, at any engine mode, this measured air is multiplied with a certain coefficient. and the resulting air flow coincided with the real one. Therefore, having data from the DC - knowing that the mixture should be 14.7, knowing the air flow from the mass air flow sensor, knowing the data from the correction table, you can quite accurately adjust this table using different programs.

Article on the topic: The heater in the car blows cold air reasons

Rolling back firmware from logs

AutoSoftos.com Literature on car repair, Programs for car diagnostics

Always fresh software and automotive literature

- Dollar – 56.95

- Euro — 69.55

- Posted by: klays067;

- Read: 16,239;

- Date: 20-12-2016, 14:00;

Stage 1. Preparation of all necessary programs for chip tuning

List of programs that we will need to roll back the firmware:

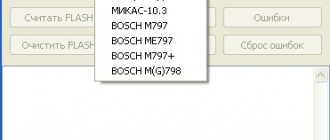

1) Combiloader 2.1.8 - flasher program, will flash the ECU. (Download)

2) Chip Tunning Pro version 3.21 - a program for editing the firmware file.

3) Enigma New (Download) - the program will be needed to unpack the compressed firmware. The fact is that after editing the firmware in the Chip Tunning Pro program, the firmware begins to weigh not 64 kb as expected, but 42 kb. This program unpacks the firmware into a standard size - 64kb. Before flashing, it is better to unpack the firmware. Although I tried to flash 42 kb firmware, everything went well, the car even started after that.

4) Atomic Tune - a program for rolling back the most important calibrations - the control center and monitoring station. Able to diagnose, show detonation, injector loading. Writes logs in ICD format, which will be useful to us for adjusting the injection phase. Can work on both January 5.1 and January 7.2, both on a standard oxygen sensor and on the ShDC.

5) FunTune (Download) - the same program for rolling back the most important calibrations - the control center and monitoring station. But unlike Atomic Tune, it can continue training sessions, but requires special cards to work with the firmware file. Cards for j7es.v17.3_dmrv firmware are available out of the box. Also knows how to write logs in ICD and EcuEdit format. I made several maps for different firmwares, the maps are located in the program folder in the maps folder. The program works only with UDC, on control units January 5.1, January 7.2.

6) OpenOLT - diagnostic program and ONLINE SETTINGS (separately some important calibrations) of the j7es/j7esa sports firmware for the NON-ENGINEERING block January 7.2 (i.e. the most ordinary ECU that cannot be configured online). Other firmware can be configured online only using the engineering unit. You can build the BCN (basic cyclic filling) and the monitoring station (correction of the cyclic filling) online with the ShDC. Works with pressure, you can adjust the turbo.

Firmware J5LS_V43B and everything connected with it.

- Log in to reply to this topic

#81 CAT

- Super moderator

- Messages: 2,280

- Car: passat 35i 1.8 RF 16v injectionj5.1

- Petersburg city

- Top

#82 passat

- Car: Passat B3, “Digital Elephant”, 1.8, PB

- Mordor City

It's a joke ? Or is there another name? Saransk for example?

- Top

#83 IIIIIIAIIIA

- Car: VW Passat B3 9A, automatic transmission 096, January 5.1

- Karaganda city

How should he share? If you have 9A, then the volume is about 2000 cubic meters, for 2112 it’s about 1600. The injectors are different, therefore their performance is different. One has a mass air flow sensor, the other has it assembled on a DAD. The threshold of the knock sensor is different and other calibrations. RSXX in different sizes 8 and 10mm. etc.. In short, there will be a lot of errors and an inadequate mixture for the engine. If only you first calculate the mixture, taking into account the volume of the cylinder and the performance of the injectors and injector components, in order to start and drive. As practice has shown, the motor does not work stably even with preliminary firmware, although everything was calculated. Lex had to remove the cylinder head, after 20 hours of engine operation, without going anywhere (without loads), so there were already traces of poor-quality combustion (coke) on the valves and combustion chamber. This is an inadequate mixture.

- Top

#84 CAT

Article on the topic: Why music stutters in the car

- Car: passat 35i 1.8 RF 16v injectionj5.1

- Petersburg city

- Top

#85 phant0m

- Car: Mitsubishi Outlander XL 3.0 V6

- City of Saint Petersburg

- Top

#86 CAT

- Car: passat 35i 1.8 RF 16v injectionj5.1

- Petersburg city

- Top

#87 IIIIIIAIIIA

- Car: VW Passat B3 9A, automatic transmission 096, January 5.1

- Karaganda city

- Top

#88 IIIIIIAIIIA

- Car: VW Passat B3 9A, automatic transmission 096, January 5.1

- Karaganda city

- Top

#89 CAT

- Car: passat 35i 1.8 RF 16v injectionj5.1

- Petersburg city

IIAIIAIIIA, on stock DD the operating frequency is different.

What is the productivity of the “deck” injectors? No matter how much I searched, I never found any data. But I bought BOSH ones from Volga for 210cc.

With your design of the throttle assembly, calibration of the TPS is necessary. As far as I remember this is done programmatically.

- Top

#90 IIIIIIAIIIA

- Car: VW Passat B3 9A, automatic transmission 096, January 5.1

- Karaganda city

- Top

#91 IIIIIIAIIIA

- Car: VW Passat B3 9A, automatic transmission 096, January 5.1

- Karaganda city

- Top

#92 CAT

- Car: passat 35i 1.8 RF 16v injectionj5.1

- Petersburg city

Article on the topic: Painting alloy wheels with liquid rubber

Then “Siemens Deca doesn’t roll at all!

DEKA 1D ZMZ 6354 Siemens performance 192cc

Siemens DEKA-1A ZMZ 155.4 grams /min

I used them on PF 1.8 for Digiphant. My golf2 with a PF engine was from the Volga, but a BOSCH with a capacity of 210cc.

- Top

#93 phant0m

- Car: Mitsubishi Outlander XL 3.0 V6

- City of Saint Petersburg

- Top

#94 CAT

- Car: passat 35i 1.8 RF 16v injectionj5.1

- Petersburg city

- Top

#95 miker

- Car: Passat

- City SPb

- Top

And so, in the corresponding forum thread we talked about a possible firmware update for the stock Vesta I765BH03. Not everything is as rosy as we would like! From observations, old versions of firmware, without any modifications, give pretty good results! Reviews confirm this!

Not all reviews come to the site, and everyone has their own reasons, however, the main one is clear to us! Since everyone is silent, it means everyone is happy with everything! Not about that at the moment...

And so, the main wish was “to do it even better”! We began to look for opportunities to implement this request, which was received through personal communication with car owners! And then new opportunities opened up for us! However, these opportunities do not take root in the mass flow!

I'll try to put it in order:

The first step, as you know, is to bring the Desired composition to the Current one. And here is the catch... As practice shows, under absolutely identical conditions, different cars with the same engine (serviceable, respectively), the actual composition of the mixture differs from the desired one, while the mixture was rolled out to full compliance on the tested car! There are various reasons for this, such as the fit of the valves, the condition of the springs, etc. and so on. This dispersion in engines was presented to us from the master’s shoulder by a VAZ car...

Based on this, we always get different characteristics (torque, consumption) and, accordingly, efficiency! Therefore, it turns out that with ideal performance on the tested car, some incidents appear on another car... Yes, undoubtedly, with an individual approach, it is possible to achieve very good results: this is acceleration, and maximum speed, and consumption, and smoothness... But when installed on similar car, this effect is not as pronounced as on the original one!

I’ll try to explain how the process of customizing the firmware for a specific car took place...

There is a phrase among tuners - “If you want to make a stock firmware, first make a non-standard firmware.” And here new doors open for us...

We did the firmware for Vesta 1.6, standard receiver, Bosch 107 injectors, USA 8.6 phase 272 shafts, spider exhaust with thermal tape, resonator - Granta Sport, rear bank - Fiat...

This screenshot shows the engine filling characteristics.

This Vesta was tuned in different configurations... Initially, the setup took place on the same shafts and exhaust, only with a 1.8 XRay receiver and standard injectors...

This screenshot shows the characteristics of the fillings with the XRay receiver.

For the 1.6 engine, I will still give preference to the standard receiver from the 127 engine.

Next... As everyone has long known, the first stage of setting up the firmware is rolling back the mixture composition... There are some difficulties with this, but everything can be solved. I repeat that the consistency of the mixture composition is a fundamental factor in the correct construction of volumetric efficiency (VE), from which the efficiency of the UOP follows...

From my experience, the optimally effective OZ is much below the detonation threshold.

Let me explain. The optimally effective SOP is not the Optimal SOP that is in the calibrations, but the ignition angle at which the engine spins up with maximum acceleration . Acceleration was recorded using an oscilloscope, followed by analysis of measurements and calculations of crankshaft acceleration with knock control disabled . There was no detonation in any of the modes of constructing the SPD, there were no variations. Although, the angle was changed until the optimal acceleration was found, within 1.50. But when analyzing the acceleration graphs, it was clear where the maximum possible acceleration of the crankshaft was. Further, the adjustment for speed and load was within the limits of the minimum realized OZ at the software level.

To realize the possibility of calculating an accurate analysis of HF acceleration, we contacted the technical support of the oscilloscope software manufacturer. To which the software author responded with understanding and a positive solution to the issue. However, this software is not freely available. The reasons for this are unknown to me...

Below is a screenshot of the HF acceleration analyses. As a result, the optimal OZ was worn. It is indicated in red. The only reason for the change in weather conditions is a drop in acceleration at high speeds. (Rain is coming)

Ultimately, after turning on the detonation channel, the detonation damping system falsely reduced the angle by a significant amount (within 60 - 90), which affected the dynamics of the car. If suddenly the question arises of how we made this conclusion, I will hasten to explain: The actual angle in the scanner is reflected as the desired one from the calibrations, but in fact it turned out that the real angle shifts by the amount recorded by the detonation rebound system. This was confirmed by analyzing oscillograms and calculating crankshaft acceleration.

Screenshot from a scanner.

Screenshot from an oscilloscope . The results of the scanner and oscilloscope are completely in test mode, synchronized!

Ultimately, we were able to calculate the false, problem areas of the detonation damping system, which were disrupted during the construction of volumetric efficiency... As a result, we synchronized both devices again and checked the adequacy of the readings. As you can see, there are NO corrections for detonation and the scanner readings and the oscilloscope readings are identical!

I am attaching screenshots from both devices.

Next on calibration.

Those problems with the behavior of the throttle valve that were highlighted earlier were resolved a year ago and confirmed by numerous checks in both standard and non-standard configurations. This included tuning engines with modified volumes, up to 1.9 liters.

On the Internet, there is an opinion, even to the point of belief, that the flow characteristic of the throttle corresponds to the mass air flow of the engine, which is fundamentally wrong for the mat. model implemented in this controller and similar modifications.

Here, for example, is the flow characteristic of the throttle of a tuned car described in this article.

If you look closely, that is, in calibration there are practically unattainable kg of air in essence... But at the same time, the throttle opens and responds to the pedal request, quite adequately!

As a result of the above, I consider it necessary to emphasize that with any variation in the hardware of a standard engine, and even more so a fundamental change when building a non-standard engine, the process of setting up the firmware requires an individual approach to obtain the most positive result.

P/S: With adequate handling and the availability of the necessary equipment, the ability to customize the car to individual requirements is guaranteed, again, based on the tools available on hand: