The mass air flow sensor (MAF or MAF) is one of the key components of the electronic fuel injection system in a car. It is installed between the air filter and the engine intake manifold. The mass air flow sensor measures the amount of air entering the engine, or air flow.

In modern cars, the intake air temperature or IAT sensor is built into the MAF. There are several types of air flow sensors, but modern cars use a sensor with thermal resistance. Let's see how it works.

How does the mass air flow sensor work?

The mass air flow sensor has a small wire that is electrically heated (thermal resistance). A temperature sensor is installed next to the measuring element, which measures the air temperature near the thermal resistance.

When the engine is idling, a small amount of air passes through the sensing element, so a very low electrical current is required to maintain the temperature of the RTD.

When you step on the gas, the throttle opens, allowing more air to pass through the sensing element. The passing air cools the thermal resistance.

The more air that passes through the wire, the more electrical current is needed to keep it hot. The amount of current is proportional to the air flow.

A small electronic chip installed inside the mass air flow sensor converts the electrical current into a digital signal and sends it to the engine control unit (ECU).

The controller uses the airflow signal to calculate the amount of fuel to inject. The goal is to keep the air/fuel ratio at an optimal level.

In addition, the ECU uses air flow readings to determine automatic transmission shift timing. If the mass air flow sensor is not working properly, the automatic transmission may also shift differently.

Checking and repairing at home

There are eight ways to independently check amplitude and frequency mass flow sensors.

Method No. 1 - disabling the air flow meter

The method consists of disconnecting the sensor from the fuel system of the car and checking the functionality of the system without it. To do this, you need to disconnect the device from the connector and start the engine. Without a mass air flow sensor, the controller receives a signal to switch to emergency operation mode. It prepares the air-fuel mixture only based on the throttle position. If the car moves faster and does not stall, it means that the device is faulty and requires repair or replacement.

Method No. 2 - flashing the electronic control unit

If the standard firmware has been changed, then it is unknown what reaction of the controller is programmed in it in case of an emergency. In this case, you should try to insert a 1mm thick plate under the throttle stop. The turnover should increase. Now you need to pull out the chip from the air flow meter. If the power unit continues to work, then the cause of the malfunction is the firmware.

Method No. 3 - installing a working sensor

Install a known good part and start the engine. If after replacement it begins to work better, the motor does not stall, then replacement or repair of the device is required.

Method No. 4 - visual inspection

To do this, use a Phillips screwdriver to unscrew the clamp holding the air collector corrugation. Then you need to disconnect the corrugation and inspect the internal surfaces of the air collector corrugation and the sensor.

Problems with the mass air flow sensor

Problems with the air flow sensor are common in many vehicles, including BMW, GM, Volkswagen, Mazda, Toyota, Nissan, etc. The sensor element may be dirty or damaged.

For example, in some Mazda Skyactiv engines, a faulty mass airflow sensor can cause the engine to crank but not start.

An incorrectly installed or dirty air filter can lead to faster failure of the air flow sensor. Excessive soaking of the washable air filter can also cause problems with the mass air flow sensor.

What to do if the MAF signal level is high?

In case of this problem, you also need to check the presence of voltage on the power circuit and the quality of the connection of the sensor to ground. The parameter is also diagnosed on the fifth pin of the connector.

The check is done like this:

- The ignition is turned off. You need to disconnect the connector with wires from the device.

- The ignition turns on, the engine does not start.

- Using a multimeter, you can diagnose the voltage on the block. The readings obtained should be the same as when the sensor signal is low.

- Then the resistance is measured; the tester must first be configured in the appropriate mode. The measurement is made between the fifth contact element and ground. If the resulting value is 0 V, then the regulator is faulty and must be replaced. Other parameters will indicate a short circuit of the 4G conductor to the power source.

Symptoms of a bad air flow sensor

A dirty or faulty mass air flow sensor may not measure air flow correctly. This causes the engine computer to incorrectly calculate the amount of fuel injected.

As a result, a bad MAF sensor causes a variety of problems, including no starting, stalling, reduced power, and poor acceleration. Additionally, a faulty mass air flow sensor can cause the Check Engine or Service Engine Soon light to come on.

A problem with the MAF can also change the automatic transmission's shift setting.

When the air flow sensor signal deviates from the expected range, the ECU registers a malfunction and stores the corresponding error code by turning on the Check Engine light on the instrument panel.

This fault code can be obtained using a diagnostic scanner or an ELM327 adapter with Torque software. Typically the following error codes are associated with the mass air flow sensor:

- P0100 - Mass air flow sensor, circuit malfunction;

- P0101 - Mass air flow sensor range/performance;

- P0102 - Mass air flow sensor, low signal level;

- P0103 - Mass air flow sensor, high signal level;

- P0104 - Mass air flow sensor, intermittent signal.

Trouble codes P0171 Too Lean Block 1 and P0174 Too Lean Block 2 are also often caused by a bad or dirty mass air flow sensor.

What is a mass air flow sensor and its purpose

In a car, this controller is a device used to estimate the volume of air that enters the engine. The sensor belongs to the class of regulators of the electronic control mechanism of the power unit. The first thing that the mass air flow sensor affects is the operation of the injection system. The device is designed to determine and regulate the air flow that enters the engine cylinders in order to form a combustible mixture. The controller in a car can be used in conjunction with air pressure and temperature sensors, which are used to change its readings.

How to check the mass air flow sensor

In modern vehicles, the only way to check the MAF sensor is to use a scan tool.

Auto mechanics measure the amount of air (mass air flow sensor readings) at different speeds. They compare the readings to the manufacturer's specifications or to readings from a known-good sensor.

The MAF sensor readings are measured at idle, 1000 rpm, 2000 rpm and 3000 rpm.

A dirty or faulty mass air flow sensor, in most cases, will show lower air flow than a known good one. In some rare cases, a faulty sensor may show higher readings.

Of course, different engines will have different readings. Air consumption depends on engine size, so the readings of a V6 or V8 engine will be higher.

Low MAF readings do not mean the sensor is faulty. A clogged air filter or clogged catalytic converter can also cause low airflow sensor readings.

Air leaks also affect the sensor readings. This is why mechanics use a known good sensor to compare readings.

Is there a way to check the mass air flow sensor readings at home? Of course, for example, here we used the Torque application to measure the mass air flow sensor readings at different speeds.

This sensor is OK.

To use any smartphone diagnostic app, you will need a Bluetooth or Wi-Fi adapter that plugs into the OBD port.

Sometimes a poor electrical connection at the sensor connector can also cause the airflow reading to be out of range. For this reason, the connector terminals, as well as the wiring, must be carefully inspected.

Often, if the air filter is not installed properly, or the air filter housing is not closed, some debris can get sucked into the MAF sensor and cause problems.

Sometimes debris can get in while replacing the air filter. In this case, the repair is simple. The mass air flow sensor must be cleaned and the air filter must be properly installed or replaced.

Checking the mass air flow sensor with a multimeter

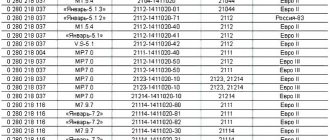

This method works on Bosch sensors with numbers: 0 280 218 116, 0 280 218 004, 0 280 218 037.

We turn the multimeter into DC voltage measurement mode and set the limit to 2 volts.

DMRV pinout:

- Yellow (closest to the windshield) – sensor signal input;

- Gray-white—sensor supply voltage output;

- Green - grounding;

- Pink-black - to the main relay.

The colors of the wires may change, but their location remains the same.

We turn on the ignition, but do not start the engine. We connect the multimeter with the red probe to the yellow wire, and the black probe to the green (to ground). Thus, we measure the voltage between the specified terminals.

It is not recommended to use needles and other additional connections, as they introduce an error in the measurements. We look at the multimeter readings.

The output voltage of the new sensor is 0.996 - 1.01 volts.

During operation, it gradually changes and, as a rule, increases. The greater the value of this voltage, the greater the wear of the mass air flow sensor.

Mass air flow sensor voltage:

- from 1.01 to 1.02 - good condition of the sensor;

- from 1.02 to 1.03 - good condition;

- from 1.03 to 1.04 - the mass air flow sensor resource is running out;

- from 1.04 to 1.05 - a dying state, if there are no negative symptoms, then we continue to exploit;

- 1.05 and above - it’s time to replace the mass air flow sensor.

The same readings can be obtained without a multimeter, using, for example, the OpenDiag mobile application.

What does a faulty air flow sensor cause?

Operating an engine with an inoperative/faulty flow meter causes detonation of the fuel mixture in the combustion chamber. This affects the operation of the crank mechanism (crank mechanism) and destroys the piston surface, which can cause a “wedge” in the engine.

What indications should a working mass air flow sensor give?

The voltage of the analog-to-digital converter (ADC) of the flow meter when the engine is not running should be 0.996 V. Indicators of 1.016 and 1.025 V are acceptable, but if they reach more than 1.035 volts, it means that the sensing element of the mass air flow sensor is clogged.

It is important to know

To accurately determine the degree of deviation of the operating flow meter values from normal values, it is necessary to evaluate the engine operation at different speeds.

For example, for an injection 1.5-liter VAZ 2111 engine, if it is in good condition, at idle (860–920 rpm) the correct readings are 9.5–10 kg/hour, and at 2 thousand rpm - 19 –21 kg/hour. If the flow meter at 2 thousand rpm shows about 17–18 kg, then the car will drive stably. If the values are from 22 to 24 kg/hour, then the vehicle will move steadily, but the fuel consumption per 100 km will be approximately 10–11 liters. In addition, the car will have difficulty starting in cold weather due to fuel overflow when the engine warms up.

Cleaning the air flow sensor

If the sensor is dirty, you can try cleaning it. Cleaning the MAF sensor is a delicate procedure and can be used as a temporary solution. Sometimes this can help.

What not to do

Do not blow the sensor with air from the compressor. You can break the conductors from the crystal to the board. They are very thin (approx. 0.01mm) and soft. They are fixed with a gel-like compound, which is dissolved by light solvents and deformed by a strong air flow. That is, by blowing with a compressor, you can blow off the compound and tear off the conductors.

Ketones and ethers should not be used for washing. For three reasons:

- Dissolve the compound.

- When drying, the crystal is cooled very strongly. It may burst or crack.

- Dissolve the “mask” on the crystal.

It is forbidden:

- climb into the measuring element with matches, toothpicks, cotton swabs, etc.;

- wash with any products like Wynn's;

- do not use carburetor cleaners “Abro”, “Hi-Gear”, etc.;

- Do not use aerosols with acetone or ethyl ether.

Using a MAF cleaner

To wash the mass air flow sensor, it is better to use a special aerosol MAF cleaner, for example, LIQUI MOLY (art. 8044) or KERRY (art. KR9091).

To do this, you need to remove the sensor, unscrew the measuring element if possible and spray cleaner on it. Depending on the contamination, repeat the procedure several times. Let dry.

Principle of operation

The principle of operation of the mass air flow sensor can be based on counting Kraman vortices or shifting the potentiometer slider by means of a blade mounted on the air supply flow.

The first option is considered more reliable, since it is not equipped with moving structural elements. In this case, the device counts Kraman vortices appearing in laminar air flow. On the way of the latter, special obstacles with sharp edges are used as resistance. An air flow breaks off from them, which linearly depends on its speed. This type of controller only works if there is turbulence in the air.

If the air speed is too high, it can lead to the formation of parasitic pressure pulsations. Therefore, the design of the devices is often supplemented with an input for changing the sensitivity of the measuring component. This may be required at low air flow rates when the power unit is idling. Vortex-type mass air flow sensors on older cars used two ultrasonic elements - a transmitter and a receiver. Then they began to use devices in which the function of measuring pulsations to count vortices is performed by a heating filament.

The StarsAuto channel talked about the design features, as well as the operating principle of automobile flow meters.

If the sensor is equipped with a measuring potentiometer, it operates on the principle of slider displacement. Its working blade is equipped with a spring and is installed in the flow of consumed air by the motor. If it increases, a proportional displacement of the blade occurs. The flow has a pulsating nature; accordingly, to reduce the effect of pulsations, the controller blade is connected to a damper. A potentiometer slider is also associated with it, which, when the sensor operates, moves to a level proportional to the volume of air flow.

Restoring and increasing the service life of Nissan mass air flow sensor

This device is one of the most expensive among all sensors in a Nissan car. Its careful operation, as well as timely cleaning measures, will help extend the life of the device and avoid large financial costs.

- Periodically wash the conductive thread and the entire cavity of the device with special sprays and products. At the same time, it is strictly forbidden to enter there with any foreign objects: ear cleaners, matches, cotton pads, etc. To avoid chemical dissolution of various connections and contacts, as well as rubber parts, it is not recommended to wash with ketone- and acetone-containing liquids. Any carburetor cleaning fluid will work here. You shouldn’t even blow through the “inside” of the sensor - you can damage both the thread itself and its contacts.

- Change air filters in a timely manner, which adsorb the lion's share of contaminants that penetrate with the air flow.

- Monitor the wear of the piston rings. Through the cracks in the rubber base of the rings, oil particles fall onto the platinum sensitive element of the sensor, forming carbon deposits, leading to complete breakdown of the device.

If a final and complete failure of the mass air flow sensor on a Nissan has been diagnosed, it must be replaced; such a device cannot be repaired.

Recommendations for extending the service life of the mass air flow sensor

The service life of the device is affected by the purity of the air flow that passes through it. Therefore, when using a flowmeter, it is necessary to prevent the formation of deposits on its working surface. To do this, it is recommended to periodically check the functioning of the air filter device. If necessary, the sensor must be changed regularly. If the car is operated in a large and polluted city, then the part must be replaced more often than indicated in the car maintenance regulations.

How to choose a new sensor?

An ordinary motorist can spend a lot of time searching for the desired intake air sensor in online store catalogs, getting lost in the existing abundance of offers. Since an incorrectly selected device may not only refuse to interact with the car’s systems, but also not fit into the mounting hole.

Therefore, when choosing, be sure to consider:

- Make of the car and specific model;

- Year of its release;

- The type and functional features of the engine installed in the car.

This approach will minimize the likelihood of error and provide the seller with the maximum necessary information. But, if you are a beginner and have little understanding of such issues, it will be much easier to select the right model using the VIN code.

The VIN code is a unique code unique to your device. If you select a new sensor for replacement using the VIN code, then the likelihood of an error is reduced to zero. This is the most accurate method for selecting equipment for your car. However, if the choice of product depends on several manufacturers, it is worth considering the most famous of them.

Among foreign companies producing intake air temperature sensors, Japanese and German manufacturers have the best quality. Among which are Denso, Bosch, Borsehung, but the price of such models also belongs to the premium segment. If you are looking for a more democratic option, then pay attention to the domestic company Energomash, the Taiwanese company Vika or the Italian Facet.

Cleaning the sensor

If you observe signs of a malfunction of the mass air flow sensor, then you can try cleaning the device.

By the way, this is the most expensive sensor of all in the line of front-wheel drive VAZ cars. But if yours is broken, don’t rush to change it. There is a small chance of restoring his “health”. For the cleaning process you will need a special liquid that is used to clean the carburetor. Star keys are also useful. Unscrew the clamp, as well as the two “10” bolts. Remove the pipe and take out the sensor. Spray the liquid onto the wire and tube. Work with extreme care, wait until this liquid has completely evaporated and leave the device to dry.

ELM327 how to use

As mentioned earlier, using any ELM327 adapter you can diagnose the engine, and higher quality models with the appropriate software can show errors in all systems. But if the car does not show errors, this does not mean that it is working properly. Errors appear when the car is completely unwell and cannot be operated without repairs, but borderline conditions, when the error has not yet occurred or has been reset, can be tracked using parameters.

ELM327 programs.

Any program that works with ELM327 and can display engine operating parameters is suitable for diagnosing a car; we will consider working with the Car Scanner program. And so you inserted the adapter into the OBD2 connector, turned the ignition key and the car did not start. We connect the phone to the adapter. If the first stage has passed, we consider the adapter CONDITIONALLY serviceable. The next step is to connect the ELM327 to the vehicle's EBU. If the connection fails, it means your car is old and requires a special connection initialization line (look for information on the Internet using the corresponding request) or your adapter is faulty (which is unlikely, since faulty adapters jam, fall off, distort information or interfere with engine operation, but they connect ). Test operation with another known-good adapter.

ELM327 battery.

And so while the ignition is on and the car is not started, we look at the battery voltage. If the voltage is in the range of 12.4-12.7 Volts, the battery is working properly. If the voltage is lower, for example 11.8 Volts, it means either the battery is old and will die soon, or the attached electronics (radio, cameras, recorder, antenna, GPS tracker, alarm) are not connected to the car correctly and you have a high leakage current when the car is not running . Next, turn on the battery voltage graph and start the car. At this moment, the voltage should rise to 13.8 - 14.5 Volts, depending on the car model. If the voltage is below 13.8 volts, the generator does not charge the battery sufficiently; if it is more than 14.5 volts, overcharging occurs, which will eventually damage the battery. If the voltage remains 12.5 volts, then the generator is not working. In the graph we see a car that has not been used for half the winter, the battery is discharged, but it started up successfully and the battery is charging.

ELM327 absolute pressure in the intake manifold.

Then the car is not started yet, we look at the “absolute pressure in the intake manifold” data. It should be 97 kPa - this is normal atmospheric pressure outside (check the weather forecast). If the numbers are very different, it means the sensor is faulty (or you are very lucky and you are high in the mountains). We start the car - on a working engine without load (headlights, heater, heated windows and audio system are turned off), the pressure should drop to 27 kPa and level off at 30 kPa. The higher the pressure in the intake manifold at idle, the worse the condition of the engine. For foreign cars, 34 kPa is not very good, 40 kPa means the engine is not working properly. For domestic cars, the pressure in the intake manifold is up to 40 kPa within normal limits; if 44 kPa, the engine is not working properly. Weak fluctuations in pressure in the intake manifold at idle indicate problems in the ignition system, and significant fluctuations indicate poor condition of the cylinders or tightness of the cylinder head (compression measurement required). When you press the gas pedal sharply, the pressure should equal the atmospheric pressure of 97 kPa, then return to normal at 30 kPa. The slower the return to 30 kPa occurs when the gas pedal is released, the worse the condition of the engine. On a dead engine, ELM327 will simply show an error.

ELM327 long-term fuel correction.

Then the car is started, we look at the “long-term fuel trim” data. On a working car, my value is 1.5% and can fluctuate up to 5%, plus or minus, and depends on the quality of gasoline and operating conditions. Long-term fuel trim values of 5 to 10% are bad (watch the readings over the course of a month, maybe the car has eaten something wrong). Long-term fuel trim values greater than 10% indicate a malfunction of the injection system. On the positive side the mixture is too lean, on the negative side the mixture is too rich. I'm talking about a malfunction with which you can drive. If the long-term fuel correction exceeds 20%, the engine malfunction light will come on, ELM327 will show you an injection system error, and that means the shaggy, furry animal SCRIBE has come to you.

ELM327 intake air temperature.

The next intake air temperature sensor should work like a thermometer. On a cold car, if it is -10 degrees Celsius outside, the sensor should show -10 degrees Celsius, then the car warms up, it becomes warm under the hood +30 degrees Celsius, the sensor shows the intake air temperature of +30 degrees. If the sensor distorts the readings, the EBU, based on its readings, will prepare the wrong mixture of gasoline and air and you will get excessive fuel consumption. If the sensor is faulty, the engine will operate at the values from the table in the EBU, and an error will appear on the instrument panel.

In general, the injection engine will operate with any faulty sensors with an illuminated error message, receiving data from calculation tables in the EBU memory. The only sensor in the event of a malfunction that prevents engine operation is the crankshaft position sensor.

ELM327 coolant temperature.

The next parameter we look at is the coolant temperature. This parameter is very important for engine operation, so its readings are displayed on the instrument panel. An engine temperature that is incompatible with its life lights up a separate light on the instrument panel and indicates the impossibility of continuing further movement without dire consequences for the engine. And believe me, this is serious for injection engines. So, the data on the coolant temperature from the EBU that the ELM327 will show you is much more accurate than on the instrument panel. The coolant temperature on a cold car corresponds to the ambient air temperature, and then smoothly and evenly rises to the optimal engine operating temperature of 90 degrees Celsius and is then maintained around this value. If you see any jumps in the graph while the car is warming up, the sensor is faulty and may fail you in the near future - it needs to be changed. If the sensor is dead, ELM327 will show an error.

ELM327 engine speed.

Another parameter that is duplicated on the panel of your car is engine speed. And the ELM327 readings received from the EBU will again be more accurate. On a cold car, the engine starts at 1200 rpm and then gradually, as it warms up, reduces the value to 800 rpm at idle. As you can see, on a warm, working car, the engine idle speed readings fluctuate by 10 units from 790 to 800 rpm. If the engine idle speed reading fluctuates significantly more and you hear that the speed is floating, check the idle speed sensor and the throttle position sensor. If any of these sensors died, ELM327 will show an error for this sensor.

ELM327 oxygen sensor.

Then, with the car warmed up, the catalyst starts working. And we look at the readings of two sensors simultaneously: “oxygen sensor 1 voltage”, which is located before the catalyst and “oxygen sensor 2 voltage”, which is located after the catalyst. They need to be viewed in pairs on real-time graphs, without readings from other sensors, so that the graphs are updated as quickly as possible. The oxygen sensor 1 voltage reading should tend to a square waveform, and the oxygen sensor 2 voltage reading should tend to a straight line. You see a graph from a recording, so there is not enough data there to construct a square waveform. The more the data from sensor 2 repeats the data from sensor 1, the worse the performance of the catalyst. If ELM327 generates an error on the first or second oxygen sensors, this may indicate three malfunctions and one failure. The first reason is that the catalyst has failed and needs to be replaced. The second reason is that the exhaust system is not sealed, the catalyst is working properly and the burnt holes in the exhaust system need to be welded. The third reason is that one of the sensors has failed and needs to be checked and replaced. Fraud - They knocked out your catalyst and installed a low-quality fake instead of an oxygen sensor. Here you need to look at the mileage of the car. With proper operation in gentle conditions, the service life of the catalyst is 200 thousand kilometers. When operating in difficult conditions and on poor fuel, the service life of the catalyst is up to 100 thousand kilometers. If your mileage is 300 thousand, and the graphs are ideal, then you have a decoy instead of an oxygen sensor, which generates such a signal.

ELM327 ignition timing.

The next parameter is “ignition timing”. The ignition timing is set by the EBU and depends on the engine operating mode; its values are constantly changing. At idle speed on a warm engine it should be 10 degrees. At idle, my ignition timing ranges from 6 to 9 degrees, and when driving, depending on the load, its value is from 5 to 35 degrees. By changing the ignition angle values, the engine EBU tries to obtain minimal engine detonation. If you have strange ignition angle readings on the ELM327 or engine detonation is observed, you need to diagnose the ignition system - coil spark plugs, and also check the serviceability of the knock sensor.

ELM327 Car Scanner.

Now regarding the Car Scanner program. It records only those parameters that are currently displayed on the phone screen and related to it. That is, if you switched the display from one parameter to another, the recording of the first parameter will most likely be interrupted and there will be a gap on the graph until you see this parameter on the screen again. In justification, I can say that even Launch devices can display up to 6 parameters simultaneously.