When the internal combustion engines that modern cars are equipped with operate, a fuel-air mixture is burned, for the formation of which, as you can easily guess from its very name, it is necessary to mix fuel with air, and in strictly defined proportions. Accordingly, the systems that are responsible for the formation of this substance must accurately “know” the consumption of each of its components at every moment of operation of the power unit. The value of this indicator for one of them helps to determine the mass air flow sensor (MAF). It should be noted that it is present in the design of only injection engines, and if drivers notice signs of a malfunction of the mass air flow sensor, then it should be checked and, if necessary, replaced.

Why do you need a mass air flow sensor?

What does a mass air flow sensor look like on a car?

The mass air flow sensor is an important sensor located directly behind the engine air filter, or more precisely, just between it and the throttle assembly. It is designed so finely that it allows you to accurately measure the flow rate of only air that is well cleared of mechanical impurities

During operation, the mass air flow sensor transmits signals to the electronic engine control system, which are processed and interpreted as the volume of air that is supplied to form the fuel-air mixture. For normal operation of the power unit, the volumetric ratio of liquid fuel (gasoline, diesel fuel) and air in it should be close to 1x14. If this proportion is violated, then either a significant loss of engine power or excessive fuel consumption occurs (these, by the way, are the main signs of a malfunction of the mass air flow sensor). The information received by the ECU from the sensor that determines the mass air flow helps to avoid this.

The mass air flow sensor measures the amount of air that enters the fuel rail per unit time. It transmits this data to the ECU, which instantly calculates the amount of liquid fuel that needs to be supplied to form the mixture, and gives the appropriate “instructions” to the engine devices responsible for this. Thus, if, for example, you press the accelerator pedal, more air immediately begins to flow, the mass air flow sensor instantly detects this, sends data to the computer, which increases the supply of gasoline or diesel fuel in the appropriate proportion. If the amount of air decreases, then the volume of liquid fuel supply decreases.

From a design point of view, there are three types of such sensors that are actively used:

- Based on pitot tube;

- With hot-wire anemometers;

- With film meters.

Mass air flow sensors built on the basis of a pitot tube are considered obsolete and are not used in the newest engine models. They are so-called vane flowmeters, the main elements of which are plates connected to potentiometers and softly fixed to the axes. Changing their position under the influence of air flow, they act on the potentiometer, which changes its electrical resistance.

Mass air flow sensors with hot-wire type meters are quite expensive, although they are very effective. They are equipped with special heat exchangers consisting of two platinum filaments, which are heated by passing electric current. One of them is blown with a flow of air, the second remains a control one, and based on the difference in the current passing through them, the ECU calculates the amount of air supplied to form the fuel mixture. Mass air flow sensors with film meters are considered the most modern. According to their principle of operation, they are almost similar to hot-wire anemometers, only they do not use platinum threads, but ceramic elements coated with platinum.

Disadvantages of the node

Please note that if the sensor fails, it is most effective to replace it with a new one. It cannot be repaired, which is its main drawback, since the price of a new one is sometimes more than two thousand rubles. But there is another minor drawback, which lies in the principle of operation. Any mass air flow sensor has this drawback. Signs of a malfunction (diesel or gasoline in the power system) are discussed in the article.

It allows you to measure the volume of air that entered the throttle assembly. But for engine operation it is important to know not the volume, but the mass. Of course, to perform the conversion you will also need to know the air density. It is for this purpose that a measuring device is installed in the air intake, in close proximity to the sensor, which measures the temperature.

Main symptoms of a malfunctioning mass air flow sensor

A malfunction of the mass air flow sensor, as noted above, leads to either an over-enrichment or a depletion of the fuel mixture with gasoline or diesel fuel, which negatively affects the functioning of the engine and can lead to serious damage. Most often, malfunctions of the mass air flow sensor are associated with a clogged air filter: the air is poorly cleaned, and the mechanical particles contained in it get into the sensor, which is the cause of its failure. It should be noted that mass air flow sensors are non-repairable devices, and if they fail, they must be replaced with new ones.

Practice shows that the main signs of a malfunction of the mass air flow sensor are as follows:

- A Check Engine error appears, which indicates that the signal level of this sensor is very low;

- The engine consumes more fuel than usual;

- The power unit does not start well, its power decreases, it begins to stall;

- The car accelerates poorly;

- The engine runs either at high or low speed.

Of course, all the signs may also appear during other vehicle malfunctions, but in any case, if at least one of them is detected, this is a good reason to visit a service station. However, you can check the mass air flow sensor for malfunctions yourself, without contacting service station specialists.

Device maintenance

During operation of an engine with an electronic control system, the sensor still becomes dirty. To clean it, there is a special algorithm embedded in the control system. It allows you to heat a platinum wire in literally one second to a temperature of about a thousand degrees. If there was any dirt on the surface of this wire, it immediately burns without a trace. This is how to clean the mass air flow sensor. The signs of a malfunction, whether it is a Kalina or any other car, will be the same.

This procedure is performed every time you turn off the engine. The mass air flow sensor is very simple in design, and its operational reliability is high. However, it is not recommended to repair this unit yourself. If a breakdown occurs, the best option is to contact competent diagnosticians and mechanics.

Video about DMRV malfunctions

The mass air flow sensor (MAF) is located near the air filter to determine the amount of air flow passing through the air filter. Malfunctions of the mass air flow sensor negatively affect engine performance. Don’t rush to replace it with a new one, try checking the mass air flow sensor first.

Other symptoms of a faulty mass air flow sensor:

Check Engine error appears; Increased fuel consumption; Doesn't start well when hot; The car began to accelerate slowly; Engine power lost. Etc.

How to check the mass air flow sensor Method No. 1: Disable the mass air flow sensor. DMRV connector VAZ 2110 Disconnect the sensor connector and start the engine. If you turn off the MVR, the controller switches to emergency mode and prepares the fuel mixture only according to the throttle position. Engine speed must be greater than 1500 rpm. Let's try to go for a ride. If the car feels “faster”, then we can say that the mass air flow sensor is not working.

By the way, for ECU Y7.2, M7.9.7. The speed does not increase when the chip is turned off!

Method No. 2: Alternative ECU firmware. If the standard firmware of the controller was replaced with another, then it is unknown what is built into it in case of emergency mode in method No. 1. Try sliding a 1mm thick plate under the damper stop. The revs will rise. Pull out the chip from the mass air flow sensor. If it doesn’t stall, it means the problem is with the firmware, or rather with the IAC steps in emergency mode without a mass air flow sensor.

How to increase service life

Try to change the air filter on time, since the mass air flow sensor will not be able to work for a long time if dirty air passes through it. The thread and the entire internal surface can be washed using special sprays for carburetors. Just try to do everything carefully and avoid touching the spirals. Otherwise, you will end up with an expensive replacement of the air flow sensor. In recent years, other designs are often used instead of such a sensor. This type of mass air flow sensor is used on some foreign cars. Symptoms of a Nissan malfunction are similar to those that occur on “tens” or “Prior”.

A pressure sensor is often installed to monitor the flow of air into the combustion chambers. To increase the service life of the mass air flow sensor, it is necessary to promptly replace the air filter, and also pay attention to the cylinder-piston group. In particular, excessive wear on the piston rings will cause the platinum wire to become coated with oil deposits. This will gradually lead to damage to the sensor.

Functionality of the mass air flow sensor

The normal ratio of the components of the fuel-air mixture is 14 to 1, where 14 is the share of air. Violation of the proportion is fraught with engine malfunctions, excessive fuel consumption and loss of engine power .

The functional purpose of the sensor is to measure the volume of intake air for the fuel-air mixture. Information from it goes to the ECU (electronic control unit) of the engine. In response, the control unit sends a signal to the injectors about the required amount of fuel. The flow meter is located between the air filter housing and the throttle valve, to which it is connected by wide corrugated pipes.

Constructive

I have mentioned many times, and I am not ashamed of this, that I have an academic education in the field of wheeled and tracked vehicles. But I prefer German, Italian and American literature on engines. There is much more correct theory, confirmed by practice. In particular, it talks about the location of the flow meter in the intake tract. “The distance from the throttle is no more than 2-3 section diameters and there are no 90 degree turns. In the worst case, there will be a large error in the readings.” Look at what distance from the damper the air flow sensor of the Niva and Shniva is located. And the location of the intake tract above the exhaust, in the case of the Niva, is a separate delight.

Articles on the topic electronics and sensors

Diagnosis, first step

Signs of a DMRV malfunction

Correct operation of the sensor can be expected up to 30 thousand km. mileage After threshold values, natural wear of the part occurs. It either fails, or the readings diverge more and more from objective reality. The following signs should make the driver alert and suspect a malfunction of the mass air flow sensor.

- fuel consumption increases;

- engine rotation speed decreases;

- loss of engine power at all speeds;

- weak or delayed response to the gas pedal.

An indirect cause of sensor malfunction may be a dirty air filter.

Chevrolet Niva cooling fan does not turn on

The Chevrolet Niva SUV, which is popular in our country, is equipped with a high-quality cooling system that allows you to constantly maintain optimal engine thermal conditions. A special role in this unit belongs to two fans, which provide the required air flow through the radiator core.

If the cooling fan on a Chevrolet Niva does not turn on, excess heat will no longer be removed from the engine, which will lead to overheating of the engine. Since the number of cooling fans on this car model has been increased, the electrical circuit of their operation has become much more complex than in classic passenger cars.

If the cooling fan does not turn on on a Chevrolet Niva, the first thing you need to do is check the condition of the fuses responsible for the operation of the unit. The fuses are located in the mounting block under the front panel, near the front passenger's feet. This car has two fuses that protect the electrical circuit of the fan motor.

The mounting block contains three relays responsible for connecting the left fan at high speed and the right fan at low and high rotation speed. The additional relay is activated when a signal is applied from terminal number 46 of the ECM to terminal number 86. In this case, the voltage to the fan motor terminals passes through a resistor.

If there is no control signal, we can talk about a failed relay. At the same time, the cooling fan on the right side does not turn on on the Chevrolet Niva

It is important to remember that the same control signal is responsible for turning on the left fan. In this case, a jumper process occurs between terminals 85 and 86

However, the fan motor on the left is powered via a separate fuse.

Removing Chevrolet Niva cooling fans

The cooling fans on the Chevrolet Niva do not turn on even if the sensor that detects the coolant temperature breaks down. According to this sensor, the system understands how much the coolant temperature has increased or decreased. In this case, the controller determines whether to turn the fans on or off.

It happens that fans do not turn on due to deformation of the plastic casings of the parts. This can happen if the temperature in the engine compartment is too high. In this case, the fan blades will touch the casing, which will lead to overheating and melting of the tips. When the fans stop, the blades will simply weld to the casing and will not be able to work the next time they are turned on.

Replacing this part is relatively easy. The on-board computer registers errors such as P0340, PO342, PO343.

Mechanical specialists, even if the sensor is in good working order, still recommend changing it every 4-5 years - such prevention will protect you from breakdowns and accidents, especially since the part is very cheap despite its importance. After all, the semiconductors inside the sensor react poorly to temperature fluctuations - remember your school physics course

There is a special offer on our website. You can get a free consultation with our corporate lawyer by simply submitting your question in the form below.

On the Niva 2123, the idle speed control is made in the form of a small electric drive with a spring and a rod ending in the form of a needle, which are enclosed in one housing. The IAC is attached to the throttle body. The sensor starts working when the key is turned in the ignition switch. At this moment, the rod rests against a special hole to count the necessary steps, after which the valve returns to its original position.

Part diagnostics

Serviceability is determined with a multimeter in voltmeter mode. The results of the check are interpreted as follows:

- The sensor is working: 1–1.02 V.

- OK, cleaning required: 1.03 V.

- average wear, readings are incorrect: 1.04 V.

- high wear, urgent replacement needed: 1.05 V.

- the part is faulty: 1.06 V. The engine operates in emergency mode, relying on the readings of the throttle assembly.

After cleaning, you need to check the flow meter again; the indicator should be at 1.02 V. If the mass air flow sensor breaks down, it cannot be repaired. If the flow meter fails, it will have to be replaced with a new part.

The vast majority of foreign cars with injection engines after 2000 began to be equipped not with mass air flow sensors, but with pressure controllers.

Checking and repairing at home

There are eight ways to independently check amplitude and frequency mass flow sensors.

Method No. 1 - disabling the air flow meter

The method consists of disconnecting the sensor from the fuel system of the car and checking the functionality of the system without it. To do this, you need to disconnect the device from the connector and start the engine. Without a mass air flow sensor, the controller receives a signal to switch to emergency operation mode. It prepares the air-fuel mixture only based on the throttle position. If the car moves faster and does not stall, it means that the device is faulty and requires repair or replacement.

Method No. 2 - flashing the electronic control unit

If the standard firmware has been changed, then it is unknown what reaction of the controller is programmed in it in case of an emergency. In this case, you should try to insert a 1mm thick plate under the throttle stop. The turnover should increase. Now you need to pull out the chip from the air flow meter. If the power unit continues to work, then the cause of the malfunction is the firmware.

Method No. 3 - installing a working sensor

Install a known good part and start the engine. If after replacement it begins to work better, the motor does not stall, then replacement or repair of the device is required.

Method No. 4 - visual inspection

To do this, use a Phillips screwdriver to unscrew the clamp holding the air collector corrugation. Then you need to disconnect the corrugation and inspect the internal surfaces of the air collector corrugation and the sensor.

Inspection of duct corrugation

There should be no traces of oil or condensation on them, the surfaces should be dry and clean. If you do not take care of the air filter and change it rarely, then dirt can get on the sensitive element of the sensor and cause it to break. This is the most common malfunction. Traces of oil may appear in the flow meter if the oil level in the crankcase is high, or if the oil sump of the crankcase ventilation system is clogged. If necessary, you need to clean the surfaces using special cleaning products.

Method No. 5 - checking the mass air flow sensor with a multimeter

To do this, you need to turn on the tester in a mode in which constant voltage is checked. The limit value for measurements should be set to 2V.

DMRV operation diagram

- The yellow wire is located closer to the windshield. It serves as an input for a signal from the flow meter.

- The white-gray wire is the sensor voltage output.

- The black and pink wire leads to the main relay.

- The green wire is used to ground the sensors, that is, it goes to ground.

The wires may have different colors, but their location is unchanged. To check, you need to turn on the ignition, but do not start the car. The red probe from the multimeter must be connected to the yellow wire, and the black one must be connected to ground, that is, to the green wire. We measure the voltage between these two outputs. Multimeter probes make it possible to connect without disturbing the insulation of the wires.

On the new device, the output voltage ranges from 0.996 to 1.01 V.

During operation, this voltage gradually increases and by its value one can judge the wear of the flow meter:

ADC flow meter readings

Diagnostics of the mass air flow sensor "Tseshkoy" is not difficult and can be done with your own hands.

If there is dirt on the removed sensor, you can clean it yourself. You can use WD-40 to wash it. To clean the mass air flow sensor, you must first remove the pipe from it, and then dismantle the device itself. Inside the device there is a mesh and several wires - sensors.

They need to be sprayed with cleaning agent and washed. Then let the liquid dry. If dirt remains, the procedure should be repeated. You need to clean the pipe with the same product. It must be free of dirt and oil stains. After replacing the air filter, all parts must be returned to their place. After the cleaning procedure, the functionality of the device can be restored to 80%, the error about the reduced sensor signal level disappears (the author of the video is “24 hours”).

Flushing the sensor will help avoid costly repairs.

Method number 6 - checking with a scanner

- Install a diagnostic program on your phone (smartphone), tablet or laptop computer (for example, Torque Pro, Opendiag, BMWhat, OBD Auto Doctor).

- Connect your mobile device or laptop to the diagnostic connector located on the vehicle's electronic control unit using a special cable, Bluetooth channel.

- Launch the diagnostic utility on your phone (smartphone) or computer.

- Wait until the program finishes scanning all vehicle components. As a result, the utility will check the serviceability of each vehicle unit.

- Decipher the error codes that the program will show after the diagnostics are completed.

To perform this method, testers are used:

Method No. 7 - checking by Vasya the Diagnosticist

To identify a malfunction of the mass air flow sensor without removing it from the car, you need to:

- Install a program called “VASYA diagnostician” on your laptop (laptop) and run it.

- Connect the adapter to the vehicle's diagnostic port.

- Select the item “Electronics 1” or “01 – Engine electronics” from the “Control unit” tabs to connect to the vehicle’s control unit.

- Go to “Custom Groups”.

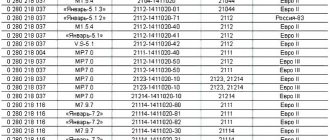

- Select 211, 212 (passport value) and 213 (current value).

- Compare current indicators with passport data. If the deviations are high, then it is necessary to replace the mass air flow sensor.

Method No. 8 - using a motor tester

This method is used to test frequency-type flowmeters.

To check the mass air flow sensor with a motor tester (oscilloscope), you need to connect it to the sensor (depending on the car brand) and start the engine.