Idle mode (idle speed, idle speed) - operation of a car engine in neutral gear. In this mode, the torque of the internal combustion engine is not transmitted through the transmission to the wheels. A fairly common occurrence during vehicle operation can be a noticeable increase in engine vibrations at idle. Among such malfunctions are noted:

- diesel engine vibration at idle;

- strong engine vibration at idle in relation to gasoline units;

- vibration of a gasoline engine when running on gas (in the presence of gas equipment);

We also recommend reading a separate article about why a diesel engine begins to vibrate strongly at idle. From this article you will learn about what malfunctions can cause increased vibration in a diesel engine.

Vibrations of varying intensity can be more often noticeable on a cold engine, although in some cases unstable operation also appears on a hot engine after the engine reaches idle speed.

POSSIBLE REASONS

- Uneven compression in the cylinders. Due to a decrease in compression, efficient combustion of the air-fuel mixture does not occur, as a result of which the piston in the problem cylinder does not receive proper acceleration. The reason for vibration at idle speed in this case is a decrease in the inertial movement of the piston during the power stroke.

- Misfire in 1 or several cylinders at once. As in the case of loss of compression, due to poor combustion of the fuel injection pump, the piston does not receive proper acceleration, which leads to uneven rotation of the crankshaft.

- Dual-mass flywheel malfunction. When in good condition, the torsional vibration damper can reduce the load on the crankshaft and transmission elements. In case of failure, engine vibrations are observed, accompanied by a characteristic rumble.

- Wear of engine mounts. The engine in the engine compartment is supported by several silent blocks. In case of cracks or tears in the rubber dampers, vibrations will be transmitted to the body and clearly felt in the cabin.

- Wear of the drive of the balance shafts and the balancers themselves. Bearing wear, chain stretching, and incorrect tensioner adjustment lead to increased noise and vibration.

ENGINE SUPPORT CUSHIONS

How to determine that the cause of the imbalance is in the pillows?

- Visually inspect the engine mounting silent blocks. The rubber damper should not peel off from metal elements or have deep cracks.

- Using a rolling jack and a small rubber spacer, jack up the engine one at a time on all sides of the mounting of the cushions (the fulcrum should be as close as possible to the location of the damper). After each change in the position of the fulcrum, observe the operation of the motor. The vibration should noticeably decrease when the engine is jacked up near the torn mount.

We recommend replacing engine mounts only using original spare parts or worthy analogues. When buying cheap pillows from unverified manufacturers, you risk running into damping inserts that are too hard. As a result, after replacement, the vibration not only will not disappear, but may even intensify.

COMPRESSION

Vibration associated with loss of compression will first manifest itself when it is cold. As the metal parts warm up, they expand, thereby reducing the gaps through which exhaust gases escape. Uneven compression in the cylinders is a natural phenomenon for an engine with a mileage of more than 100 thousand/km. But for normal operation, the spread should not exceed 0.5-1 kgf/cm2. At higher values, vibrations may already be observed when cold.

Compression should be checked on a cold engine. You can find out what compression should be in the engine from the repair and operation manual for your car. Following the check, you can determine what exactly caused the loss of compression: a problem with the CPG or timing parts. To do this, pour 25-30 mg of engine oil into the problem cylinder, then repeat the measurements. If the compression levels out, the reason is the wear of the CPG. The absence of changes indicates problems with the timing belt. A more accurate diagnosis of the cause of vibrations at idle can be done with a pneumatic tester.

MISSING

Self-diagnosis of modern engine ECUs allows you to determine the cylinder number, which greatly facilitates the search for the cause of vibrations at idle. Multiple misfires indicate intermittent problems in several cylinders at once. It does not at all follow from the term that the cause of interruptions in operation is in the ignition system, since the ECU determines misfires by uneven rotation of the crankshaft. What elements most often cause misfires and increased vibration?

- Fuel injectors (TPVS over-rich or too lean).

- Spark plug. Interruptions in the spark supply are caused by oil deposits on the spark plugs, erosion of the electrodes, damage to the ceramic insulation, and improper air gap.

- High voltage wires.

- Ignition coil/ignition modules.

- The engine control unit.

Do not forget about the problem of air leaks and many other reasons due to which the engine rattles and vibration is transmitted to the body. In any case, we recommend proceeding with troubleshooting only after reading the error codes.

Causes

Vibration in the body during acceleration occurs due to an imbalance in the chassis of the car, for several reasons:

- The structural reason is due to the design of the part that disrupts the balancing, for example, a tire inflation valve affects the balancing of the wheel (may disrupt it);

- Technological reason, here the vibration is caused by a deviation from the dimensions and parameters of the elements that are being replaced;

For example, the mass of the repair connecting rod may deviate from the normal value, which causes uneven load distribution in the engine and, as a result, vibration during acceleration, while driving, and even vibration in the body at idle.

- Operational reason, vibration occurs when a part is unevenly worn, deformed, or perhaps due to the loss of properties (destruction) of vibration isolators.

Vibration isolators are motor mounting pads, boxes and others. They reduce shocks that are transmitted from the engine to the frame and body of the car. These supports (pillows) are usually made of a pair of metal elements that are separated by a layer of rubber. Body vibration during acceleration and at idle may occur due to their destruction. Occurs when the rubber material is worn out or the manufacturing technology is violated. If during acceleration the vibration of the body is caused by the cushions, they should be replaced immediately

If the engine vibrates constantly, then the most effective way is to balance the parts. Of course, it will be difficult to eliminate vibrations that originate from the engine 100%, but it is possible to significantly reduce the vibration level to a minimum.

When performing the balancing procedure, the part is subjected to diagnostics. Using a special device, its heaviest side is determined. Then the master decides whether to lighten the heavy part or make the opposite side heavier. This option is used when balancing wheel rims. It is important to note that it is almost impossible to independently determine the light and heavy sides of the wheel, and the crankshaft, especially without equipment and experience.

VAZ engine vibration at idle speed

In VAZ cars with a carburetor engine, vibration almost always appears at idle . This is due to the design of the motor and until it warms up to the optimal temperature, it will not disappear. The reason for this behavior of a serviceable power unit is largely the fuel-air mixture, which the carburetor prepares before entering the combustion chamber. Due to the low temperature, combustion in the cylinders occurs ineffectively, which leads to engine vibration. As a rule, when the optimal temperature is reached, stability in the operation of the power unit appears.

Vibration that occurs after replacing clutch elements

There are few reasons why vibration occurs after replacing a clutch. Vibration usually appears in two forms:

- The pressure plate (clutch basket) is not balanced;

- During assembly, the driveshaft was installed in a different position from the original installation (but this only applies to rear-wheel drive or all-wheel drive vehicles).

By and large, on cars with front-wheel drive, you can inaccurately secure the wheel drive (CV joint), and the movement of the car will be accompanied by vibration and knocking, but this does not happen often.

If the clutch basket creates vibration, you can try moving it to a different position. As a rule, the pressure plate mounts are symmetrical. On many models, the basket is attached to the flywheel with six bolts, and the basket can be placed in three positions. In one position the vibration may disappear completely or be minimal. But it is better to exchange the warranty part immediately for another one. This will be less hassle for the car owner.

Help me guys!

So we have a VAZ 2110 (2006 1.6 8kl) There is vibration in the body at idle!!! The door cards are cracking so bad! The check is not lit (the light bulb is not burned out) compression in all cylinders 12 valves adjusted, the pillows are intact, the protection has been removed! damn it's the 2nd month of dancing with a tambourine! The pressure in the fuel rail is excellent! The ignition module is working! guys, help me out, I don't have the strength anymore =(

And what are the rpm xx? Was there a re-flashing? Is it just vibration or is the engine running unevenly? Are the skips fixed?

It wasn’t the reel, the DIAGNOST was sitting in the cockpit!

rpm 800! was not stitched in front of me! (interest Ask). gaps are normal. If you don’t look at the engine and listen, it works smoothly, but the **** is shaking!

Could this happen from a generator?

Then the problem is not in the engine itself. It has nothing to do with the generator. What about the speed on the tachometer? If the engine is working properly, then the problem is not in it, but in the fastenings, etc...

It wasn’t the reel, the DIAGNOST was sitting in the cockpit!

Damn, can a support not hold without visible damage?

Posted by

DenivenSo we have a VAZ 2110 (2006 1.6 8kl) There is vibration in the body at idle!!! The door cards are cracking so bad! The check is not lit (the light bulb is not burned out) compression in all cylinders 12 valves adjusted, the pillows are intact, the protection has been removed! damn it's the 2nd month of dancing with a tambourine! The pressure in the fuel rail is excellent! The ignition module is working! guys, help me out, I don't have the strength anymore =(

Hasn't this happened before? Are the BB wires normal?

VAZ-2114 1.6 16V 98Hp 2010 Skoda Rapid FL 1.6 115Hp (cwvb + chip) 2022

yes it came with the time of the month for 1.5 centuries they rang ok

check the speed and misfires with a scanner, also check the lambdas in one go, find out the firmware and which ECU

It wasn’t the reel, the DIAGNOST was sitting in the cockpit!

or misfires, but more likely the airbags.

So I was asking about the pads, maybe the rubber just lost its rigidity,

I peeled them off from the bottom and from the top they were intactPosted by

DenivenSo I was talking about pads and was asking if the rubber just lost its rigidity

I climbed them from the bottom and from the top, intact

I don’t even know a way to test them... it’s just an axiom, vibration at idle-pillows. Well, maybe some kind of flywheel... but this is bullshit, not an idea...

Message from

GRom 22rusI don’t even know a way to test them... it’s just an axiom, vibration at idle-pillows. Well, maybe some kind of flywheel... but this is bullshit, not an idea...

If the flywheel were crooked, it would wobble from the very beginning.

VAZ-2114 1.6 16V 98Hp 2010 Skoda Rapid FL 1.6 115Hp (cwvb + chip) 2022

Have you changed the spark plugs recently?

VAZ-2114 1.6 16V 98Hp 2010 Skoda Rapid FL 1.6 115Hp (cwvb + chip) 2022

By the way, the vibration is wave-like!

I think least of all for perfumes are new candlesbenz 95 lew

You won't see whether the pillows are torn or not. Either remove it completely, or jack up the internal combustion engine and look for gaps

The dog barks - the caravan moves on

By the way, even 800 rpm is not enough...

The dog barks - the caravan moves on

Is it possible that for an injector 800-850 idle is normal?

Message from

TomskBy the way, even 800 rpm is not enough...

seems to be the norm... but I have 900. I think it’s a lot, but it’s turned down to a minimum and works perfectly, so I don’t bother. Although the consumption because of this (especially in winter when warming up) is clearly higher than it should be.

The revolutions are hardwired into the firmware and cannot be adjusted. 800 is normal if they are present, of course. The reason for the incorrect revolutions is the xx regulator. Usually it goes away after washing.

It wasn’t the reel, the DIAGNOST was sitting in the cockpit!

Related topics

- Replies: 702

Last message: 09/11/2011, 10:14 - Answers: 23

Last message: 07/23/2010, 06:07

- Replies: 5

Last message: 07/11/2010, 22:18

- Answers: 18

Last message: 04/07/2010, 07:23

- Replies: 9

Last message: 05.12.2009, 05:34

Current time: 22:17. Time zone GMT +3.

Topic: VAZ 2110 16kl. jerks when moving!

Theme Options

- print version

- Subscribe to this topic...

VAZ 2110 16cl. jerks when moving!

Gentlemen, this is the problem. When the engine is running at low speeds, the car starts to twitch and jerk. As soon as the engine picks up speed, everything becomes normal. But this is not always the case, like every other time. There is no oil in the wells, the wires are new, replacing the throttle position sensor did not help. Where else to dig?

Answer: VAZ 2110 16kl. jerks when moving!

I can assume that the injectors require cleaning. (and throttle for one)

Answer: VAZ 2110 16kl. jerks when moving!

Possibly an air leak

Answer: VAZ 2110 16kl. jerks when moving!

Answer: VAZ 2110 16kl. jerks when moving!

Try replacing the MZ, check the wires going to the injectors.

Answer: VAZ 2110 16kl. jerks when moving!

. Start with the candles, maybe even sandblasting can help.

Answer: VAZ 2110 16kl. jerks when moving!

You can measure the compression, check the vacuum brake booster and the vacuum seal itself for air leaks.

Answer: VAZ 2110 16kl. jerks when moving!

look and maybe change the crankshaft position sensor, sometimes they are faulty

Answer: VAZ 2110 16kl. jerks when moving!

The spark plugs are new and the wires too. By the way, after replacing the throttle position sensor, it became even better, the speed almost does not fluctuate, but when you stand, you press the trigger sharply, the engine first choke, and then the work seems to level out. It is recommended to look at the fuel filter. What do you say?

Answer: VAZ 2110 16kl. jerks when moving!

if, with a sharp increase in speed, the engine choke (as if it first fails, and then smoothly picks up speed with a twitch), probable reasons: -1 (and the most probable) IGNITION COIL! (if you don’t have a coil per cylinder, but one large block with a built-in switch. And it sits on top of the engine, it appears more often when it’s hot) -2 Air flow sensor. (You can actually check it either with a scanner or by replacing it) -3 Pressure in the fuel line (should be 2.7-3.5, or simply at least be dumped into the return line) ) -4 high-voltage wires (just check the resistance) -5 injectors are clogged (well, then wash it.)

As a rule, other options with sensors provoke the recording of errors in the computer by these sensors, and with the above listed, errors may be recorded for misfires in the cylinders, and precisely in those where the non-working part of the cylinder (the coil consists of two modules) 1-4 or 2 -3. or where the injectors are clogged.

Answer: VAZ 2110 16kl. jerks when moving!

BC is silent like a partisan, he likes everything! I decided to go down the path based on the high cost of the parts. Now I’ll try to change the fuel filter, I have a suspicion that it hasn’t been changed for a very long time! Then I'll tell you the result.

Answer: VAZ 2110 16kl. jerks when moving!

then make it simpler: -1 check for the presence of gasoline in the return line, i.e. after the reduction gear. if it’s not there, then screw the pump; if there’s a good flow, then everything is ok. and the filter has nothing to do with it.

-2 if there is gasoline in the return line, pinch it (even with pliers) and try to rev it up. If the dips go away, or become much smaller, then the injectors are clogged. If the dips remain the same, then there are two options: the woman or the data flow. air

The engine vibrates strongly at idle: possible reasons

The normal operation of a serviceable motor requires minimal vibration, which is quite acceptable. It should also be taken into account that in the cold season the engine may vibrate somewhat more strongly. After 3-5 minutes of warming up, the vibration level should return to normal. In parallel with this, there should be no jerks, dips or omissions, as well as extraneous sounds in the engine operation.

The appearance of noticeable vibrations indicates that certain malfunctions are possible. Let us immediately note that increased vibrations are detrimental to the internal combustion engine, so such a problem must be diagnosed and eliminated as quickly as possible.

Among the main reasons why the engine begins to vibrate (shudder, twitch) at idle, experts identify the following:

For normal operation of the power unit, idle speed is usually around 750-950 rpm, which depends on the type of engine. Reducing the idle speed will cause the engine in this mode to start running less stable and may even stall at idle. An increase in speed naturally leads to increased fuel consumption, as well as an increased load on the CPG and other components of the internal combustion engine. As a result, motor life is reduced. For this reason, an optimal balance is maintained for each engine to achieve maximum efficiency and stability at idle.

Motor troits

If the engine starts to stall, then uneven operation of the cylinders is observed. The most severe engine vibration at idle is felt if one of the cylinders is not working. Pressing the gas pedal allows you to partially compensate for the resulting imbalance by increasing the crankshaft speed, but engine power will still be reduced.

The load on the crankshaft when the cylinder is not working or is misfiring remains uneven, which causes jerking and jerking of the engine. The driver usually feels a noticeable shudder and vibration in the steering wheel, which can also be transmitted to the body. The engine vibrates most strongly at idle, and also under load when driving at low speeds.

It is necessary to eliminate the problem with an inoperative cylinder as quickly as possible, since in addition to vibrations that destroy the engine, normal fuel combustion does not occur in the combustion chamber of the problem cylinder. As a result, excess fuel washes away the lubricant from the walls of the faulty cylinder, thereby increasing wear on its mirror. Also, on worn-out engines, there is a high probability of unburned fuel leaking through the seals, which leads to fuel getting into the engine oil and losing its beneficial properties. In this case, the engine wears out faster, cokes more, etc.

Additionally, it is worth noting the engine vibrations that appeared after replacing the timing belt. In this case, it is necessary to eliminate the possibility of an error when installing the belt, since a displacement of even one tooth leads to a violation of the valve timing. The result is engine malfunctions and engine tripping.

Mounting and malfunction of engine mounts

A common problem that causes increased engine vibrations is a defect in the power unit mounts. Most often, the problem lies in the engine supports (so-called mounts), which can become unusable over time. These pillows are a kind of dampers that not only hold the internal combustion engine, but also dampen vibrations.

Also, an increase in the level of vibrations can occur after replacing one or more pillows with products with greater rigidity.

You can diagnose the problem as follows. Invite an assistant and open the hood, then rock the car with sharp jerks by moving the car forward and backward. The assistant must record the angle and degree of engine deflection during such rocking. Normally, the engine should swing forward, backward, and also to the sides evenly and equally.

If deviations are detected, that is, the motor has a greater tilt in one direction, the corresponding motor mount will need to be replaced. Please note that experts recommend replacing engine mounts even if there are no visible defects or damage on the part itself. Also, after replacing the support, it is necessary to carefully adjust.

Balancing the crankshaft and CPG

During the process of repairing an internal combustion engine, which involves grinding or replacing the crankshaft, it is necessary to subsequently balance the part with the flywheel and clutch. To balance the crankshaft, specialists drill out extra grams in its body. It is also necessary to weigh the pistons, piston pins and other parts of the CPG before assembling the engine. Differences in the weight of parts can cause a serious increase in vibrations.

Rubber

There are often cases when vibration when accelerating appears due to the installation of low-quality tires. Most often these are tires from budget and extra-budget manufacturers. The peculiarity of such rubber is that when checking on a balancing stand, a discrepancy that causes discomfort when driving a car may not be noticed. In the second case, balancing only temporarily delays the reappearance of vibrations. Only replacing the tires will solve the problem.

The next reason for the appearance of unwanted vibrations is typical for owners whose car is shod with low-profile tires. The side cord of such tires does not have the rigidity and elasticity that is inherent in civilian versions of tires. Therefore, prolonged downtime, especially in the warm season, can cause temporary deformation of the tire at the point of contact with the road surface. Therefore, vibration during acceleration may be observed for a short time after the start of movement. The first kilometers should be covered with extreme caution.

Uneven wear

Asymmetric wear of the tread on the tire and the appearance of “bumps” will lead to the fact that the suspension elements will experience additional vibration load. Of course, the whole car as a whole will vibrate at speed.

Wheel bearing

A malfunction of this unit is indicated by wheel play. To diagnose, hang up the wheels and shake each of them in the longitudinal and transverse directions. The play will be a signal for an immediate replacement.

Suspension and steering

Worn suspension elements cannot cause constant or periodic vibrations when driving. Their purpose is to dampen shocks that come from the road surface. Therefore, a car with a faulty suspension can scour the road, make squeaks or knocks when turning the steering wheel, or make dull or loud “echoes” of obstacles overcome.

But keep in mind that in the case of worn rubber products, hinged, elastic elements (ball joints, support bearings, shock absorber struts, steering tips and others), the beating, for example, from unbalanced wheel rims will be felt much stronger.

To safely drive a car, it is worth solving the problem comprehensively.

In the case of steering, variations in the design of different systems do not allow us to draw clear conclusions. From the personal experience of the author of the article, I recall a case when the steering rack guide bushing, the so-called “binoculars,” was to blame for the runout at speed (more so when braking).

Messages 1 to 20 of 25

1 Topic by denix 2016-09-19 19:48:39

- denix

- New member

- Inactive

- Registration: 2016-05-13

- Posts: 24 Thanks : 0

- Car: VAZ 2110

Topic: VAZ 2110 has rough idling and there is vibration on the steering wheel

Good afternoon, the car is a VAZ 21104, engine 1.6, 16 valves, the problem is that the revolutions fluctuate from 800 to 840, while vibration is felt in the steering wheel (this never happened before), I washed the remote control, changed the IAC, changed the spark plugs, checked the coils, checked for suction with a smoke generator . In general, I can’t find any problems, where should I dig?

2 Reply from Sergey VAZ 2111 2016-09-19 23:12:44 (2016-09-20 04:49:57 edited by Sergey VAZ 2111)

- Sergey VAZ 2111

- Connoisseur

- Inactive

- Registration: 2013-11-21

- Messages: 513 Thanks : 145

- Car: VAZ 2111

Re: Rough idling of VAZ 2110 and there is vibration on the steering wheel

I will list the reasons for the uneven xx. DMRV. Rhh. Dpdz. And to the hot DC. But in your case, DK is unlikely. It could also be the throttle body itself, compression, fuel pressure, clogged injectors, and poor contact in the plug of the listed sensors. Spark plugs, ignition module. Air filter. And the gasoline itself. Look for it yourself. But my advice is, if you don’t have a tool to check - sensors, pressure and wiring - go for diagnostics. You can spend a lot of time searching at random.

3 Reply from Admin 2016-09-20 05:59:28

- Admin

- Administrator

- Inactive

- Registration: 2012-02-20

- Messages: 3,257 Thanks : 624

Re: Rough idling of VAZ 2110 and there is vibration on the steering wheel

Also check the engine mounts, there should be no vibration

4 Reply from denix 2016-09-20 06:50:55

- denix

- New member

- Inactive

- Registration: 2016-05-13

- Posts: 24 Thanks : 0

- Car: VAZ 2110

Re: Rough idling of VAZ 2110 and there is vibration on the steering wheel

I will list the reasons for the uneven xx. DMRV. Rhh. Dpdz. And to the hot DC. But in your case, DK is unlikely. It could also be the throttle body itself, compression, fuel pressure, clogged injectors, and poor contact in the plug of the listed sensors. Spark plugs, ignition module. Air filter. And the gasoline itself. Look for it yourself. But my advice is, if you don’t have a tool to check - sensors, pressure and wiring - go for diagnostics. You can spend a lot of time searching at random.

I went to the diagnostician, he couldn’t find anything, they checked everything, the pressure was 3.9, he measured the compression using software, it was also normal, I checked the air leaks with a smoke generator, I cleaned the injectors, changed the IAC, the air pressure sensor when diagnosing at idle shows 0, air consumption shows 9, new spark plugs were installed, the coils were also checked, they are also in order, I cleaned the remote control not so long ago (5 months ago). I don’t have the strength anymore, I don’t know where else to go. I can send screenshots with diagnostic parameters, if you can understand something from them

Added: 2016-09-20 09:50:55

Also check the engine mounts, there should be no vibration

I changed the airbags, but they have nothing to do with it, before my speed stood rooted to the spot at xx, but now it jumps a little

Source

Engine mounts, tie rods and other problems

There is another group of problems that cause vibrations when accelerating a car. It is difficult to collect these problems into one bundle, because they are all different and arise for various reasons. Vibration often occurs when one of the engine mounts is broken. This can easily be checked by increasing the speed while shaking.

The gearbox may also be the culprit for this type of problem. If the car starts to shake at 80 kilometers per hour, you can very easily check the fault of the gearbox by performing the following procedures:

- accelerate to a speed of about 85 kilometers per hour;

- depress the clutch and observe the vibration change;

- engage third gear and smoothly release the clutch;

- try accelerating from 50-55 kilometers per hour in last gear.

DUAL MASS FLYWHEEL

Symptoms of damping flywheel failure:

- creaking, grinding noise when starting and stopping the power unit;

- rumbling sound when the engine is idling;

- vibration transmitted to the body and interior (with non-critical wear only in cold weather).

The reason for this behavior is the backlash of the elements of the spring-damper system, which is designed to dampen torsional vibrations. On cars with manual transmission, to check the flywheel, just squeeze the clutch. If the engine begins to run smoother and vibrations have decreased, it means that the reason for unstable idling is the dual-mass flywheel. The owner of a car with a robotic gearbox is left to rely on indirect signs and defects after disassembly.

KNOCKING AND UNEVEN OPERATION IN COLD

Accelerated wear of cylinders and pistons is a real problem for many owners of Volkswagen and Skoda cars with gasoline engines. Recently, cases of scoring in cylinders on Hyundai cars have become more frequent. Due to the tendency to lighten the CPG elements, reduce the thickness of the piston rings, the flame zone and the length of the skirt, repositioning the pistons is associated with heavy loads. Local overheating associated with operating a car in traffic jams (disturbed air flow, long periods of idle time), improper engine warming up in winter, lead to wear of the CPG.

As a result, the engines begin to knock when cold. As it warms up, the knocking, and with it the increased vibration in the body, stops.

Let's sum it up

If you are unable to find the problem that is causing the body or steering wheel to vibrate in your car when accelerating, you should contact a professional. Do not leave this problem, because it can worsen and create dangerous travel conditions for the driver and passengers of the car. It is necessary to respond as quickly as possible to all possible problems and eliminate them by replacing failed machine elements.

Often, to determine the problem, you don’t even have to go to a service station and use expensive diagnostics. It is enough to inspect the car yourself and determine what problems caused the body vibrations. Have you had similar problems in your experience, and what parts of the machine caused them?

Strong vibration of the engine at idle speed VAZ 2110 8 valves

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Vibration began especially at 3000 thousand rpm, and at idle it does not work smoothly

Alternatively, the valves get stuck. Adjust again and make the gaps 0.05 -0.1 more than normal, nothing terrible will happen and if the valves were tightened, you will immediately feel the difference. Servicemen like to tighten the gaps so that the timing belt works more quietly, but the other side of the coin is stuck valves (symptoms like the author of the topic), and later burnt valves. Good luck.

The vibration is such that you can’t hold the gear lever in your hand.

Senya58

I thought that instead of guessing on coffee grounds, install any MK that shows error codes. Firstly, you will save a lot of money on further diagnostics, and secondly, without all these would-be specialists, you will begin to understand where something is faulty. Without knowing the error codes, you can make up a lot of things here.

I once got a fantastic vibration on the nine by installing the generator drive pulley crookedly. The car shook feverishly - I would never have thought that such a small mass of the eccentric would cause such consequences. Installing a pulley on the injector crookedly is unlikely, because... DPKV, but still don’t be lazy to remove it and check it just in case. If it suddenly cracked or was installed incorrectly, the eccentrics at the services can sculpt anything.

Source

Vibration during acceleration at high speeds (VAZ 2110 1.6 16 cl)

Please tell me if anyone has encountered what the problem might be. Vibration when accelerating at high revs, as the revs drop, the vibration disappears even at a speed of over 100 if the car is already coasting

Comments 110

Hello, please tell me, did you find the reason?

Hi all! I re-read everything and realized that the cause of the vibration was never found. Today I noticed a vibration at rpms above 2500 in my 10. At first it seemed to me that something was rustling when I accelerated. Well, I always drove with music, the rustling was not always audible, but today without music, you can hear everything where everything is. Arriving home, I decided to find the rustler. When you reach 2500 rpm, something starts to vibrate, and the vibration gets into the gear shift knob, and it, in turn, rustles, because when you lift it, the rustling stops, but this vibration is felt by your hand. After consulting with my father what it could be, he hypothesized that it was the input shaft bearing. And I would like to know if they have already found where this vibration came from or if they still haven’t parted with it. Because I didn’t find the rustler right away. The vibration is not strong enough to be felt by the whole body, but it is there, and when you hold the gearshift knob you feel how hard it hits your hand with a small tremor.

Why else might the engine vibrate at idle?

Now let’s imagine a situation where the engine runs smoothly and the support cushions do not cause any complaints, but vibration is transmitted to the car body.

- The culprit may not be the motor itself, but some attachment or element that is in contact with the body. To determine, it is necessary to carefully examine the engine compartment, as well as perform diagnostics from below. The optimal solution would be to use a lift, drive the car into a pit or drive onto an overpass.

- Another cause of engine vibration can be failure of the balancing shafts. These shafts are installed on some engines that are inherently prone to vibration to minimize vibration and achieve optimal balance.

- Note that a fairly common cause of engine vibration is contamination of the fuel system or refueling with low-quality fuel. The engine begins to operate especially unstable if water gets into the fuel. Vibration is accompanied by increased fuel consumption and a drop in power. Usually the problem is eliminated by pumping out low-quality fuel from the fuel tank or diluting the volume already in the tank with high-quality gasoline or diesel fuel.

- Next, you need to check the filters (air and fuel), since contamination of the filter elements and a decrease in their throughput can cause unstable operation of the power unit. The fact is that the composition of the fuel-air mixture in such conditions is far from optimal for the idle mode.

- You should also pay attention to the elements of the ignition system. It is necessary to check the spark plugs and high-voltage wires, the ignition coil.

Engine idle speed is affected by the condition and serviceability of certain sensors in the electronic engine control system. Should be diagnosedMass air flow sensor

, idle speed sensor, TPS,

DPRV

,

DPKV

etc.

- A heavy load on the generator quite often causes engine vibration at idle. The simultaneous inclusion of powerful energy consumers (air conditioning, heated windows, mirrors, seats, etc.) on cars with a small-volume internal combustion engine often leads to an increase in the level of engine vibration. This vibration should disappear when the speed increases after pressing the gas pedal. Sometimes the generator itself may need to be checked, since its malfunction can lead to increased vibrations at idle.

- The appearance of engine vibrations that are reflected to the body can occur due to breakdowns of both the manual transmission and the automatic transmission. This does not depend on the type of automatic transmission (automatic transmission, CVT, classic automatic transmission, etc.). The problem may lie both in the transmission itself and in the clutch, which is structurally present in manual transmissions and robotic gearboxes.

Tips and tricks

As you can see, to prevent vibrations, regardless of whether the engine is carburetor or injection, it is necessary to maintain the cleanliness of the fuel system, the functionality of the ignition system, etc.

The fuel pump and ECM sensors, fuel and air filters deserve special attention; the fuel injectors, idle air valve, and accelerator pedal need to be adjusted. It is important to understand that vibrations that are not eliminated in a timely manner lead to the following negative consequences:

- cracks in the car body;

- gradual unscrewing of even the most tightly tightened nuts and bolts (which can lead to an emergency);

- premature wear of parts, resulting in, for example, oil leakage, destruction of bearings, seats, fasteners, etc.

Also, drivers often deliberately lower idle speed to save fuel (especially if they have LPG). At the same time, the consequences of engine vibrations will subsequently lead to repairs, which in cost will cover all the savings on fuel.

Even while driving, it is important to consider at what speed to drive. The fact is that if the car is used incorrectly, vibrations can also occur. To prevent this from happening, you should adhere to the following rules:

- upshifting must be done between peak torque and peak power;

- when vibration occurs, it is necessary to switch to a lower gear to avoid engine damage;

- if the car does not pull, you must also switch to a lower gear, but do not allow vibrations to occur.

This approach will avoid premature wear of parts, while ignoring it will quickly damage engine pistons, transmission bearings, clutch basket, crankshaft liners, etc. Carbon deposits and wear appear on the walls of the cylinder liners; due to constant vibration, oil seals begin to leak, and shafts begin to run out.

Engine mounting as one of the causes of vibration

As you know, the engine is mounted on supports, also called cushions. These are a kind of brackets, which in one part are attached to the car body, and the second part is made of hard rubber and one of the points of the power unit is already attached to it. Namely, the rubber base of the supports dampens the natural vibration of the engine that occurs during its operation. And in the event that the engine mounts are worn out or damaged and engine vibration occurs in a VAZ car. In this case, it is necessary to replace damaged supports.

Faulty ignition system

Engine vibration can occur during certain malfunctions in the ignition system, in which sparking at the spark plug electrodes is disrupted. Misfire, spark plug failure, damage to the high-voltage wire, distributor malfunction, incorrectly adjusted ignition leads to the engine starting to misfire and, as a result, vibration occurs. Eliminating all of the above reasons will help restore stable operation of the power unit.

Engine vibration after a major overhaul

If, after assembling the engine after its repair, vibration is felt in all modes, then there may be a number of reasons. Firstly, the crankshaft is not balanced. During assembly, before installation, the crankshaft must be balanced on a special stand. The engine flywheel also needs to be balanced. Secondly, incorrectly set gas distribution mechanism marks lead to disruption of gas exchange phases during engine operation.

Vibrations at low engine speeds

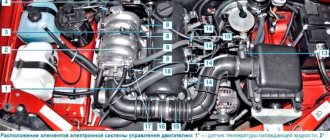

Installing an engine on a VAZ 2109 car

The heart of any car is its engine. The comfort of movement of the driver and passengers depends on its uninterrupted and quiet operation. But sometimes a situation arises when vibration is observed on the VAZ 2109 when the car is moving. This article suggests that you familiarize yourself with the causes and methods of eliminating engine vibrations with your own hands.

Causes of vibration in a VAZ 2109 car

The main reasons for the occurrence of vibrations of any unit are:

- Imbalance of its rotating components. For a car, this is the engine crankshaft and flywheel, radiator and heater fans, clutches, brake drums, wheels.

- There is a big difference in the mass of moving parts such as engine pistons and connecting rods.

The reasons for the imbalance may be:

- Structural, depending on the design features of the parts. So on the wheel, in order to pump it up, there is a valve; its mass upsets the balance.

- Technological, they take into account permissible deviations in the parameters and dimensions of parts during their manufacture; they appear when manufacturers strive to ensure the interchangeability of products during repairs.

- Operational, which are accompanied by uneven wear of parts, their deformation, defects in vibration isolators and other reasons.

A vibration isolator is an engine mounting element that reduces transmitted vibration; these are supports for the motor. They are a metal element with a rubber mass. Support designs can also be hydraulic, spring or combined. Particular troubles arise when the engine vibrates, which occurs when the fuel mixture burns unevenly in one cylinder - it begins to shake. The reasons for this may be:

- No ignition.

- No compression.

- Poor quality of the mixture.

To determine the operation of the cylinder, you need to remove the tip from the spark plug and reduce the idle speed. But during such a check, the switch may break, or the cover of the distributor or slider may break through. Using this method, you can reduce the negative effects on the engine by very quickly placing the removed tip on any bolt, which will ensure the appearance of a spark.

Advice: We must not forget about safety precautions: before carrying out work, you need to turn off the engine, remove the tips, then put them on, very often they stick to the spark plugs. After such development of the tips, you can start the engine.

- You cannot be struck by an electric current coming from high-voltage wires while the engine is running, but you need to remove the tips using pliers whose handles are insulated, and the metal jaws of the tool, when removing the tips, must be grounded to the car body with a piece of wire. If an electric shock occurs when touching the tip, you need to replace it or use a new high-voltage wire.

- If there is vibration at idle speed on a VAZ 2109 carburetor engine, you need to slowly pull the throttle cable with your hand so that the speed increases to approximately 3,000 rpm.

Tip: To ensure good access to the carburetor, if a breakdown is detected, it is better to remove the air filter. Plug all unused vacuum tubes. You can remove the impact of exhaust gases by closing the exhaust pipe, for example, with a plastic screwdriver handle.

After completing all the work, increasing engine speed, its reactions are possible:

- When the speed increases above 1300 rpm on the VAZ 2109, the vibration from the engine stops. This may indicate that the cause of the shaking could be in the power system or afterburning system. In this case, the ignition system is in working condition, there is not a single malfunction in it. As engine speed increases, other carburetor systems come into operation, but they cannot all fail at once.

- Air can leak through cracks or holes; excess air has less negative impact on the operation of the system when engine speed increases. Engine shuddering can be caused by one of the cylinders not working from time to time.

- Engine vibration may occur due to ignition problems. The requirements for spark formation at idle speed are higher than at 2,000 rpm. Therefore, with the slightest defects in the ignition system, engine failures at low speeds will be much greater, which will lead to engine vibration.

- The power system may also be to blame for shaking. This is either an excessively rich mixture, but such a phenomenon is rare, or a lean mixture, more often. The reason for this phenomenon may be excess air that enters the power system and then goes into the combustion chamber. But this can happen in relatively new engines. In older cars, the engine may vibrate at the slightest deviation.

- The cause of the shaking may be that the carburetor is overfilled with fuel. In this case, the exhaust gases will be black and not gray as expected. An engine when hot will be very difficult to start, but when cold there will be no problems.

- The cause of excess fuel may be deformation on the tip needle, which will cut off the fuel supply, or fatigue. A hole may appear in the float.

How to eliminate vibrations

There are some ways to balance nodes:

- Static. In this case, the part is not subject to forced rotation. This method does not require complex equipment; it can be used in a garage, but it will not be possible to completely eliminate the imbalance. It can be used to troubleshoot relatively small parts, such as the clutch disc or engine flywheel. They can be balanced “on knives” or “bearings”. In this case, when rotating around its axis, the part self-aligns and takes a position when the “heavy” side occupies a position below its axis of rotation. When performing work, the prisms must be positioned strictly horizontally, and the bearings must have minimal resistance “on a suspension” or “on a support”. Under the weight of one of the sides, the part deviates from the horizontal line. Let us apply this method to units with cylindrical support journals.

- Dynamic. It involves installing the part on special equipment and its constant forced rotation. Suitable for parts of any size, can eliminate any imbalance on the driveshaft, crankshaft and other similar products.

The mass of the part that needs to be removed to eliminate the imbalance is determined experimentally during static balancing. And with dynamic, this is performed by a computer installed on a balancing stand. After that:

- They lighten the “heavy” side by removing excess metal. This may be drilling or other machining of the part. Flywheels, cast iron brake drums, crankshafts, clutch baskets, drive pulleys, and wheel hubs must be balanced in this way.

- They make the “light” side heavier by adding additional weights. In this case, leaf springs are used, the metal is welded, or the elements are glued with a special glue.

Advice: This technology should be used if it is impossible to remove excess material from the “heavy” side without compromising the strength of parts such as wheels with brake discs made of light alloy and clutch driven discs.

Each person has his own threshold for the perception of vibration. But vibration can be considered unacceptable if: with the gearbox in “neutral” position, with the car stationary and the clutch engaged, the pedal is not pressed. A slow increase in engine speed leads to:

- There is a noticeable vibration on the steering wheel even when you lightly touch it with your fingers.

- Objects lying on the dashboard move.

- The image in the rear view mirror located inside the car is blurred.

- When the car moves, unpleasant vibrations are felt on the controls, floor, and seats.

Advice: Before you start searching for the source of increased vibration, you need to determine the modes and conditions for its manifestation: while driving or while the vehicle is stationary. After that, remember the moment of its occurrence - it was originally on a new car, it appeared during operation or after the repair of a component.

When diagnosing a car, you must take the following precautions:

- When feeling with your hand while the engine is running, do not touch “suspicious” areas with very hot or rotating parts;

- When hanging the car, it must be placed on reliable stands.

- When driving on roads with a large number of vehicles, you must not interfere with the movement of other cars.

When the vehicle is stationary, vibration most often occurs if:

- The engine and its attachments (generator, air conditioning compressor) are running.

- The radiator and heater fans turn on;

- There were defects in the exhaust system and suspensions of the power unit.

To find the source of vibration, you can follow the following sequence of actions:

- With the engine turned off and then off, inspect the suspensions of the exhaust system, power unit and parts around them. The suspension elements must be intact. There are cases when power protection is located very close to the engine sump. Their contact may cause vibrations.

- Parts that have become unusable must be replaced.

- Check that fasteners are securely tightened and tighten loose ones.

- You can determine that the vibration is coming from the fan by turning it off or removing the impeller.

- Disconnect the attachments one by one (remove the drive belts) and, starting the engine, check the vibration level in its operating speed range. An element that has become unusable must be replaced or balanced, for example a pulley.

- With the engine running, depress the clutch pedal or set the automatic transmission selector lever to the “N” position. If vibration cannot be eliminated, then its main sources may be: the torque converter, crankshaft, flywheel, clutch basket or automatic transmission parts, or the difference in the mass of the pistons and connecting rods is greater than the permissible value.

- On a VAZ 2109 car, vibration at speed usually occurs from the chassis or transmission elements. If its level depends only on the speed of the car, and does not change when the car coasts, it means that vibration is created by a unit located after the gearbox driven shaft. These can be drive or cardan shafts, hubs, wheels, transfer case elements. Moreover, the vibration frequency from the cardan is almost four times higher, compared to wheels, discs and brake drums.

- When vibration only occurs during braking, the source is most likely the brake drums or rotors. They, and also the hubs, may be made with large deviations in the beating of the working and seating surfaces.

- When using low-quality tires, the reason may be its uneven hardness, which increases during braking due to increased load on the front wheels.

- Vehicle vibration in a small speed range of approximately 10-15 km/h is caused by wheel imbalance. You can remove it on the wheels by balancing them, as shown in the photo.

Car wheel balancing

- Additionally, the imbalance of the front wheels is manifested by the steering wheel beating. When rearranging the rear and front wheels or after checking for balancing, you can verify that they are defective.

- Hang up the drive wheels one by one.

- Start and warm up the engine, engage the highest gear (fourth or fifth), slowly release the clutch pedal and at the same time increase the engine speed until noticeable vibration appears.

- If there was no vibration when the drive wheels were suspended, it is most likely created by parts of the driven axle - the brake drum (disc) or the hub. This can only be clarified after a second check during the next replacement with good wheels, for example from another car.

- Unbalance of the brake disc, drive parts, or hub can cause vibration on one side of the car. In this case, you need to remove the wheel and brake drum one by one, then replace the axle shaft and hub with ones that are already aligned and in good working order, and repeat the check each time. Vibration on a new car can be caused by improper assembly of components that are sources of vibration, or installation of units with a known increased level of vibration.

The cause must be sought on a stationary machine and a moving one.

Advice: When inspecting, you must pay attention to the correct use of vibration isolators. They can be almost identical in appearance, but differ in characteristics when equipping the car with some elements. Therefore, you need to compare the markings of the parts and the hardness of the rubber to the touch.

If vibration on a VAZ 2109 car suddenly appears when starting, it is advisable to recall previous events in memory. Perhaps you had to cross a deep puddle immediately after heavy braking, when the temperature of the parts was high. The reasons why vibration occurred during acceleration on the VAZ 21093 may be:

- In a brake disc that was warped from rapid cooling with water.

- The car hit the curb with the CV joint or the wheel ran over the edge of a hole or obstacle.

- The start of vibration indicates damage to parts (wheels, shaft, tires).

Shaking that occurs after repairs when replacing rotating parts may indicate a large imbalance of newly installed elements or errors during repair operations that led to incorrect assembly of the unit or deformation of the part. The instructions for preventing unacceptable vibration suggest replacing all the parts that cause it with new elements or repairing old ones. When installing new components, it is useful to check them, and then, based on the test results, either exchange or balance them, then the cost of subsequent repairs will be much lower. How to properly balance parts and assemblies can be seen in the video.

Ways to eliminate vibrations

After competent, professional installation of the causes of engine vibrations, they must be eliminated as soon as possible. The methods of “treatment” are very diverse, it all depends on the “diagnosis”.

Low compression

One of the reasons for engine tripping is low compression levels in the cylinders. This may occur due to the failure of any part that is part of the cylinder-piston group. In order to fix this problem, you will have to resort to disassembling the engine itself.

The cause of low compression may be a worn piston, piston rings and/or valves. In this case, the most optimal and rational option for eliminating vibration will be only a complete professional replacement of defective parts.

If you replace it yourself or restore it, further, more significant breakdowns may occur, and therefore costly repairs of the entire power plant.

Uneven air flow

If air enters the combustion chamber disproportionately, this can be corrected by simply replacing the air filter. You should also carefully inspect the air supply system for cracks and chips. It is recommended to replace the mass air supply and throttle sensors.

Incorrect fuel supply

In this case, professional car mechanics advise performing the following algorithm of actions:

- carefully inspect and clean the injectors;

- if after this the problem has not been resolved, then the injectors must be completely replaced;

- carry out an inspection of the condition and operation of the fuel pump, if necessary, replace the assembly;

- identify and reset ECU errors

Ignition system

When diagnosing early or, conversely, later ignition timing in the system, you should pay attention to the condition and soot of the spark plugs, as well as the integrity of the high-voltage wires. If replacement is required, it is best to do this with the entire set.

Engine mounts

If the fastening elements become loose or the engine mounts fail, it is necessary to strengthen the fastenings accordingly and consistently. Check the pillows for cracks and other defects; if necessary, replace them in pairs or completely.

In addition to the above measures, to eliminate strong vibrations emanating from the engine, proper installation of the timing belt, professional balancing of the crankshaft, as well as replacement of CPG elements of different weights (worn out) may be relevant.

Thus, the “dancing” of the power unit can occur for various reasons, which are also eliminated accordingly, each according to its own algorithm. Eliminating the causes of vibrations is a necessary process, since such vibrations, in addition to causing discomfort to the driver and passengers, can lead to expensive repairs of the car engine itself.

In addition, one of the common causes of strong vibration is the spontaneous loosening of fasteners. And if a major engine overhaul is an expensive procedure, but still fixable, then loose bolts and nuts, especially while the car is moving, can lead to irreparable consequences.

Painfully banal

If the body vibrates when accelerating, you should not be upset and immediately count out a large amount for repairs. Below are some common and not so common cases that can cause discomfort when driving:

- Dirt or ice block stuck to the inner rim of the wheel rim. Diagnosing the adhesion of dirt is not difficult, since noticeable beating will occur only after off-road driving. In winter, every driver should be prepared for such troubles;

- Incorrect installation of brake and wheel discs. If the mating plane has not been cleared of contaminants or is deformed, this will cause an increase in vibration load during movement;

- discrepancy between the landing dimensions of the wheel rims. Each disk has its own installation parameters, violation of which can lead to imbalance. This mainly concerns disc bolt patterns;

- loose disk fastenings. This is the first thing to check when you notice runout in the steering wheel. The consequences of neglecting this advice can be very dire.

There can be a huge number of possible problems with a car, and a specific breakdown does not always give specific signs of its presence. Drivers often complain about body shaking when accelerating or at a certain speed. There can be quite a lot of problems that determine this indicator. If your car has vibration during acceleration, you should look at all possible breakdowns and immediately replace the failed components.

It is not always possible to tell by the nature of the vibration where exactly the problem lies. On different cars, only the steering column can vibrate, putting it in the driver’s hands, but the entire body can shake. It all depends on the design, nature and degree of damage to the components and assemblies that need to be replaced. Let's look at the main causes of vibration during overclocking.

How to remove engine vibration 2112 (fifth support)

VAZ 2110 (10th family)

Does the engine vibrate, which reverberates throughout the entire car, and also produces unpleasant sounds? Removing vibration is not difficult.

Recently the gearshift knob started to rattle. I thought it was the same problem as on the 99th. But after reading the forums, I decided that it was necessary to install a standard support on the box from the 8-valve 10. Installed. I started it - everything seemed fine, there was no vibration, I went for a ride - it was great, the gearshift knob stood rooted to the spot. But like most people (I found this out later), vibration appeared at idle. After reading the forums I found out why this is happening. Today I decided to install the support correctly. Indeed, when I looked at the support again, I realized where the vibration was coming from - I pulled it tightly to the body.

In general it should be set like this:

- Assemble the mount and support BEFORE installing it in place.

- Screw 2 bolts first TO THE BOX, the pillow hangs. But do not tighten the bolts completely, otherwise it will be difficult to install the mounting bolts to the body.

- Now we need to figure out how many wide washers need to be laid between the support and the body on the left and right, after tightening, the rubber in the middle (damper) should under no circumstances be pressed against the iron (this is exactly what happened to me the first time, although I installed washers), There MUST BE A CLEARANCE!

Because My car is far from new, which means the pillows are tired. They write on the forums that they put in 2 to 4 washers, I didn’t think twice and put in as many as 5 washers. Maybe it could have been less, but in my opinion it was just right. The washers are approximately 2 millimeters thick. Take washers with an outer diameter equal to the width of the U-shaped mounting of the pillow.

By the way, there are no bolts with the support and I didn’t immediately figure out which ones were needed. But as they say, Google is here to help.

In the factory configuration, the support is attached to the body with studs, but I replaced them with two bolts.

To attach to the body:

To attach to the box:

- Bolt M12x1.25x70 - 2 pcs.

- M12x1.25 self-locking nut - 2 pcs.

Here she is darling:

I tried the bolts on the body:

I secured the support to the box, but did not tighten it yet:

I secured the support to the body.

Here the cause of vibrations at idle is highlighted, although there were already two washers:

But I didn’t know about vibrations yet, so I fixed it as it was:

And this is a converted version; the washers are visible in the photos.

Source

Why does the car jerk when starting off?

Any car malfunction makes its owner nervous. One of these problems is the car jerking when starting off. This can be caused by both trivial reasons, the elimination of which does not require large expenses, and serious breakdowns. In any case, it is imperative to establish the cause of such jerks and eliminate it.

Why does the car jerk when starting off?

If the car starts to jerk while starting from a stop, the reason is usually due to a malfunction of the clutch or CV joints. In such cases, it is imperative to carry out diagnostics in order to immediately determine the breakdown and begin to eliminate it.

The main thing is not to panic, you need to make sure that before you start driving, the engine is warmed up to operating temperature, there are no problems with the ignition and the fuel supply system. If everything is normal here, then we need to further look for the cause.

Driving style

Inexperienced drivers often abruptly release the clutch pedal, causing the car to start jerking away. There are no malfunctions, you just need to change your driving style, learn to smoothly release the clutch and add gas at the same time.

It is necessary to determine the moment of clutch actuation on the car. To do this, start off without adding gas and smoothly release the clutch. Having determined in what position the clutch begins to engage, you can move away smoothly. On a car with an automatic transmission there is no clutch pedal. In order for such a car to move without jerking, the gas pedal must be pressed smoothly.

Problem with CV joints

In front-wheel drive cars, the force from the gearbox is transmitted to the wheels using internal and external CV joints. If these parts partially fail, the car will jerk when moving away.

Signs of CV joint failure:

- backlash;

- knocking while driving;

- crunching when turning.

Replacing CV joints can be done at a service station or independently. These are relatively inexpensive parts that require little time to replace. Having an inspection hole and a set of keys, you can replace the CV joints with your own hands.

Procedure for replacing the CV joint:

- Removing the wheel from the side where the CV joints will be replaced.

- Loosening the hub nut.

- Unscrewing the bolts that secure the outer CV joint to the main drive shaft.

- Removing the axle shaft. It is removed along with the inner and outer CV joints.

Clutch faults

Very often, problems associated with car jerking at the start occur when the clutch breaks down.

Main clutch malfunctions:

- wear or damage to the driven disk, repair consists of replacing it;

- jamming of the disc hub on the gearbox input shaft. Clean the slots from dirt and remove burrs. If the damage is large, you will have to replace the disk or shaft;

- wear of the linings or loosening of their fixation is eliminated by installing a new driven disk;

- weakening or breakage of springs, window wear is eliminated by replacing the disk;

- Seizure on the flywheel or pressure plate. You will have to change the flywheel or clutch basket;

- loss of elasticity by the spring plates located on the driven disk. Eliminated by replacing the driven disk.

Replacement of the clutch driven disc is carried out in the inspection pit. You can raise the front of the car using jacks or a winch.

Work order:

- Preparatory work. Depending on the design of the car, you will need to remove the starter, driveshaft, resonator, exhaust manifold and other parts.

- Removing the gearbox allows access to the clutch.

- Removing the clutch basket cover. After this, all parts are removed from the flywheel. A new driven disk is installed and the mechanism is assembled.

ICE CYCLE DIESEL

Vibration transmitted to the body is one of the features of the operation of a diesel engine, which is determined by the nature of ignition and combustion of diesel fuel. But it is important to distinguish the normal level of vibration from obvious symptoms of a malfunction.

We recommend that you start checking the fuel system with computer diagnostics, or more precisely, with real-time reading of injection correction. A positive correction will indicate an overflow of fuel, respectively, a negative correction will indicate a decrease in the injection time by the computer. This indicator does not mean that the injector is faulty. But it perfectly shows how, by adjusting the amount of fuel injected, the ECU tries to maintain stable engine operation at idle.

The cause of increased vibrations may well be the high-pressure fuel pump itself. If vibration is transmitted to the body only in the first minutes after a cold start, most likely the cause is a faulty glow plug. Also, do not rule out problems with loss of compression.

IMBALANCE AFTER REPAIR

If vibration at idle appears after a major engine overhaul, the reason may be due to negligence in the selection of parts. Negative factors include:

- installation of pistons, connecting rods, which differ significantly in weight;

- discrepancy between the gaps in the cylinder-piston group, as a result of which the relocation of the pistons occurs with an impact;

- unbalanced crankshaft;

- critical wear of seats, poor lapping of valve chamfers, incorrect adjustment of thermal clearance. These factors can cause loss of compression and vibration.

On cars with a manual transmission, vibrations at idle and medium speeds appear after installing a low-quality clutch kit. The imbalance transmitted to the body will increase if, after repeated overheating, the flywheel has not been machined and balanced. If the flywheel is excessively lightened and the inertial mass is reduced, smoothing out the uneven rotation of the crankshaft, the engine will operate unstably at idle speed.

Many engines begin to vibrate at idle after removing the balancer shafts. Owners get rid of the balance shaft mechanism so as not to spend money on their repair. Removing balancers not only provokes vibrations, but also increases the load on the crankshaft, which reduces its service life.

Thanks for visiting this article. Please give the article a thumbs up, this will help spread it and subscribe to the channel , read my old articles and wait for new ones.

We study wheels and chassis - the main cause of vibrations

The main indicator that the wheels or drives of these same wheels are to blame for your problems is shaking at a certain speed. Often these are body vibrations in the range of 80-100 kilometers per hour, but sometimes the shaking may not go away even after 60 km/h, so in any case you need to fully diagnose the chassis.

In this case, it is not necessary to go to a service station and carry out expensive diagnostic operations. It is enough to apply all your knowledge and study each chassis unit for possible breakdown. The most common problems in this case are the following:

- the wheel mounts are unscrewed, which causes vibration on one of the wheels;

- The brake disc is poorly fixed; at speed it begins to vibrate;

- the wheel drive shaft is bent - the body vibrates constantly, with increasing speed the vibration intensifies;

- damaged CV joints - this is the most common problem that causes vibrations on the body;

- The wheel bearings are damaged, which causes shaking at any speed.

The most common problem in this manifestation is CV joints. To check their serviceability, just grab the shaft with your hand and try to turn it. If the shaft has play of more than a couple of millimeters, the CV joint must be replaced. Interestingly, vibrations of the car body during acceleration can be caused by both external and internal CV joints.

You can also easily determine if there is a problem with this chassis mechanism by examining the anthers. If the rubber part of the boot ruptures, we can safely talk about problems with this mechanism. If water, dust and dirt get into the CV joint, the unit will not survive more than a few days.

How to reduce engine vibrations

If the car has a carburetor, then to reduce vibrations this element requires careful adjustment, after which the idle speed is set. At the same time, the fuel pump is checked.

On injection cars, the fuel pump, injectors, electronic control system sensors, and fuel pressure regulator in the fuel rail are also checked. Additionally, it is recommended to clean the throttle valve and check the idle air valve, which supplies air bypassing the throttle valve at idle. Vibration of a diesel engine at idle may indicate certain malfunctions of the fuel injection pump or injectors, which will also require careful diagnosis and subsequent adjustment.

VAZ 2110 troits when cold, but after warming up it works fine

The operation of the motor can be accompanied by various problems. All of them must be immediately eliminated. For example, a VAZ 2110 engine with an 8-valve injector shakes at idle, but after the car warms up enough, everything comes back to order. Many car owners try not to focus on this and continue to operate the car. Meanwhile, they do this in vain, since the existing problem requires a solution.

Reasons for needing an engine check

The operation of the engine should be like a clockwork. It should not twitch, but work smoothly. Sometimes there are suspicions that the engine is unstable. VAZ 2110 troits when cold, but after warming up it works fine. It’s better to immediately put emphasis on this and open the hood. After this, you should listen carefully to how the engine operates. If the engine “troubles”, it means that some cylinders are not involved in the work. This is due to conditions that are absent for the normal course of processes in the combustion chambers.

The result of this is that the vehicle's power decreases and fuel consumption increases significantly. The reasons for this can be very different in nature. First, you need to find out which cylinder is the result of the fact that when the engine is cold, it is running rough, and as soon as it warms up, everything returns to normal. This can be determined by removing the high voltage wire from each of the spark plugs. During normal operation of the cylinder before this, a failure will be observed. The revolutions will also drop. The tachometer will tell you about this.

What is the reason for engine instability?

The situation in which the VAZ 2110 troits when cold and then works normally can be due to a number of reasons:

- In all likelihood, the spark plug is faulty. She might just get wet.

- In some place there is a breakdown of the high-voltage wire.

- Extremely low quality of gasoline poured into the tank.

- The operation of the vacuum brake booster is accompanied by air leaks.

- The exhaust manifold has lost its seal.

- The valves need to be adjusted.

- The valve or piston is burnt.

- The piston rings have failed.

- The valve levers have exhausted their service life.

- The cylinder head gasket is broken.

- The valve stem seals have become unusable.

If the problem is a non-working spark plug, then it simply needs to be replaced. This fully applies to a broken wire. If sparking is noticeable in the dark, this may indicate damage to the high-voltage wire.

VAZ cars have always suffered from problems related to valves. You should always remember that after every 20 thousand mileage, the valves must be adjusted. It is necessary to ensure that they are completely closed and opened.

Situations in which valves and even piston burn out do not happen often. But to determine this, compression measurements in the cylinders are required. You can determine when the piston rings have reached the end of their service life and their destruction by pouring a small amount of motor oil into the cylinder. Increasing compression indicates a problem in the rings.

Vibration in the cabin from the VAZ 2110 engine

Post edited by DENiX: 08/23/2016 - 11:28

Student (08/23/2016 - 11:29) wrote:

- Group: Users

- Messages: 22,193

- Group: Users

- Posts: 3,912

Yuri Petrovich (08/23/2016 - 13:28) wrote:

Post edited by Straj_59: 08/23/2016 - 14:33

Straj_59 (23.08.2016 - 14:32) wrote:

- Group: Users

- Posts: 3,912

DENiX (23.08.2016 - 15:34) wrote:

Post edited by Straj_59: 08/23/2016 - 16:55

Source

Design and purpose of tens engine mounts

Over the years, vast practical experience has been accumulated on the topic of how to change engine mounts on a VAZ 2110, and videos of repair processes can also be found in abundance.

However, few people pay attention to the features of the part. And, it must be said, it is in vain, because such knowledge will help to accurately determine the source of vibration and purchase the necessary spare part for repair. The main purpose of the engine support is to reduce the level of vibration transmitted from the power unit to the car body. The rubber-metal structure consists of a steel base with a thick rubber cushion. The device has proven itself well, since it is quite reliable and is worth the money. The eight-valve Lada 2110 engines are attached to the body at three points: right, left and rear. The side supports connect the body to the engine block through through holes. The rear support is attached with two bolts to the gearbox, and two nuts to the body. The importance of this damper part is very significant - it prevents longitudinal vibrations of the internal combustion engine during braking and acceleration.

VAZ engine vibration

Why does engine vibrate ? Many inexperienced car owners of domestic VAZs ask this question. Engine vibration can occur in various modes, but it manifests itself to a greater extent at idle speed, since in this mode the engine operates with minimal power, which has a beneficial effect on the occurrence of various minor malfunctions. However, despite this, vibration of the VAZ engine can also occur at high speeds. Why this happens, and what may be the reason for the unstable operation of the power unit, as well as how to eliminate the vibration of the VAZ engine will be discussed in this material.

Vibration on the steering wheel of a VAZ 2110: causes and solutions

VAZ 2110 - steering wheel vibrations

Car owners often face the problem of play and wobble in the steering wheel. Thus, vibration on the steering wheel of a VAZ 2110 is a fairly common phenomenon, observed more often at a speed of 90 km/h. The shaking increases more and more when driving exceeds 100 km/h, regardless of the road surface. Let's try to figure out in this article why vibrations occur on the steering wheel of the VAZ 2110?

Left support - removal and replacement

- We drive the car into a pit or onto an overpass;

- Remove the engine splash guard (protection);

- We install a jack under the gearbox (it is better to place a small wooden block between the jack and the gearbox) and lift the box slightly, thereby freeing the left support;

Take a 15mm socket wrench with an extension and unscrew the support stud nut;

Remove the upper support stop;

We release the jack a little so that the box drops slightly and remove the support pin;

After this, using a 13mm socket wrench, you need to unscrew the 2 bolts that secure the support cushion to the body bracket;

Slightly move the cushion towards the engine and remove it;

- Remove the lower support stop.

Replacing the front lower support

This support is also installed only on the “two-piece”. Its functions include additional mitigation of vibrations that occur during engine operation. Replace it as follows:

- First, remove the engine mudguard;

- Using a “15” wrench, unscrew the screw that secures the bar (front suspension cross member);

- To remove the rod from the front support mount, you will need 2 open-end wrenches “15”. After unscrewing the nut, the screw is removed;

- Remove the engine support.

Installation should not cause any difficulties. But, only if there are remaining supports in the proper places. To align the holes you need to slightly rock the engine.

Replacing the front upper support

This support is only available on 12 models. It’s not on the “tens”. But some craftsmen can strengthen it there. In this case, removing the pillow will be similar. The work consists of several stages:

- Use a “17” wrench to unscrew the bolt securing the support rod to the body of your car. In this case, the nut may fall out of the box. Hold it;

- Remove the nut and bolt;

- Next, the bolt securing the rod to the engine is unscrewed. To do this you will need 2 keys “15”;

- The bolt is also removed;

- All that remains is to remove the bar.

Installation is in the reverse order. There is one small nuance. When installing, do not immediately tighten the threaded connections. First, tighten all the bolts, and only then tighten them. It is better to start from the place of attachment to the power unit.

Replacement on 16-valve engines