Air flow sensor

If the IAC turns out to be serviceable, then you should check the air flow sensor. To do this, you will also need a multimeter set to voltage measurement mode (in the range of up to 20 volts).

Measurements are carried out as follows:

- turn off the engine and turn on the ignition;

- measure the voltage at the sockets used to connect the yellow and green wires;

- if the voltage value is in the range of 0.98 - 1.02 volts, then the sensor is working. If not, then action should be taken.

DMRV VAZ 2114

First, you can try to clean the sensor by blowing it with a composition for cleaning carburetors (in the form of an aerosol), although this does not always help. If after purging the voltage readings return to normal, then the “repair” was successful; if not, then the sensor will have to be replaced with a new, similar one.

Is the EGR system on the injector working?

"Floating" speed can be caused by jamming of the exhaust gas recirculation (EGR) valve, which is installed in the exhaust manifold. It is necessary to periodically remove dirt from the valve seat and its seat using a carburetor cleaning aerosol, avoiding liquid getting on the sensor diaphragm.

Keep the valve seat clean

Attention! If cleaning the unit does not give a positive result, the device must be replaced.

Other reasons

Sometimes the engine may shut down due to a stuck idle air valve. Solving this problem is quite simple - you only need to adjust the throttle cable. True, the car’s performance will not be restored for a long time. But there will be enough time to get to the car service center.

If the car does not start when cold, then it is worth looking for a fault in the battery. Perhaps one of the terminals is not holding well. It is also worth resetting the ECU settings by turning off the power. After this, the on-board computer will reboot. This measure will be enough for several trips - then the system will accumulate enough information to start working normally, and the engine will most likely stall again.

Finally, if none of the above helps, you will need to pay attention to the injectors. Improper operation of this element is caused by:

- wear;

- clogging.

For cleaning, you should use a special liquid - WD-40.

Is the idle air control valve working correctly?

The IAC is checked by measuring the electrical resistance at the contacts - to diagnose the device you will need a tester (multimeter) set to the “ohmmeter” operating mode. To check the details:

- Let's turn off the ignition.

- Disconnect the connection block.

- Let's measure the resistance on contacts A - B and C - D of the device. The optimal readings of the device vary from 40 to 80 ohms.

- Let's repeat the measurements with contacts B - C and A - D. In this case, the multimeter should show “infinity” or an open circuit.

Any violation of the normal resistance values means a malfunction of the regulator. IAC failure is a common cause of floating engine speed at idle, and if a malfunction is detected, the device must be replaced. Before you begin dismantling the part, you must disconnect the negative wire from the battery. After installation, the new IAC is calibrated - the removed terminal is returned to its place, the ignition is turned on and after 5-10 seconds (there is no need to start the engine).

IAC failure is a common cause of floating engine speeds.

Conclusion

Many car enthusiasts do not know the reasons for the high idle speed effect, much less how to eliminate it. So, of course, experts and car mechanics recommend contacting a car service straight away, but our man won’t stop until he tries it himself.

There are many reasons for the effect of increased speed, from faulty sensors to errors in the electronic control unit. You can also fix the problem at home, which is what owners of VAZs and other domestic cars do. But owners of foreign cars will have to contact a car service center, where repairs can amount to a considerable amount.

Good afternoon. Help with advice. In general, in the cold weather the check light came on. At first the speed just started to jump a little. Now the idle is kept at 1.5k almost all the time. And if you press the clutch at speed, it increases up to 3k. From time to time the check does not disappear for long, but the problem does not go away, you have to revise the throttle all the time so that the speed drops. Also, all this is accompanied by increased gasoline consumption. Unfortunately, there is no BC, and I consider it a waste of money to go for diagnostics; they rarely help anyone significantly.

After reading a lot of posts about this, I realized that it was necessary to sin on one of the following: IAC, DMRV, DPS or lambda probe.

But I changed the pxx recently, when the speed, on the contrary, dropped to 0.5, plus if there are problems with the pxx, the check light does not light up.

The main task of the idle speed system (mode) is to maintain engine speed at a minimum level, ensuring complete combustion of the fuel-air mixture in the cylinders. The number of idle speeds on different engines may vary, the range is 700-950 rpm. Excessively low tachometer readings lead to unstable engine operation, which may stall. On the other hand, high engine speeds at idle are fraught with excessive fuel consumption and more toxic exhaust. Below we discuss the main reasons for the increased and unstable crankshaft speed at idle for a carburetor and injection engine.

Idling

Idling of a car is the operation of its engine when the gear is in neutral. At the same time, the fuel load, as well as the load on the engine, is minimal.

Idling is used in several cases:

- To “bleed” the oil after the car has been parked for a long time.

- To warm it up during cold weather.

- To keep the engine running for a long time without driving the vehicle.

Idling VAZ 2114

Engine idle operation looks like this: first, the speed quickly rises to 2,000 or even 2,500 rpm, after which it gradually decreases and stops around the 800 rpm mark.

This type of engine operation is absolutely normal. If, in idle mode, the VAZ 2114’s revolutions jump (either sharply increase or drop sharply, and the interval of “jumps” can be up to 1,500 rpm), then a malfunction has occurred in the engine system. In most cases, such a sharp fluctuation in speed leads to the engine stalling.

Idle speed control

The first thing you should check is the idle speed control. To do this, you will need a tester (multimeter) set to ohmmeter mode.

The check is performed as follows:

- turn off the ignition;

- disconnect the block;

- measure the resistance between contacts A * B and C * D of the regulator. If it is working properly, the device will show a resistance value in the range from 40 to 80 Ohms;

- measure the resistance between contacts B * C and A * D. If the regulator is operational, the ohmmeter will go off scale (on some devices an “open circuit” may be indicated).

Dirty IAC VAZ 2114

If the results obtained during measurements differ from those given above, then the idle speed controller is broken. By the way, its failure is one of the most common reasons why the idle speed of a VAZ 2114 injector fluctuates. If a breakdown is detected, the part should be replaced with a new, similar one (since the IAC is not a repairable device). Do not forget that before starting to replace the device, you should disconnect the battery ground terminal.

Injector

Here everything is much more complicated: the operation of an injection engine is associated with many sensors, ECUs and other elements of the power unit, in particular the fuel system. But first things first.

Idle air control sensor (IAC)

If this device is faulty, the engine may stall at idle, or its speed will float, making jumps in the range of approximately 600-1200 rpm. Therefore, it is necessary to ensure that the device is working properly. This can be done using a multimeter. Procedure:

- First, measure the supply voltage on a pair of outer terminals A and D. To do this, place the black probe of the device to ground (any unpainted metal part of the car body), and the red one to the indicated terminals in turn. When the ignition is on, there should be 12 V. If this is not the case, check the voltage at the ECU terminals (for the VAZ 2110 these are pins 4 and 54). If there is 12 V here, look for an open circuit in the wiring.

- Set the tester to ohmmeter mode. Resistance between terminals A and B, C and D: should be 40-80 Ohms.

- Check the motor for short circuit. To do this, measure the resistance between A and D, B and C: the arrow of the device should tend to infinity.

That is, a throttle position sensor, which is responsible for the amount of fuel mixing with air. If the fuel supply is incorrect, the ECU will automatically give a command and the idle speed will increase. Therefore, it is necessary to check the TPS:

- Unclip the connector that fits the sensor: you will see 3 contacts: for the control signal, power and ground.

- Start the engine and measure the voltage at the power terminal: it should be approximately 5 V.

- Stop the engine and switch the tester to resistance measurement mode (throttle valve closed). Measure it between ground and signal contact: it should be 0.8-1.2 kOhm. When the damper is closed, the value is 2.3-2.7 kOhm.

How to remove and install a new sensor

To dismantle, simply unscrew a couple of mounting screws. Next, disconnect the end of the damper shaft and, rotating the new sensor, align the holes to screw in the screws. Put the connector on.

After completing the work, it is necessary to delete the error from the controller’s memory. To do this, remove the terminals from the battery for a period longer than 8 hours. If the error has not cleared, try driving in a gentle mode so that the ECU resets it itself. If you fail again, you will have to contact a car service (you will need a motor tester).

Throttle valve

Jamming of this mechanical device will result in an increase in the amount of air supplied to the cylinders. As a result, the ECU will work again and begin to increase the volume of fuel to balance the mixture. To solve the problem, remove the damper and clean it with chemicals. If there is no result, the part will have to be replaced.

Optimal engine speed VAZ

Sooner or later, everyone asks the question: driving at what speed is optimal for normal operation of a car engine? There are two opposing sides to this issue: supporters of driving at low engine speeds and supporters of driving at high speeds. VAZ cars have gasoline engines with a maximum speed of 5500 rpm. However, both low and high speeds each have their own negative factors that affect engine performance.

Fans of driving at low speeds cite fuel economy as the main argument. All instructors in driving schools force their students to drive at low speeds (their interest is precisely in saving more fuel). Then these students graduate and begin to drive themselves at engine speeds of up to 2000. However, they forget about one thing: the instructor at the driving school does not care at all about the engine life of a government-owned car. And when you drive a car that you bought with your own blood and sweat, you begin to think: “How can I drive so that the car lasts longer? ". And here it turns out that low speeds have a significant disadvantage: engine lubrication is worse at these speeds. In order for the lubricant to circulate well in the lubrication system and to be sprayed onto the components of the lubrication system, revolutions of more than 2500 rpm are required. That is, at low speeds, engine lubrication is significantly worse. Another disadvantage of low revs is poor charging of the battery, since the lower the revs, the less power the generator provides. It won’t be a very pleasant surprise to walk up to your car in the cold morning and not start it because the battery is not fully charged.

Now let's look at driving at high speeds (4000 or more). At such speeds, the lubrication pressure is high, lubricant circulates through the system, but too intensely - because of this, the lubrication channels may become clogged (especially if the engine oil has not been changed for a long time). The second negative factor is engine overheating. Even if everything is in order with the engine cooling system, it will not always withstand driving at high speeds for a long time. Well, if there are any problems: the thermostat does not open completely, the coolant level is low, the cooling system is clogged, then engine overheating is guaranteed. Antifreeze will begin to boil away, the cylinder head gasket may burn out, or the engine may even jam. In general, high speeds are also not an option. We are not even talking about the fact that when driving this way, fuel consumption is much greater than during normal driving.

The best option for VAZ cars is to drive at a speed of 2500-3500 rpm; it is the most optimal for engine operation, for the cooling system and in terms of fuel consumption.

Adjusting the injector on a VAZ-2114

Today, the carburetor on gasoline engines, so familiar to us, is gradually being replaced by a more advanced mechanism - the injector. The impetus for the development of a new fuel system back in the 60-70s was the need to reduce harmful emissions into the atmosphere and reduce the harm from exhaust emissions. The emergence of new injection engines has made it possible to successfully solve this problem.

Advantages

But reducing emissions is not the only advantage of injectors compared to an older carburetor. There are many more advantages:

- firstly, the air-fuel mixture is dosed perfectly under the control of the computer, which can significantly reduce vehicle consumption. In practice, an injection engine is 20-30% more economical than its carburetor predecessor;

— secondly, the toxicity of exhaust gases is reduced significantly. This was largely possible thanks to the use of special sensors;

— thirdly, the power of the power unit increases by an average of 10-12%. This is due to a clear setting of the advance angle (here the electronics come into force), as well as an increase in the quality of filling the cylinders;

— fourthly, the dynamic properties of the car are significantly improved, it becomes more playful and responsive during acceleration. The electronics respond perfectly to the driver’s commands, accurately and efficiently adjust the air-fuel mixture;

- fifthly, the car becomes much easier to start at any temperature (carburetor engines could rarely boast of this).

It is important to note that the operation of the system directly depends on the program flashed into the ECU and information received from numerous sensors. Thus, the following controllers take part in the operation of the system - throttle position, mass air flow, crankshaft position, coolant temperature, detonation and oxygen

When to make adjustments?

Despite its reliability, the injector is not a perfect system. There are also possible failures here that the car enthusiast can correct and correct. For example, during operation, unpleasant “dips” of the engine may appear, fuel consumption will increase, and “floating” idle speed may occur. All this may be evidence of incorrect injector settings.

Many people believe that the injector is a completely maintenance-free unit that is difficult to adjust. Car enthusiasts complain that it is impossible to change the advance angles, adjust the supply of the air-fuel mixture, and so on. But with certain knowledge, everything is not so tragic. You can still make some adjustments to the VAZ-2114 injector yourself.

First, you need to make sure that all sensors are in good working order and clearly perform their task. Only in this case can you start setting up. There are many known cases where car enthusiasts spent several hours on adjustments in vain. As a result, the cause of all the problems turned out to be one of the sensors. If everything is fine, continue checking.

Turn on the ignition and wait until the injector is pumped with fuel. At the same time, the malfunction lamp should light up on the instrument panel (don’t worry - this is how it should be). Turn on the on-board computer and wait for it to perform diagnostics. In this case, all the main parameters of the car should be displayed. If no errors are found, continue further.

Check the throttle device. Turn on the ignition and use a multimeter to measure the voltage of the sensor and the on-board network. At the same time, look at how much the throttle has opened. If there are no problems, the voltage level of the sensor should be about 0.5 V, and the on-board network should be about 12 Volts. As for the throttle valve, it should be open to one percent. If after the test these parameters are obtained, then there is no need for adjustment.

It is advisable to carry out a similar throttle check with the gas pedal fully pressed. In this case, the voltage at the sensor should be about 4.5 Volts, the throttle opening should be 90-100%.

Chip tuning

Please note one nuance - to carry out a full adjustment, it is advisable to have a laptop on hand, a special adapter for connecting to the diagnostic connector, as well as configuration software. In this case, you can connect to the “brain” of the car and make the necessary changes. Moreover, using a computer, you can personally see all the parameters set at the factory and make their adjustments. Naturally, acting at random is dangerous - you must clearly understand what you are changing, why and what results you plan to achieve in the future. If you wish, you can find ready-made programs on the Internet with the necessary settings, which you can simply download through the car’s ECU.

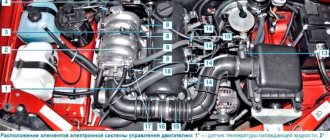

Sensors, their purposes and malfunctions

Let's now talk in more detail about each of the sensors, let's look at where they are and what they look like.

Idle speed (IAC)

The device is located in the throttle assembly. It is a small induction coil with a needle inside. Depending on the controller readings, one or another voltage is applied to the coil winding and the needle extends a certain distance into the throttle pipe, regulating the air supply. With this, the idle speed is adjusted.

Idle speed control

There is no indicator responsible for this sensor. Therefore, if this node fails, then this can be understood by the following “symptoms”:

- The engine stalls at idle or when changing speed;

- “Floating”, unstable idle speed;

- When turning on a cold engine, there is no increased speed.

To replace the sensor, you must turn off the power to the machine's wiring, completely disconnect the throttle assembly, and then remove the sensor from it, after first disconnecting the terminals that supply electricity to it. In place of the old sensor, you need to install a new device and place the throttle assembly in place.

Detonation (DD)

The knock sensor is located between the cylinders on a car engine and reacts when the fuel detonates inside the cylinder. In essence, it is a piezoelectric element. When gasoline detonates, the sensor converts the resulting vibrations into electricity. Current is supplied to the on-board computer and signals a fuel explosion. After this, the ignition timing is automatically adjusted.

If this type of sensor breaks down, the fuel begins to detonate in the engine. To check the device for functionality, you need to disconnect it using a key from its mounting location, connect it to a voltmeter and knock on it. If voltage was applied to the voltmeter, then the unit is working; if not, it is faulty.

To replace a device, you need to unscrew it from the seat using a key, disconnect the terminals from it and install a new device.

Oxygen (Lambda probe)

The oxygen sensor, also known as a lambda probe, is installed on the exhaust pipe close to the cylinders. It measures the amount of oxygen contained in exhaust gases and the environment. It only works when the engine is on, as it must be heated to function. When oxygen molecules hit the sensor, electricity is generated, which is supplied to the control unit. The on-board computer, based on sensor readings, regulates the supply of oxygen to the engine cylinders.

If the sensor fails, the following consequences occur:

- Unstable gasoline consumption: sometimes more, sometimes less;

- “Walking” speed at idle;

- A sharp drop in power when accelerating.

In order to replace this sensor, you need to turn off the power to the car, disconnect the wires going to the device, unscrew it with a key, and then put a new one in its place.

Crankshaft position (CPCV)

This sensor regulates the ignition of the combustible mixture in the cylinders depending on the position of the crankshaft. This position is determined by reading electromagnetic pulses from the toothed pulley of the electric generator. The sensor itself is located in close proximity to it.

Crankshaft position sensor

Symptoms of device failure may include:

- Idle speed instability;

- “Floating” speed;

- Power drop;

- Problems when turning on the engine.

At home, the performance of the sensor can be tested using a multimeter in ohmmeter mode. The resistance at the device contacts should be from 500 to 700 Ohms. If it differs greatly from these values, the sensor is faulty.

To replace the sensor, you need to turn off the power to the car's wiring, disconnect the battery, disconnect the electrical contacts from the device, and then unscrew the mounting bolt, remove the sensor and install a new one.

Camshaft position (CPRV)

This sensor, called DPRV for short, reads data from the camshaft. This happens with the help of a special gear installed on the shaft, on which two teeth are missing. This sensor is needed to adjust the ignition angle by the car’s on-board computer.

Camshaft position sensor

If this device breaks down, idling becomes unstable and the engine's fuel consumption increases.

The sensor is located to the left of the engine, near the air filter. Before replacing it, you need to de-energize the vehicle's wiring. Then you need to unscrew the sensor fixing bolt, remove it, disconnect the contact terminal, and then install a new device.

Coolant temperature (CLT)

The coolant temperature sensor (abbreviated as DTOZH) is located between the cylinder head and the thermostat. It measures the coolant temperature and transmits the resulting readings to the on-board computer. Based on this information, the rotation speed of the cooling fan is automatically adjusted, as well as the intensity of the pump pumping up antifreeze.

Why does the car accelerate on its own when idling? Learning to make diagnostics

Sometimes you can hear questions about why the car accelerates on its own at idle? This can manifest itself at the most inopportune times, and the strength of the “self-reversal” often varies. In some cases, the speed may fluctuate slightly between 800-1200 rpm. In other situations, the car can scare others at traffic lights, spontaneously raising the speed to 4000-5000. But, regardless of the size of the jumps, it is advisable to fix the problem as soon as possible. This will avoid many unpleasant moments, including increased fuel consumption, as well as increased wear of parts.

Why does the car accelerate on its own when idling? To answer this question, you will need to conduct a detailed diagnosis. There are many reasons for this behavior of the car, so you will have to take turns checking all the parts whose malfunction can lead to such jumps. You should start with the simplest options and end with the most complex elements. It’s not bad if it is possible to conduct computer diagnostics. This will simplify the troubleshooting process.

VAZ 2114 idle speed fluctuates: causes of malfunction and ways to solve the problem

The five-door hatchback VAZ 2114 is a restyled model of the famous “nine”, which rolled off the assembly line of the car plant from 2003 to 2013. At various times, the manufacturer installed on the car power plants with carburetor or distributed fuel injection (injector) of its own making, and since 2007 the car has been equipped with an electronic engine control system. Note that all these engines have one common and very significant drawback - when they switch to idle mode, their crankshaft speed suddenly begins to “float”.

Adjusting XX on the carburetor

Owners of cars with a carburetor dosage of the air-fuel mixture have probably more than once encountered the need to perform the process of adjusting this device. Strictly speaking, there is nothing complicated in this procedure, and this is one of the few advantages of a carburetor over an injector.

Before you start adjusting the idle speed, prepare the minimum required set of tools (you will need a screwdriver and wrenches, the specific sizes of which depend on the type and model of the carburetor). The principle of adjustment is to set the number of idle revolutions at which stable operation of the power unit at minimum crankshaft speeds will be ensured.

Since the vast majority of carburetor cars operated in our country are AvtoVAZ products, it makes sense to consider the features of adjusting the idle speed on Solex carburetors - they are installed on these cars.

Having a tachometer will be of great help, with the help of which it is convenient to monitor the actual rotation speed of the HF, but not all models have this device installed as standard. In particular, on younger models, which are currently not produced, there is no tachometer (“penny” family -2101/21011/21013).

However, in this case there is a way out - connecting an external device to the on-board electrical network. In principle, many drivers do not look at the tachometer readings, guided by hearing and other external signs when determining the required crankshaft speed. However, it is possible to set the idle speed most accurately only on cars with a tachometer.

So, the procedure for adjusting the idle level on a carburetor engine is performed in the following sequence:

In most cases this is sufficient, but sometimes the adjustment process requires additional steps. The reason is that by turning only the screw for the amount of air-fuel mixture, it is not always possible to achieve stable operation of the engine at minimum speed. Then you need to try to “play” with the mixture quality screw.

Usually there is a plastic plug installed on it, which will have to be removed. The problem is that you can't do this with your bare hands. Usually a self-tapping screw is screwed into the plastic and then pulled out along with the plug. The second method is to pierce the plastic with an awl, and a hook or something similar can be inserted into the resulting hole.

Before adjustment work, by twisting the quality screw, you must make sure that the ignition timing is set correctly and that the high-voltage wires and spark plugs are in good condition. It is also necessary to make sure that there is no air leakage from the outside. Get ready for the fact that you may have to make fine adjustments more than once.

Algorithm for setting the XX fuel assembly quality screw:

How to eliminate high speed when cold

Eliminating the problem of high speed when starting a cold engine always depends on the reasons. Accordingly, depending on the failed unit, it will be necessary to carry out a number of checks and repair measures.

First of all, check the condition of the throttle valve and its operation. Over time, a significant amount of carbon deposits accumulates on its surface, which should be removed using a carb cleaner or other similar cleaning agent. As they say: “In any unclear situation, clean the throttle valve.” The rod may also jam in the air channel. Depending on the design of a particular engine, their control system can be mechanical or electronic.

If the design involves the use of a drive cable, then it would be a good idea to check its integrity, general condition, and tension force. When the damper is controlled using various electric drives or solenoids, it is worth checking them with a multimeter. If you suspect a malfunction of any of the sensors, it should be replaced with a new one.

If there are corresponding symptoms, it is imperative to check the fact of air leaks in the intake tract at the connection points.

It is also worth paying attention to the cooling system, in particular its elements such as a thermostat and pump. You can accurately determine the incorrect operation of the thermostat by the poor operation of the stove.

And if there are problems with the pump, leaks or extraneous noise will be visible.

Conclusion

It is necessary to understand that short-term high speeds on a cold engine are normal. And the lower the ambient temperature, the longer the increased speed will take place. However, if the time exceeds approximately five minutes or more, then this is already a reason to perform diagnostics. First of all, you need to scan the memory of the electronic control unit for errors in it. These could be errors in the idle speed controller or the sensors listed above. If there are no errors, you need to perform additional mechanical diagnostics according to the recommendations described above.

Troubleshooting

It is not difficult to understand that the problem is in the sensor; for this you do not need to go for expensive diagnostics. There are visible indicators that help determine this breakdown:

- The idle speed of the VAZ 2114 floats. This is especially noticeable if you additionally turn on some devices, such as a stove, car radio, light;

- When switching to neutral speed, the engine stalls;

- The motor is tripping;

- Body vibration is also possible. All together, these are already signs of a malfunction of the idle speed sensor. Also an indicator is the lighting of the “Check engine” icon, but in this case it may not always light up.

There are several solutions to this problem:

- clean it;

- replace the failed spare part with a new one.

But before we decide what will be necessary in this particular case, we first find out whether it can be repaired. In any case, for accurate diagnosis, the regulator must be removed. Below is a picture that, to simplify the search, will show what the idle speed sensor looks like.

Replacing the IAC on a VAZ 2114

We have decided on the appearance, but in order to remove it, we need to decide where the idle speed sensor is located. We focus on the gas pedal, to which the cable goes. We look for the idle speed regulator on the VAZ 2114 opposite this cable, namely on the throttle valve, which is located below its position sensor. It is glued or attached with just two bolts.

To remove it you need:

- Be sure to turn off the car’s ignition and remove the battery terminals;

- Pull out the connector by disconnecting the wires leading to it;

- Unscrew the wires with a suitable screwdriver and remove the spare part itself;

- If the sensor is glued, you will first have to pull out the throttle assembly completely, and then carefully peel off the sensor.

When releasing the gas, the speed is increased or “freezes”: common malfunctions

Let's start with the fact that on many cars with an injector, the ECU raises the speed while the internal combustion engine is warming up. This is necessary to ensure that the power unit operates stably after a cold start.

However, after the temperature rises, the control unit reduces the idle speed, bringing it to normal. On many cars with a carburetor, the driver independently increases the speed during warm-up, using the so-called “choke”.

Moreover, after the engine is warmed up, the normal idle speed is, on average, 650-950 rpm. If you press the gas and release the accelerator, the speed should increase, and then decrease again to the specified values.

Also, a situation often arises when the speed drops slowly or is constantly kept at around 1.5 thousand rpm, 2 thousand revolutions, etc. Naturally, in such cases, consumption increases and the internal combustion engine wears out more, which indicates the need for diagnostics.

So, let's start with common carburetor problems. Often the engine speed does not drop due to problems with the throttle valve. For example, when the driver steps on the gas, the throttle must be opened wider to allow more air to enter the cylinders to burn fuel. After the gas pedal is released, the throttle closes and the speed decreases.

If the damper does not close completely, an over-enriched mixture enters the cylinders, and the speed is increased. The cause may be severe contamination of the throttle assembly or damage to the valve itself (deformation). First you need to clean the damper; carburetor cleaning liquid is suitable as a cleaner.

We also note that the damper does not close tightly even when the drive cable is worn out. In this case, the cable must be replaced. On carburetor cars, engine speed often does not drop even if the gasket between the carburetor and the cylinder head has failed. The culprit may also be an intake manifold that is damaged.

It should be noted that

after cleaning the carburetor

and the fuel system, the engine speed slowly drops due to a failure in the adjustments of the idle system itself. In other words, after any manipulations with these nodes, you should separately configure and

adjust carburetor

The main task is to find the correct ratio of fuel and air. Often, a high level of fuel in the carburetor float chamber also leads to increased speed. The check should begin with the needle valve.

Now let's move on to the injector

Please note that on many injection cars, after cleaning the throttle valve, the assembly also needs to be additionally “trained”. As for problems, the injection system itself is more complex, that is, there are more reasons for high speeds compared to a carburetor

As a rule, problems with speed can be caused by problems with both mechanical elements and electronic components. In the list of main malfunctions, experts highlight malfunctions of the coolant temperature sensor, which is installed in

cooling system

In simple words, if the specified sensor gives an incorrect signal, the ECU considers that the engine is cold and activates the warm-up mode. In this case, the control unit raises the speed so that the power unit operates stably and reaches operating temperature faster.

Also, problems with speed may begin due to malfunctions and malfunctions

RXX

(idle air control). It also happens that the throttle cable gets stuck and becomes wedged. The spring that closes the throttle valve may also become stretched or damaged.

Special attention should be paid to gaskets, since air leaks can lead to disruption of mixture formation. This means that you need to separately inspect manifold gaskets, injector seals, etc.

Carburetor internal combustion engines

Here the vast majority of reasons lie in the dosing device itself. High idle speed in this case is due to:

- Incorrect idle speed setting. It is necessary to adjust the composition of the mixture supplied to the carburetor using the appropriate screws.

- A jammed air damper: if it does not open completely, little air will flow into the cylinders.

- The shutter of the 1st chamber. It may not close completely due to a mechanical defect or an incorrectly adjusted actuator.

- Fuel level in carburetor float chamber too high

Ignition system

The reason for floating speed may lie in a damaged ignition distributor cap, high-voltage wires or spark plugs. These elements should be checked and replaced if necessary.

It is also worth noting completely banal reasons that are typical for both types of engines: incorrect adjustment of the accelerator pedal drive and jamming of the accelerator pedal itself, associated with corrosion of the mounting shaft and spring due to the car being idle for a long time.

What is high engine speed

The rotation of the engine depends on the amount of air supplied. The air mixture enters through the throttle valve, then passes through the intake manifold into the cylinder block. The throttle position sensor (TPS) transmits data about the opening angle to the ECU. The computer calculates the amount of air entering and determines how much fuel to supply to create the working mixture. Accordingly, high speeds arise due to incorrect calculation of the ECU or excessive air entering the engine.

During normal engine operation during startup and operation without load, i.e. at idle speed, the speed is not high: up to 600 - 1000 per minute. The readings are displayed on the tachometer. It is permissible to rotate the motor at high speeds, 1100 - 2500 rpm, “cold” in winter for 10 seconds. During this time, the engine will warm up the oil and coolant to an operating temperature of +80℃…+90℃. The motor will become noisier.

If the tachometer needle does not decrease for a long time, you need to look for the reason why the speed is high.

https://www.youtube.com/watch?v=nfg_O5KOhsk

Similar article Do-it-yourself repair of 402 ZMZ engine

Methods for solving the problem

Before proceeding directly to the process of solving the problem, you need to understand that diagnostics and repair of these components should be performed only with knowledge of the matter. Also, it is worth separately noting that for a carburetor and injection engine there will be different diagnostic methods, but the principle of the causes is the same.

So, it is worthwhile to consistently understand the diagnostic and repair work that will eliminate high idle speed.

IAC sensor

It is not often possible to find an idle air control sensor on carburetor engines. This is usually done using a quality and quantity screw. To normalize high idle speeds, you should not carry out the process cold. First, you should warm up the engine to operating temperature, and only then begin adjustments. If after making the adjustments the speed remains high, then the reason is different.

For an injection engine, the opposite is true; all adjustments are made by the IAC sensor. In order to correct the malfunction, it is worth checking the sensor with a multimeter, and then, if the element is faulty, replace it with a new one.

The wrong amount of air entering the combustion chamber can cause the ECU to over-idle. If the throttle position sensor is faulty, it must also be checked. This can be done with a multimeter or oscilloscope. If it is discovered that the TPS is faulty, it is worth replacing it.

Throttle valve

A stuck throttle can cause a large amount of air to enter the engine. This fact will force the electronic control unit to increase the amount of fuel injected to balance the mixture. This will increase the fuel consumption and accordingly.

In order to solve the problem, it is necessary to dismantle the unit and clean it using special means. If cleaning does not give the desired result, the throttle must be replaced, but you should be prepared that this will not be cheap.

Floating speed on the carburetor

On carburetor versions of the VAZ 2114 there is no electronic control unit as such. But this does not mean at all that the problem of floating speed is not alien to him.

Tachometer with high speed

Floating speeds do not occur as often as in the case of an injector, but still. The reasons, as well as troubleshooting methods, vary.

- The idle speed is set incorrectly, or it got lost during operation. In such a situation, the setting shifts to combining the fuel-air mixture. Here you will need to adjust the speed to the range of 800-900 units.

- The solenoid valve is faulty. The engine will only run if the choke is pulled out. If you remove it, the engine will immediately stall.

- The idle jet or channels are dirty. In such a situation, the fuel lacks air. Clean the jet and the problem will go away.

- Excessive air is sucked in. The mixture becomes leaner, so the engine sputters and stalls.

- The level of gasoline in the float chamber increases or decreases.

- The air filter is clogged. The problem is solved by simply replacing the element.

If engine vibration occurs at idle speed of the VAZ 2114, there is no need to worry. It's all about the design of the engine. A similar phenomenon is typical for carburetor engines during cold starts. The engine just needs to warm up to the optimal temperature, after which the vibrations disappear.

https://youtube.com/watch?v=p3TpjbZBjo8

The reason for the vibrations is the air-fuel mixture that the carburetor prepares before entering the combustion chamber. Low temperatures lead to inefficient combustion of the mixture. Hence the “shaking”.

Although it is not uncommon for vibrations to occur due to the cushions, that is, the engine mounts on which it is mounted. When they wear out, vibrations are possible. Moreover, this does not depend on what type of engine is used - injection or carburetor.

You should always pay attention to the floating speed of the VAZ 2114 and not wait for the problem to manifest itself in some other way. If you delay in identifying the causes and eliminating faults, repairs can be much more expensive.

Sources

Mass air flow sensor

After IAC, the air flow sensor should be checked. In addition to problems with idle speed, the following symptoms will be detected: failures when pressing the gas, increased fuel consumption, loss of power. To diagnose the sensor, disconnect the chip from it, while carefully monitoring the operation of the engine. If it breaks down, an emergency operation mode is activated, which already includes average indicators. Therefore, if the engine operation does not change, this indicates a malfunction.

Try treating it with cleaner and putting it back in place. The sensor is sensitive and can malfunction at the slightest contamination.

Causes of malfunction

Among the reasons leading to improper engine operation in idle mode are problems with sensors that transmit information to the electronic control unit. These include sensor malfunctions:

- idle speed controller (IAC);

- mass air flow (MAF);

- crankshaft position (CPCV);

- throttle valve position;

- vehicle speed (VSA).

The appearance of floating crankshaft speeds also causes:

- malfunction of the idle speed solenoid valve;

- dirty air filter and spark plugs;

- damage to high-voltage wires;

- wear of gaskets and plugs at the junction of the intake manifold with the cylinders;

- malfunction of the EGR valve, which regulates exhaust gas emissions.

The cause of a stalled engine is a power supply failure

In this type of problem, 3 reasons may be involved:

- Poor contact with the terminals of the new battery;

- Detection of poor contact or breakdown along the entire length of high-voltage wires;

- The appearance of malfunctions in the generator or ignition coil system of the car.

If the problem lies in damp high-voltage wires, then it is best to replace them completely along with the battery contacts. If the terminals make poor contact, you need to carefully clean them with sandpaper and try to reconnect them.

If the generator is found to be inoperable, the problem usually boils down to problems in the following parts:

- Broken timing belt;

- There is a malfunction inside the housing of the unit itself.

A problem with the generator is easily detected when the corresponding indicator on the dashboard turns on. In addition, if there is insufficient energy supply, the backlight of the on-board panel will gradually fade, and a set of other diagnostic sensors will show incorrect values.

From the list of reasons that are directly related to the car engine, you need to move on to problems that arise in the fuel and air supply systems, as well as malfunctions of components responsible for exhaust gas removal.

Ignition coil

Cleanliness of the damper assembly

The throttle valve assembly is diagnosed by visual inspection for contamination. Clean the part with cotton swabs and a toothbrush moistened with a cleaning solution. For ease of work, the device is dismantled. After cleaning, it is recommended to blow out all channels and pipes of the unit with compressed air using a tire inflator.

To clean the part, it must be dismantled

Attention! It is recommended that the channel responsible for removing gases from the crankcase be completely filled with a cleaning solution before purging - the diameter of the element is very small and there is no other way to access it.

Video: How to clean the throttle body

Is it possible to diagnose DPKV and DSA?

A breakdown of the DPKV and DSA (Hall sensor) is indicated by the Check Engine indicator that lights up on the car’s dashboard. Testing these devices is only possible using special instruments (oscilloscopes). You can first check the integrity of the wiring; if it is broken, the damage should be repaired.

- The DPKV sensor is installed on a bracket located in close proximity to the generator drive pulley.

- The DSA is located on the speedometer drive mechanism of the gearbox.

For a more detailed introduction to methods for detecting faults associated with engine malfunction in idle mode, it is recommended to watch the following video.