Clutch mechanism of a VAZ 2106 car

A device with the simplest design that ensures the engagement of the power plant and gearbox. The mechanism is primitive, which makes its repair and maintenance as accessible as possible for the average motorist.

Description of design

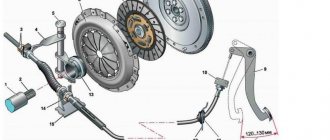

Here are the elements:

- clutch pedal;

- master cylinder;

- pressure main;

- working cylinder;

- clutch fork.

Inside the structure there is a special liquid that ensures the transfer of impulse from the pedal to the fork.

How does the clutch drive work?

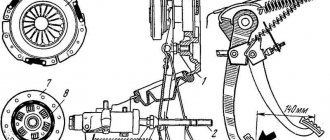

The principle of operation is this.

- The driver presses the pedal.

- The master cylinder piston, connected by a hinge to the pedal lever, forces fluid through the cylinder, creating excess pressure inside the line.

- The oil passes through the pressure line and enters the working cylinder.

- Next, the piston is pushed out and the clutch fork moves.

- The mechanism comes out of the hook and the motor is disconnected from the gearbox.

The principle of operation is the same for all modifications and versions. Some car enthusiasts install a dry clutch. The actual difference is only in the working element - the classic one contains liquid, the dry one contains a cable.

Clutch failure

Among the most common “diagnoses” of auto mechanics are:

- Breakdown of the head or working cylinder seal. Liquid flows out of the system, causing it to become airy.

- The pressure line is clogged or coked. The problem is a consequence of using counterfeit oil or not replacing it in a timely manner.

- Mechanical damage to the fork or working cylinder. The parts are located at the bottom of the car. Typically, users can damage the mechanism when driving over off-road roads or curbs.

- The easiest problem is the spring stretching or falling out of the mounting groove.

Symptoms of malfunctions

Problems arising from improper clutch adjustment.

- The car jerks. This means that the disc does not move far enough from the basket and that when the drive is pressed, the motor is not completely disconnected from the gearbox.

- The gears don't want to turn on. The symptom that arises in the above problem is similar.

- When you press the gas pedal hard, the car does not respond or accelerates too slowly. Jerking may also occur during steady driving.

- The clutch pedal is falling/too hard and the gears will not engage.

What to do if the gear shift mechanism does not work?

If the clutch pedal fails on a road with heavy traffic, you should not be nervous, but act calmly with a “cool head” and get to the nearest parking spot, or even better, to a garage or service station. To do this, you can use a tug, tow truck, or drive yourself.

How to drive independently if the clutch system breaks down?

You can use the following tips from proven car enthusiasts:

You can also drive to the repair site with a VAZ2106 or VAZ2107 car without a clutch, engaging second gear in the same way when starting to drive. Only in this case it is necessary to take into account some important nuances:

- the car should be either on a horizontal section or on a downhill slope, but not uphill. If the car goes uphill, then this method will not work; Before you start driving, you need to warm up the engine;

- Since the car will move in a lower gear no higher than second, you should carefully think through the route so that you do not have to stop at intersections, giving way or at traffic lights. If possible, take the main road and pull at the green light to avoid getting caught;

- it is necessary to check: whether the alarm system is turned on;

- It is important to remember that other road users do not know about your problem, so you need to maneuver less. If you don’t have time, it’s better to stop the car and then do this procedure again;

- when you don’t have confidence in your abilities, the optimal solution would be to call a tow truck or tug.

In VAZ cars with a rear-wheel drive wheel pair, the clutch mechanism is a separate hydromechanical unit that interacts between the power plants and the transmission.

When is clutch adjustment necessary?

It is not difficult to understand that the mechanism needs to be adjusted. The machine itself will tell you this. The following factors are clear signs of disorder of the unit.

- Pedal dips - when you press, you feel your foot drop to a certain level.

- Loss of elasticity under pressure.

- The car begins to move at the beginning or end of the pedal stroke.

- Loose lever or complete lack of working play.

- Difficulty shifting gears.

- Slipping of the clutch disc during acceleration and braking of the car.

Other deviations in the normal operation of the gearbox unit and unit are also acceptable.

Clutch adjustment options

If it is necessary to adjust the mechanism, the machine begins to behave inappropriately. The pedal sinks, changing gears becomes more difficult, jerking and jerking appear.

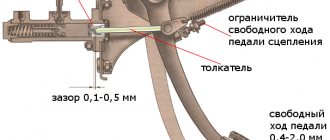

There are factory recommendations that establish strict tolerances for backlash.

What pedal stroke is considered normal?

In the correct position and in fully working order, the movement of the pedal until the mechanism disengages is 2.5-3.5 centimeters. The reference standard is established by the manufacturer and is considered a recommendation value.

Some car enthusiasts reconfigure the system to suit themselves, adjusting it within the range of 45-55 mm.

How to measure your car's pedal travel

Experienced craftsmen recommend measuring the stroke like this.

- A ruler is applied to the pedal at an angle of 90 degrees.

- Next, note the pedal height in centimeters.

- Press the lever until it stops.

- Make a mark on the ruler.

Measure the difference in values; normally, free play is limited to 25-35 mm.

Frequency of setting

There is no strictly established time interval for servicing the mechanism. The manufacturer insists that clutch adjustment is mandatory after performing any repair and service work related directly or indirectly to the device.

Eg:

- replacing the clutch disc/basket;

- pumping of highways;

- installation of new cylinders.

Tips and tricks

The main advice is to prevent this phenomenon from causing slippage. First of all, responsible drivers are obliged to promptly carry out preventive measures to inspect the body and components, promptly lubricate the necessary elements, timely replace cracked clamps and failed clutch elements.

However, the method of operating the car is also an important factor. Sudden starts from a standstill, hard gear shifting, the use of cheap counterfeit materials during repair work, as well as vehicle operation under high loads do not contribute to the long-term operation of all vehicle components, especially the clutch. Because of hard switching, the disk and basket constantly collide, causing mechanical damage due to friction. As a result, even a high-quality foreign clutch will not be able to exist in good condition for a long time. That is why responsible drivers should not allow natural slipping when the unit is working properly, and also follow the rules for using the car, since the standard clutch is not designed for high loads.

Also, when increasing engine power, tuning and improving other driving characteristics, it is necessary to take into account the torque limit for which this part is designed. Since classic VAZ cars have modest torque, the clutch is therefore also designed for low power. However, when tuning the engine, owners often forget about installing a reinforced clutch, which often leads to rapid breakdown. The standard part simply cannot cope with the increased power. Therefore, when increasing power, it is necessary to look for a clutch that is suitable in terms of geometric and other parameters, which can “digest” the increased torque without loss of service life and reliability.

Setting up the VAZ 2106 clutch

You can check whether the clutch position on a VAZ 2106 is set correctly in this way.

- Place the car in neutral and warm up the engine to operating temperature. With the engine running, without touching the accelerator lever, turn on the “R” position. The response to the action should be a smooth movement of the lever without extraneous sounds or excessive force.

- During the operation of the car, all gearbox positions work clearly, there are no crashes, squeaks, or crunches.

- During sharp acceleration, the increase in engine speed is proportional to the acceleration. If the clutch disc slips, the engine starts to spin up without a manual transmission.

If any malfunctions or malfunctions are detected, it is necessary to perform more detailed diagnostics of the unit. You may need to replace the disk or repair the basket.

Possible reasons for clutch pedal failure

The clutch pedal is depressed when depressed and does not return

This problem can be easily solved in stationary conditions either at a service station or with your own hands in the garage. To replace or repair the main clutch or control valve in the garage, you must have repair kits for the clutch slave and master cylinders.

Reasons for failure and non-return of the clutch pedal of VAZ2106 and VAZ2107:

- a break in the clutch cable where the tip touched. This problem is not easy to fix on your own. You can, of course, carry a spare cable with you just in case, but cases are different and it is not realistic to provide for everything;

- the spring that performs the function of returning the pedal to its original position may burst or fly off. If the spring has flown off, then it is enough to put it back in place, and if it has burst, then, as in the case of a cable break, you must either tow the car or try to get to the garage or service station under your own power.

How to properly bleed the clutch on a VAZ-2106

The sequence of the operation is as follows.

- Drive the car into a pit or put it on trestles. Securely secure the car.

- Clean the expansion tank and bleeder fitting from dirt. The latter is located on the working cylinder.

- Open the RB cover.

- Check that the fitting can be unscrewed and put a pre-prepared hose on it. Place the other end of the tube into the waste container.

- The assistant sits behind the wheel and pumps up the pressure 4-5 times by pumping the pedal. At the end you need to pinch and hold it.

- Next, the shut-off fitting is unscrewed and the liquid, along with the air, goes into a container for draining the waste. At the same time, you need to monitor the oil level in the RB and add it if necessary.

- When the bubbles are completely released, the fitting closes.

- To eliminate any remaining air in the line, it is recommended to repeat the operation 2-3 times.

What caused the problem?

So, if the clutch pedal in your vehicle has fallen, then first you need to determine the cause of the breakdown.

There can be many reasons, so your task, as a motorist, is to reliably identify them:

- The first and one of the most common causes is a broken clutch cable. Usually the cable breaks near the tip, on the engine compartment side. It is quite possible to solve such a malfunction on your own and right on the spot, but for this you will need the cable itself. You will learn more about the replacement below.

- Failure of the return spring of the clutch system (hereinafter - CC), which could either burst from wear or simply fly off. If the spring bursts, then there is only one way out - only replacement, so you need to go to the nearest service station either in tow, or as we will describe below. If the spring just flew off, then you can try to find it and put it in place.

- Often the pedal fails when air gets into the hydraulic drive. Driving such a vehicle will also be impossible until air is removed from the system. By the way, instructions for bleeding the system are available on our website, you can find them here.

- Failure of the CC fork can also cause the clutch pedal to drop. It is unlikely that you will be able to solve the problem on the spot, unless you are a car repairman. There is only one way out - replacing the element.

- Incorrect operation of the master cylinder CC, in particular, defects in the mirror, wear or failure of the cuff. In this case, the clutch pedal has failed, but periodically it can be returned to its place by pressing sharply. For normal driving of the car, it is necessary to replace the main cylinder of the system itself.

- Driven disk failure. As a result of this, if the clutch pedal fails, it will be very soft, you will feel it. Failure of the driven disk may be due to the appearance of defects, mechanical damage or deformation of the element. In addition, the cause may be a fluid leak from the hydraulic system or a pipeline breakdown. In this case, the driven disk could fail as a result of the breakdown of the main and working cylinders, or one of them.

We change the clutch with our own hands without removing the transmission

The operation is performed like this.

- Place the machine on a viewing hole or a lift and securely secure it to prevent it from rolling away.

- Disconnect the cardan and slave cylinder from the gearbox.

- Remove the protective cover of the mechanism and the traverse.

- Unscrew the box cushion.

- Using your hands or using a lever, push the gearbox housing away from the power unit until it stops. For insurance, you can install a support under the box.

- Next, you will need to unscrew the 6 bolts securing the basket from the flywheel.

- The box basket needs to be moved all the way and the clutch disc pulled out through the resulting gap.

- Similarly, slide the basket back and remove it.

- The last step is to dismantle the release fork and remove the bearing of the same name from the gearbox input shaft.

- Installation of new parts is carried out in reverse order.

Clutch faults

There is a list of VAZ 2106 clutch malfunctions, which are presented in the table in this article. If the clutch is lost, you should look for a defect in the unit here:

Clutch faults | How to fix |

| The clutch "drives" | |

| 1. Large gap in the hydraulic drive | 1. Make adjustments |

| 2. Deformation of the driven disk | 2. Repair or replace |

| 3. The surfaces of the friction linings of the driven disk have defects | 3. Remove with a metal brush |

| 4. Weak rivets or defective linings | 4. Replace |

| 5. Incorrect operation of the clutch disc hub on the splined part of the manual transmission shaft | 5. Clean and lubricate; if worn, replace |

| 6. Defects in the connecting plates between the flange and the clutch body protection | 6. Replace the necessary parts |

| 7. Air locks in hydraulics | 7. Bleed the clutch |

| 8. Hydraulic fluid leaks through joints or defects in hydraulic pipes | 8. Tighten fasteners, replace defective spare parts, bleed the hydraulic system after it is tight |

| 9. Fluid leakage from the main circulation system or dispenser | 9. Change the O-rings, bleed the hydraulic system after it is tight |

| 10. The hole in the cover of the clutch reservoir was clogged, which created the effect of a vacuum in the pressure in the hydraulic fluid mass and the suction of air masses into the cylinder through the sealing gaskets | 10. Blow out the air channel in the cover with a compressor, bleed the hydraulic system after it is sealed |

| 11. Lack of tightness due to a worn gasket ring. | 11. Clean the seal; if defective, replace it |

| 12. Weak rivets of the pressure spring fasteners | 12. Replace the clutch housing and basket |

| If the VAZ 2106 clutch slips | |

| 1. There are no gaps in the hydraulic drive | 1. Make adjustments |

| 2. Increased wear or burning of the ferrado | 2. Replace the ferrado or the entire slave disk |

| 3. The friction linings are dirty with oil, as are the working parts of the flywheel and clutch basket. | 3. Wash and degrease working and mating surfaces, eliminate oil leaks |

| 4. The GCS compensator hole is clogged | 4. Rinse and clean the hole-compensator of the main fluid circulation system |

| VAZ 2106 clutch “tears” | |

| 1. The hub of the driven disc “sticks” on the splines | 1. Wash and clean the splines; if the shaft or disk splines are worn, replace the product |

| 2. Ferrado linings in engine or transmission oil, as well as the working surfaces of the flywheel and clutch basket | 2. Wash and degrease working and mating surfaces, eliminate oil leaks |

| 3. Increased wear of friction disc linings | 3. Replace with updated products, and also test for defects in the disk mating areas |

| 4. Weak rivets on the Ferrado | 4. Change defective rivets, and, if necessary, linings |

| Increased noise when disengaging the clutch mechanism | |

| 1. Oil leak and release bearing defects | 1. Exchange the product for a new one |

| 2. Oil leakage and defects in the manual transmission shaft bearing | 2. Exchange the product for a new one |

| Increased noise when engaging the clutch mechanism | |

| 1. Defects in the springs of the damper device | 1. Exchange the product for a new one |

| 2. Defects in the mechanism fork return spring | 2. Replace the product with a new one or strengthen the fasteners |

| 3. Defects in the plate connections of the protective housing with the disk | 3. Exchange the product for a new one |

The table shows the most common clutch malfunctions in practice.

We conduct an inspection and analyze the situation

Disassemble the joint in which the head cylinder rod is connected to the clutch pedal mechanism. If the pedal return spring is broken, the lever will freely rotate on the hinge to its previous position. A similar situation occurs with a spring that pushes back the clutch release tab and the working cylinder rod mounted on the engine crankcase. From time to time, the springs look intact, but their stiffness and elasticity are obviously not enough to return, due to poor hydraulic performance. Therefore, it would not be superfluous to remove and check their functionality.

Most of the symptoms indicate a recurring pattern of malfunction, due to which pedal turns poorly or does not turn at all. If the prerequisite for poor performance was a weak spring, the lack of pedal return would remain unchanged.