What components does the VAZ-2106 clutch consist of? Clutch master cylinder and slave

Everyone believes that if a car has a simple design and low cost, then the VAZ-2106 clutch is not complicated.

The clutch master cylinder, installed in the engine compartment and connected to the pedal, has a relatively complex structure. Almost all modern budget cars are equipped with a cable transmission. Hydraulics are the domain of expensive cars. But the six was considered elite at one time, and the designers spared nothing for it. The hydraulic system imposes certain requirements - it is necessary to carry out timely replacement of elements and maintenance.

Final check of the clutch for functionality!

It is recommended to check after completion of work, and this check should be done as follows:

In this case, the reverse gear should engage without grinding or knocking or any other extraneous noise!

- Now you can try another test, for this, when accelerating the car, try to engage each gear at the moment when it is necessary, but if the gears are engaged without grinding or knocking, then in this case the clutch is working properly.

- And finally, try to pay attention to the acceleration of the car, that is, the car should accelerate normally when accelerating, it should not be the case that you press the pedal in the red zone and the car does not move.

This example indicates that the clutch is slipping!

If this check does not give any results and the clutch still does not work correctly, then in this case, try to bleed the clutch first, and if this does not help, then remove it and, as a result, repair the clutch by replacing its worn parts with new ones.

You can also learn how to adjust the free play of the fork pusher from the video below:

Didn't find the information you are looking for? on our forum.

Clutch drive system

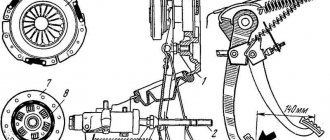

There are only two main components in the VAZ-2106 clutch system. The clutch master cylinder allows pressure to be created in the pipes using the driver's muscular strength. The worker acts on the fork, which drives the release bearing. Briefly, the operation of the entire system can be described as follows:

- When you press the pedal, the rod in the master cylinder moves. Since the system is closed, the pressure rises sharply.

- Under the influence of this pressure, the piston is extruded in the working cylinder, which is installed on the clutch housing.

After releasing the pedal, the reverse process occurs:

- When the pedal is released, the master cylinder rod returns to its initial position, as a result of which the volume inside the system increases and the pressure decreases.

- A return spring acts on the working cylinder, which allows the rod to move to its initial position.

- The system has an expansion tank into which liquid is filled.

DOT-3 type brake fluid is used as the working fluid. It contains many additives, they contribute to the normal operation of the mechanism. These additives have a beneficial effect on the metal and allow the cylinders to cool better.

Try to fill the system only with those fluids recommended by the manufacturer. Effective operation depends directly on the quality of the liquid that is poured into the system. Never allow the level to drop to the minimum level. Add fluid if necessary.

Preparing for repairs

Before putting the car in a pit and removing the box to replace the clutch, you need to visit the store and buy all the necessary spare parts:

- Clutch disc.

- Basket (drive disk).

- Release bearing.

- If necessary, clutch fork.

- If there is significant wear, the crown on the flywheel will also need to be replaced.

- Bolts securing the basket to the flywheel.

It is also important to have a good set of tools on hand, WD-40 penetrating lubricant, sometimes even a gas torch is necessary (if the bolts and nuts are very rusty).

It is advisable to carry out all the work in an inspection pit or overpass (it is unlikely that the average driver of a six will have a lift in the garage, so we do not mention it). If everything goes smoothly and the nuts unscrew well, you will complete all the work very quickly.

Place the car on the pit, fix it in one position by placing stops under the wheels. All work is divided into two stages: under the car and above it. Please note that there is no need to drain the oil, since if you dismantle it carefully, you will not spill a drop.

And don't forget about the alignment of the clutch disc. The price of a special device is quite high - about 500 rubles. but you can use a small piece of pipe without any problems, as long as the diameter is suitable.

Major breakdowns

Despite the high cost of the design, the VAZ-2106 clutch breaks quite often. The clutch cylinder fails and leaks appear. This happens for the following reasons:

- Excessive wear on the slave and master cylinder parts.

- Using brake fluid not recommended by the vehicle manufacturer.

- A decrease in the liquid level in the expansion tank due to its damage or loosening of the pipe clamps.

The price of the VAZ-2106 clutch master cylinder is 400-600 rubles, depending on the manufacturer. But you can also find more expensive parts. The repair kit is a little cheaper - about 300 rubles.

Symptoms of malfunction

The very first thing that should concern you is a decrease in the fluid level of the working cylinder. Even in the absence of drips, this sign indicates that the system is leaking liquid and the box is running almost dry.

If there are leaks, the situation is the other way around. The parts are most likely clogged and do not allow liquid to pass through, so pressure is created in the tank and it begins to leak out. In both cases, the box will work almost dry, and the clutch cylinder of the VAZ 2106 will need urgent repairs.

If the gearbox operates for a longer period of time, when the working cylinder breaks down, a third sign will appear - a characteristic sound (crunching) that occurs when changing gears, as well as difficulty when trying to place the lever in the gear cell. In this case, repairs should be done very urgently, otherwise the box may jam, and then there will be no cost.

Pedal dips

A dip in the pedal is one of the main signs that the VAZ-2106 clutch mechanism has become unusable. The clutch master cylinder may have lost its seal. But you shouldn’t blame it right away; you need to carefully examine all the elements of the system. The pipes connecting the cylinders must not have brake fluid leaks. There should also be no traces of it on the cylinder bodies themselves. If the pedal fails, the clutch will not work normally.

The following problems may occur:

- Difficulty changing gears.

- Drop in fluid level in the expansion tank.

- When used for a long time in this mode, the release bearing, basket, and disk fail.

If you notice a pedal failing, try to carry out repairs as quickly as possible, since with each press the fluid will come out of the system.

Checking the quality of clutch bleeding

Regarding the pumping itself, it should be noted that the process itself should not be long: on a VAZ-2106 - 4-5 pumps followed by draining and 5-7 sharp presses on the pedal with a leisurely release - on a VAZ-2107.

If the process takes more steps, you need to look for where air got into the system, fix the problem, and then pump it again.

You can check the operation of the drive after bleeding while driving.

Start the car, move slowly and change gears. If there are no signs of hydraulic drive malfunction, we can assume that the pumping was done correctly.

Replacing the working cylinder

This is the mechanism that is installed on the clutch housing of the VAZ-2106. The clutch master cylinder is mounted opposite the pedal. Sequencing:

- Remove the retainer from the pusher.

- Remove the return spring.

- Carefully unscrew the nut located on the liquid hose.

- Drain the remaining brake fluid by unscrewing the hose.

- Remove the two bolts that secure the cylinder. The pushrod must be pulled out from the clutch fork.

When removing, it is necessary to install a rubber gasket with a washer on the new hose. It is not included in the repair kit. Assembly is carried out in reverse order. Using a nut located on the rod, the travel of the clutch pedal is adjusted. But this should be done only after pumping.

Work on top of the car

So, a start has been made, the goal is to remove the gearbox to replace the clutch. On VAZ 2106 and similar cars this is done quite quickly, it is only important to follow a certain sequence:

- Inside the car, remove the gear shift knob. It is attached using plastic latches. Sometimes difficulties arise with dismantling, and it gets to the point where the latches break off. The price of a new set of fastenings is no more than one hundred rubles, and you can purchase it even after repairs have been carried out. Therefore, do not be afraid if you suddenly break the plastic antennae.

- Go to the engine compartment, unscrew the four nuts that secure the exhaust pipe to the manifold. The fact is that the exhaust pipe will interfere with the removal of the box, but it is enough to move it a little to the side.

- Disconnect the battery and remove it from the car.

- Unscrew the two top bolts of the starter, disconnect the power wires for the windings and the solenoid relay from it.

- Disconnect the ground wire that goes to the gearbox.

Replacing the master cylinder

The work of replacing the clutch master cylinder on a VAZ-2106 is carried out in almost the same way. It is fixed opposite the pedal. The master cylinder rod is connected to the pedal mechanically. The replacement procedure is as follows:

- Drain the brake fluid from the system.

- Unscrew the hose going to the expansion tank.

- Unscrew the tube going to the working cylinder.

- Unscrew the two bolts that secure it to the partition.

After this, the master brake cylinder is removed and repaired or completely replaced.

About the hydraulic drive device

To better understand what will be discussed, it is necessary to at least schematically imagine the design of such a drive. Let’s leave its purpose, structure, and role in the vehicle aside; in this case, the hydraulic drive itself is important.

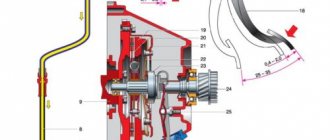

Its implementation, as an example, as one of the possible options, can be seen in the figure below. This is enough to understand the structure and operation of the clutch drive, as well as to understand its role and significance in the vehicle.

- reservoir for filling brake fluid (1), which is used as a filler for the hydraulic drive;

- clutch master cylinder (2);

- hydraulic pipes (3,4,5) and hose (7);

- clutch slave cylinder (8);

- pedal (6) and return spring (9).

Bleeding the system

The design of the VAZ-2106 clutch master cylinder is approximately the same as on a similar element of the brake system. Pumping is done in the same way:

- The entire system is assembled, threaded connections are tightened.

- Liquid is poured into the expansion tank to an average level.

- A tube is put on the bleeder fitting and lowered into a small container with brake fluid.

- An assistant presses the clutch pedal several times and then locks it in the pressed position.

- At this time, unscrew the bleeder fitting a little so that the air comes out.

Repeat the last two steps several times until air stops escaping from the system. Be sure to monitor the brake fluid level. Otherwise, the mechanism will run dry, and it may be necessary to disassemble the VAZ-2106 clutch master cylinder for repair.

Source

What you can do yourself

The simplest repair is possible without the help of specialists at a service station . The first thing to do is determine whether a belt is needed at all. First bleed the hydraulic drive. This is done simply: connect the hose to the bleeder screw, then lower its other end into a container filled with brake fluid. Afterwards, fill the small reservoir of the master cylinder with liquid. Once inside the cabin, press the pedal. Air bubbles will begin to appear. If the process of their formation does not end, repairs are necessary.

Remove and disassemble the cylinder. You will need a metalworking tool and a vice in which it will be convenient to disassemble the cylinder. The protective cap and pusher are removed, the piston is removed and with a little effort the lock ring located on the piston is removed. Next you need to remove the spring and seals. Now the following is done: the fitting is washed with brake fluid, as well as the holes in the cylinder. It is strictly forbidden to wash parts with gasoline, oil or anything else. The seals are replaced with new ones. If necessary, the spring can also be changed. If there is no damage to the cylinder mirror or the outer surface, the cylinder can be assembled and put in place.

In case of serious mechanical damage to the metal element, the working cylinder will have to be replaced. In theory, its repair is possible in this case, but the residual life can vary from several tens of thousands of kilometers to a couple of hundred. We do not recommend taking risks.

Clutch master cylinder

According to its principle of operation, the clutch master cylinder of the VAZ 2106, like its counterparts on other brands, is mounted in the upper position, and acting on it with the corresponding foot pedal entails an increase in pressure in the hydraulic system. As a result, the clutch slave cylinder is activated, and the required vehicle mechanisms are connected.

Signs indicating defects in the six clutch master cylinder:

- incomplete disengagement of the clutch mechanism with the engine (“drives”);

- the presence of leaks from various elements of the system, incl. from under fasteners, rubber products and pipelines;

- “wedge” of the clutch master cylinder when the brake pedal is in a recessed position.

The necessary replacement of the clutch cylinder is carried out in the following order:

- We free the hydraulic drive reservoir from liquid using a special bulb.

- We disconnect the hose and the fitting of the product, having first unscrewed the clamping clamp.

- We dismantle the tube fitting using a wrench set to “13”.

- We dismantle the 2 elements fastening the product to the studs for fastening the foot pedal, using the anchor head at “13”.

- We dismantle the product itself.

- Installation is carried out in reverse order.

- We fill the clutch reservoir with a special fluid and, using pumping, give the hydraulic drive a working condition.

About choosing brake fluid

When starting to replace the cylinder, you should remember: any manipulations with this device are accompanied by leaks of brake fluid. And these leaks will then have to be replenished. Consequently, the question arises: what kind of fluid can be poured into the hydraulic clutch of the “six”? It is recommended to fill with DOT3 or DOT4 grade fluid. The best option both in price and quality would be the domestic liquid ROSA-DOT4.

Filling the liquid is extremely simple: unscrew the cap of the expansion tank, and fill the liquid to the upper horizontal mark on the tank. In addition, many car enthusiasts recommend slightly loosening the fitting on the clutch slave cylinder before adding fluid. This is done in case a small amount of air has entered the system. When filling in a new portion of liquid, this air will come out of the system, after which the fitting can be tightened again.

Clutch slave cylinder

An element such as the clutch slave cylinder is a cylindrical element in the mechanism that moves the clutch fork. This element is mounted in the lower part of the power plant and contains a fitting for bleeding the clutch.

When replacing the “six” clutch cylinder, you need to prepare the necessary bench tools - wrenches, pliers, etc. To remove the clutch slave cylinder, the following is required:

- At the initial stage, we slightly loosen the fastening of the hydraulic drive hose to the clutch slave cylinder by loosening the screw.

- Disconnect the tension spring from the clutch fork and then remove it.

- We determine the location of the clutch slave cylinder pusher and unpin it.

- We dismantle the fasteners (bolts) of the clutch slave cylinder to the clutch housing using wrenches.

- We take out the spring bracket of the quickdraw and remove the pusher from the clutch fork.

- It is necessary to disconnect the hose from the product, for which it is necessary to hold the tip of the hose from twisting, while using rotational movements we disconnect the connector from the working cylinder.

- We also dismantle the sealing washer, and when subsequently installing the clutch slave cylinder on a vehicle, it must be replaced with a new sample.

- We prepare an empty container for draining the fluid used as working fluid from the brake cylinder.

Dismantling of the product is considered complete; at this stage it is necessary to prepare a new product for installation and carry out its installation. After installing the installation product, it is necessary to bleed the hydraulic drive for disengaging a vehicle unit such as the clutch.

Source

If the setting didn't help

The absence of a positive result after tuning may indicate that the device is damaged or there is serious wear on the internal components.

Air congestion in the pipelines can also be a common cause. Air ingress can also be easily eliminated.

Clutch failure

Among the most common “diagnoses” of auto mechanics are:

- Breakdown of the head or working cylinder seal. Liquid flows out of the system, causing it to become airy.

- The pressure line is clogged or coked. The problem is a consequence of using counterfeit oil or not replacing it in a timely manner.

- Mechanical damage to the fork or working cylinder. The parts are located at the bottom of the car. Typically, users can damage the mechanism when driving over off-road roads or curbs.

- The easiest problem is the spring stretching or falling out of the mounting groove.

Operating principle and replacement of the master and slave cylinders of the VAZ 2106 clutch

A vehicle unit such as a clutch is considered one of the main components of the automotive system, which is involved in the formation of the most important function of movement mechanisms - movement. Hydraulic elements of all rear-wheel drive cars, such as the clutch cylinders of the VAZ 2106, ensure the correct operation of all mechanisms that are responsible for the interaction of the power unit and transmission components.

According to their purpose, there are two types of such products, which are called the clutch master cylinder, installed in the upper plane of the power plant, and the clutch slave cylinder, which is directly involved in the operation of the vehicle’s clutch fork.

Technical parameters of the “seven” clutch: classification and parameters

VAZ models are equipped with a single-disc clutch with a central spring. Motorists interested in which clutch is best to install on a VAZ 2107 should take into account that its type depends on the power of the power unit. The units differ in the parameters of the pressure spring, casing and dimensions of the driven disk, and the entire set consists of three elements:

- Pressure disk.

- Slave disk.

- Release bearing.

Pressure plate

On VAZ classics, two types of such mechanisms are used:

- 2103 – for cars with engines up to 1.5 liters.

- 2121 – for cars with engines up to 1.7 liters.

Externally, they are almost identical, they can easily be confused - the diameter of the disk in both cases is 200 mm. However, there are still distinctive signs:

- On product 2121 there is a mark in the form of a six-millimeter hole in one of the slots in the diaphragm spring blade.

- The width of friction linings 2103 is 29 mm, and 2121 – 35 mm.

Driven disk

To decide which clutch is best to install on a VAZ 2107, it doesn’t hurt to know that a “classic” disc is quite easy to distinguish from a “front-wheel drive” one by the bends that partially cover the damper springs. Driven disks are available in two sizes:

- 200x140 – for engines up to 1.5 liters; There are two brands: 2103 and 2107, the latter has asbestos-free linings.

- 200x130 - according to the documentation, the disk is brand 2121 and is designed for the Niva, but installation on the “seven” is also possible. In addition to its size, it features a reinforced damper with reinforced diaphragm springs.

Another noticeable factor is that the 2121 driven disc has a larger number of rivets on the linings than its 2103 counterpart.

Release bearing

The part is supplied complete and has an additional name - release clutch. For “classics”, its marking also begins with a set of numbers 2101. The bearing is visually distinguished by the presence of wire brackets, which is familiar to car enthusiasts who have replaced the working cylinder on a Lada.

A set of clutch parts for Niva can be installed on any classic car. Such parts are designed to withstand heavy loads, and therefore will last longer. The only inconvenience is that the “Nivov” basket will require a lot of effort on the clutch pedal.

This is interesting: Injector for VAZ 21099 - all the features of the device

Disassembling the mechanism

Pedal and clutch master cylinder: 1 — master cylinder body; 2 — bypass (compensation) hole; 3 — fitting gasket; 4 - fitting; 5 — lock spring washer; 6 — piston of the main cylinder; 7 - sealing ring; 8 — pusher piston; 9 - hook; 10 — pedal axis; 11 — bracket for clutch and brake pedals; 12 — clutch servo spring; 13 — clutch pedal release spring; 14-clutch pedal travel limiter; 15 — clutch pedal; 16 — piston pusher; 17 — protective cap; 18 — retaining ring; 19 — inlet; 20 — sealing ring (ring valve); 21 — piston bypass hole; 22 — working cavity of the cylinder; 23 - spring; 24 - gasket; 25 - plug; 26 — inner pedal bushing; 27 — outer pedal bushing; 28 — spacer sleeve; 29 — brake pedal

It is easier to independently disassemble the VAZ 2106 mechanism on a flat area or a workbench, where you can fix it in a vice. The part is cleaned of dirt; it is advisable to do this with an iron brush. They do this so that dirt does not get inside during disassembly. After unscrewing the plug, remove both the retaining ring and the protection cap from the body, which allows for removal:

- o-ring;

- floating piston with sealing ring;

- piston and its return spring.

In practice, this happens like this: the plug that holds the return spring is clamped with a vice and unscrewed with a 22 key. Unscrew the nut and pull out the spring. The clutch rod boot is removed. After removing the retaining ring, carefully (in the direction of the retaining ring) use a screwdriver to press out the piston. The mechanism has been disassembled and can be inspected and repaired.

A thorough inspection of the disassembled mechanism should either confirm the possibility of further functioning of the cylinder, or the need to replace it.

Return to contents