Nobody wants to experience discomfort while driving, especially if it is associated with problems in driving. Owners of domestic “classics” have to devote more time and effort to the condition of their car, because they are used to doing everything with their own hands. We can say with complete confidence that if a car owner has already mastered the process of wheel alignment adjustment , then he can also repair the hydraulic drive of the transmission clutch, just study the technology.

VAZ 2107 clutch: device

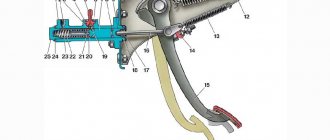

The “Seven” has a dry single-disc clutch. The clutch hydraulic master cylinder is located directly under the pedal, when pressed, the pusher moves, acting on the master cylinder piston, creating pressure. The brake fluid that fills the hydraulic drive is squeezed out and flows into the working cylinder.

The piston of the working cylinder is connected to the clutch fork by a pusher. When you press the pedal, the latter moves the fork, it displaces the release bearing and separates the support and pressure discs. As a result, the torque from the crankshaft flywheel is no longer transmitted to the gearbox and it becomes possible to change gear.

If the clutch unit malfunctions, when you press the pedal, the gearbox shaft continues to rotate and changing gears becomes difficult or even impossible. If the clutch is adjusted incorrectly, the discs may slip, which is accompanied by accelerated wear.

You cannot continue to drive a car with a faulty clutch - both the clutch discs and the gearbox may be damaged. Therefore, at the first sign of a malfunction, you should start repairing and adjusting it.

Symptoms of clutch malfunctions

As we have already noted, many drivers, when problems arise with the clutch, understand that the car has begun to behave strangely, but often get used to it without taking any active action. As a result, a minor breakdown develops into a serious one, leading to a situation where the car becomes immobilized.

If you know the main signs of a clutch malfunction, you can avoid such risks by carrying out timely repairs yourself or contacting the nearest service station or service center.

So, we will describe the main signs of possible clutch malfunctions and the specific unit responsible for the “wrong” behavior.

Replacing the clutch master cylinder VAZ 2107

The simplest way to repair a VAZ 2107 clutch is to change the worn cylinders (main and slave). Their price is low, and the labor intensity of the operation is much lower than when carrying out repairs. Therefore, car owners often prefer to replace rather than repair clutches.

Let's start by replacing the master cylinder. The order of operations is as follows:

- Drain the brake fluid from the clutch reservoir into another container. This can be conveniently done using a syringe.

- Loosen the clamp and remove the hose from the master cylinder fitting.

- Unscrew the fitting of the metal tube going from the master cylinder to the slave cylinder and disconnect the tube.

- Using a 13mm wrench or a socket with an extension, unscrew the two nuts securing the master cylinder to the body bulkhead and remove the master cylinder.

The new clutch master cylinder can now be installed. Before doing this, you should check the condition of the flexible hose of the clutch reservoir. If it cracks at the end, it needs to be trimmed slightly or replaced with a new one.

When installing a new cylinder, it is necessary to ensure that the clutch pedal drive rod fits inside the cylinder. For convenience, you can ask your partner to slightly press the clutch pedal and hold it. Then follows:

- Install the master cylinder onto the studs and tighten the nuts.

- Attach and tighten the metal tube fitting.

- Place the pipe from the clutch reservoir and tighten the clamp.

- Fill the reservoir with brake fluid, following the level marks.

The clutch master cylinder has been replaced.

Product location

The master cylinder on a VAZ 2107 is located under the hood, directly on the wall separating the interior from the hood, near the driver’s feet. Directly above it is the expansion tank, and next to it are the vacuum booster and the brake master cylinder. Usually, simply looking at the product is enough to determine the problem. The presence of a leak indicates that the part is faulty and requires repair or replacement.

Purpose of the device

Cars are equipped with clutch master and slave cylinders, without which the operation of the mechanism is impossible. The VAZ 2107 clutch master cylinder is designed to push out brake fluid. Below is a diagram from which you can visually find out the operating features of the unit.

When you press the clutch pedal, the piston moves in the device in question, thereby pushing out the brake fluid. This liquid enters the working cylinder through a tube, where the reverse process is observed (the liquid pushes out the piston). Brake fluid drives a piston, which is connected by a fork to the clutch disc. As a result, the clutch disc and flywheel are separated, allowing you to change gear. The GCS is also called the main one, since it is with its help that force is supplied from the pedal when it is pressed.

The need to replace the device: when required

Like all parts of any car, the GVC tends to wear out, resulting in the need for repair or replacement. The simplest breakdown of a product is wear of the boot, which can be determined by the characteristic signs of a fluid leak.

To identify a cylinder malfunction, an initial visual inspection is required. It is possible to repair a failed main circulation system on a VAZ 2107; for this you can look for repair kits, but this is not always rational due to the quality of modern spare parts, so it is easier and faster to replace it entirely. The malfunction can also be determined by the characteristic loss of pressure in the system, which is determined by pressing the pedal. Let’s take a closer look at how to change a faulty VAZ 2107 mechanism.

We change it ourselves

Replacing the VAZ 2107 clutch master cylinder begins with the need to pump out the brake fluid from the hydraulic reservoir. This can be done using a syringe or a rubber bulb. Together with this socket or a 10mm wrench, unscrew the bracket securing the expansion tank and move it to the side to gain access to the cylinder.

The next step involves removing the clutch expansion tank hose. To do this, you need to loosen the hose clamp, then disconnect the hose and position it so that it does not interfere with further work. If you want to remove the tank completely, this is done very simply.

Further actions are performed in the following sequence:

- Using a “10” wrench, you need to unscrew the pipeline securing nut to the device. Once the nut is unscrewed, the tube can be moved to the side.

- There is a hose nearby near the steel pipeline, which also needs to be disconnected from the main device. This can be done by loosening the fixing clamp.

- The GCS is fixed to the body using two fastening nuts. To unscrew them, you will need to use a wrench with an extension and a “13” socket. After unscrewing the two nuts, you can remove the product and drain the remaining brake fluid from it. If it is not possible to dismantle the unit, you can press the clutch pedal, as a result of which it will move.

- But repairs are usually not rational, so after removing the old one, a new unit is installed in its place. Installation is carried out in the reverse order of removal. After installation, it is necessary to carry out the process of pumping the hydraulic drive, first pouring fuel fluid into the tank. You can find out how the system is pumped from the relevant material on the website.

After the work is completed, you can test the operating features of the new GVC. If necessary, the RCS (working cylinder) should also be replaced, but you can find out more about this in the corresponding material.

You will need: a “10” wrench, a “13” socket head, a special “10” wrench for pipeline nuts, an extension, a wrench, and pliers.

1. Unscrew the reservoir cap and pump out (for example, using a large medical syringe) the brake fluid from the section of the master cylinder reservoir that supplies the hydraulic clutch release actuator.

The reservoir, common to the brake and clutch master cylinders, is divided into three separate sections: two for separate hydraulic circuits for the brakes and one for the hydraulic clutch release.

2. Using pliers, compress the ears of clamp 2, slide the clamp along the pipe of the clutch master cylinder and disconnect the pipe from the master cylinder.

3. Unscrew the nut securing the clutch pipeline tube to the master cylinder and move the tube to the side.

4. Under the instrument panel in the car interior, disconnect the master cylinder pusher from the clutch pedal (see “Repairing the pedal assembly”).

5. Unscrew the two nuts 6 securing the clutch master cylinder to the body and remove the master cylinder.

6. Install the parts in the reverse order of removal and remove air from the hydraulic drive (see “Bleeding the clutch release hydraulic drive”).

7. Check the operation of the drive and, if necessary, adjust the travel of the clutch pedal (see “Checking and adjusting the clutch release drive”).

As a rule, the main and slave cylinders are fairly reliable parts that very rarely fail. In most cases, they cannot be repaired. The good news is that these units are inexpensive and easy to replace yourself. For minor faults, it is recommended to carry out repairs, which is not a difficult undertaking. Below we will look at how to replace both clutch cylinders.

Replacing the clutch slave cylinder VAZ 2107

Removal of the working cylinder should be done from the inspection hole or using a lift. The order of operations is as follows:

- Remove the return spring from the slave cylinder bracket.

- Unscrew the fitting of the tube coming from the master cylinder. To prevent brake fluid from leaking from it, you can put a cap on it, removed from the cylinder bleeder fitting, or direct it into a container prepared in advance.

- Unscrew the two bolts connecting the slave cylinder to the gearbox and remove them together with the plate.

- Remove the clutch slave cylinder.

The new working cylinder is installed in the reverse order of removing the old one.

After replacing any of the cylinders, the hydraulic drive system must be pumped. The work must be carried out together with a partner. This is done like this:

- Place a hose on the fitting of the working cylinder and immerse its end in a prepared container for brake fluid.

- Depress the clutch.

- Unscrew the fitting on the working cylinder 1 turn.

- Wait until air bubbles stop coming out and tighten the fitting.

- Repeat the operation until air stops coming out of the fitting. At the same time, monitor the fluid level in the clutch reservoir.

- Tighten the fitting and put on the cap.

There are several ways to bleed the clutch on a VAZ 2107, here is a video about the most popular ones

Basic faults

The slave cylinder has several rubber seals, which often become unusable or become oily, causing the car’s clutch to “slip.” Replacing old seals with new ones will require using a lift or inspection hole, since the main cylinder is located in an inconvenient place.

When replacing seals, do not forget that there is brake fluid in the system; it must first be drained.

It is advisable not to touch the flare nut, otherwise additional adjustment will be required later. In order to replace the gaskets without removing the master cylinder, certain skills and experience are required.

VAZ 2107 clutch repair

Repairing clutch cylinders is somewhat more difficult than replacing them, but much cheaper.

Once the cylinders are removed, disassembly can begin. Let's start with the master cylinder:

- Use a thin screwdriver to remove the retaining ring.

- Remove the fitting and gasket.

- Remove the boot by prying it off with a screwdriver.

- Unscrew the cylinder plug using a 22mm wrench.

- Pull out the retaining ring and use a screwdriver to remove the inside of the cylinder.

To restore the master cylinder, the rubber seals must be replaced. It is also necessary to check the condition of the spring, the inner surface of the cylinder and the piston. If there are burrs or damage, parts must be replaced.

Before assembly, parts should be thoroughly cleaned and dried. It is unacceptable for gasoline or oil to get inside the cylinder - they destroy the rubber seals.

Assembly is carried out in the reverse order of disassembling the cylinder.

The clutch slave cylinder, despite some design features, is repaired in the same way as the main one.

After repairing the cylinders and installing them in place, it is necessary to bleed the hydraulic clutch drive.

DIY repair

So, the part has been removed and is ready for disassembly. First, unscrew the air bleed valve and remove the retaining ring. After disassembling the part, we inspect the condition of all elements - spring, piston, pusher and sealing rubber bands. They must not show any signs of mechanical damage. Next, we wash the insides of the element. There is no need to do this with aggressive liquids like gasoline and diesel fuel. Fill a medical syringe with hydraulic fluid and use pressure to clean out the dirt inside it. If the damage is only local, we need a repair kit to restore it. It is worth noting that even with one damaged part, all the entire elements are replaced, be it an elastic band, boot or spring. This will increase the service life of the working cylinder.

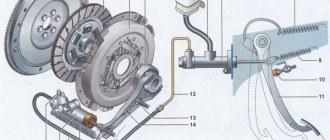

The device of the clutch slave cylinder VAZ 2107-2101

This part in the clutch system plays a fairly important role as the final link in the distribution of hydraulic load. In the classic VAZ clutch system, the master cylinder is located, respectively, in the engine compartment near the gearbox and has a fairly convenient outlet for repairing the VAZ 2106 clutch slave cylinder. The part consists of several main parts, which together form a single small but important unit:

- The piston directly serves to squeeze out the fluid located in the main tank (as usual, special brake fluid is poured there). When the clutch pedal is pressed, it is the piston that activates the hydraulic pressure mechanism and applies forceful pressure to the fork in the clutch.

- The case is the fundamental part in which the entire mechanism is enclosed. The outer part in modern versions is made of durable plastic. In early models on old Soviet designs, a metal body is sometimes found, but this design is less reliable not only due to age, but also due to the likelihood of corrosion.

- The rod is driven by a piston and acts as a pusher both when the pedal is pressed and after it is released. When pressed, this part pushes liquid into the system, and then closes the housing for liquid.

- The protective cap serves to maintain integrity inside the system when liquid enters. Otherwise, it is simply called a cover that covers the housing parts from excessive contact of substances with the mechanical parts of the unit.

- The spring acts as a single unit together with the piston when the gas pedal is pressed and actually “serves” the unit during the return action. One of the main reasons for system failure is often the wear of the spring, which causes the cylinder to not close properly and the fluid to escape beyond the closed circuit.

- A valve for bleeding air, which is also a common cause of failure of the entire part due to its inoperability. This part is designed to remove excess air during piston operation. Excess air, if present in the system and liquid penetrating inside, leads to the disappearance of the clutch, which can lead to an emergency. It is the valve that serves to remove the formed air, but for some reasons this unit can wear out and fail. Moreover, despite its simple design, such a part can rarely be repaired and most often must be completely replaced, not only because of the impossibility of the repair itself, but mostly because of the low cost of both the complete assembly and its individual parts.

Diagnostics of the master or slave cylinder

Car diagnostics is becoming increasingly popular today. The need for this procedure cannot be overestimated, since it allows you to monitor the condition of the machine throughout the entire operational period. With its help, you can prevent any breakdown and eliminate defects at the initial stage of development, which in turn has a positive effect on the cost of repair work. In this section, we will figure out how to check the master and slave cylinders yourself without using special equipment.

- Visual inspection of cylinders . It is necessary to carefully check the surface of the cylinders and tubes for drips. The problem may be depressurization of parts connecting parts or damage to the housing.

- Check for fluid . If you notice a significant decrease in the level of the working mixture, this indicates a leak. As a rule, the cause of this problem is a cuff failure or a piston malfunction.

- Testing for the presence of air . The presence of air inside the system may be indicated by failure of the clutch pedal. To correct the problem, you need to bleed the clutch. If the procedure does not help, replace or repair the clutch cylinders.

- Presence of extraneous sounds . When you press the clutch pedal and change gears, you hear strange sounds or feel vibration on the gear shift lever. First check the entire system thoroughly. The problem may be the failure of one or more elements.

It is worth understanding that if there are any signs of malfunction, it is necessary to urgently diagnose and repair the breakdown. Otherwise, such a small problem can lead to a more complex one, the elimination of which, at best, will require significant financial costs.

The principle of operation of the clutch slave cylinder VAZ 2107-2101

The operating principle of this part is quite simple, however, despite its small dimensions, the function of pushing fluid into the system is very important in the operation of the entire clutch. The principle of operation of this unit is to briefly disconnect the gearbox and the motor itself during gear shifting. When you press the clutch pedal, fluid enters the master cylinder under the influence of a piston, which also presses on the clutch fork. This, in turn, acts on the gear selection clutch through a bearing, which also presses on the driven disk, disengaging the clutch.

Subsequently, when the pedal is released, the cylinder is returned to its original position by means of a spring, and the liquid flows back into the tank. The clutch also returns to its original position regardless of whether a particular gear is engaged or the vehicle is in neutral. Thus, this part is an important link during switching and acts as the main part of the hydraulic drive system. The advantage of this system is the simplicity of the design with the presence of a small number of mechanical parts, thereby limiting the friction process and increasing the overall resource. It is also worth noting the ease of repair and low cost of spare parts.

Selecting a clutch slave cylinder for a VAZ 2107-2101

On the domestic market of automobile parts there is a huge number of parts and spare parts for classic cars of the VAZ family. In addition, there are a large number of repair kits for the VAZ 2101 2107 clutch slave cylinder. Over the decades of production of these models, the design has not undergone significant changes, accordingly, the parts must be sharpened and completely match in all respects. Moreover, on all rear-wheel drive models, virtually the same unit is installed, which has similar characteristics and dimensions. The main criterion when choosing a part to replace the VAZ 2101 clutch slave cylinder is the factor of quality and reliability of this unit. Taking into account the large supply from various enterprises, sometimes not in any way connected with the manufacturer, and the varying costs, the quality remains very unstable.

The optimal solution when choosing this system is to purchase an original repair kit or the entire assembly from the automaker. Although the cost of such a unit is often higher than its third-party competitors, the likelihood of receiving a counterfeit product is still disproportionately lower, and, given the importance of the unit in the process of driving a car, it is not possible to rely on chance.

Malfunctions of the clutch slave cylinder VAZ 2107-2101

The most common system malfunctions, which can lead to complete failure of the entire unit, include:

- Presence of excess air in the system. This situation can arise if there are cracks in the rubber pipes or sealing joints, as well as as a result of fatigue of the plastic housing and the presence of microcracks. In this case, a complete replacement of the failed part is carried out, since excess air does not allow creating the necessary pressure to open the bearing and clutch, thereby the owner simply will not be able to engage the gear correctly.

- Wear due to various reasons of the components of the assembly themselves. Thus, as a result of the breakdown of any part of the assembly, the general principle of operation is violated, since, despite the simplicity of the design, each element, performing a specific function, directly affects the performance of the system as a whole. In this case, in addition to simply replacing the entire system, the option of disassembling and eliminating a specific malfunction may be considered by replacing a certain component in the form of a part using a repair kit.

Repair of clutch parts

Defects in clutch parts and their elimination.

The clutch may have the following defects: slipping and incomplete disengagement of the discs, wear of the linings and the discs themselves, warping of the pressure plate, risks and cracks on it, loose fastenings, loss of elasticity of the springs, wear of the pedal axle bushings, etc.

Ferodo disk burst

Repair of clutch parts consists of replacing faulty parts with new ones, straightening them and welding cracks. If the thickness of the pressure plate is less than the nominal value, in addition to thermal insulating washers, metal spacers can be installed under the springs.

When replacing worn friction linings, they are riveted to the disk so that the heads of the rivets are buried in the linings by at least 1-1.5 mm. The driven disk with new linings is checked for runout using the transmission drive shaft as a mandrel.

Output from intermediateDiscs that have circular marks and burrs are leveled on a surface grinder, sometimes with preliminary turning on a lathe. If there is significant warping or cracks, the discs are replaced with new ones. The worn surfaces of the switch levers are fused with steel using gas or electric welding, and then processed according to a template and hardened.

Do-it-yourself replacement of the VAZ 2107-2101 clutch slave cylinder

Carrying out independent repairs of this drive will require the owner not only to have a certain set of tools in the form of various keys with different head sizes and repair kits, but also certain repair skills. Self-repair is quite within the capabilities of an experienced owner of a VAZ classic. Also, the owner will definitely need a lift or MA in the garage, since the part is located in the lower part of the engine compartment, in close proximity to the gearbox.

For beginners, in most cases you will need an assistant. In total, there are two main types of work with this part - removing and installing a new device into the system, which will not require additional time, and repairing the original part with complete or partial disassembly, which will require a sufficient amount of time, this directly depends on the experience of the owner.

How to remove the clutch slave cylinder VAZ 2107-2101

The procedure for removing the unit as a whole takes place in several main stages:

- All fluid must be removed from the clutch reservoir. To do this, you will need a regular small volume syringe. This tank is located in the upper part of the engine compartment. This is necessary to prevent the substance from spilling onto the owner or outside the system.

- After this, it is necessary to loosen the fastenings of the tank itself and, if necessary, dismantle it. At the same time, use a 13-mm wrench to loosen the rubber pipe leading from the tank to the master cylinder, thereby freeing up free access to the system.

- After this, also use a 13 key to disconnect the part from the other clamps of the clutch system and unscrew the 2 mounting fasteners using a regular screwdriver, which hold the body in the seat. After this, the part can be completely removed.

Repair of clutch slave cylinder VAZ 2107-2101

Repair work also takes place in several stages and is carried out immediately after dismantling the device itself:

- Using a 22mm socket wrench, unscrew the plug and remove the boot along with the locking ring.

- Then move the VAZ 2106 clutch slave cylinder rod all the way and then remove the fitting from the seat. This opens access to all internal parts of the device.

- These parts are located inside the housing and are arranged in a certain sequence.

Installation of the clutch slave cylinder VAZ 2107-2101

Reinstallation of a repaired part or installation of a new device occurs in the reverse order:

- The tank and cylinder linkage assembly must be secured in the standard mounting points in the engine compartment using keys.

- After this, it is necessary to connect the main part with the branch pipes of the vehicle systems, while choosing the correct tightening torque for the clamps.

- After this, connect the tank to the general hydraulic drive system and fill the liquid in accordance with the level.

Do-it-yourself clutch master cylinder repair

The main job of the clutch system is to transmit torque from the engine to the wheels. To put it simply. The clutch mechanism disconnects the engine from the gearbox at the right time, after which it smoothly connects this duo back. During this time, the driver manages to switch to another gear.

The clutch release drive consists of the following elements:

1. Clutch pedal.

2. The clutch master cylinder, it is located directly in the chain itself behind the pedal.

3. The clutch slave cylinder, the one that moves the pressure bearing into the fork.

4. Clutch release fork.

5. Pressure bearing.

6. Pipeline system (pipe).

What is the design of the clutch master cylinder? This is just a piston, cylinder, cuffs, body. The job of the clutch master cylinder is to transmit force from the pedal, which the driver presses on the clutch slave cylinder, through the working fluid.

The need to repair the clutch cylinder

If the piston fails or brake fluid leaks through the cuffs, it is necessary to repair or overhaul the clutch master cylinder. In addition, air can enter the clutch hydraulic drive through damaged clutch master cylinder o-rings. In this case, repair of the clutch master cylinder is simply inevitable.

It will not be difficult to detect a fluid leak, since it can be seen by the “strange” behavior of the clutch pedal. When air enters the hydraulic drive, this is also accompanied by a characteristic dip in the clutch pedal.

In short, if any of the above “symptoms” are present, repairs must begin. Often, a complete replacement of the clutch master cylinder can be avoided and you can “get off duty,” as they say, with “little loss” by doing a little work with your own hands. For this purpose, car dealerships have a special repair kit for the clutch master cylinder.

As a standard, such a repair kit contains all the most frequently worn parts. A complete replacement of the clutch cylinder should only be done in extreme cases, when neither bleeding nor a complete overhaul will help.

Master brake cylinder: overhaul and repair

Dismantling and installation of the master cylinder is usually carried out according to the traditional scheme. That is, you should remember how you dismantled it, so that later you can easily install it back in place, only in the reverse order. Sorry, but I won’t describe this process in detail, since I don’t think it’s necessary.

I do not recommend disassembling the master cylinder on their own for those who do not have the slightest idea what it is or do not have basic plumbing skills. In such “severe” cases, it is better to either seek help from a specialist or completely replace the master cylinder.

After the main cylinder is disassembled, you can begin the procedure of washing the cylinder parts. This is done exclusively using brake fluid. It is advisable to change all the parts that are included in the repair kit, for example the return spring, o-rings.

When inspecting the cylinder, pay special attention to the following details: the general condition of the body, as well as the condition of the mirrors and rods. If there is slight corrosion or some minor scuffs, they can be removed using fine-grained sandpaper. However, be careful, sometimes scuffing may indicate a violation of the gap between the cylinder and the piston

However, be careful, sometimes scuffing may indicate a violation of the gap between the cylinder and the piston.

Here are some useful tips for repairing the master cylinder:

1. When removing the clutch master cylinder, the working fluid from the hydraulic drive may not be completely drained.

2. When washing cylinder parts, it is prohibited to use liquids such as mineral oil, diesel fuel, gasoline or kerosene. It is necessary to flush only with brake fluid in order to prevent swelling of the rubber parts.

3. Before assembling the cylinder, wipe all parts with brake fluid.

4. When the installation of the master cylinder is completed, be sure to bleed the hydraulic drive.

Do-it-yourself clutch master cylinder repair

Tips and tricks

As the main advice when choosing this unit, you should mention the quality of materials when purchasing. The purchased parts must have the manufacturer's markings and series and batch numbers. Many enterprises have their own information resources where you can check the originality of a part by simply checking the batch numbers and the specific part.

Also, in the process of replacing the VAZ 2104 clutch slave cylinder, it is necessary to strictly follow the sequence of actions and accurately calculate the tightening torque of the hoses and pipes from the fluid tank to the main part in order to avoid cracking of the rubber and plastic parts of the body.

Also, once every few thousand kilometers, it is necessary to carry out an inspection of the entire assembly, since the vast majority of cars of these models have significant mileage, the likelihood of unexpected breakdowns is quite high.

Prevention

To ensure that the clutch system lasts as long as possible, monitor the level of remaining fluid in the system. After 2 years or 50 thousand kilometers, it must be drained and filled with a new one. After this procedure, be sure to bleed the system. Remember that hydraulic fluid absorbs moisture well. If replacement is delayed, rust will form in the system, which will shorten the life of the clutch master and slave cylinders. Make sure the tubes are tight, especially in the places where metal and rubber connect. It happens that the material cracks or rubs against the wheel (if we are talking about the front ones). This is very dangerous, since if the system depressurizes, you will be left without a clutch and you can only get to your destination by towing or ruining your gearbox.

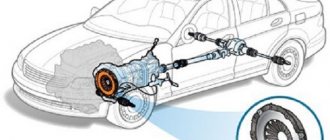

What is a hydraulic drive

The clutch in a car is controlled using a pedal. The force from it to the disk can be transmitted in two ways:

- Using a cable.

- Hydraulic drive.

The simplest and most common is the first method, while the “seven” uses the second. Its essence, without going into details, is as follows.

The hydraulic drive consists of two cylinders connected by tubes and hoses. It is designed so that pressing the clutch pedal leads to a significant increase in pressure in the system. It is mechanically transmitted to the driven disk and disconnects the transmission from the engine. The key elements of the system are two VAZ-2107 clutch cylinders: the main and the slave. One of them transforms the force acting on the pedal into excess pressure in the system tubes, the other does the opposite work, acting on the driven disk.

Clutch master cylinder UAZ loaf, device and replacement

So, I was driving home after the mushrooms and suddenly there was an incomprehensible crunching sound and the clutch died, it became very soft and incomprehensible, just like that. Having slowed down on the side of the road, I inspected the pedals as best I could and did not find any springs on the clutch pedal. Having decided that it was just a spring, I moved on. However, the clutch began to work absolutely disgustingly, but nothing, the gears somehow engaged, it was possible to move. Having hobbled home the next day, I started repairing, deciding at the same time to do some tuning ^_^. Namely, to replace the standard UAZ GCS with the Zhiguli one. (As it seemed to me then, it was all the fault of the cylinder, because it had worked poorly before, did not hold the clutch depressed, and gradually released) The following were purchased: 1. GCS from the classics (VAZ 2101-07 ATE 1101.3 -760 rub.) 2. A pair of bolts with nuts and washers 3. Clutch master cylinder tube VAZ 2101-07 - 19 rubles (threads are different for UAZ and Zhiga)

Clutch design VAZ-2107

The main components of the “seven” hydraulic drive are:

- Main cylinder.

- Metal tube system.

- Clutch slave cylinder VAZ-2107.

- Pedal equipped with a pusher.

- Clutch fork.

The master cylinder is combined with a reservoir into which brake fluid is poured. It is located under the hood of the car, on the wall of the engine compartment. This location allows for a mechanical connection between the cylinder and the clutch pedal. For this, a steel rod, the so-called pusher, is used.

The working cylinder is attached with two bolts to the gearbox housing and is connected to the fork by a rod. The entire length of the metal rod is threaded, which allows you to adjust the clutch. Both cylinders are connected to each other by a copper tube and hoses.

Design

Unlike front-wheel drive foreign cars, on all-wheel drive UAZ Patriot vehicles the clutch slave cylinder (its adjustment is at the end of the article) is hydraulic and is controlled using fluid pressure, and not a cable. The design of this element includes several components. This:

- Frame. It is made of plastic or metal.

- Piston (working rod).

- A valve that releases air when the clutch system is bleeding (adjusting).

- Retaining ring.

- O-rings. Made from durable rubber.

- Return spring.

- Pusher. It affects the previous element.

The principle of operation of the VAZ-2107 clutch

The force of pressing the pedal is transmitted via a rod to the master cylinder of the VAZ-2107 clutch. The liquid contained in it is squeezed out into the pipeline. Due to the tightness of the system and the absence of air in it, the force is transmitted to the working cylinder. The rod, extending, acts on the fork, which presses the driven disk. Releasing the pedal causes the rods and brake fluid to move back. As a result, the system returns to its original position.

It is obvious that the basis of the hydraulic clutch drive of the “seven” is the cylinders. They bear most of the load in the form of repeated movement of the rod, during which hydraulic pressure also acts on the internal elements. Therefore, the cylinders are the first to fail. Since they are dismountable, and corresponding repair kits are available for sale, some faults can be repaired yourself. True, more often car enthusiasts prefer to change the entire cylinder.

The fact is that in this case, labor costs for repairs are often inadequate to the cost of the assembled unit. For example, the price of a VAZ-2107 clutch master cylinder is about 1,500 rubles, and you will have to spend a decent amount of time restoring it, especially if you have no experience. However, whether to repair or buy a new one is up to the owner of the “Seven”.

Clutch replacement

Replacing absolutely all transmission parts is a procedure that not everyone can handle. In addition to knowledge in the field of automotive mechanics, a person will need a set of fairly advanced equipment: an inspection pit, an overpass or a lift. You will also have to use a list of specialized tools, various keys, nuts, bolt connections, etc. You may need several bottles of silicone lubricant - some components may “stick” to each other and simply cannot be unscrewed without prior spraying.

It is not difficult to guess that only a driver with a set of relevant knowledge can change the clutch on a VAZ 2107 car. Fortunately, today in specialized stores you can find a complete transmission kit for this car, which includes absolutely all the necessary components and parts. You should think about installing a set consisting of a driven disk, a basket and a release bearing when the following situations arise:

- transport cannot climb a sufficiently flat hill;

- when the transmission is deactivated, noise appears in the flywheel area;

- there are problems with engaging first gear at the beginning of the movement;

- the gearbox begins to “growl”, indicating a clutch failure;

- at the moment of acceleration, the vehicle begins to jerk, and rattling noises are heard from its internal parts.

Each of the presented breakdowns may indicate the need for work to completely replace the transmission. As mentioned earlier, the clutch for domestic classics is supplied assembled, which greatly simplifies the purchase of the necessary parts.

Design and operation of the VAZ-2107 GCS

The clutch master cylinder is a rather complex assembly consisting of a large number of parts. However, in order to understand the principle of operation, it is enough to name the main ones. These include:

- main body with brake fluid reservoir;

- cylinder piston;

- union;

- return spring.

The principle of operation of the cylinder resembles the operation of a conventional piston pump and is as follows: pressing the clutch pedal causes the movement of its pusher, which acts on the piston. Moving forward, it creates pressure in front of itself, which is transmitted through tubes and hoses to the working cylinder. Its rod extends and displaces the clutch fork, the driven disk disengages the transmission. When the pedal is released, the reverse process occurs.

Replacing cuffs

As mentioned above, the entire clutch cylinder is rarely replaced. Much more often, the car owner disassembles it and repairs it. About 80% of cylinder failures are associated with a violation of its tightness. The cylinder begins to leak due to wear of the sealing collars. So the repair of this device in the vast majority of cases comes down to replacing the seals, which are sold in the form of repair kits in almost all spare parts stores. The standard VAZ clutch repair kit includes three o-rings and one rubber cap. This kit costs about 300 rubles.

Sequencing

All we need to replace the cuffs is a thin screwdriver or an awl.

- The piston removed from the cylinder is thoroughly wiped with a rag, then washed with brake fluid.

- The old cuffs on the piston are pryed off with an awl or a screwdriver and removed.

It is convenient to remove the cuffs from the master cylinder piston by prying them up with a screwdriver - In their place, new seals from the kit are manually put on. When putting the cuffs on the piston, you need to make sure that they fit into their grooves evenly, without distortions. If the cuff is slightly skewed during installation, it can be carefully straightened with a screwdriver. If this is not done, the seal of the cylinder will again be compromised and all efforts will go down the drain.

Typical faults

A large number of rubber gaskets and seals are used for various seals in the cylinder. Most often, they are the reason for the unsatisfactory performance of the GVC. The symptoms will be the following:

- the clutch does not disengage;

- the pedal is not pressed;

- brake fluid leaks on the cylinder body;

- The clutch pedal does not return to its original position.

Such signs are characteristic not only of a malfunction of the main circulation system. Only leaks of brake fluid on the body indicate it reliably. You will have to repair or change the clutch master cylinder of the VAZ-2107, the price in the second case will be noticeably higher, but the service life will also be longer.

Removal and repair

Regardless of whether the owner decided to restore the GVC or preferred to buy a new one, the first step is to dismantle the old one. To work you will need:

- set of spanners;

- medium sized screwdriver;

- pliers;

- brake fluid for topping up;

- repair kit for clutch cylinder VAZ-2107 (in case of repair);

- small container for draining brake fluid.

The sequence for removing the clutch master cylinder is as follows:

- It is necessary to drain the brake fluid from the reservoir. This can be done using a syringe. However, it will be more professional and faster to loosen the clamp, remove the hose from the fitting and quickly place a suitable container under it.

- Using a 10mm open-end wrench, unscrew the metal tube from the main center and move it to the side.

- Using a 13mm socket, unscrew the two nuts securing the cylinder to the engine compartment bulkhead.

- The GCS can be removed.

First of all, the cylinder must be inspected. This will help you decide on repair or replacement. It makes sense to restore the cylinder only if the rubber seals are worn out. The work is carried out in the following sequence:

- Unscrew the plug at the end of the GCS; if necessary, it will have to be clamped in a vice.

- Pull out the return spring.

- Using a screwdriver, remove the rubber cap.

- Now you need to remove the retaining ring.

- Using a screwdriver from the side of the unscrewed plug, push out the cylinder piston.

- Replace all rubber gaskets, rings and seals. To make installation easier, they must be pre-lubricated with brake fluid.

Assembly and installation of the VAZ-2107 clutch cylinder is carried out in the reverse order. After installing the reservoir, it must be filled with brake fluid. True, the clutch will not work yet. Air must be removed from the system.

Repair work

If the pedal fails, in order to avoid unreasonable disassembly of the cylinder, it is worth initially pumping the system and expelling air from there that could get in when the liquid in the tank drops below the minimum permissible level. If this does not help in principle, it is worth starting repairs. For this case, there is a repair kit for the clutch master cylinder on sale, which, depending on the make of the car, contains the main wearing parts: cuffs, return spring, rod, retaining ring, etc.

The master cylinder is located under the clutch pedal. Depending on the car model, dismantling will have to be done either from the engine compartment or from the car interior, having previously dismantled the floor covering in the driver’s area. Having removed the clutch master cylinder, we begin disassembling it, after which we need to wash all the parts

During the subsequent inspection, after disassembly, it is worth paying special attention to the body and the condition of the rod and mirror; if there are visible scuffs, this may indicate the appearance of wear in the cylinder or wear of the rod

In general, experienced craftsmen recommend changing all the parts in the repair kit, especially the cuffs.

When repairing the clutch master cylinder, it is advisable to follow some tips:

- in the event of a malfunction and subsequent repair of the cylinder, it is not possible to completely remove the fluid from the hydraulic drive;

- When washing parts, it is highly not recommended to use kerosene, diesel fuel and gasoline for this; after this, the cuffs and other rubber products may swell; the best option for washing is brake fluid;

- Before assembly, it would be useful to lubricate all parts with brake fluid; only the spherical surface of the rod in contact with the pusher needs to be treated with grease.

If faults are found that cannot be eliminated with the spare parts contained in the repair kit, then a complete replacement of the clutch master cylinder is necessary.

How to bleed the clutch

Removing air from the system is necessary after any repair of the central circulation system. It is better to carry out work with an assistant. Bleeding the VAZ-2107 clutch cylinder is carried out in the following sequence:

- prepare a small diameter hose and a container with brake fluid;

- fill the tank without adding 1.5 - 2 cm to the top;

- “release” the working cylinder fitting a little and put the hose on it;

- lower its second end into a container with brake fluid;

- press and release the clutch pedal until all the air is released from the system, this can be determined by the absence of bubbles;

- as soon as this happens, you need to fix the pedal pressed and tighten the fitting;

- check clutch operation.

If necessary, the process should be repeated.

Source