Advantages of the robot

Why did AvtoVAZ decide to produce Vesta with this type of box? The fact is that:

The robotic gearbox of the Lada Vesta is cheaper to design than a classic automatic; Vesta with a robot uses fuel more economically, unlike other gearboxes; A special feature of the AMT in comparison with an automatic transmission is almost three times less transmission oil consumption; The electronic mechanism provides protection against engaging the wrong gear while driving (this happens on mechanics);

The robot rarely breaks down, there is no need to frequently diagnose and maintain; The clutch engages and disengages smoothly when starting from a stop and changing gears, the lever does not vibrate while driving; Manual transmission is less noisy, unlike manual transmission; Inside the box there is an option to compensate for clutch wear - it further extends the service life service of transmission elements; The box is used in automatic or manual mode, whichever is more convenient.

Video of installing a manual transmission instead of an automatic transmission

Especially for you, dear readers, I have selected a video review on replacing an automatic transmission with a manual one. Because I can’t describe it in more detail, because it would take kilometers of words. Yes, and it’s difficult to read when you’re all eager to install the mechanics as quickly as possible in order to try the new powerful acceleration dynamics.

So watch the video, download it to your phone, and go to the garage. Be sure to leave feedback in the comments when you're done changing the transmission. Did it work? What difficulties did you experience?

Removal process

- We place the car on a lift, apply the parking brake, turn off the ignition, open the hood and disconnect the negative terminal of the battery.

- Remove the front wheels of the car.

- Remove the engine splash guard and the front suspension subframe.

- We disconnect the resonator pipes 1, Figure 1, inlet from the air intake and the air filter housing, use a 10mm head to unscrew the two fastening bolts and remove the resonator.

- Using pliers, press out the clamp 1, Figure 2, fasteners and disconnect the upper hose 3 of the crankcase ventilation from the pipe of the cover 7 of the cylinder head.

- Using a Phillips screwdriver, loosen the fastening clamp 2 and disconnect the intake pipe hose 4 from the throttle pipe.

- Using a 10mm head, unscrew bolt 5 securing the air filter and remove air filter 6 assembled with hose 4 of the intake pipe.

- We recess the buttons 2, Figure 3, of the cable end clamps and disconnect the ends of the shift cable 4 and gear selection cable 5 from the levers of the gear shift mechanism 6.

- We move the clamps 1 for fastening the cable sheaths in the direction indicated by the arrow, remove the cable sheaths from the mounting bracket 3 and remove the gear selection and shift cables from the work area.

- Disconnect harness 4, Figure 4, of the ignition system wires from the block of harness 1 of the oxygen sensor wires.

- We disconnect the block of the harness 1 of the oxygen sensor wires from the bracket 3 of the fastening, remove the wiring harness of the oxygen sensor from the bracket of the 2nd fastening and remove the harness from the work area.

- Disconnect the ignition system wiring harness block from switch 4, Figure 5, reverse light.

- Using a 13mm head, unscrew bolt 1 of bracket 2 securing the outlet hose.

Using a 13mm head, unscrew the two bolts 1, Figure 6, fastenings, remove the cylinder 2 of the hydraulic clutch drive without disconnecting the hydraulic drive 3 from the tube, and hang the cylinder on the technological hook.

Using a replaceable Torx E10 head, unscrew three bolts 1, Figure 7, remove bracket 2 for fastening the clutch hydraulic cylinder, remove starter 3 and hang it on a service hook.

Using a 17 socket, unscrew fastening nut 1, Figure 8, remove the earth terminal 2 from the stud and remove the wire from the work area.

- Using a 17mm spanner, unscrew plug 1, Figure 9, and drain the oil from the 3rd gearbox.

- We degrease the threads in the gearbox housing and on the plug, and apply sealant to the threaded part of the plug.

- We screw plug 1, Figure 9, into the oil drain hole in the 3rd gearbox housing. The tightening torque of the plug is 29 – 46 Nm (2.9 – 4.6 kgf.m).

- Using a 18mm head, unscrew bolts 3 and 5, Figure 10, fastenings and remove the amplifier 4 brackets and rod 1 of the rear engine mount.

- Using heads 16 and 18, unscrew bolts 2, 6 and 8 of the fastening and remove bracket 7 of the rear engine mount.

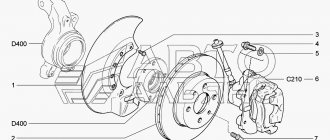

- Using a 8mm head, unscrew the three bolts 1, Figure 11, fastenings and remove the lower clutch housing cover 2.

- We knock out and remove the internal hinges of the front wheel drives from the gears of the differential axle shafts and install transport plugs in their place.

How AMT works and works

AMT (automatic-manual transmission) - an automated/manual transmission with mixed mode is a conventional manual transmission in which the functions of on/off the clutch and gear shift are assigned to actuators driven by electric motors at the command of an electronic control unit. Thus, mechanical transmission drives (clutch pedal, cables or rocker), which were previously controlled by the driver, are excluded.

Lada Priora mechanism inside

Before starting to operate the vehicle, a one-time adaptation process (subsequently periodically repeated during routine maintenance) is performed, which consists of programming the electronic gear shift and clutch control device.

Sequence of actions for dismantling and installing AMT on a Lada Vesta car

- We hang the car on a lift and remove the front wheels to ensure proper access to the axle shafts.

- In the engine compartment, remove the terminals, battery, and battery mount.

- We dismantle the air filter, housing, pipes.

- We disconnect a number of sensors in the engine compartment. Be careful as the plastic plugs will break.

- We unscrew 12 bolts from under the bottom of the car and remove the metal protection of the oil pan.

- We place the container under the drain plug on the box and grind off the waste. This step is forced, since in the future we will dismantle the axle shafts, from the base of which lubricant will flow.

- We remove the right and left drive shafts.

- We disconnect the ball joints, tie rod ends, stabilizer struts.

- We lower the subframe.

- Remove the clutch actuator and starter.

- We disconnect the robot from the clutch flywheel.

Next, we inspect the unit, troubleshoot it, and replace worn elements with new ones. We install the transmission in its original place in the reverse order.

Common gearbox problems

The problem concerns the first gear speed. It turns on very hard, there is an extraneous sound when changing gears, the speed drops while driving.

The reasons may be the following:

- The synchronizer may have failed.

- The retainer spring has burst or has a defect.

- Speeds may change independently due to the weakening of the lever.

- The problem is in the stem or fork. They need to be replaced.

The next problem concerns second gear. Most often, car enthusiasts are faced with the fact that the second speed jumps out or difficulties arise when turning it on.

The following reasons may lie behind this:

- The gear teeth are worn out, as a result of which they do not cling well to the gear shift clutch. In this case, it is necessary to repair the VAZ 2110 gearbox. In the future, this may cause the transmission to crash.

- If the transmission slips out exclusively when driving over bumps, then we can say with confidence that the reason for this is a problem with the clutch.

Very often, in order to fix a problem with the second speed, you just need to change the retaining spring. If, after replacing the spring, the speed continues to drop, then you need to remove the gearbox and do a major overhaul.

The occurrence of extraneous noise in the gearbox may be due to bearings that have failed. In order to find out, you need to check the play of the roller bearings that are installed in the clutch housing, and the rolling bearings located on the primary and secondary shafts.

You need to check the forks and gear rods very carefully. These parts tend to deteriorate very quickly. If there are any obvious signs of wear on these mechanisms, then they need to be replaced immediately with new ones. You can buy these parts at auto stores.

If a car enthusiast has a little experience in repairing a VAZ 2110 gearbox, then he can safely carry out repair work on the gearbox on his own. From this article it is clear that this is not so difficult to do. Even a car owner, without sufficient experience and skills, can cope with this problem.

https://youtube.com/watch?v=AsPYdykgMWc

But if a person is still far from this, and has no idea what or how to do, in this case turning to a specialist for help would be the right decision. Of course, turning to specialists for help will cost the car owner some money. But it’s better to pay money and get a quick and high-quality gearbox repair.

voice

Article rating

How much will a replacement cost?

Are you still here? Want to read to the end? Probably, you’re not in a hurry to go and replace the automatic gearbox yourself?

If you decide to put your car in the hands of an experienced mechanic, then in this block I will tell you how much it costs to change an automatic transmission to a manual transmission in service centers.

Read

Lexus automatic transmission repair

I have already written about the workhorses of the German company Volkswagen. At the service center you will pay $700 for the labor and $500 for a used mechanic. This is for modification B5. And for a Volkswagen Passat, changing the automatic transmission will cost 200 and 400 dollars, respectively.

For a Ford Focus or Mazda 3, this price tag will rise to $800 and 600 for the gearbox.

Therefore, draw conclusions and decide: to change or not to change.

The appearance of a variator on the Lada Vesta

Almost immediately after the presentation of the Lada Vesta to the public, there was talk about the possible configuration of the car with a CVT. In September 2022, the company officially confirmed testing with a CVT. A month later it became known that the Jatco JF015e unit was installed on the car.

In February 2022, AvtoVAZ representatives announced that the continuously variable transmission will be paired with a 1.6-liter Renault-Nissan engine.

In September 2022, the head of the press service announced the start of the preparation phase for the production of Lada Vesta with a continuously variable transmission. Final changes are being made to the car's design to allow the installation of a CVT. The company is negotiating with component suppliers. For the first time, the release date of the Lada Vesta with a CVT is announced. The first cars were supposed to go on sale at the end of 2022.

In November 2022, validation tests of the variator began on another model of the company's car. At the end of 2022, a postponement of the start of production of the Lada Vesta with a CVT is announced. The car's new release date is initially set for the third quarter of 2022. A little later, the debut of the Lada Vesta with a CVT is postponed to the fourth quarter of 2022.

According to the latest data published on 03/19/19 on the Lada Vesta production plan for 2022, the car in modification with the Jatco JF015e variator will appear on the assembly line in December of this year. The car with a continuously variable transmission should go on sale in early 2022.

The advantage of a CVT over a robotic automatic transmission is the ease of speed control. The continuously variable transmission allows you to accelerate smoothly, without dips or jerks. According to the manufacturer, the Lada Vesta should be more dynamic with a CVT.

Engineers promise the reliability of the continuously variable transmission at a very decent level. Provided that the car owner does not try to start a car with an automatic transmission from a pusher, participate in races, or storm high curbs, the CVT is expected to last 250 thousand km. At the same time, an oil change is necessary every 70 thousand km.

One of the main disadvantages of a CVT is that it is more expensive than a robotic automatic transmission and manual transmission. The additional payment can be 50-100 thousand rubles. At the same time, the torque limitation will not allow the use of a continuously variable transmission with the entire range of engines.

CVT for Lada Vesta

The Franco-Japanese corporation Renault Nissan is providing Russian designers with a CVT, which they plan to install on AvtoVAZ’s new product. This device has proven itself when used on units that require a stepless reduction or increase in the gear ratio.

- the variator creates smoothness during vehicle acceleration;

- the mechanism reduces the car's fuel consumption;

- expensive repairs are the only drawback of the variator.

Russian enthusiasts will have to wait for this device to arrive on the markets, as it will be installed together with a reliable and powerful new engine from the Renault-Nissan alliance. Now is the time to evaluate the work of both the robot and the automatic transmission, and then compare them with a rare phenomenon for the domestic automotive industry - a CVT. It’s difficult to say how much this device costs.

Winter mode or start from second gear

Yes, this mode has been implemented in the new firmware. But there is no separate button to turn it on; we manually shift the automatic transmission lever to manual mode and select second speed. We press on the throttle and get moving.

After the creeping mode, which was discussed above, we expected engine jerks and complete discomfort in the cabin. But the expectations were not met. The Lada Vesta drove smoothly in second gear. This means you can move freely in winter on ice and packed snow, the wheels will not slip.

This feature was not available in previous versions of AMT on VAZ. In winter it was difficult to start driving on a slippery surface; this required certain skill from the driver. During these times, many regretted that they did not have simple mechanics.

Standard clutch - article number and price

The VAZ 2170 Priora comes from the factory with a clutch manufactured by LUK. Catalog number (article): 21703-1601130-00. You can find it at a price of two thousand rubles, and if you do not need the entire set of the mechanism (not counting the drive mechanism), you can find the parts by catalog numbers:

- Clutch assembly (release bearing): 21703-1601180-10;

- Driven disk: 21703-1601130-00;

- Pressure plate assembly: 21703-1601085-00;

- Bolt: 21080:1601207-00.

The “native” LUK kit is considered “softer” than its analogues and, moreover, comes with a reinforced basket.

Which transmission is better?

AvtoVAZ has really done a huge amount of work in order to provide motorists with a popular model with various types of transmission. Both mechanics, automatic machines, and robots have their advantages and disadvantages. The manual transmission model has become widespread partly because it is the most affordable. Despite the occasional hum and noise, a car with a 5-speed manual remains a good choice. But for residents of big cities, a car with an automatic transmission is best.

An automatic transmission with a torque converter will ensure comfortable control of the car and will not cause serious trouble. The version of the model with AMT is considered technologically advanced, modern, but at the same time the most problematic. There is a possibility that in the future the manufacturer will abandon the robot, giving preference to a CVT variator, as was done in the Lada Vesta. A sedan with a robot can be bought either new or second-hand on the secondary market. The second option is the most dangerous and unpredictable: often on manual transmissions, even before 100 thousand kilometers, the servomechanisms fail and the clutch wears out. It is extremely expensive to maintain and repair such a unit.

Lada Granta

Lada Granta

Interior of Lada Granta with automatic transmission Jatco JF414E

Interior of Lada Granta with robotic transmission

Automatic transmission

With modern gearboxes, torque converters are blocked immediately after start, even at the lowest stages. Therefore, the efficiency of current automatic transmissions is only slightly lower than that of manual transmissions. And clutches and brake bands of planetary gears now compete in shift speed with clutches and DSG actuators.

In tests, Solaris outperformed AMT and CVT in both disciplines. The latter is more expensive and capricious.

A well-tuned hydromechanical automatic is an ideal transmission antidepressant for traffic jams.

Lada Granta with automatic and robot

After the appearance of the Granta version with an automatic transmission in 2012, which was installed on this model until 2022, many experts agreed that AvtoVAZ really brought to the market a high-quality budget model with an automatic transmission.

In fact, the experience of ordinary car enthusiasts confirms that this is indeed the case. The reason is quite obvious, since VAZ did not experiment and went along the proven path, equipping the Grant with a “classic” 4-speed hydromechanical Japanese automatic transmission.

If you follow all the rules and recommendations for maintenance and operation, such an automatic machine can easily cover 200 thousand km. and more without repair. The main thing is to change the transmission fluid every 40-50 thousand kilometers. As a last resort, replacement is allowed at 60 thousand km. It is also strongly recommended to fill with original ATF EJ-1 or Matic-S oil.

Putting aside the significant increase in price of the Lada Grant with an automatic transmission, the increased fuel consumption, the need for more expensive and frequent maintenance, as well as a slight decrease in acceleration dynamics, otherwise there are no complaints about the automatic transmission on the Grant.

It is important to understand that any torque converter boxes are sensitive to slipping (clutches burn), overheating and large “shock” loads (sharp starts, towing a trailer, etc.). Also, in some cases, leakage of oil seals and gaskets, damage to the automatic transmission pan due to its low location, as well as contamination of the oil in the machine as a result of active wear of the friction linings of the torque converter lock-up were noted

Also, in some cases, leakage of oil seals and gaskets, damage to the automatic transmission pan due to its low location, as well as contamination of the oil in the machine as a result of active wear of the torque converter locking friction linings were noted.

Taking into account the disadvantages of the automatic transmission and the high cost of the unit, which led to an increase in the price of the car as a whole, VAZ decided to replace the classic Jatco automatic transmission with the AMT 2182 robotic gearbox.

The specified manual transmission began to be installed on Grant at the beginning of 2022. It is based on a 2180 mechanical transmission, where instead of cables and a clutch pedal, an electromechanical gearbox drive developed by the Germans from the ZF company is used.

As a result, the Lada Granta with the AMT robot has become more economical compared to an automatic transmission, acceleration dynamics have improved, and transmission maintenance costs have decreased. However, such a robot is a cheap solution, which also has disadvantages.

For example, if you drive calmly at first speed and sharply press the gas pedal to accelerate, the transmission “thinks” for quite a long time, is in no hurry to engage second, immediately switching to third gear, etc. In other words, a robot in automatic mode can behave unpredictably, which excludes the possibility of actively using the car and practicing aggressive driving.

At the same time, during a quiet ride, jerks during switching, as well as delays and dips, are kept to a minimum. For lovers of active drive, it is recommended to use the manual shift mode (similar to the Tiptronic automatic transmission).

This mode is semi-automatic, that is, the driver does not fully control the box, as is the case with a manual transmission, but when independently controlled, the manual transmission behaves more predictably in manual mode.

Some owners in this situation are helped by changing the oil in the robotic box, while others still note the presence of extraneous noise to a greater or lesser extent even after this procedure.

Lada Granta: manual gearbox

So, when it comes to the VAZ Lada Granta model, a manual or manual transmission is the most popular type of unit on this car. The reason is obvious, since “mechanics” is the most affordable, reliable and at the same time simplest transmission, both in maintenance and repair.

It is noteworthy that the production of Lada Granta has been established since 2011, and the first versions were equipped with a manual 5-speed gearbox VAZ-2180. Later, the model began to be equipped with an automatic transmission, and later with a manual transmission robot.

As for mechanics, the Lada Granta 2181 cable manual transmission began to be installed on the car in 2012, but later this gearbox was modernized, as a number of certain shortcomings quickly appeared during active operation.

One way or another, the mechanics of the Lada Granta manual transmission are based on the same well-known 5-speed gearbox, which was installed on the VAZ 2108. The first versions of the Grants received a 2180 gearbox. This gearbox received a shift rod, the gear selection mechanism was located at the bottom parts inside the unit housing.

The same box was installed on the Lada Kalina of the first generations. Subsequently, VAZ introduced a modified gearbox with the index 2181 and 2190. Upon closer examination, the Lada Granta gearbox, device and a number of features have changed noticeably compared to the previous initial version.

First of all, the gearbox became a cable one (the gear shift rod was replaced with cables, and the gear selection mechanism was at the top and was placed separately, that is, outside the body). Also, the first and second speeds were equipped with a multi-cone synchronizer, and the clutch housing also underwent changes.

It should also be noted that the oil volume in the Grant gearbox has decreased by almost a third (from 3.3 liters to 2.2). The use of cables in the design instead of a rod made it possible to significantly reduce the level of vibrations on the body, achieve higher speeds and increased clarity of switching.

The driver no longer needs to search for a gear for a long time before engaging it; the gearbox has begun to work more smoothly. It would seem that the unit was modern and improved, but in reality a serious problem immediately appeared. When driving, the VAZ 2181 gearbox began to howl and make noise.

The problem was widespread, so AvtoVAZ was forced to modernize and improve the technology for processing shafts and gears. As a result, in 2014 Grant received an updated version of the manual transmission.

The howl and noise of the gearbox when driving were minimized, but it was not possible to completely get rid of the characteristic shortcomings. For example, second gear may engage with a characteristic crackling and crunching sound, and shifts may not be as clear as they should be with a cable drive.

Also, some car enthusiasts note that the mechanics continued to howl in second and third gears, increased vibration was noted during active acceleration, the gearbox lever may rattle at 3rd speed, etc.

Pre-production tests

However, the Granta, equipped with an automated manual transmission, is now on the agenda; sales begin in February. To approach this date fully armed, a number of tests were carried out. One of the pre-production cars immediately went to Germany so that AvtoVAZ's partners from ZF, for their part, could conduct their own tests and allow the car to be put into production.

Starting with the Priora platform, cars have undergone a huge number of tests in various climatic zones and under a variety of programs. Tests took place in the Alps and Altai mountains with the participation of partners from Germany, at low temperatures reaching -55°C, in the Far North in Surgut. Speed tests were successfully carried out at the Porsche test site with humidity of almost 100 percent and temperatures exceeding +30°C. These tests were followed by accelerated road tests of 80,000 km and 100,000 km. Difficulties that arose during the testing process were resolved promptly, quickly and professionally.

The new gearbox is a product of Russian engineering, since the burden of solving most of the problems fell on VAZ’s shoulders. Engineers from Russia have demonstrated that their level is not inferior to the quality of engineers in the best European companies.

In general, the design of the new box consists of 80% Russian parts, and this says a lot.

Advantages and disadvantages of the robot on Vesta

Let's start with the advantages. According to reviews of the robot on Vesta, the machine has the following undeniable advantages:

- Equipped with the “Slope Start Assistant” program – even if you park or get stuck in a traffic jam on a slope, this option will help you avoid rolling back when starting. The gearbox increases speed at the start, the clutch becomes stiffer.

- Increased clutch life - thanks to the soft and smooth operation of the AMT, the service life of the part will be long even with careless driving. The shift box is protected against accidental pressing of the lever: if you start shifting it chaotically, the car simply will not react.

- AMT is adaptive and has 26 behavior patterns that it selects depending on the driver’s behavior. How it works? The program reads how the driver operates the gas pedal and, depending on this, switches the clutch at the right moment.

- Fuel economy is hard to believe, but the robot on the Lada is really more economical than a manual or automatic transmission. Thanks to smooth switching, you can use several times less gasoline.

- AMT consumes less oil than manual transmission - also a significant factor in favor of choosing a new configuration.

Reviews of the robot box on Vesta also show the disadvantages of an automated manual box:

- The absence of a parking mode makes parking more difficult; when parking, it is better to leave the control lever in manual or automatic mode to avoid rolling back.

- Gear changes are jerky - between 1st and 2nd gears there is a decrease in speed, which can noticeably slow down the car.

- Slow acceleration - a car with AMT takes a few seconds longer to pick up speed than a car with a manual transmission.

- The inconvenience of the manual mode is that the gearbox is not designed very well, and this makes manual driving of the car less convenient.

ME, SELECTOR AND TWO PEDALS

“Before you start, press the brake,” instructs Vladimir Petunin, the ideological inspirer and project manager. — This is foolproof: the engine starts only in “neutral” and with the brake pressed.

By the way, the car itself will remind you if the driver does not put his foot on the brake - there is a warning light on the instrument panel. The selected transmission mode is also displayed there.

- Now move the selector to A - and let's go. I’ll say right away: I expected the worst. It has long been in my head that a robot with one clutch cannot compete in smooth shifting and efficiency with a classic automatic. But modern designs have moved far from the first designs. The automated gearbox of the Priora does not cause irritation at all. Delays during switching are inevitable, but they are tolerable. And the box moves smoothly from step to step. You can, of course, change the firmware and add speed to the box, but the ride will become jerky and the synchronizers will not last long.

— Try manual mode. It's sharper.

Indeed, the box began to shift a little faster under my control. But I prefer the smooth automatic mode - after playing with the switches a little, I return the selector to position A again.

The box understands commands well. When you press the gas sharply, it quickly downshifts and holds the gear longer, allowing the engine to rev to maximum power. I tried to take off on an incline: it was easy, since on a slight slope you don’t have to hold the car with the handbrake. When you press the gas, the clutch closes quickly, but without jerking, and the car does not have time to roll away. We even managed to get stuck in a long traffic jam - absolutely no problem.

For comparison, I drove a Citroen DS3. It was his box that was taken as a model when setting up the Priora robot. I didn’t feel any difference in behavior with the “French” transmission. If so, congratulations to the developers - good job!

Automatic expected

Many people are concerned about the issue of the machine gun. The predecessors Kalina and Grant already had a four-speed Jatco automatic, why isn’t it on the 2180? The fact is that there is no suitable base for the machine gun on the Lada Vesta. The mentioned box is already outdated, and purchasing a new one will significantly increase the price of the car, which is contrary to the policy of the Volga Automobile Plant.

Company President Nicolas More denied rumors about a 4-band automatic transmission for the most popular Lada models. So will the Lada Vesta have a gun? Most likely Yes. It will be a 6-speed modern transmission. Negotiations are already underway on the creation of a new plant in the Russian Federation; automatic transmissions will be created at the plant with the support of foreign companies. The appearance of an automatic machine on the Lada Vesta should be expected in at least 4-6 years.