29.08.2019

| (Votes: 5, Rating: 5) |

Issues discussed in the material:

- How does a clutch work in a car?

- Why does the clutch pedal vibrate?

- What problems inside the clutch does pedal vibration indicate?

- What to do when the clutch is faulty

When faced with vibration of car pedals, most car owners experience justified concern. Abnormal behavior of vehicle components and assemblies should be treated with close attention, since they are a signal of internal malfunctions. In the article we will talk about what may cause vibration of the clutch pedal when pressed.

Where does noise come from when a car's clutch operates?

Noise, manifested in the form of buzzing sounds of different tones when the clutch is operating (it is turned on, off and when the engine is idling), indicates the occurrence of quite serious problems that require a quick solution.

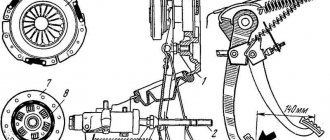

Clutch device for VAZ 2108, 2109, 21099 cars and their modifications

Using the example of the clutch of VAZ 2108, 2109, 21099 cars, we will try to figure out where the noise came from when the clutch was operating and what ways there are to solve this problem.

Where did the noise come from when the car clutch operates?

Clutch noise when engine is idling

If you listen, from the clutch and gearbox side, while the car engine is idling, you can hear a continuous, distinct noise. When you depress the clutch pedal, the noise disappears or noticeably decreases.

Such signs may indicate a failure of the gearbox input shaft bearing on which the clutch basket and driven disc are “mounted”. The shaft begins to “dangle” together with the broken bearing, making noise, and when the clutch is disengaged, the load on it is reduced and the noise disappears. This malfunction is often accompanied by oil leakage from the gearbox under the input shaft oil seal. In the early stages, the malfunction is practically unnoticeable, but as the bearing deteriorates, it makes itself known.

The release bearing can also make noise and even howl at idle, since its working surface is always pressed against the leaf pressure spring of the basket and rotates with it (the clutch on the VAZ 2108, 2109, 21099 is backlash-free). A bearing malfunction may be a consequence of lubricant leaking out of it, after which a play appears and it will begin to make sounds when its moving part rotates. See photo at the beginning of the article.

To determine what exactly is noisy at idle - the releaser or the shaft bearing, we will do the following.

Disconnect the cable from the clutch release fork. We start the engine and leave it idling. Then turn the fork slightly clockwise. The release bearing will come out of contact with the clutch pressure diaphragm spring and the sound should disappear. The howling has disappeared - the release valve is faulty and needs to be replaced. If it does not disappear, you will have to remove the box and replace the input shaft bearing, or replace the oil in it with a better or thicker one.

Checking the serviceability of the clutch release bearing on VAZ 2108, 2109, 21099 cars

Noise when disengaging the clutch

If a howling sound is heard from the clutch housing when you press the pedal, then the release bearing has most likely failed. We release the pedal, the noise disappears or decreases. If the bearing jams or is completely jammed, then it will not be possible to press (disengage) the clutch normally. The engine will stall, and it will become almost impossible to “stick” the gear.

Also, when you press the pedal, the clutch may make noise if its drive is not adjusted correctly. It “drives” - the driven disk does not completely move away from the flywheel when turned off, it rubs against it and makes noise. The malfunction can be eliminated by adjusting the drive.

Noise when engaging clutch

When the driver releases the clutch pedal, turning it on, a distinct noise or even rattling, metallic ringing and knocking is heard from the gearbox and clutch.

This indicates wear or breakage of the driven disk (wear, deformation, loosening of its linings, breakage of damper springs) or loosening of the gearbox to the engine.

Notes and additions

— On VAZ 2108, 2109, 21099 cars, the clutch is constantly engaged, that is, the input shaft of the gearbox rotates together with the clutch basket and driven disk. See “Design and principle of operation of the clutch of VAZ 2108, 2109, 21099 cars.” When you press the pedal, the release bearing comes into operation, which presses on the pressure spring of the basket, forcing its drive disk to move away from the driven one.

— The operation and serviceability of the clutch can be fully assessed by carrying out a comprehensive check. See “Checking the clutch on VAZ 2108, 2109, 21099”.

Source

The clutch pedal rattles on the grant

Many owners of Lada Granta, Kalina and Priora notice the creaking of the clutch pedal.

Moreover, this problem may arise after the first kilometers of driving. We will tell you about the possible causes of this disease, as well as ways to solve it. First, make sure your car's clutch is adjusted correctly. While holding the clutch cable end in an extended position, measure the size between the fork and the driver, it should be 27 mm. How to adjust the clutch cable is shown in the video:

About 11% claim that the cause of clutch squeaking was the clutch cable. Pay attention to the presence of a spring in the tension mechanism; Lada Kalina 2 and Lada Granta may not have it. It is worth noting that this spring is present on the clutch cable of the Lada Priora and the owners of these cars practically do not encounter a squeaking clutch pedal. If there is no spring, then it should be installed. Also, it would be a good idea to lubricate the clutch cable using a thin tube, or, if suitable, install a clutch cable from Lada Priora (catalog number: 21700-1602210).

Even less often (about 4% of owners) they solved the problem of a squeaking clutch pedal by lubricating the tip of the clutch cable. Apply lithol to the contact point between the plastic cable nut (No. 2) and the clutch fork (No. 1).

And about 3% of owners solved the problem with the help of lubricant (graphite) of the gearbox input shaft. To do this, you will have to remove the boot from the clutch fork lever (No. 6), and then lubricate it by inserting a tube from a lubricant can into the hole.

Most often (in 24% of cases), the creaking comes from the plastic pedal bushing, which rubs against the bracket. In this case, you should simply lubricate the rubbing areas with lithol.

In conclusion, I would like to note that it is better to start diagnosing a malfunction by determining the source (direction) of extraneous noise. Then you won't have to do extra work. Let us remind you that knocking noises on Lada cars can also come from the steering rack.

To comfortably select gears on a manual transmission, it is necessary that the gearbox is easily disconnected from the engine. This function is performed by the clutch. Excessively tight pedal movement is unacceptable. This is not only discomfort for the driver, but also excessive stress on the knee joint. And with regard to the unit itself, the identified malfunction allows us to draw certain conclusions about the need to replace some parts.

The clutch started making noise. What's happening?

The noise or hum that occurs when the clutch pedal is depressed can be barely noticeable at first. It disappears as soon as the driver releases the pedal, does not cause discomfort and does not give any particular cause for concern. Over time, the noise increases, but the car owner’s hearing gradually gets used to this sound, and meanwhile, this is a sure sign of increased wear of the release bearing. Moving along the axis of the gearbox shaft, the bearing puts pressure on the petals of the basket, briefly stopping the transmission of engine torque.

Adjustment instructions

The procedure itself is simple and after reading our article and watching the video, even an inexperienced car owner can handle it.

Where is?

The main element that we need is an adjusting nut, which is located in a fairly convenient place - on the cable sheath.

Tools

- tape measure or ruler;

- 2 keys for 17;

- gloves (as you will have to touch contaminated surfaces). Necessary tools

I can hear the clutch being pressed

A couple of days ago I completely replaced the clutch (406 doors). During the first start of the engine I noticed a noise. I get behind the wheel, squeeze the clutch - the noise disappears, let go - it makes noise again!

Has anyone encountered such a problem? And what could be the problem.

Have you changed the input shaft bearing?

Added after 2 minutes 29 seconds And most likely a squeeze. New doesn't mean good.

The same thing. I changed the oil seals on the box, well, I think, let me change the release button, it made a noise, when I pressed it was silent. I reached into the box (5 mortar), found that the outer race of the bearing of the 1st shaft was cracked, replaced it, the rest seemed to be ideal. The noise did not disappear. Today I took it to market 4x mortar for $35 (so that the car does not stand, it is very necessary almost every day), I pumped up manuals from the Internet, my 2CDs for GAZ, advice from mechanics from the taxi company - this weekend I will change it to a 4x mortar - and with God for the bulkhead (only myself, and I won’t trust any locksmith), slowly and carefully, at least for a month. Then I’ll write back.

That’s exactly what I did - I temporarily installed a 4-speed gearbox and took off my 5-speed gearbox for repairs.

Reason for repair _________________

The gearbox rustles at idle - and especially in 5th gear, the gears are switched on indistinctly - and only when you shift the throttle (synchronizers clearly do not perform their function)

Now I’ve disassembled it - detailed troubleshooting of the parts is underway. But we can already say with confidence that the bearings were rustling, as soon as you turn them by hand, they make a lot of noise - although everything is in grease. and there are no backlashes at all. The reason, it seems to me, may be in the fit on the shaft - perhaps too tight, we will measure it, and also, there were a few chips in the box - a wear product - from the coupling forks, the chips could be scattered with the oil - and fix it bearings in appearance - balls in bearings - with micro inclusions. In general, once I’ve done everything, I’ll post a detailed report on the work done with photos.

Added after 4 minutes 5 seconds and more

Car produced in 2001. I plan to put in the box updated double synchronizers (clutch assemblies), forks for them, as well as tapered bearings for the intermediate shaft..

Source

Prerequisites - clutch noise

As a rule, the whistle occurs suddenly, but for an attentive driver such a phenomenon will not go unnoticed. Always, before the clutch squeal appears, it will begin to vibrate and make a little noise. This noise can be regarded as follows: press the pedal - the noise appears, release it - the noise disappears.

If you drive for a long time with such noise, you will eventually hear a squeal or a very loud whistle when you press the clutch pedal. A trip with such a problem will not be long, so you need to take action.

Why do clutch problems occur?

This unit is designed for a mileage of about 150,000–300,000 km. Vibration of the clutch pedal when pressed and a reduction in its service life as a whole is possible due to:

- a car driving style in which the driver sharply squeezes and throws the pedal, since in this case the lining wears out faster;

- increased loads on the vehicle (relevant for trucks);

- towing a vehicle with a larger weight can cause the clutch to burn out (if you smell a burning smell, you must stop immediately).

- holding the unit pedal half-pressed unless absolutely necessary.

Causes of Squealing, Whistling, or Clutch Noise

The most common reason is the release bearing. If you hear a squeal or whistle when you press the clutch pedal, then with a 90% probability it is the one that has failed. As a rule, the car still starts to stall. But in some cases the motor continues to operate. The fact is that after working for a long time without proper lubrication, the release valve began to jam. This manifested itself in vibrations or noises, and then it just jammed and this whistle appeared.

But there is another reason - these are the crankshaft half rings. They prevent axial movement of the crankshaft when the clutch is pressed. If one of them falls into the pan, then the appearance of such a whistle cannot be avoided. You can find out about the movement of the crankshaft and the condition of the half rings with the following test:

- The partner gets behind the wheel and squeezes the clutch.

- You are looking at the crankshaft pulley.

- If there is noticeable play of more than 2 millimeters, then the half rings must be replaced

If the half rings fall out, they need to be replaced as soon as possible, otherwise, in addition to the half rings, you will also have to change the cylinder block with the piston.

Defects associated with clutch replacement

Replacing a clutch means replacing the drive or driven disc. Both are often changed. The release bearing is also replaced along with them. After this, many people develop defects that were not previously observed.

There are several reasons for this:

- unprofessionalism of the auto mechanic;

- new low quality parts;

- the cause of the failure was identified incorrectly and not all parts were replaced.

The cause of the problem is individual in each case, but they all have some similarities.

Clutch pedal vibration

There are two main reasons why vibration appears after replacing the clutch:

- The clutch basket (or pressure plate) is poorly balanced. It is also worth checking the diaphragm and damping springs.

- The driveshaft was installed incorrectly (this problem is typical only for cars with rear-wheel drive or all-wheel drive).

The vibration of the pedal that appears after replacing the clutch in cars with front-wheel drive is due to the fact that the wheel drive was poorly secured. But this happens quite rarely.

Solved the problem of a crackling sound under the hood when pressing the clutch or brake pedal in 5 minutes.

Not long ago I began to experience a strange crackling noise coming from under the hood and only when I pressed these two pedals. The sound was just when pressed, short-lived. Over time it began to intensify.

Since I initially heard it from the clutch pedal, I thought that it might be the release lever; over time it wears out and makes this unpleasant, uncritical rustling noise, but it is irritating. Then I started to hear it directly from the brake. As it turned out, the sound was caused by pressing the brake, I just attached most importance to the clutch.

From the speculations that I had, all that remained was either the clutch cable or the release cable was clicking. But what does the brake pedal have to do with it then?

Hero of the occasion.

Somehow I forgot about this problem, gave up, but it was still annoying. One day while doing something else and looking under the hood with an endoscope, I came across a noise.

I found it simply. While the car was starting, a friend accidentally pressed the brake pedal and suddenly I heard this crash.

It was located in the area of the brake fluid barrel and the vacuum booster.

It was he!

Moving closer to the “vacuum” and asking to press the brake pedal again, I heard where the sound was coming from. It was a check valve

, which is installed on the “vacuum amplifier”. He made this terrible cracking sound.

Eliminating glass chatter in a Lada Granta car

Sometimes a car owner is faced with the problem of loose glass installation. Lada Granta glass rattling must be eliminated, and this becomes an urgent task for the car enthusiast. It happens that on large bumps the rear windows begin to drop a little, and the rattling sound becomes unpleasant.

How can you deal with rattling glass on Grant?

To eliminate glass rattling, you need to purchase a special D-shaped seal from an auto parts store. It is usually produced in a size of 8 mm. It is sold in construction stores, and the cost does not exceed 50 rubles. To seal all car windows, it is enough to have 7 m of such an accessory. You can even equip your windshield with it.

How the clutch works, what are its typical malfunctions, and how to avoid them

An important element of a manual transmission is the clutch, which serves to briefly disconnect the engine from the transmission. In addition, the clutch is a kind of damper that protects the engine from overloads. How does it work and how to extend its life?

How does the clutch work?

Most passenger cars with a manual transmission use a dry single-plate clutch. Its design is quite simple: it consists of two mutually adjacent disks - a drive (basket) and a driven one, a release bearing and a drive system. In the single-disc version, the transmission input shaft fits into a splined clutch in the center of the driven disk, and the surfaces of the engine flywheel, driven disk linings and basket pressure disk fit tightly together. Due to this, the transfer of power flow from the engine to the gearbox is ensured, and a working clutch calmly “digests” all the power developed by the engine.

In everyday life, the clutch drive disc, which includes a pressure plate (with a smooth shiny surface), a diaphragm spring (petals in the center) and a casing, is called a basket

When you press the clutch pedal, the release bearing acts on the plate springs of the basket, causing the surfaces of the driven and driving discs to separate. Accordingly, the input shaft is disconnected from the flywheel - that is, the engine and gearbox are physically disconnected, which allows you to change gear or engage neutral. When the clutch is engaged (the pedal is released), the release bearing stops pressing on the leaf springs, and the discs close again, and the damper springs in the central part of the driven disc dampen the torsional vibrations that occur during movement.

The four damper springs of the clutch driven disc are clearly visible, as well as the worn friction linings

When the clutch operates normally, it does not attract attention to itself. But if it malfunctions, the driver, for example, will not be able to shift gears or move away. What problems are possible?

What malfunctions can occur during clutch operation?

So, what problems in clutch operation can you encounter in practice? Firstly, this is an incomplete release of the clutch - as experienced drivers say, it “leads”. When you press the pedal, the surfaces of the flywheel and the driven and driving disks do not open completely in this case, and attempts to change gear are accompanied by the crunching and grinding of the synchronizer carriages, because complete separation of the gearbox and the motor does not occur.

The opposite problem is clutch slipping: that is, its incomplete engagement. In this case, the surfaces of the flywheel, driven disk and drive disk, on the contrary, do not fit tightly against each other and slip, which can cause a characteristic smell of burnt friction linings of the driven disk, and an attempt to suddenly pick up speed only leads to an increase in crankshaft speed. In this case, only a small part of the power is transferred from the engine to the wheels - until the wear of the surfaces becomes critical.

If the clutch “slips”, instead of the car, only the tachometer needle “accelerates”

Finally, malfunctions such as the occurrence of vibrations and extraneous sounds when the clutch is turned on and off are also possible.

What causes clutch malfunctions?

Usually, every clutch problem that arises has its own background. For example, the clutch may begin to slip due to severe wear on long vehicle runs, when the friction linings of the driven disk are worn out, and the working surfaces of the basket and flywheel are worn out.

Secondly, the clutch can simply be “burnt” - for example, due to inexperience or after prolonged overload. This, for example, happens to fans of long, “rocking” rides on the roads or in deep snow, as well as to fans of sudden starts with the gas pedal to the floor.

Source