It’s quite easy to “lose” the engine of your nine!

Among the many reasons is its critical overheating.

Not much is needed:

- on a hot day there is a traffic jam at a traffic light,

- scale in the radiator,

- fan failure

- — avalanche-like increase in temperature.

Result:

- smoke from under the hood,

- fireworks in the form of a flying tank cap

- and a fountain of splashes of hot antifreeze and oil into the engine compartment.

An impressive sight, but not only that: as a result, serious and sometimes catastrophic problems with the engine are the price to pay for carelessness and inattention.

Hence the first important conclusion: in cars of the Samara line of early releases, the operation of the fan is determined “by ear”.

There are no alarms in the cabin about failures in the cooling system. This situation can hardly be called normal.

Operating experience of the VAZ-2109 speaks of numerous cases of accidents and engine destruction due to the fact that the fan does not work.

The cooling radiator uses the principle of convection, but not of air, but of coolant: antifreeze, antifreeze. This is the principle of heat exchange of liquid, which, rising through the radiator tubes, transfers excess temperature to it. Thus, both the efficiency and stable operation of the motor itself increases.

However, the radiator itself gets hot. If the reason is poor circulation, the liquid goes back into the engine hot. This is typical under load operating conditions of the engine: frequent short-term jerks from a standstill,

Cooling circuit malfunctions:

- thermostat,

- pipes,

- radiator,

- fan,

- electrical circuit.

That is why AUTO VAZ declares constant monitoring of the temperature while driving.

Working fluid temperature in VAZ - 2109 engines: 92-98 degrees (depending on engine type).

Who and how controls the start of the fan, which the drivers jokingly called “Carlson”?

Coming from the engine, hot antifreeze heats the sensor.

When the temperature rises above the set point, an electrical signal comes from the sensor to the relay coil, which is activated and closes the power circuit.

The fan turns on and “brings down” the temperature.

The relay opens and the power circuit is interrupted.

Note that the sensor itself is not repairable.

If it malfunctions, it is replaced.

There is no point in saving on it.

The circuit elements are located on the circuit board under the hood, on the driver's side under a plastic cover.

In the latest Samara models, the mounting block model 2114-3722010-60 (blade fuses) is located differently, but the relay itself is not there.

Examination

On VAZ 2109 engines, the operating temperature is 90 degrees.

If the indicator needle crosses the 100 degree mark, the car should be stopped immediately, the engine should be turned off and the power unit should cool down. Without doing this, you risk major, expensive engine repairs.

The motor can overheat for various reasons:

- The thermostat has failed;

- The radiator is clogged;

- The radiator fan has failed;

- The fan switch sensor is broken;

- The coolant level in the system has dropped;

- The pump has failed;

- The integrity of the wiring in the fan circuit has been compromised.

All these reasons can and should be checked before purchasing new parts.

Here is an example of checking a fan and sensor.

| Object to be checked | Method |

| Fan | Take one wire about a meter long. Preferably with two crocodiles at the ends. The mass goes to the fan. Your task is to supply voltage directly from the battery to the fan. Apply 12 volts to the second contact of the fan. If he's spinning, he's fine. If not, you'll have to change it |

| Fan sensor | Turning on the ignition, close the sensor contacts with a screwdriver. Normally, when it is closed, the fan should start spinning, and if it is open, it should stop. Please note that different types of sensors have a certain response temperature - from 87 to 90 degrees or more |

Checking the cooling system

System design

What to do if the VAZ 21099 carburetor cooling fan does not work? As soon as the car owner notices the first signs of overheating, that is, the temperature sensor needle has approached the red zone, but the carburetor has not yet begun to emit smoke from under the hood of the VAZ 21099, you need to check the operation of the cooling system.

- Open the VAZ radiator tap, as well as the car air damper, which controls the air flow.

- Turn on the electric motor that regulates the operation of the radiator at maximum power.

- Inside the VAZ car, turn on the emergency button, then press the clutch pedal with your foot and very carefully drive off the road, stopping the car on the side of the road.

- Leave the VAZ 21099 carburetor engine running for several minutes at normal idle speed with the radiator on.

- After turning off the engine, the coolant system heats up precisely in those places where it comes into close contact with hot parts, resulting in the formation of so-called vapor locks.

Keep in mind that an overheated engine will not be able to shut down immediately. But such work is quite harmful to the VAZ engine, so it needs to be completed regardless of the resistance of the car.

Checking all wire connections

Step-by-step instructions for checking the cooling system.

- First you need to open the hood of the car and inspect the entire space under it. Find a source of steam. Check whether there is enough coolant in the tank, whether all rubber hoses, the radiator and, of course, the thermostat are intact. Perhaps it is these parts and systems that need to be replaced.

- Look under the foot mats to see if there is any liquid there. There must be a good reason why the car engine is not cooling.

- If fluid is not found, you need to see if the sensors that start the radiator motor are working. To do this, you need to remove two wires from the sensor mounts located inside the radiator and connect them. After this, turn the ignition key on the car. If, after connecting these wires, the cooling fan begins to spin, it means that the fluid level in the cooling system must be brought to the desired level.

- The cooling fan itself must be running constantly. You need to check the sensors in the radiator. At the first opportunity, it is worth replacing these parts with new ones, as well as replacing the pipes.

- If the cooling system fan does not work when the wires are shorted, the cause may be a blown fuse or a broken fan relay. Another possibility is a burnt-out cooling system motor. In this case, it is necessary to replace all faulty parts.

- After replacing failed elements, a control check should be carried out. To do this, you need to short-circuit a pair of wires that are connected to the car cooling fan switch and turn the ignition key. If the fan motor can turn on, the problem has been resolved.

- If the cooling fan does not turn on, you need to check it by supplying power to the electric motor from the battery.

- The engine of a VAZ 21099 carburetor can overheat even if the thermostat, which regulates the passage of liquid in the cooling system past the radiator or through it, has failed. In order to understand whether this is so, you should check the temperature of the hoses connecting the engine and radiator. If the bottom hose is cold, the thermostat is faulty.

General characteristics of the model

Dream car in the 90s

The dimensions of the car have changed somewhat due to the lengthening of the wing and enlargement of the hood. In addition, a completely new, improved VAZ radiator grille and, of course, an updated dashboard appeared. The length of the VAZ 21099 compared to other cars in this group has increased by 20 cm.

The VAZ 21099, like other models of this family, has many advantages:

- it is capable of developing a fairly high speed;

- has excellent controllability when driving;

- Stable on completely different types of roads.

In 2004, this model of car was no longer produced in Russia, but its production continues in Ukraine.

VAZ 21099 cars come in two types.

The VAZ 21099 has a carburetor, just like the VAZ 21099 has an injector, the layout of the fuel supply system is almost identical.

In the VAZ 21099 injector, the supply of gasoline when you press the gas pedal is controlled by a computer. In a carburetor engine, such emissions are controlled by special damper plugs.

Quite often, the owners of this car are faced with one problem: the VAZ 21099 carburetor cooling fan does not work.

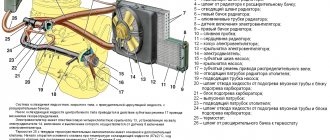

Cooling system VAZ 2109

The liquid cooling system of the engine of the VAZ 2109 injector is a closed-type system with forced circulation of coolant (coolant). The system consists of the following units:

- water pump with impeller, driven by a timing belt;

- a thermostat that directs coolant in a small or large circle depending on the degree of engine warm-up;

- a radiator consisting of two plastic containers for coolant flow and aluminum tubes for heat dissipation, located in the front part of the engine compartment to facilitate air access;

- an expansion tank equipped with inlet and outlet valves to maintain standard pressure in the system;

- radiator cooling fan located directly in front of the radiator for efficient heat dissipation.

The operation of the fan is critical in the hot season when traffic is slow. Under these conditions, overheating of the motor is especially likely and, accordingly, high-quality operation of the fan is necessary. The cooling air flow must be properly supplied to the radiator. If the VAZ 2109 injector cooling fan does not work, then the cooling system may “boil.”

Checking and replacing the temperature sensor

On a VAZ-2109, the cause of untimely operation or complete failure of the fan is often the coolant temperature sensor. Therefore, it needs to be checked secondarily. The sensor is located at the bottom of the radiator, two wires come from it. Before unscrewing it, you need to accurately check the operation of the cooling system:

- Connect the ends of the wires leading to the sensor together. If after this the fan starts working and the sensor gets hot, then this controller needs to be changed. When testing on a hot radiator, you may find that the sensor body is also warm. In this case, check the thermostat.

- If the fan does not work even after shorting the wires, then the problem may lie in the relay or fuse. The relay should be checked if the sound of its operation is not heard. Depending on the type of car, it may be located in the mounting block (for models with carburetors) or in the passenger compartment under the driver’s storage compartment (for injection cars). The easiest way to check this device is to install a similar device in its place. If after replacing the relay the fan starts working, you don’t have to carry out further testing.

- Sometimes the device does not work, but the sound of the relay operating is present. In this case, check fuse F-8.

If you do not find any faults in other systems, then you need to replace the temperature sensor in the cooling system. This is done according to the instructions:

- Turn off the ignition, remove the terminal from the battery and drain the fluid from the expansion tank and the generator. To do this, you need to remove special plugs.

- Then disconnect the sensor from the terminal block.

- Using a spanner wrench, unscrew the sensor from its place without applying excessive force.

How to check a fuse

This is the simplest part of the test, suitable if the power plant is equipped with a carburetor. You need to find a mounting block in the engine compartment of the VAZ-2109. In it, in place of F-4, there is a fuse responsible for the operation of the cooling fan. Pull it out of its seat, and then use a multitester to take a test measurement (performance test).

If the fuse is working, look for another fault. Otherwise, you need to put a new one in its place marked 16 A and run it in. If the fan is working, you don't need to do anything else. Otherwise, examine other parts of the cooling system.

Sensor

Don't rush to change the fan right away. Often the problem was a sensor, relay, fuses, or simply broken wiring. First of all, we will check the sensor and also tell you about the features of replacing it.

Signs of a faulty sensor may include failure to turn on when the coolant temperature is high or turning on when the engine is cold.

The fan switch sensor is located at the bottom of the radiator. A couple of wires come off it.

Searched device

Accurate check

In order not to rush to conclusions, experts first advise checking the sensor for functionality.

- If the fan does not want to turn on according to the standard circuit, try shorting the wires that go to the sensor. If the fan is running and the sensor is hot, the problem lies there. If the radiator is hot during testing, the sensor housing may be warm. This suggests that you should check the condition of the thermostat and the coolant level in the tank. You may need to change and top up accordingly.

- If, after closing the wires, the fan does not turn on, the sound of the relay being activated is not observed, check the condition of the relay and fuse. It is number 4 in the mounting block.

- By shorting the wires, the fan did not start, but the relay worked. Here you should check fuse number 8.

- If the fan starts randomly on a cold engine, it does not turn off for a long time, try disconnecting one wire from the sensor. If the fan stops, the sensor contacts are stuck. If the fan continues to turn, sticking has occurred on the contacts of the control relay.

Having discovered that the regulator has failed, there is nothing left to do but change the radiator fan activation sensor.

Replacing the sensor

Changing the sensor is quite simple:

- Turn off the ignition;

- Drain the coolant from the expansion tank;

- Disconnect a pair of wires from the sensor terminal block;

- Using a 30 mm wrench, unscrew the regulator from its seat. You shouldn’t apply a lot of force; you risk breaking the seat;

- Following the reverse sequence, install the new sensor.

Disabling the sensor

You can change the sensor without draining the coolant. To do this, you need to quickly unscrew the old regulator and screw in a new one in its place. A small part of the coolant will spill out, but you won’t have to drain it for a long time and then pour it back in.

Fan activation principle

The fact is that on VAZ 2108 and 21083 engines the electric fan comes into action thanks to a sensor installed on the right side of the cooling radiator. The fan is switched on directly when its contacts are closed at a temperature of 99°C. On cars manufactured before 1998, the sensor controls the fan through a special relay 113.3747 located in the mounting block. And on the VAZ 2111 injection engine, the cooling fan operates only through a relay based on a signal from the control unit.

Fan

If the problem lies in the injector or carburetor cooling fan, then you will have to remove it. It is quite possible to repair the unit by replacing the electric motor or impeller.

Diagram with casing, radiator, fan and impeller

To remove the valve, perform the following operations:

- Disconnect the negative terminal from the battery;

- Disconnect the wire terminals. One of them is mounted on the fan casing;

- Take a wrench and unscrew a couple of connecting bolts. They fix the vent casing on the left tank;

- Next, unscrew another lower nut holding the device casing;

- Now you will need a socket extension to unscrew the right nut on top that secures the vent housing to the radiator;

- All that remains is to unscrew the fan pressure plate. To do this, remove the pair of left nuts;

- Remove the pressure plate by hand;

- Now remove the fan along with the casing.

You have removed the unit. Now you have a choice - change the entire unit, or try to repair it by replacing the electric motor or impeller if they are damaged.

Replacing the electric motor

- Disconnect the fan motor wire that is held in place by a clamp on the casing.

- The electric motor is held on the casing by three nuts. They all need to be unscrewed.

- Remove the electric motor from the fan housing.

- Be sure to check the condition of the rubber bushings of the electric motor, which will remain on the casing. If cracks or signs of deformation are detected, they must be replaced.

- Check the electric motor for functionality. If it fails, you can purchase a new one and insert it into the old casing.

Electric motor

It is not uncommon that the performance of a radiator fan is impaired due to a deformed impeller. By replacing it, you can restore functionality to the device.

Replacing the impeller

To change the impeller, follow the instructions:

- Pry up the lock washer using a flathead screwdriver. It is located directly in the center of the impeller;

- Lift the washer and remove it;

- In some cases, the impeller is secured to the fan motor with a nut. Therefore, if you have one, unscrew the mount;

- Remove the impeller and assess its condition. If it is worn out or deformed, replace it with a new one;

- Many people, instead of a standard 4-blade impeller, install a more advanced 8-blade impeller.

Changing the impeller

During reassembly, make sure that the motor pin fits into the longitudinal hole on the impeller, as shown in the figure below.

Direct the pin into the longitudinal hole

Replacing an electric fan in a car

- We park the car on a flat surface and immobilize it with the parking brake.

- Open the hood and disconnect the negative terminal.

- Using a 10mm wrench, unscrew the fastenings of the air filter housing.

- Using a screwdriver, loosen the air duct clamp on the air flow sensor and remove the corrugation.

- We unscrew the screws securing the cover of the air filter housing and remove the filter element.

- Using a size 8 wrench, unscrew the air intake mount and remove it.

- Using a 10mm wrench, then an 8mm wrench, unscrew the nuts securing the fan casing around the perimeter (6 pieces in total).

- Disconnect the wire block on the fan connector.

- Carefully remove the fan casing along with the drive.

- Using a 10mm wrench, unscrew the 3 bolts holding the electric motor to the casing.

- We put a new one in its place.

- We install the structure in place, fix it, and connect the connector.

- We carry out further installation in the reverse order.

Possible causes, their search and solution

There may be several reasons why the cooling fan turns on on a cold VAZ 2114 engine.

The most likely of them are:

- low level of coolant in the system;

- sensor failure;

- fan short circuit;

- thermostat failure.

You should start your search with the first reason, since it is the most probable and at the same time the most quickly resolved. When the coolant level is low, the sensor can operate almost immediately after starting the engine, thus turning on the fan. This is due to the fact that a small amount of liquid heats up very quickly, while the engine itself is still “cold”. In order to solve this problem, you just need to add coolant to the required level.

Coolant level VAZ 2114

If it turns out that there is enough antifreeze in the system, and this is not the reason, then you should check the sensor itself. It happens that it “sticks” in the closed position, as a result of which the fan circuit is always on. You can check the functionality of the device using a multimeter.

If you measure the resistance at the sensor contacts with the engine off, the tester should go off scale or show 0, depending on the model of the device (that is, the resistance will tend to infinity). If the multimeter shows very specific numbers, then the sensor is permanently closed, and it should be replaced with a new, similar one.

Temperature sensor VAZ 2114

If the sensor also turns out to be working, then you should check the fan. Sometimes (especially if the housing is poorly screwed on or the wires are poorly insulated), it shorts to ground, as a result of which the fan starts working directly from the battery, without the participation of an electronic circuit with a sensor. This cause can be eliminated by checking and tightening all fasteners, as well as insulating exposed wire sections.

Checking contacts

It should be remembered that such a malfunction is quite serious and can cause:

- Rapid fan wear.

- Battery discharge (if you leave the ignition on without the engine running).

- Car fires (due to strong heating of wires).

That is why special attention should be paid to searching for possible faults (exposed sections of wires). The last reason that can lead to the fan turning on spontaneously is a breakdown of the thermostat (or rather the control sensor installed on it)

The bottom line is this: if the thermostat sensor fails, the electronic unit automatically starts a fan to cool the system, since the electronic unit cannot accurately control the temperature of the liquid. A kind of “reinsurance” is performed in case of possible overheating

The last reason that can lead to spontaneous turning on of the fan is a breakdown of the thermostat (or rather the control sensor installed on it). The bottom line is this: if the thermostat sensor fails, the electronic unit automatically starts a fan to cool the system, since the electronic unit cannot accurately control the temperature of the liquid. A kind of “reinsurance” is performed in case of possible overheating.

Thermostat VAZ 2114

In order to identify a sensor failure, you will again need a multimeter. When checking, you should measure the resistance between the sensor contacts (with the engine off, of course). Normally, it should be no less than 100 and no more than 500 Ohms. If the values obtained during measurement are outside the limits of this norm, then the sensor should be replaced with a new one. Finishing the conversation about the possible reasons for the fan turning on spontaneously, we should say a few words about how to prevent them.

To do this you will need:

- promptly monitor the coolant level in the system;

- periodically check the condition of the electronic wires of the cooling system;

- clean the sensor contacts from emerging oxides (it is recommended to carry out a similar procedure twice a year - in autumn and spring).

If you notice that the fan begins to turn on on its own, then the search for a breakdown cannot be put off until later, since the consequences (in some cases) can be extremely serious.

Fan diagnostics

In order to check the operation of the unit, you will need a one and a half meter wire, preferably with “crocodiles” at the ends. With the engine off, connect a wire from the plus terminal of the battery to the fan contact directly. A working unit should begin to rotate. If it doesn't start, it's faulty. If the cooling fan does not turn on when the engine overheats, although diagnostics indicate that they are working properly, you should check the DTOZH.

When testing, you will need an ohmmeter to measure the resistance of the sensor. An ohmmeter is included in any, even the simplest portable digital multimeter. The procedure is as follows:

- With the cold engine turned off, remove the wires from the DTOZh contacts.

- Set the multimeter mode switch to the “resistance measurement” position.

- Measure the sensor resistance. At room temperature it should be approximately 2,200 - 2,800 ohms.

- Reinstall the sensor wires.

- Start the engine and let it warm up at idle speed to about 80 degrees.

- Turn off the engine. Remove the wires from the sensor contacts.

- Measure the sensor resistance. At 80 degrees, the resistance should be in the range of 270 - 389 Ohms.

If for some reason the sensor resistance does not meet the standard, the part must be changed. And if it does, but the unit does not turn on, something is not working in the electronic engine control unit. This should be addressed to a service station. To diagnose and flash the ECU, you need special equipment.

The VAZ 21099 sedan is the final model of the Samara series. It was manufactured on the basis of the VAZ 2109; it was slightly different from other variants of this family by the front end of the body.

Fan removal and repair

Before removing a burnt-out fan from the car, disconnect the power from the electrical system. Remove the terminal from the negative terminal of the battery. Next follow the instructions:

- Open the hood and remove the air filter from the engine for easy access.

- Disconnect the wiring block from its counterpart attached to the fan casing.

- The casing is attached to the left tank with two screws. Unscrew them completely.

- Remove the nut that secures the lower part of the casing to the body.

- Unscrew the nut securing the casing to the radiator. Use a socket and extension.

- Unscrew the two nuts securing the bracket and remove it.

- Tilt the fan towards the engine and remove it from the engine compartment.

The reason why a fan does not work, as a rule, is the failure of its electric motor. To replace, disconnect the power supply wires, unscrew the three screws securing the motor to the casing and the nut securing the impeller to the engine. When removing the impeller, take care to preserve the key that prevents the impeller from turning on the axis. It is very small and easily lost. After replacing the electric motor, reassemble the unit in reverse order. Do not forget to thoroughly tighten the nut securing the impeller on the fan axis. A poorly tightened nut can cause it to come loose, causing beatings and vibrations to begin, and extraneous sounds to appear.

The fan activation system of the VAZ 2109 injector is much more reliable than that of the 2109 carburetor version. Therefore, there is usually no need to engage in tuning by installing a second fan or installing a button in the cabin to force the fan to turn on. The standard configuration works quite satisfactorily.

From the moment electric fans began to be used on VAZs with carburetors, car enthusiasts often began to experience their failure. Previous mechanical models were considered almost eternal. In most cases, when a VAZ-2109 fan with a carburetor is said to not work, the unit completely stops performing its functions. In this case, the engine temperature exceeds 100 degrees, and the car may fail. To avoid major repairs of the power unit, it is necessary to stop driving after the temperature needle deviates into the red zone. Then you need to find the reason why the fan is not working.

You should start checking with the liquid level in the cooling system (check the expansion tank), and then gradually eliminate faults in other parts of the system:

- fuse;

- temperature sensor;

- electric fan motor;

- impeller (it can be deformed, which leads to jamming).

While performing work, you will have to check the condition of the power circuit along the way. All conductors should be visually normal. It is best to eliminate the probable causes of failure one by one so that the system operates stably.

Checking the inclusion of the fan on the VAZ 2111 engine

In case the injection engine gets hot, you should first check the fuse protecting the electric fan circuit, then the auxiliary relay. The cooling fan relay can be found in the passenger compartment on the passenger side under the glove compartment. At the same time, make sure that the fan motor is activated in forced mode.

In addition, the electric fan on the VAZ 2111 engine is turned on according to data from a sensor located on the engine exhaust pipe. However, to determine the malfunction of this sensor, service computer diagnostics is required.

- VAZ 2111 - antifreeze boils, the electric motor of the engine cooling system fan does not turn on, causes and solutions

- Cooling system 2108 – Encyclopedia of the magazine “Behind the wheel”

- Maintenance, installation and repair of VAZ 2108, 2109, 21099 cars – Electric motor of the engine cooling system fan

- VAZ 2108, Checking the cooling system fan relay, Lada Samara

What to do if the cooling fan on a VAZ-2109 does not work

From the moment electric fans began to be used on VAZs with carburetors, car enthusiasts often began to experience their failure. Previous mechanical models were considered almost eternal. In most cases, when a VAZ-2109 fan with a carburetor is said to not work, the unit completely stops performing its functions. In this case, the engine temperature exceeds 100 degrees, and the car may fail. To avoid major repairs of the power unit, it is necessary to stop driving after the temperature needle deviates into the red zone. Then you need to find the reason why the fan is not working.

You should start checking with the liquid level in the cooling system (check the expansion tank), and then gradually eliminate faults in other parts of the system:

- fuse;

- electric fan motor;

- impeller (it can be deformed, which leads to jamming).

temperature sensor;

While performing work, you will have to check the condition of the power circuit along the way. All conductors should be visually normal. It is best to eliminate the probable causes of failure one by one so that the system operates stably.

The radiator cooling fan does not turn on - reasons, troubleshooting

Problems with the cooling fan usually occur in used cars with decent mileage. This breakdown manifests itself in different ways; the fan may not work stably, may turn on late or not turn on at all. Today we will talk about the last fault, that is, the situation when the cooling fan does not turn on at a certain moment. You will learn about why this happens, where to look for the reason, and also in what sequence. Let’s take the “nine” as an example, but the method and reasons will be almost the same for all VAZ models.

Finding a breakdown is not so much labor-intensive as it is comprehensive, since there can be quite a few reasons why the fan does not turn on, from a banal fuse blown to more complex problems associated with a malfunctioning thermostat or problems with the electrical wiring of the vehicle’s on-board network.

If the engine boils, but the fan still does not turn on, then the first thing that comes to mind for most motorists is problems with the fan wiring. However, very often the wiring has nothing to do with it, and the real reason lies precisely in the thermostat. The device designed to monitor the temperature of the coolant (coolant) may fail or simply jam, after which the coolant stops circulating through the radiator, as a result, the radiator sensor does not work, and the fan itself does not turn on. Read this article on how to check the thermostat.

Modernization

If you want to improve the operation of your radiator fan on the VAZ 2109, we offer the appropriate instructions.

To upgrade, you will need to install a second sensor and modify the system somewhat.

- The standard power sensor will be responsible for the operation of the fan at maximum speed.

- An additional sensor will include a reduced speed. It is installed at the top of the cooling system.

Now let’s talk more specifically about how to organize all this.

- Take a temperature sensor whose response temperature is similar to the standard regulator.

- Install it in the upper pipe fitting to the radiator.

- To mount the element, you will need a pair of washers and a nut. Be sure to lubricate the washer with sealant to prevent leakage from the installation hole.

- Buy a resistor to install on the stove fan. It has several outputs, so if desired, you can make several operating speeds.

- It is necessary to make an additional control circuit. Through it, less voltage will be supplied to the motor winding.

- The temperature sensor located in the upper part of the cooling system is responsible for turning it on.

- It is better to do control not by plus, but by weight.

- The system will work through a button in the cabin. To the left of the dashboard there is a grille with two plugs. Cut out one of them and set it to turn off on two modes. You can take the heater switch from a VAZ 2107.

- In the first position the low frequency will be switched on, and in the second – the maximum speed.

- One common wire is fed to the minus.

Such modernization is not provided for by the design of the VAZ 2109. These are modifications made by car enthusiasts. Therefore, installing a second sensor is entirely your personal responsibility.

The fan is an important component of the cooling system of VAZ 2109 injection and carburetor engines. If you wish and have time, you can easily replace or repair it yourself.

Electric fan connection diagram

The electric fan is turned on using a temperature sensor installed in the radiator. Some cars have an additional sensor in the engine block that turns on the fan at reduced speed. This is done by powering the motor winding through a resistance. The control scheme may also differ on different cars. The simplest circuit consists of the fan itself, a fuse, a temperature sensor and connecting wires.

The fuse is selected based on the fan power. And the sensor acts as a power switch. As a rule, the sensor is installed in the gap of the negative wire. For example, on the VAZ 2109, starting in 1996, exclusively this switching scheme was used. The designers made a small mistake, since the wire that goes from the sensor to ground is very long. During operation, it may become damaged, causing the entire circuit to stop working.

The temperature sensor may also fail, this is not uncommon. To replace it, you need to drain the coolant from the radiator, since the sensor is located in the lower part of it on most cars. The electric fan control circuit, which uses an electromagnetic relay, is a little more complicated, but due to this relay itself it has less reliability. An extra part that can fail at the wrong time. But on the other hand, the sensor has low currents; all the high current passes through the relay contacts.

Causes of fan malfunction

In a VAZ 2109 car, the cooling system fan may make extraneous sounds during operation. There can be many reasons for this behavior:

- It is possible that the bolt that secures the fan to the engine has simply become loose. Because it doesn't hold up well, it wobbles while riding. Actually, this leads to the formation of incomprehensible sounds.

- The radiator is not installed correctly. That is, he is not in his place. Perhaps it lies on the cross member of the suspension, which is also not very good.

- The fan may have broken on one side, causing an imbalance.

Note: it is not necessary to change it completely. It is enough just to replace the damaged part.

- There is dirt on the impeller. This seems like a complete trifle, but it leads to an imbalance. The result is an incomprehensible tapping sound.

VAZ 2109 turning on the cooling fan

- The cushions are not clamped well, so they do not hold the motor well. The cushions may be compressed (this happens after long-term use). As a result, the motor vibrates.

Note: this problem can be corrected by replacing the pillows or inserting rubber gaskets.

- If the fan makes a loud noise, it means it lacks lubrication (you need to urgently lubricate the engine with oil).

- The bearing broke. This problem occurs because the impeller has been damaged for a long time, so there is an imbalance in the system.

Note: there is only one way to solve this problem - replace the bearing. However, before this, you need to correct the position of the impeller, since another bearing may soon be damaged due to it.

Connecting a VAZ 21099 fan

Failure of the cooling system can have various causes, since the electrical circuit for turning on the VAZ 21099 cooling fan includes:

- Mounting block that contains the cooling system relay.

- Coolant temperature sensor. It is located to the right of the cooling radiator. This sensor automatically closes the circuit when the coolant temperature approaches 99 degrees.

- The fan motor itself.

- The problem may also be with the wiring.

How to change the impeller or align it

If, after dismantling the fan, you notice that the impeller is damaged or uneven, you need to remove it:

- There is a lock washer in the center of the impeller; pry it up with a flathead screwdriver and remove it. If there is an additional fastening in the form of a nut, unscrew it.

- Remove the impeller and inspect it. If there is any deformation, it is best to install another impeller.

During this work, you can upgrade the fan by installing an impeller with 8 blades instead of the standard 4.

Where is the fan relay located?

4 – electric fan relay; 5 – electric fuel pump relay; 6 – main relay (ignition relay).

Attention: the order of the relays and fuses can be arbitrary, we are guided by the color of the wires. Therefore, we find a relay from which comes a thin pink with a black stripe wire coming from the main relay (pin 85*) (not to be confused with the thin, red with a black stripe wire coming from the controller) and a thick power white with a black stripe wire (pin 87) (white and pink wires we need), this is the fan relay.

Control circuit modernization

The cooling fan on the top ten turns on at a temperature of 100-105°C, while the normal operating temperature of the engine is 85-90°C, so the fan turns on when the engine overheats, which naturally has a negative effect.

This problem can be solved in two ways: adjust the switch-on temperature in the “brains” or make a button. We'll focus on the second one. Turning on the fan from the button is very convenient: if you get into a traffic jam, turn it on, drive out, turn it off, and no overheating occurs.

A button for selecting the fan operating mode was installed in the cabin (always off, constantly on, automatically turned on via a sensor) - this “tuning” is not mandatory, but will be a very useful addition.

There will be a large current at relay contacts 87, 30, on the wire from the battery to the fuse and the fan ground, and therefore we must use wires there with a cross-section of at least 2 mm, otherwise the thinner wire will not withstand it and will burn out.

VAZ 2114 heater fan does not work reasons

Hello. If you start the car in severe frost or on a hot summer day, and the heater fan on the VAZ 2114 stops working and does not blow, do not be upset, as this problem can be quickly solved by reading this article. In order to understand the reasons why the stove fan may not work, let's first look at the electrical diagram for connecting the stove motor.

Heater fan diagram VAZ 2114, 2115, 2113

And so, here is a list of all components of the scheme:

- Mounting block (aka fuse block).

- Egnition lock.

- Ignition switch relief relay.

- Heater fan speed switch.

- Additional resistors.

- Stove motor.

- Rear window heating switch with warning lamp.

- Rear window heating element.

The scheme works as follows. When you turn the key in the ignition switch (2), its unloading relay (3) is turned on. The unloading relay supplies power to fuse f7 in the mounting block (1).

After the fuse, power goes to the rear window heating switch (7) and the fan speed switch (4), which distributes which of the resistors (5) the power will go to next.

Output 1 from the switch (4) corresponds to the slowest blowing speed, and output 3 goes directly to the heater motor (6), i.e. highest blowing speed.

Reasons why the VAZ 2114, 2115, 2113 heater motor does not work

The reasons why a fresh flow of cold air in summer or a hot stream in winter does not come from the air ducts of your VAZ 2113, 2114, 2115 can be of two types:

- mechanical

- electric

Let's look at them in more detail.

Mechanical reasons why the VAZ 2114, 2115, 2113 heater fan does not work

First of all, mechanical reasons include clogging of the air duct.

As you can see in the photo, leaves, branches and other debris get under the casing and clog the air duct of the heater motor. Debris can get into the section with the blades itself and jam the stove fan. Usually before this, a whistle or grinding noise is heard from under the soot space.

Mechanical reasons for the inoperability of the stove motor include jamming of the blades due to improper installation of the stove fan housing. When removing the stove motor, the latches securing the two parts of the housing are often damaged. And if these parts are not firmly fixed to each other, then there will be a gap between them and the air flow that should go into the cabin will fall into this gap. Also, parts of the housing may generally jam the motor blades, then it will not spin at all.

Electrical heater fan problems

In this section, we will consider the circuit to the VAZ heater fan by components.

Fuse

Let's follow the scheme given at the beginning of the post. If your heater fan does not work together with the heated rear window, then the problem is 100% in the fuse.

Check fuse f7 in the mounting block, if it is ok, then use a multimeter to see if the plus is coming to it from the ignition switch unloading relay.

To do this, with the ignition on, place one multimeter probe on the fuse and the other on the car body. If everything is in order, look at the circuit from the fuse to the speed switch and the heating switch.

Heater fan speed switch

We figured out the fuse - let's move on. And then we have the stove motor speed switch. To check it, remove the connector from it. The connector has three inputs nearby and one is located, as if separately from them. We connect any of these three inputs with a wire to the one that stands separately. If the motor starts working, then the speed switch is to blame; if not, we move on.

Additional resistors

If the fan works, but only at the third (fastest) speed, then the additional resistors are to blame. In the third mode, power is supplied directly to the fan, bypassing additional resistors, so it does not work in other modes.

Heater motor VAZ 2114, 2115, 2113

If checking all the components listed above shows they are working, the reason is in the stove motor itself. Most likely it is burned out or has a bad mass. To check, we remove it (read how to do this here) and connect it directly to the battery (the black wire screwed to the body is a minus). If it works, it's a bad mass. If it doesn't work, we change the motor.

What to do if the fan fails?

The simplest case is a blown fuse. To restore, you just need to find its location according to the diagram and replace it with a similar one. You cannot install a fuse whose operation current is much greater than it should be. The same applies to “bugs”. But if the temperature sensor fails, you will have to act with an eye on the current situation. If you are moving along the highway, then the flow of oncoming air should be enough for cooling.

But if you are driving around the city, then the best solution would be to short-circuit the sensor terminals. The same should be done if a relay is installed in the control circuit, but it burns out. But if the damage is somewhere in the wiring, then the best way out of the situation is to connect the fan to the battery terminals. Just remember to turn it off before turning off the engine.

The reasons for radiator fan failure are related to its electrical or mechanical part. As a result, under certain conditions, the car engine begins to overheat.

Causes of the malfunction: “the radiator fan does not work” of the cooling system

Using the example of the radiator fan of the carburetor engine cooling system of VAZ 2108, 2109, 21099 cars.

— The radiator fan sensor has failed

On carburetor VAZ 2108, 2109, 21099 and their modifications, the sensor is located on the right radiator tank. Its failure is the most common cause of radiator fan failure. Turn on the ignition. We close the sensor contacts with a piece of wire (do not remove the wires from them). If the fan starts working, the sensor is faulty, if not, its electrical circuit is faulty.

— The electrical circuit of the sensor is faulty

Description of DTOZH and DVV

Where is the coolant temperature and fan activation sensor located in 2109 with an injector or carburetor engine, what should I do if the device does not work? First, let's look at the basic questions regarding the purpose, device and principle of operation.

Purpose and functions

The main purpose of the DVV is to activate and deactivate the ventilation device on the engine radiator in order to cool the power unit. The device turns the fan on and off based on the temperature of the liquid in the cooling system. On injection machines, this is DTOZH; turning the fan on and off is controlled by the brain according to the readings of this sensor.

As for the TOZh controller in the VAZ 21093, this device is intended to display readings about the antifreeze temperature on the car’s dashboard in the cabin. With its help, the driver can find out about possible overheating of the power unit.

Location

As for the location, in models 2108, 2109 and 21099 the DTOZH is located between the engine cylinder head and the thermostat, in particular, on the intake hose. The DVV is installed in the threaded hole of the expansion tank with coolant. If you look in the direction of travel of the car, the refrigerant container is installed on the right.

Fan control

If a VAZ 2109 car has an engine with distributed injection and an injector, then it does not have the switch sensor familiar to owners of a carburetor model at all. The fan is turned on and off by the controller of the electronic motor control unit. This controller receives information from the coolant temperature sensor (DTOZH), which is installed in the outlet pipe between the thermostat and the cylinder head. The sensor is used to control not only the operation of the fan, but also the engine. This includes:

- optimization of the degree of enrichment of the air-fuel mixture: in a cold engine the mixture is over-enriched, as it warms up it becomes leaner;

- increasing the crankshaft rotation speed when starting the engine so that the engine does not stall immediately after starting;

- setting the ignition timing to ensure fuel economy;

- holding the recirculation valve in the closed position until the motor enters operating mode.

To determine the temperature of the DTOZH VAZ 2109, the injector uses a thermistor - a resistor whose resistance depends on the temperature. The VAZ 2109 uses a thermistor with a negative temperature coefficient. This means that as the temperature increases, its resistance decreases.

Voltage is supplied to the thermistor; by its change, the sensor determines the temperature of the coolant and transmits it to the ECU. And this unit turns the radiator fan on and off.

Causes of fan malfunction

There are times when the radiator cooling fan runs continuously. This is also wrong. What to do in this case? What is the cause of the malfunction?

There may be a broken circuit in the temperature sensor. This will be indicated by a constantly lit sensor light. In this case, you simply need to replace the temperature sensor or the injection system unit. The relay may need to be replaced. Also, the contacts on the radiator thermal switch that triggers the relay may not open. To fix the problem, you will need to replace the thermal switch.

To find out the cause of the fan malfunction, you will need to remove it.

- Disconnect the fan block and harness by disconnecting the wires.

- Disconnect the motor wire by unscrewing the left nut. If necessary, use suitable keys.

- Under the hood, unscrew the two screws that secure the fan.

- Take out the casing.

- Remove the two fan mounting bolts.

- Remove five more bolts and the air intake grille.

- Lift the fan support and pull it towards you.

- Rotate the fan itself 90 degrees and remove it.

Fan motor connection diagram

If there is any breakdown in the car, regardless of whether the fan has stopped working or something else, you should contact a specialized workshop. Experienced technicians will always find the cause of the problem, select suitable parts, sensors and carry out repairs. Of course, many car owners want to repair their vehicles themselves; this gives them a lot of pleasure and requires minimal costs. But in this case there is a risk of making a mistake with the selection of parts and the correct diagnosis. A car enthusiast can spend a lot of time and effort and end up not getting the desired result. To prevent this from happening, it is better to contact a specialist.

Troubleshooting on VAZ 2108 and VAZ 21083 engines

Thus, to eliminate a malfunction on a carburetor engine, you must first check the integrity of the fuses in the mounting block. Burnt fuses are easy to see with the naked eye. On cars produced before 1998, the electric fan relay should also be checked. If it is found that there is electrical contact between terminals “c” and “b” or no contact between “c” and “d”, the relay must be replaced.

Also, do not exclude the possibility of failure of the sensor installed in the car radiator, as well as the electric fan itself. In order to test their functionality, it is enough to remove the contacts from the sensor and close them together. If the cooling fan starts working, it’s all in the sensor, but no, the problem lies in the electric fan motor.