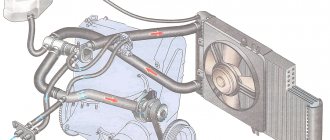

All the main electrical circuits and modifications for connecting the liquid cooling fan (CO) in VAZ cars of various models are provided. What is the essence of VO’s work? An electric motor with an impeller on a shaft is installed inside a rectangular metal frame, with which it is attached to the back of the radiator. When voltage (12 V) is applied to the contacts of the drive, it begins to work, rotating the blades and creating a directed stream of air, which, in fact, cools the antifreeze or antifreeze.

If the cooling fan does not work, do not rush to contact a car service. You can determine the cause of the malfunction yourself. Moreover, it is not at all necessary to have special skills for this - just study the reference material from 2shemi.ru and follow the instructions for checking/replacing it.

Operating principle

A fan is a device that allows you to increase the efficiency of a cooling radiator. The radiator takes heat from the engine and releases it into the air. This process is accelerated by blowing through the blades of an electric fan.

The coolant flows through a closed, sealed system. Its task is to remove excess heat from overheated engine parts. Hot antifreeze flows into the radiator, is cooled here and returns back. While in the radiator, the coolant passes through a system of thin tubes. The incoming air flow while the car is moving helps to quickly remove excess heat from the engine compartment.

But when the car is stuck in traffic or idling, the air flow stops cooling it. In this case, the cooling system may not cope with its task. An electric radiator fan is designed to create air flow artificially. The temperature for turning on the fan on a VAZ 2114 is 85 degrees Celsius.

Having received a signal that the permissible temperature value has been exceeded, the sensor starts the device’s operating mechanism. An artificial air flow is created that removes heat from the radiator. The mechanism operates until the temperature level drops to an optimal state.

The thermal switch then receives a signal that the normal temperature has been reached and turns off the fan.

The device consists of four plastic blades that are mounted on the EDF shaft. A special controller regulates the automatic operating mode. The thermostat is equipped with a solid filler that is sensitive to temperature changes.

There are main and additional valves. When the temperature reaches 85 degrees Celsius, the main valve opens.

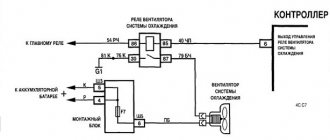

Connection diagram

Knowing the electrical diagram for turning on the radiator fan, it will be easier to find problems in its electrical circuit.

The cooling fan has 2 inputs: the first input leads to the generator through fuse F5 and the connection busbars in the mounting block (2). The harness block (3), nicknamed the chip by drivers, connects the electric fan via a relay to the injection controller connected to the ignition relay. From the wire coming from the controller, a branch leads to an auxiliary relay with a fuse.

Causes of malfunctions

The fan may not turn on for the following reasons:

- the fan drive (electric motor) is faulty;

- fuse is blown;

- the relay has failed;

- broken electrical wiring;

- lack of contact in the temperature sensor connector;

- The temperature sensor is faulty.

Search for reasons

Diagnosis of a fan malfunction should begin with the fan itself. To do this, disconnect the connector on the fan and connect it, observing the polarity, directly to the battery terminals. If it turns on, it means the drive is working, the reason needs to be looked for further. If the fan does not work, this is the reason. But let's take things in order.

The fan did not turn on. We check the integrity of the wiring and the condition of the contacts on the sensor. If everything is in order, we move on to the fuse and fan relay. They are located under the hood on the left side closer to the driver, in the mounting block.

Fuse F4 is 20A, double, for the sound signal and the cooling fan (it is very easy to check; if there is no sound signal and the fan does not work, then most likely it is the culprit).

You can check the fuse with an ordinary autotester. With relays the situation is more complicated. To make sure that this is not the case, it is better to get a one hundred percent working relay somewhere and temporarily install it in the socket for testing. If the fan does not work even with it, we go to the sensor.

If the sensor is de-energized, the controller must start the fan in emergency mode for constant blowing. Disconnect the connector from it and turn on the ignition. Turning on the fan will indicate that the sensor has failed and requires replacement.

When is it necessary to change a fan?

If the cause is still in the fan itself, you can try to repair it. The problem is usually the brushes or bearings. But it also happens that the electric motor fails due to a short circuit or break in the windings. In such cases, it is better not to experiment and replace the entire drive.

It is strictly forbidden to operate a vehicle with a non-working cooling fan. Overheating of the coolant will inevitably lead to the destruction of rubber pipes and hoses, as well as cylinder head gaskets and valve covers. In addition, high engine temperature can cause destruction of the piston group elements.

How much does a cooling fan cost on a VAZ 2114

You can buy a new cooling fan for a VAZ 2114 for 1500-2500 rubles. Replacing this part at a service station will cost 300-400 rubles. But you don’t have to spend money on this. Dismantling the old fan and installing a new one at home will take no more than 30 minutes.

Differences from its predecessor

In particular, the designers changed:

- the shape of the front wings;

- the shape of the headlights and side lights;

- back panel shape;

- hood and trunk lid.

As a result, the overall dimensions of the car also changed, but it remained the same front-wheel drive, four-door, five-seater sedan car.

Advice: video materials from thematic forums where VAZ 2115 owners share their impressions of year-round operation of the car can serve as a good help in evaluating a car.

Step-by-step algorithm of work

In each specific case, fan repair will differ depending on the existing breakdown. It is necessary to carry out appropriate diagnostics, which will allow us to determine why the radiator cooling fan on the VAZ 2114 does not turn on in a timely manner, which will simplify subsequent repairs. First of all, it is recommended to disconnect the fan connector, and then, observing the polarity, reconnect the connector directly to the battery terminal. If, with such a direct connection, the fan begins to rotate, this indicates a working drive, and the reason in this case may be electrical wiring, a faulty temperature sensor, or problems with the fuse. You can check the fuse responsible for the operation of the cooling fan without opening the plastic box. The fact is that such a relay is dual and is simultaneously responsible for the operation of the horn. Therefore, if the car's sound signal disappears and the fan does not work at the same time, this indicates a blown fuse. The block with such relays is located under the hood in a small plastic box. To open it, you need to remove two latches, then use tweezers to remove and change the fuse you need. Relay failures are difficult to diagnose. We can recommend that you get a 100% working relay, temporarily install it in the socket and check that the fan is turned on correctly. If during such a test the fan starts working, then you should simply replace the relay used with a working one. To check the temperature sensor, from which the signal goes directly to the radiator, disconnect the connector from the sensor and then turn on the ignition. In this case, the automation starts the fan for constant blowing in emergency mode. If, when the connector from the sensor is disconnected in this way, the fan turns on late, then we can therefore conclude that the temperature sensor has failed and will require replacement. The temperature sensor itself is fixed with two bolts, which can be unscrewed with a simple Phillips screwdriver. This sensor replacement usually takes no more than 5 minutes. If the cause of the breakdown is still the fan, you can try to repair it first or immediately replace it with a new one. The problem may be with the bearing or brushes. In this case, you can replace such damaged parts, which will completely restore the functionality of the cooling system fan. If the cause of the fan breakdown is the electric motor, then the repair presents certain difficulties, and such a failed drive is best replaced with a new one.

How to make a replacement

If you are convinced that the cause of the malfunction lies in the fan motor, then the easiest way to carry out repairs is to completely replace the device. In this case, there is no point in spending money on a new casing. It will be cheaper to just buy a new electric motor.

Necessary tool

No special tool is needed. The work is carried out simply using 8 and 10 socket wrenches and a Phillips screwdriver.

Step-by-step algorithm of work

You can replace the cooling fan motor without removing the radiator.

- Disconnect the connector and device wiring harness from the casing.

- Unscrew the mounting bolts using a 10mm wrench.

- Unscrew the lower fastening nut.

- Using a 10 mm socket wrench, unscrew the mounting nut from the radiator.

- Using a size 8 socket wrench, unscrew the two pressure plate nuts.

- Remove the plate.

- Remove the electric fan along with the casing.

- Let's start dismantling the electric motor. Using a 10 mm wrench, unscrew the three mounting nuts and remove the engine along with the blades.

- Using a screwdriver, pry up the lock washer.

- And take it off.

- Remove the impeller.

- Put the impeller on the new motor. Make sure that the shaft pin fits into the impeller groove.

- Reassemble in reverse order.

Possible causes and their diagnosis

The main reasons why the fan on the VAZ 2114 does not work are as follows:

- the electric motor of the fan burned out;

- fuse is blown;

- the relay is broken;

- there was a break in the wiring;

- the sensor contacts have oxidized;

- The sensor has failed.

In order to check the fan motor, it is enough to disconnect it from the control unit and power it directly from the battery. If the propeller starts to rotate, then the motor is working; if not, then the fan itself will have to be replaced.

The next step in finding the problem is to check the fuse. To do this, you should find a 20 amp fuse F4, located in the common block. It should be checked with a multimeter and, if necessary, replaced with a new, similar one. At the same time, you should also clean the contacts in the fuse socket, because their oxidation can also cause a malfunction.

There is an easier and faster way to check the serviceability of fuse F4 - just honk the horn. If the signal works, then the fuse is also good - after all, they are both connected to the same fuse.

If the fuse is working, you should check the fan relay 2114. This can be done in two ways - ring the relay with a tester (for this the relay must be in the closed position) or replace the relay with a new, working one.

The second method is the most preferable, since testing with a multimeter may not always give an accurate result. If the relay turns out to be broken, then it should be replaced with exactly the same one (installing any other devices instead of the standard relay is extremely undesirable, since in most cases their operation will be incorrect).

If the relay is also working properly, then you should check the wiring. To do this, it is enough to ring all the wires included in the electrical circuit of the fan. If a break is detected, the faulty wire should be replaced, but if no breaks are found, then there will be only one possible cause - the VAZ 2114 fan sensor.

Before checking the sensor itself, you should check and clean its contacts - because if they oxidize, the device will not work correctly or will not work at all. To check the sensor itself, it should be disconnected from the power supply.

If it is operational, the fan will turn on and operate continuously (in emergency mode). After this, you should disconnect the sensor connector going to the controller and start the engine.

If the fan rotates, the sensor is faulty and should be replaced.

Cooling fan diagnostics - trying to find the problem

There will be two temperature sensors: one, which is on the thermostat, is connected to the ECU. It is necessary to turn it off - leave the second one as it is.

DTOZH on engine 11183

We disconnect the connector, but do not remove the sensor itself. Then we turn the key to position 1, and so on.

Electrically, things look complicated: the fan relay is in one box, and the fuse is in another. We need fuse F5 (20A). By the way, both a fan and a horn are connected to it.

Mounting block 2114-3722010-60 and 2114-3722010-10

The main mounting block is installed under the hood, and the additional one is located at the left foot of the front passenger.

Additional mounting block (option 1)

In the additional block we see three relays. The "main relay" is located at the bottom. And then there are possible options:

- The fan relay is mounted in the middle;

- This relay can also be installed at the top.

The second option is shown below.

Additional mounting block (option 2)

By the way, there is always a fuse located near the relay we need. It is part of the fan circuit.

Connection diagram for the fan switching sensor in injection engines

Unlike carburetor cars, where the sensor directly closes and opens the cooling fan circuit, in injection engines the device operates only with an information signal. After processing the received data, the ECU sends a control action to the fan relay installed on the radiator. The main advantage of this scheme is the possibility of emergency operation of the cooling system in the event of a loss of communication with the sensor or its failure. The ECU can also adjust the engine operating mode by influencing the injectors.

To determine where the fan switch sensor is located, you need to pay attention to the thermostat. In injection engines they are located next to each other. In some car models, wires go from the sensor to the dashboard to indicate the status of the device or to display the current coolant temperature.

How to replace a temperature sensor

Before starting work, you need to partially drain the coolant from the cylinder block.

- Remove the wire.

- Using a 21 wrench, unscrew the temperature sensor.

- Take it off.

- Install the new one in reverse order.

Maintenance of the electrical wiring system in Lada Samara

In a car with an injection or carburetor engine, maintenance of electrical wiring consists of protecting and repairing it. The electrical equipment in the car will last a long time, and it will only have to be repaired as a last resort if you carefully ensure that no moisture gets into the wiring system, and that high-voltage wires are not tangled and are located as far as possible from the hot parts of the engine. The VAZ 2115 electrical diagram will help with this.

You need to pay special attention to the condition of the contacts and connectors; if necessary, they should be cleaned of dirt and dust. Burnt out sections of wiring should not be replaced; it is much better to replace the entire wire. The VAZ 2115 wiring diagram will become a visual aid and will help you carry out minor repairs yourself or even completely replace the electrical wiring in the car. The VAZ 2115 diagram is clear and intuitive to the user; its especially important details are highlighted in color or a different font.

Without a diagram of the location of electrical components in a machine with 8 valves, it is impossible to repair or replace the main relay or other unit.

Often the cooling fan does not turn off due to a failed fan relay. It is installed in an additional mounting block “four”. This block is located near the front passenger's feet and is covered with a decorative trim.

Design Features

A novice car enthusiast is recommended to study the operation of an injection engine. The injector includes a system that injects gasoline. After familiarizing yourself with the device, you won’t have to contact a service center for minor problems, but rather fix them at home yourself. The fuel supply is considered distributional, because gasoline is injected into each cylinder using a specific injector.

The VAZ 2115 is based on the VAZ 21099 model. In the new car, unlike the previous one, the shape of the hood, rear and front bumpers, a new configuration of the front wings, as well as improved aerodynamics of the body have changed. A spoiler was placed on the trunk lid - a wing. The exterior decoration was decorated with plastic elements, since metal ones were corroded by corrosion. For added safety, the model was supplemented with a brake signal and rear lighting.

Thanks to the electronically controlled injection power unit located under the hood, the electrical circuit of the VAZ 2115 differs significantly from the 99 modification.

The supporting structure of the car body is welded, metal, integral. The drive is front transverse. It has a 5-speed gearbox and the front wheels are connected to the drive. The engine has a capacity of 1.5 liters and is a four-cylinder, petrol, four-stroke and in-line. Distributive fuel injection systems are controlled electronically.

Under the rear seats, behind the bottom, there is a fuel tank. Gasoline is supplied from the gasoline pump located in it. The pressure level in it should not fall below 3.2 bar.

Hidden interior sub-cabinet wiring connects the located equipment. The mounting block is placed in the engine compartment. It consists of powerful consumers: wipers, high beam headlights, starter. All of them are connected to the on-board network using an intermediate relay.

Why doesn't it work

There are several reasons why the propeller may not turn on when the temperature situation requires it:

- The electric motor of the fan, that is, the drive, has failed;

- The fuse broke and burned out;

- Relay failed;

- The wiring is broken;

- The sensor connectors have lost contact;

- The sensor has failed.

Finding the fault

Problem search area

Explanation

The connector on the propeller is disconnected and connected directly to the battery. If the fan starts working, everything is fine with the drive. If the propeller still does not spin, the problem is in the electric motor.

Wiring and contacts

If the propeller does not work, you must check the condition of the wiring and make sure that the sensor contacts are working properly

You can find these two elements in the engine compartment on the left, closer to the driver, inside the mounting block. The fan is supplied with a fuse designated F4 with a rated current of 20A. The test can be performed by pressing the horn button. Why? Yes, because it is also connected to this fuse. Or check with a tester

It is located in the same place as the fuse. For an effective test, it is best to take a relay that you are 100% sure is working, install it in place of the old one and check

To test the sensor, disconnect power from it. If it works, the propeller will start working in emergency mode, that is, it will blow constantly. Disconnect the connector and turn on the ignition. If the propeller spins, then the sensor is broken. Need replacement

When to change

If the fan itself is the cause of all the problems, it is not necessary to change it, since in some cases it can be repaired. Failures are often associated with bearings or brushes.

If the cause of the breakdown is the failure of the electric motor due to a broken wiring or short circuit, it is not worth the risk of repairing it. It is easier and better to replace the entire drive.

Checking for open circuit

If you drive a car that does not have a cooling propeller, this will lead to overheating of the coolant and destruction of pipes, rubber elements, gaskets of the main cylinder block and valve covers. It is not far from destroying the components of the piston group.

Fuse

Operating a vehicle with a broken fan is strictly prohibited.

Price issue

Before starting to solve the problem of a radiator propeller not working, it is important for many people to learn about the cost of components and labor.

A new element today will cost approximately 1.5-2.5 thousand rubles, depending on the model and region. The cost of replacement at a service station will be from 400 rubles and more. Although it is not necessary to spend money on this, since replacing it yourself will take you no more than half an hour. Yes, and there is nothing particularly complicated here.

temperature sensor

At what temperature does the VAZ 2114 fan turn on?

What is the temperature of the fan on the VAZ-2114: at what temperature should it operate

Many motorists, while using the VAZ-2114, have encountered the fact that the engine cooling fan is turned on. Only now, not everyone knows at what temperature it should work. This indicator is inextricably linked with the cooling system device and the computer programmed by the computer.

Engine temperature indicator

Before moving on to the temperature at which the cooling fan turns on, it is worth understanding the operating principle itself. This circulates coolant through the system and removes heat from the engine to the radiator. This element, in turn, conducts natural cooling of the liquid by countercurrent air.

If natural cooling is not enough, the fan turns on. This happens under certain conditions.

Many motorists during the operation of the VAZ-2114 have encountered the fact that the engine cooling fan turns on. But not everyone knows at what temperature it should operate. This indicator is inextricably linked by the design of the cooling system and the embedded ECU program.

Before we begin to directly consider the temperature at which the cooling fan turns on, it is worth understanding the operating principle itself. So, coolant circulates through the system and removes heat from the engine to the radiator. This element, in turn, conducts natural cooling of the liquid with a counter flow of air.

If natural cooling is not enough, the fan turns on. This happens under certain conditions.

- Reasons for fan failure

- Sensor check

- Replacement

Every driver knows that engine overheating is very bad. It can't lead to anything good. To protect the engine from overheating, cars are equipped with radiator cooling fans. And sometimes he is far from alone.

Today we’ll talk about a very important cooling element - the fan sensor. It is responsible for turning on this cooling device in a timely manner, preventing unwanted overheating.

Appearance of the device and location

A little theory

| Characteristic | Explanation |

| Location | The sensor is located in the heater radiator. It is not difficult to determine that this is the one in front of you, since in the radiator it is the only element to which the wires are connected. And if you take a 30 key, then only the sensor has the appropriate fastener size. |

| Response temperature | Sensors may have different temperature limits. But for the VAZ 2114, switching on occurs at 102-105 degrees Celsius, and switching off occurs at 85-87 degrees. When choosing a new meter, focus on the one that has failed, or purchase one with an on and off indicator of 102 and 87 degrees, respectively |

| Operating principle | There is a special contact group inside the sensor. When the coolant in the radiator heats up, this group heats up and expands. When the expansion reaches a certain limit, the contacts close, they transmit a signal to the wiring and the fan turns on |

There are a number of reasons why the fan sensor can eventually fail other than the sensor itself. Therefore, they should first be excluded to make sure that the sensor is to blame.

What to do?

This subsection is so named because professional auto mechanics strongly disagree that fan problems can have anything to do with the part mentioned below. Meanwhile, VAZ owners insist that following these instructions has a significant (and positive) effect on the cooling system in general and on the operation of its fan in particular.

Probably, the subtlety is not in the lid itself, but in the pickling valve, which reduces the pressure that has reached critical levels. But how the operation of the fan depends on it is a mystery shrouded in darkness. But it works! If you have already checked everything possible, but still don’t understand why the cooling fan of the VAZ 2114 does not work, try following the advice of experienced people and replacing the cover - maybe it will help.

The fan serves to generate air flows that are directed to the engine radiator. This is necessary in order to cool the liquid that circulates through it.

If the car is moving at high speed, the fan is not particularly required, since the engine receives all the necessary cooling from oncoming air flows. But when the car goes into slow driving or idle mode with the engine running, the role of the propeller becomes indispensable.

Switching on occurs after the corresponding signal is sent from the electronic control unit. The ECU, in turn, learns about the need to turn on the fan from the temperature sensor. The switching threshold is 103-105 degrees Celsius.

In the case of the VAZ 2114, the fan (propeller) is located in the engine compartment on the back side of the radiator.