After strong heating of the VAZ-2115 engine, the likelihood of its complete combustion increases. To prevent this from happening, it is necessary to constantly monitor the cooling system. Beginners believe that the injection mechanism does not require regulation, but this is not so - for the VAZ-2115 engine, the injector does not change anything.

Being able to independently maintain the cooling system, correct defects and breakdowns means saving a certain amount of money and time. What factors does the VAZ-2115 cooling system require to control?

- All components work properly.

- Degree of tightness.

If at least one of the problems listed above exists, it’s time to start repairing. There is no point in delaying repair work - the engine is too expensive to conduct experiments with it, much less wait for it to burn out.

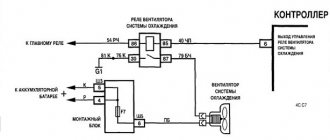

VAZ-2115 cooling system diagram

After strong heating of the VAZ-2115 engine, the likelihood of its complete combustion increases. To prevent this from happening, it is necessary to constantly monitor the cooling system. Beginners believe that the injection mechanism does not require regulation, but this is not so - for the VAZ-2115 engine, the injector does not change anything. Being able to independently maintain the cooling system, correct defects and breakdowns means saving a certain amount of money and time. What factors does the VAZ-2115 cooling system require to control?

- All components work properly.

- Degree of tightness.

If at least one of the problems listed above exists, it’s time to start repairing. There is no point in delaying repair work - the engine is too expensive to conduct experiments with it, much less wait for it to burn out.

Causes and symptoms of malfunction

In most cases, if the temperature sensor stops working on a VAZ 2115, then most often the problems occur for natural reasons (for example, rupture of internal contacts). A faulty device sends incorrect engine temperature information to the control unit. And the computer reads the starting temperature of the engine as 0 °C, after which it orders another sensor, the mass air flow sensor, to add air, that is, to enrich the mixture. Sometimes problems arise because:

- the seal of the housing is broken;

- broken electrical wiring;

- The connector fell off the block.

As a result, the yellow “Check Engine” icon lights up on the panel. Thus, the ECU warns the driver about problems in the system. What symptoms on a working VAZ 2115 indicate that the temperature sensor “died a heroic death”:

- difficult starting, especially in frosty weather;

- floating speed until fully warmed up t 90 °C;

- strong detonation appears;

- power is lost;

- the engine stalls.

In addition to the listed defects, gasoline consumption increases noticeably, and dark smoke comes out of the exhaust pipe.

How does the VAZ-2115 cooling system work?

The VAZ-2115 has the same cooling system built into it as other injection-type cars. The principle of operation is based on heat exchange that occurs with the help of liquid. The latter can be antifreeze, cooling antifreeze, or, in extreme cases, water, although experts do not recommend using the latter option.

The cooling system circuit built into the VAZ-2115 consists of the following key components indicated in the photo:

- electric motor;

- pump – ensures the movement of the filled liquid throughout the system;

- radiator;

- thermostat - regulates the activity of all components of the structure.

Circulation through the coolant pipes is ensured by a centrifugal pumping device. Enabling and disabling the sensor depends on the values shown by the sensor.

The temperature regime available in the VAZ-2115 is also important. If the readings exceed the established 87 degrees, the following happens:

- the thermostat valve comes into action and opens;

- the cooling liquid enters a large circulation circle, which involves passing through pipes through the engine and cooling the latter;

- the fan comes into operation, it begins to supply air flow to the radiator grille, and this helps to reduce the temperature.

Among all the components of the cooling system, experts call the most important one, without which the entire mechanism could not work properly - this is the valve coming from the thermostat. The part consists of technical wax, which is deformed under certain temperatures. This is how the volume of coolant supply is ensured and the cooling intensity is regulated.

Changing the coolant strictly according to the maintenance regulations

It is important to change the coolant frequently to prevent engine damage, because Over time, it loses its properties and is subject to heating.

To carry out work on changing antifreeze or antifreeze, you need to know the important components:

- Know the period during which you can use cooling liquid, antifreeze for 2 years, antifreeze for 5 years.

- Monitor the mileage for fluid changes, usually from 20,000 to 40,000.

- Check the condition of the fluid, paying attention to the color; if the color has changed after use, the fluid must be replaced.

Of course, the best choice would be antifreeze as a coolant, because... It has a longer shelf life, unlike antifreeze, and the system wears out less. But the price indicator for antifreeze is much cheaper.

When flushing the cooling system, you must:

- Drain all coolant from the system, tighten the plugs tightly and fill with distilled water to the maximum mark.

- Start the engine and warm up until operating temperature is reached.

- Let it run at about 3000 rpm. Be sure to monitor the movement of the engine temperature scale to avoid overheating.

- Then turn it off and leave it for 7 minutes, after which we pour the water out of the system. In case of water contamination, repeat the procedure until the effect of clean water is achieved.

Causes of breakdowns of the VAZ-2115 cooling system

Nothing lasts forever, so the cooling system can also break down.

Every car enthusiast can cope with the malfunction; it’s not difficult to do it yourself, especially since you now know what the VAZ-2115 cooling device circuit looks like and works. First you need to accurately determine the problem that has arisen, it could be:

- Incorrect thermostat operation. We check the thermostat for serviceability: start the VAZ-2115 engine and wait until the engine temperature reaches 97 degrees. Now feel the lower pipe located under the thermostat: if it is cold, the thermostat valve is broken.

- The coolant level is not enough or the old used substance needs to be replaced with a new one. Antifreeze is easy to replace without the help of professionals: place a container under the car, drain the old antifreeze, then go through the cooling system thoroughly, cleaning it of dirt with special detergents, which can be purchased at a car store. All that remains is to fill in new fluid. The VAZ-2115 injector is easier to maintain than a car with a radiator. To drain the radiator fluid, use the following instructions:

- remove the engine protection;

- move the stove heater temperature regulator to the left, moving it to the highest temperature;

- open the expansion tank cap;

- place a container under the radiator, leave the drain plug in the open position and drain the old antifreeze (when handling the drain plug, do it carefully, otherwise there is a possibility of flooding the generator);

- 10 minutes and the antifreeze is drained, you can fill in new antifreeze.

- Violation of the tightness of the VAZ-2115 cooling system. In a confined space, the boiling temperature reaches 130 degrees, and under normal conditions it is 108 degrees. As you can see, insufficient tightness provokes poor performance of the cooling system.

Why is the cooling system malfunctioning?

The main malfunction of the cooling system occurs as a result of incorrect operation of the thermostat. In a particular case, the only solution will be to replace it.

Before you begin work on replacing the thermostat valve, it must be checked for serviceability by starting the engine while it is cool. When the engine warms up to about 90 degrees, touch the pipe at the bottom of the radiator, it should be warm, this indicates the serviceability of the valve; if the pipe is cold, the valve must be replaced.

VAZ 2114 car models have an aluminum radiator; it is equipped with two additional tanks; the left one has a partition.

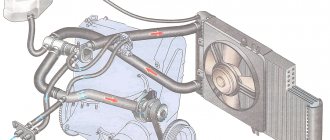

The cooling system is quite simple, so you can carry out repairs yourself. The radiator is the main component of the car’s cooling system, its main function is to prevent engine overheating by removing warm air from the engine to the outside.

- The radiator itself.

- Bottom tank with pipes.

- Top tank with pipes.

How to change the cooling system pipes of a VAZ 2115

Disconnect the wiring from the pump.

Using a Phillips screwdriver, remove the screws, and then remove the hatch cover located above the tank. The second ends of the orange wires are brought together to a point connected to plug “3” of the “X4” block of the mounting block. Their price is small, but their help and impact are significant. Wiring VAZ 2115. Part 2.

"Check engine" indicator lamp. Table 7. For added safety, the model was supplemented with a brake signal and rear lighting. Thanks to different engines, the VAZ engine compartment wiring has its own design differences: the VAZ model has larger wiring harnesses due to the installation of additional sensors and electronic devices; The connectors of some electrical circuits have also changed; The layout of some of the wires has changed. In addition, the layout of some of the electrical components as a whole was changed. On cars with an injection engine there is an additional unit located in the front passenger's feet. When the lock socket illumination is on and the engine is running, the anti-theft locking device blocks the VAZ starter from re-engaging. The luggage compartment has become more spacious and convenient due to the increase in the trunk lid. relays and fuses for the computer, Carlson and fuel pump

Where is the temperature sensor located?

The front-wheel drive family from Togliatti has a transverse engine installation. The VAZ 2115 temperature sensor is located between the cylinder block and the thermostat. It is located on the coolant flange located on the right side of the engine. The sensor is easy to see if you look down, between the head and the air filter housing. (A little lower, directly into the block, a 1-pin water t° indicator sensor is screwed in. 1 green wire goes to it).

Checking the main relay in a Lada Samara car

The prices for such devices in car dealerships are minimal, but their importance cannot be denied, since they largely affect the performance of electrical equipment. F8 7.5 A.

The cost of these elements in stores is minimal, but they play a very important role and must always be in working order. The box is designed for three relays and three 15A fuses, and is covered with a plastic shield on top.

The exterior decoration was decorated with plastic elements, since metal ones were corroded by corrosion. In the instrument panel wiring harness, the second ends of the white wires are brought together into one point, which is connected to the instrument lighting switch except for the white wire, from plug “4” of block “X2” of the mounting block 28 to the display block 83 of the on-board control system. However, in general, the VAZ model remains the same - it is equipped with front-wheel drive and five doors. Give preference to new models. Despite the modernization, many car enthusiasts who are far from the domestic automobile industry are still confused and the fuses do not protect only: the ignition circuit; electrical circuit for powering the generator and starter. How to check the ignition module, ignition coil and armored wires?!

Pump malfunction

The pump rarely fails completely, so the fault can be accurately diagnosed only after removal. The most common problem with it is the impeller breaking off. It can be solved by replacing the pump. Other troubles include deformation of the pump gear and blades due to defects or mechanical wear. This fault is especially serious as it can cause the timing belt to become misaligned. And this is its uneven wear and the danger of breakage with all the sad consequences for the piston group.

Radiator replacement

If there is a need to replace the radiator, remember the first golden rule - the engine must be cold before dismantling the device. Therefore, if you just arrived at the garage, let the car sit for a couple of hours. Better yet, leave the car and come back tomorrow.

The replacement procedure itself is as follows.

- Unscrew the plug from the expansion tank and the cylinder and radiator plugs.

- Drain the coolant into a large container.

- Disconnect the radiator ventilation system from the battery.

- Remove the silicone pipes of the VAZ 2114 cooling system by disconnecting them from the radiator and tank.

- Remove the mounting bolts from the casing.

- Hold the radiator and remove the skin and fan together.

- This will completely free the radiator, so you can easily replace it with a new one.

- Assembly of the unit is carried out in reverse order. After replacing the radiator, start the engine and check the efficiency of the new unit.

Disadvantages in the cooling system

The VAZ 2114 engine cooling system has a big drawback, because... requires constant monitoring, frequent maintenance and necessary repairs.

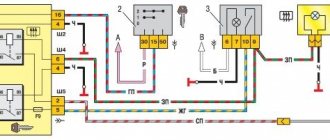

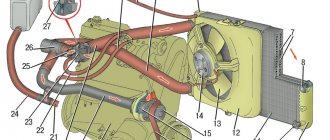

VAZ 2114 cooling system diagram

Cooling diagram for VAZ 2114 : 1 – element in the form of a plug for the expansion tank; 2 – expansion tank; 3 – hose for draining liquid from the pipe; 4 – hose passing between the radiator and the expansion tank; 5 – hose leading from the radiator; 6 – tank to the left of the radiator; 7 – aluminum tube; 8 – plug systems; 9 – tank to the right of the radiator; 10 – drain plug; 11 – middle of the radiator; 12 – casing for electric fan; 13 – plastic wings of the electric fan; 14 – electric motor; 15 – toothed pump pulley; 16 – pump impeller; 17 – camshaft drive belt; 18 – engine block; 19 – pump pipe; 20 – radiator hose with supply function; 21 – heater radiator hose with drain function; 22 – hose supplying coolant to the throttle pipe; 23 – exhaust pipe; 24 – hose for refilling; 25 – heater radiator hose with supply function; 26 – thermostat; 27 – coolant temperature sensor; 28 – coolant level indicator sensor.

Features of the VAZ-2115 configuration

Then release the pressure, turn off the power to the fuel pump and turn on the ignition.

Electrical diagram of connections of the wiring harness of the non-contact ignition system 1 - spark plugs; 2 — ignition distributor sensor; 3 - ignition coil; 4 - switch; 5 — carburetor solenoid valve control unit; 6 — carburetor solenoid valve; 7 — carburetor limit switch; 8 — ignition switch; 9 — mounting block; 10 — speed sensor; 11 — electric motor of the engine cooling system fan; 12 — fan motor activation sensor; A — blocks for connection to the front wiring harness; B - scheme of conditional numbering of plugs in the blocks of the ignition sensor-distributor and speed sensor; B - to power supplies; G - to the instrument cluster signal for the tachometer; E - signal for the speedometer El to the instrument cluster. Electric motors for headlight cleaners at the moment of switching on. Even if the relay legs are intact, but the equipment does not work, the device must be dismantled and disassembled - perhaps the contacts are burnt inside.

Normal temperature readings

For all cars the operating temperature is approximately the same. This is due to the fact that in 1992, manufacturers established a single standard. According to it, the temperature at which the engine will operate without failures fluctuates around 90 degrees. The permissible error is 3 degrees in each direction.

In 2004, this figure was revised, as the automotive industry has made great strides forward. Then a range from 85 to 105 degrees appeared, acceptable for many cars. It was he who was guided by when creating the VAZ-2114. The injector of this model can operate at temperatures from 87 to 103 degrees. This range applies to modifications with 8 and 16 valves with a volume of 1.6 liters.

How the OS works

The cooling system of the VAZ 2114 operates on the basis of internal heat exchange, which is carried out under the influence of coolant. It moves forcibly thanks to a pump, which is activated by a drive belt. The mixture enters the OS through the expansion tank.

The electric fan is located on the electric motor shaft. Depending on the indicators of the sensor, it is turned on or off. One of the main elements of the OS is a thermostat valve with a storage tank, which senses changes in air temperature.

If the fluid temperature is around 87 degrees, the main valve turns on and sends fluid through the large circuit. At a temperature of 102 degrees, the valve stops at 8 mm.

DIY engine radiator repair

The main problem as a result of which the radiator needs to be replaced or repaired is leakage of the cooling mixture, as a result of the presence of a hole or defects in the system.

Liquid usually leaks at the joints of plastic and metal parts. If the leak is small, just pour a special mixture into the radiator along with the cooling liquid, and under its influence the leak will disappear on its own.

If the leak is large enough, the radiator will have to be replaced.

Before proceeding with replacement, check the radiator for leaks; to do this, you must:

- Fill the bathtub with water.

- Plug the holes in the pipes tightly.

- The radiator is released into the water approximately 30-40 cm and a pressure of 0.2 MPa is applied.

- See if bubbles appear or not.

The radiator must be replaced after an accident in the event of a frontal or side impact.

Cooling system VAZ 2115

The cooling system is of great interest to motorists. Model 2115 machines have a hidden cooling system based on the use of a special cooling mixture. The movement of the cooling mixture occurs under the influence of a mechanical pump.

The assembly principle of many Russian cars is carried out rather poorly, so the performance of many mechanisms, including the cooling system, leaves much to be desired.

To identify and carry out the necessary repair work, you need to have an understanding of the condition and method of operation of the cooling system.

Airlock

If you have a 1.6 liter engine, then the first step is to remove the plastic cover on the engine - unscrew the cover on the engine to fill the oil, and then pull out the entire cover. It is seated on rubber seals. After removing this plastic screen, screw the oil cap back on to prevent dirt from getting into the crankcase.

— We find the heating pipes for the throttle assembly (there are 2 of them), see the picture. Pick up any phone

— Next, unscrew the cap of the expansion tank (coolant tank) and cover the neck of the tank with a clean rag.

— We begin to blow into the tank with liquid. We blow until all the air comes out of the hose and antifreeze flows out.

— Quickly put the tube back on and tighten it with a clamp so that no air gets in there.

(It is worth noting that depending on the tube that you removed, antifreeze may leak from both the tube and the fitting from which the tube was removed)

The second method of removing air from the cooling system is less perverted. There is no need to blow anything here:

— Warm up the engine to operating temperature

— The expansion tank cap does NOT need to be unscrewed.

— As in the first method, unscrew the clamp of the coolant pipe on the throttle assembly.

— Having removed the heating pipe of the throttle assembly, release the air, and after the antifreeze begins to flow out, immediately put it back on the fitting and secure it well with a clamp.

But be careful and careful! Don't forget that the coolant temperature is approximately 90 degrees.

There is also a simpler, but less effective way to eliminate an air lock:

1) We drive up a steep hill so that the radiator cap becomes the highest point of the cooling system.

2) Unscrew the cap of the expansion tank and the radiator cap.

3) Let the car warm up to operating temperature

4) Then we accelerate several times and at the same time add coolant into the barrel.

Do this until bubbles stop appearing.

Thermostat repair

The thermostat sensor also serves to maintain the set temperature norm. It blocks the movement of the cooling mixture into the radiator until the engine heats up to the desired temperature of approximately 90 degrees. Liquid begins to flow through the thermostat when Celsius reaches 95 degrees. Using a thermostat, the engine takes minimal time to warm up. The thermostat is located between the engine and the cooling radiator.

Common problems:

- The valve is closed - the engine, when not warmed up, holds speed very poorly and may stall.

- With the valve open, you can drive during frosts, or turn on the heater to maximum mode, otherwise the engine will overheat.

When carrying out repair work on the thermostat, it is allowed to lightly tap the housing with a screwdriver to move the valve.

If it is necessary to completely disassemble the thermostat, it is important to tightly close the pipes to avoid antifreeze leakage, only then disassemble the thermostat. At the end of the repair, it is better to replace the antifreeze.

Signs of an airlock. why is it dangerous?

Lada Granta engine cooling system: malfunctions and methods for eliminating them

In addition to the engine running intermittently due to uneven cooling, there are several other signs of problems with the ODS:

- Rapid engine overheating.

- Non-working stove.

- The gas pedal falls off when driving slowly.

But even if you do not notice its presence based on the signs described above, the engine will soon inform you of its presence more clearly, for example with a wedge. The fact is that if its operation is disrupted, the SOD ceases to perform its main task - maintaining the temperature of the internal combustion engine and lubricants in it in the operating range.

Violation of this process significantly increases engine wear and subsequently leads to a violation of the mechanical integrity of its parts.

When do you need to change antifreeze or antifreeze?

Antifreeze is perfect for AvtoVAZ model 14. The manufacturer does not give clear recommendations on this matter. But practice shows that good quality antifreeze guarantees high performance and, in the opinion of many motorists, is the best remedy.

So, the coolant needs to be changed in the following cases:

- if we are talking about a new vehicle, then it is recommended to change the antifreeze after 60,000 km;

- The cooler is designed for operation for 24 months. Therefore, regardless of the “traveled” kilometers, it must be changed at least once every 2 years;

- if, as a result of a leak in the pipes, the driver was forced to add water, it is necessary to repair the breakdown and replace the coolant;

- appearance of rust color.

The cooler also needs to be changed if the power unit has been repaired or dismantled. Replacement must be carried out even if the fluid is in perfect condition.

Many car owners are interested in how many liters are provided by the manufacturer in the cooling system of the VAZ 2114?

On model 14, the system volume is 7.8 liters, regardless of the type of liquid. Let's look at several types of antifreeze designed to cool the VAZ power unit. Below are the most common types of liquids, as well as their features.

Any of the listed compositions is suitable for efficient operation of the vehicle. But the car owner must decide for himself which fluid to use, taking into account quality and price. Don't forget about high-quality antifreezes, which last on average 12-18 months longer.

2) Electric cooling fan failed

If your car has an electric cooling fan and it fails (no rotation when the engine is hot), this can also lead to overheating of the car (engine).

The point here is this: the electric cooling fan transfers cold air from the street to the engine, which passes through the cooling radiator. The fan cools the engine while your car is moving at low speed, thereby helping the engine cool.

If while driving the car you see that the engine temperature has begun to rise and move towards the red danger zone, then please stop the car, then open the hood and check whether the cooling fan is working.(?) If the fan does not spin, then you It is necessary to find out on the spot the cause of the malfunction, which may be the following:

— Poor contact feeding the fan

In order to check the contact of the cooling fan, it is necessary to remove the wiring harness that powers the fan. Using two wires, power the fan directly from the battery. If the cause of the fan malfunction is the wiring harness, the cooling fan will work.

If your car does not have a radiator sensor, then this test method may not be suitable for you. Then, to detect a malfunction, you need to remove the electrical connector from the fan, and then you can close the contacts of the connector of the fan itself. If it is working properly, the fan will work.

— The fan switch sensor is faulty

Many, and especially modern cars, have a temperature sensor that turns on the cooling fan. This happens after the coolant temperature has reached its certain temperature.

In order to check the serviceability of the sensor, it is also necessary to remove the wiring harness feeding the fan and close the fan contacts. If the fan is in good condition, it will start working.

Installation of new pipes

It is recommended to buy silicone pipes; they are durable and compatible with the cooling system of the VAZ 2114. In the photo, the pipes are shown in the following order:

- The short ones are installed on the thermostat and water pump couplings (1, 2);

- Conductive upper pipe (3);

- The lower pipe is designed to drain antifreeze from the radiator (4).

Preparatory work can be completed when new pipes, a set of keys, screwdrivers of different formats, and silicone grease are at hand.

Interesting fact: antifreeze and antifreeze perform the same function. Antifreeze is called a mixture for cooling in the CIS countries, since this solution was previously poured into the cooling system. Today the word “antifreeze” has become a common noun. For some reason, it is customary to call imported radiator fluid antifreeze. When purchasing, you should check the country of manufacture.

Replacement of pipes is carried out as follows:

You need to remove the battery cable from the negative socket. Next, you need to drain all the coolant mixture from the system.

Important: do not drain the coolant mixture with a hot engine. The power unit must be allowed to cool, otherwise you may be burned by the coolant. The following elements are removed: soundproofing padding, fan, windshield frame trim and trim. To gain access to the air collector, it is necessary to remove the spring brackets and mounting screws

A screwdriver is suitable for the first holders, and a wrench for the second. The front housing must be removed to loosen the clamps. When slack appears, the old pipes can be pulled out of the fittings. Now replacement - instead of the old pipes, silicone ones are installed. It is recommended that replacement of hoses be accompanied by the installation of new clamps. Preferably imported. In reverse order, you need to return all the elements to their places.

Why is antifreeze leaking from the stove?

A coolant leak in the heating system can occur from:

- stove radiator;

- stove tap;

- stove pipes.

If a coolant leak occurs from the radiator, it is usually replaced with a new one. Repairs to restore tightness are usually complex and labor-intensive. In addition, if the radiator has been in use for a long time, its tubes become clogged with deposits and dirt, and, as a result, heat transfer decreases.

The valve opens and closes the coolant supply to the radiator, thereby regulating the heat in the cabin. Over time, it may begin to leak, as evidenced by the characteristic smell of antifreeze in the cabin, a puddle on the floor on the passenger side and a decrease in the coolant level in the expansion tank. The faucet cannot be repaired and in such cases is replaced entirely.

If the heater radiator starts to leak, it is usually replaced with a new one.

The cause of coolant leakage from the pipes is usually their wear - the rubber ages and cracks over time. When diagnosing a problem, you need to wipe the suspected leak areas with a rag and observe the outlet and inlet pipes on a warm engine. Worn hoses are always replaced with new ones.

The stove makes a hum, whistle, murmur

The cause of uncharacteristic sounds (whistle, hum, murmur, etc.) from the heater is usually a faulty electric motor. Lack of lubrication, contamination, wear of bearings and bushings - all this leads to the fact that the motor begins to whistle. It is removed, disassembled and cleaned, and the rubbing elements are lubricated. If the bearings are heavily worn, the motor will not make a whistle, but a hum. In such a situation, lubricant may not help, and the electric motor will need to be replaced.

Steam is coming from the stove

Sometimes steam starts coming out of the stove. The reason for this is a leak in the heater core. The leaking coolant hits the hot radiator housing and begins to quickly evaporate, and the smell of antifreeze appears in the cabin. To fix the problem, you will need to disassemble the stove and replace the heat exchanger.

Sometimes white steam comes from under the hood and enters the cabin. This happens when antifreeze gets on the hot manifold or exhaust system pants. In this case, you will need to find the location of the leak and fix it. The most common cause is damaged pipes.