Despite the fact that a modern car is not only a high-tech vehicle and is manufactured to the most advanced standards. Even they have problems. These faults can manifest themselves as a knocking sound in the front suspension of the Lada Vesta.

Although the suspension turned out to be successful, malfunctions periodically arise, which the manufacturer analyzes and makes recommendations for eliminating squeaks in the Lada Vesta. They may appear as extraneous sounds or knocks.

Recommendations from repairmen

Reliability and long service life of the suspension are among the priority characteristics of the car. Even at the design stage, engineers set the task of developing a suspension that would be maximally adapted for domestic roads.

The result turned out well; the design even caused delight and surprise among some car enthusiasts. The average resource of suspension elements exceeds 100,000 km. Despite a number of positive aspects, there is always a fly in the ointment.

conclusions

If the service life of some units has come to an end, then they need to be replaced urgently, since one breakdown can lead to others, and the entire mechanism will go into disarray.

If we return a little to squeaks, then with significant fatigue of the ball joints, steering tip and rack, failure of the shock absorber, or its broken supports, unnatural irritating sounds may appear. Then it is best to go for a diagnosis and then treat the problem.

Despite the fact that a modern car is not only a high-tech vehicle and is manufactured to the most advanced standards. Even they have problems. These faults can manifest themselves as a knocking sound in the front suspension of the Lada Vesta.

Although the suspension turned out to be successful, malfunctions periodically arise, which the manufacturer analyzes and makes recommendations for eliminating squeaks in the Lada Vesta. They may appear as extraneous sounds or knocks.

Knocks and noises in the front suspension of Lada Vesta

- Many car enthusiasts note the appearance of a squeaking sound in the front axle area immediately after purchasing a car from a dealership. Driving through speed bumps turns into real hard labor. The culprit is the rubber bushings on the stabilizer bar.

Service station technicians do not recommend lubricating sealing products with grease or transmission oil. The creaking will go away, but for a short time, then it will resume again. To get rid of annoying squeaking, use polyurethane stabilizer bushings from Chevrolet Niva. (Cat. Art. 17012680).

- The play of the tip in the ball joint can also cause knocking. According to the regulations, replacement is carried out complete with suspension arms.

- Often inexperienced drivers confuse the creaking of suspension elements with a dull knock in the exhaust system area. The muffler mount is another defect from AvtoVAZ. The rubber retainer must be lubricated with silicone grease. The unpleasant sound will go away for a long time.

- The front suspension is knocking or rattling - contact a service station for help. Specialists identify the source of the breakdown with high accuracy. Self-diagnosis does not always bring the desired result due to the lack of special equipment.

- Do not forget that play in the chassis of the car can also be perceived as a malfunction in the suspension. Carry out diagnostics carefully and take a comprehensive approach to identifying the breakdown.

The support bearing on Vesta knocks and makes noise

If the support bearing is knocking on Vesta, an experienced driver will hear about it on the first trip. Beginners are recommended to carry out manipulations that will allow them to understand for sure whether it is worth changing the mechanism.

How to understand that the bearing is at fault

There are three methods that allow you to understand exactly whether the support bearing on a Lada Vesta is working properly.

First: the hood is opened and the protective plastic element is removed from the place where the support is attached to the car body. The upper platform of the front strut rod is pressed by hand. Then you need to ask to rock the car from side to side, first applying force to the trunk so that the car rises and falls, and then to the doorway.

Second option: the examiner’s hand is placed on a spring mounted on the front pillar. You should first unscrew the wheels from the front axle for convenience. The second person gets behind the wheel and starts turning it from side to side. A metallic knock and beating in the hand indicates critical wear of the bearing.

The last option: when driving on a rough road, you need to turn off all devices that produce sound: radio, air conditioner, fan and the rest. Afterwards, you should listen to the work of the suspension while cornering, speed bumps, bumps and holes.

A characteristic knock will be heard from under the front wheel arches.

Unlike the hub, you can check the support cup right outside in the yard, so it is recommended to do this every 20 thousand kilometers.

Causes of knocking

The only reason why the support bearing on a Lada Vesta makes a characteristic knock is that it is completely worn out.

If a car enthusiast recently changed the mechanism and it started knocking again, then the reason may be the quality of the product.

The mechanism also breaks due to falling into a deep hole. Immediately after this, a characteristic sound appears in the cabin.

Knocks in the rear suspension of Lada Vesta

In the process of identifying a malfunction, distinguish between knocking (dull) and squeaking, rubber friction. One of the weak points of the rear suspension is the upper shock absorber mount. There is a gap between the mount and the body, as a result of which on uneven surfaces the rod hits the metal surface. The defect is typical for all Lada Vesta models, this is the factory design.

To eliminate knocking, place a rubber or asbestos gasket between the upper support and the body mount.

The following can also produce crunching noise:

- poorly tightened discs that rattle at speed;

- equipment, cargo, suitcase with tools in the trunk;

- metal cable of the parking brake lever;

- trunk lid dampers;

- locks of the rear sofa, seat backs.

How to eliminate knocks and squeaks in the Lada Vesta suspension

09 February 2016 LadaOnline 125 411

The front and rear suspension of Vesta is significantly different from the one that AvtoVAZ used on Grant, Priora, Kalina, etc. All the reviews tell us that the new chassis design is better than before. However, during the first months of operation, the owners began to notice extraneous noises (knocks, creaks, rattles, crunches) in the front and rear suspensions of Vesta, which occur when driving over speed bumps or other road irregularities...

Grinding, creaking in the front suspension

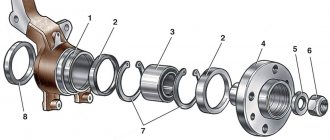

A dull sound, as if the racks are touching the plastic, or a creaking sound reminiscent of rubber friction. The reason is the poor quality of the stabilizer bushings (No. 8) or insufficient lubrication of the muffler mounts.

It is enough to lubricate the gingerbreads (muffler mounts) with grease. There is no point in lubricating the rubber bushings of the stabilizer, because... this doesn't last long. You can solve the problem of front suspension squeaking like this:

Question to AvtoVAZ: When will the problem of squeaking bushings be resolved? New cars from October-November continue to creak.

Answer: Improvements were introduced (replacement of rubber, lubricant) at the end of November 2016.

A knock in the front suspension may occur due to wear of the stabilizer struts (No. 7) (replacement), which should be replaced with new ones. This case is discussed in the video:

Also, knocking noise from the front of the car can come from the upper engine mount or from the brake caliper.

Knocks, crunching in the rear suspension

In the rear suspension, knocking is eliminated according to AvtoVAZ's instructions. It is necessary to remove the rear shock absorber strut and place a washer under the upper support (No. 5).

It is worth noting that after such modification, a gap appears between the support and the body, into which dirt can get in. To eliminate this, it is recommended to install a gasket according to the following dimensions:

Other sources of extraneous noise from the rear:

- handbrake cable (fasten to ties);

- trunk lid dampers (lubricate with silicone grease, loosen);

- trunk lock (lubricate the lock, eliminate play);

- in the area of the rear support, pull the bump stop down along the strut rod (pull it out of the support sleeve), spray silicone spray into the support sleeve and put the bump stop in place.

- rear seat back locks (lubricate, apply electrical tape).

- things or tools in the trunk.

How to diagnose the Vesta suspension yourself. If the rear knock only appears when braking, then this is a different case.

If you encounter a similar problem, we recommend contacting your personal manager. Have you noticed the appearance of knocks or creaks in the Vesta suspension? How did you manage to get rid of them? Leave your reviews and recommendations in the comments.

From February 5, 2022, the stabilizer bar along with the bushings will be replaced under warranty. See Information Letter No. 10-19

Let us remind you that another drawback of this sedan is associated with the creaking of the glass seals. Other instructions for tuning and modifying the new Lada can be found in this category.

Loose wheel bolts

For various reasons, personal carelessness, including insufficient tightening of bolts, contributes to the appearance of extraneous sound. If you detect an uncharacteristic sound, check the tightening of the bolts yourself. If you do not have a wheel wrench, contact a service station for help.

After tightening, be sure to check that the wheel does not knock and make sure that the cause has been eliminated.

We do not recommend doing your own repairs while the machine is under warranty. Otherwise, it may be classified as a breach of contract by the consumer. It is not uncommon for a factory warranty to be voided prematurely.

How the body is made

Let's admit: the Lada Vesta, which is attractive in our opinion, is very well assembled in terms of its bodywork. The measured gaps are everywhere at the level of a couple of millimeters. Well, the softness and silence with which the doors close are completely worthy of applause. And everything would be absolutely wonderful if we had not started studying the car from below.

In general, of course, there is no “crime”. The first thing that caught my eye was the sloppiness of the anti-corrosion treatment, in the category of “we’ll apply it here, but it’ll do just fine.” It can be seen that some areas were treated over the protective film, which was then torn off along with the protection. Moreover, in the same place it was done with completely different quality (carefully and clumsily).

An incident was discovered under the hood - at the factory, a piece of paper was attached to one of the side members with tape, apparently with an example of a color called “platinum”, in which it was necessary to paint the car from the inside. Actually, they painted this piece of paper, forgetting to tear it off - naturally, there was a stripe under it without painting.

Another point is the accuracy of internal bends and connections of individual body parts. Between some of them there are considerable technological holes into which, of course, dirt, salt and road chemicals will get clogged. Considering that some of these connections have not been exposed to anticorrosive agents, they are likely to become centers of corrosion, especially in the wheel arches.

Wear of stabilizer bushings

The first sign of “fatigue” of the stabilizer sealing bushings is a dull knock when overcoming a speed bump. Even in Lada Vesta, the manufacturer saves on materials and uses the cheapest ones. As a result, the service life of the bushings is short; creaking of the Lada Vesta suspension appears after several tens of thousands of mileage.

Other signs of bushing wear:

- knocking in the area of the front axle when the car rolls;

- beating in the steering wheel at speeds over 60 km/h;

- play in the steering wheel when maneuvering;

- arbitrary deviation of the machine from a given course. Car enthusiasts say that it “takes away” to the side.

The final conclusion will be given by a mechanic after conducting a comprehensive diagnosis.

Self-diagnosis of problems

If there is a knocking sound in the steering wheel or the Vesta suspension rattles, you should immediately contact the dealership.

If this is not possible, you can diagnose and identify problems yourself. To do this, just hang up the Lada wheels and do the following work:

- Let's rock the wheels in different planes; if play is felt when the brake pedal is released, this indicates that the hub bearing has failed;

- If there is a problem with the suspension, play is felt regardless of whether the brake pedal is pressed or released;

- If the ball joint is defective or the strut is poorly secured, play is felt in the vertical plane;

- Failed tie rod ends are accompanied by play in the horizontal plane.

Sequence of actions when replacing roll bar bushings

Catalog number - 8450006748, cost of original spare parts - from 350 rubles/piece. As an alternative, use polyurethane bushings from Chevrolet Niva (17012680).

- TORX 40 wrench, heads “13” and “16”;

- knob;

- extension wrench;

- torque wrench;

- new bushings, preferably polyurethane ones, as they have a longer service life.

- We hang the front part of the car with a jack and use a hydraulic lifting mechanism.

- Unscrew the steering gear casing (head at “10”).

- We unscrew the steel brackets that secure the rubber bushings (the key is set to “13”).

- Unscrew the front bolts (T40 key) and remove the bushings.

- We insert new ones and assemble the structure in reverse order.

Tighten the bolts with a force of 2.0 kgf/m.

Replacement procedure

If you look at the photo, then structurally all OPs look approximately the same. The layout of the front struts on different cars also has minor differences.

But this does not give reason to use, for example, a Zhiguli repair manual in the process of replacing a support bearing on a Renault Logan, Nissan Almera, Hyundai Accent or Mitsubishi Outlander car. I recommend arming yourself with the instruction manual that came with your machine. Even if you bought a used car, and the previous owner did not give you the manual, it will not be difficult to find it online or buy it in stores.

It is this manual for a specific car with a specific engine that is the best guide for self-repair and maintenance. So that you understand what is involved in the process of replacing a support bearing, I suggest that you familiarize yourself with the approximate process.

I tried to highlight the main points that each of you needs to know.

- If the bearing is completely or partially broken, then there is no point in trying to repair it. There are no elements that could be restored. So feel free to buy a new bearing right away. Its price can be from a couple of hundred rubles.

- Loosen the tension on the nuts that secure the support. On most cars it is located in the engine compartment. There are 3 of them.

- Raise the part of the car with a jack where repairs are planned. Remove the wheel.

What conclusions can be drawn? OP, that is, the support bearing, is a relatively small suspension element. At the same time, it plays a huge role in the quality of its operation and the safety of driving. Therefore, it is important to monitor its condition and replace it on time.

Write in the comments what you think about this. Be sure to subscribe and invite your friends and acquaintances. Together, as they say, it's more fun.

Subscribe to updates and receive articles by email!

We guarantee: no spam, only new articles once a week!

Wear of stabilizer link joints

Catalog number of the original stands (bones) - 8450006750, length - 283 mm. Due to poor-quality road surfaces, pins (hinges) often fail prematurely.

Replacing the “bones” yourself is not at all difficult if you follow the instructions for using the technical device.

- wrench 16, 19, Torx 30;

- a set of new “bones”.

- Jack up the car and remove the wheel on the right.

- Unscrew the upper and lower fastenings of the “bone”.

- We insert a new one, tighten the nuts, and screw the wheel.

- By analogy, we repair on the left.

Front suspension. What might be a concern?

Wheel bearing noise can be detected by ear even by a less experienced driver. It howls and rustles when moving and, gradually increasing, begins to drown out all other noises in the cabin. To make sure that it is the bearing that is making noise, you need to turn the steering wheel a little when driving at speeds above 60 km/h. If the rumble appears in one steering position and stops in another, it means the bearing has definitely failed. You can also check this by lifting the car wheel and spinning it. If you hear a characteristic rustling sound, it means the bearing needs to be replaced.

Stabilizer links are the most vulnerable part of the suspension. Due to the poor quality of roads, they often fail and begin to produce a slight but constant noise from under the bottom of the car. You can determine if the struts are broken by resting the lever on the subframe and shaking the stabilizer. If during these actions a knock is heard and play is felt, it means that the stabilizer links are out of order.

These parts are usually replaced in pairs, and you can do it yourself. To do this, you need to hang the front wheels of the car, and using a 16 wrench, unscrew the hinge nuts, while holding them with a 5 hex wrench on the back side so that the hinges do not turn.

The sound of a broken ball joint can be difficult to distinguish from other suspension noises. You can check the play of this unit by moving the suspended wheel in a horizontal plane. If the fault cannot be determined, you can insert a pry bar between the subframe and the lever and press on the resulting stop. This is the easiest way to identify a loose ball pore.

At the service center, the ball joint is replaced along with the lever and silent blocks. But these parts also exist for sale as a separate unit.

Replacing a ball is not an easy operation, so you can tackle it yourself only if you have the necessary tools and metalworking skills.

Many drivers complain about the knocking of Lada Vesta shock absorbers, but their design itself eliminates this possibility. The telescopic strut consists of two cylinders that dampen vibrations while moving on uneven roads. When they break down, the car begins to “sit down”, the road holding is poor, all the unevenness and bumps become clearly noticeable, and the steering deteriorates. In this case, the outflow of liquid or gas from one cylinder to another is disrupted, and the shock absorber rod begins to make characteristic sounds that resemble knocking.

Ball joint knock

After 60 - 65 thousand kilometers, owners note the appearance of a knocking sound in the area of the axle shaft. Most often when turning at low speed.

The tip of the ball joint is rolled into a plastic sleeve. During the systematic operation of the car, the moving surfaces wear out and play forms.

The process of replacing the ball joint yourself is not difficult, but be careful not to violate the installation technology.

To verify that the ball is faulty, just jack up the side of the car. Loosen the wheel up and down, the presence of knocks and clicks will be a sign of wear on the ball joint.

Wheel bearing noise

At the initial stage of wear, the noise is practically inaudible. The appearance of extraneous sound in the cabin is a sign of moderate wear.

To verify that the bearing is faulty, it is enough to drive onto an open highway and accelerate to 50 km/h. Gradually rotate the steering wheel left and right. When turning to the left, the right bearing is worn out, and when turning to the right, the left bearing is worn out.

It often happens that a hum or rumble is heard on both sides, then the left and right bearings must be replaced, respectively.

Support bearing knock

Often, car enthusiasts perceive the shock of the shock absorber rod as the knock of the wheel bearing. This can be explained by the design of the rack: two cylinders and a metal rod.

During systematic use, the bypass valves wear out and the strut does not dampen vibrations. With a sharp push, a blow occurs, which is perceived as a knock of the support bearing.

To guarantee that the latter is faulty, it is necessary to conduct a comprehensive diagnosis. It’s not difficult to do this yourself; in the transport position of the car, it’s enough to bleed the strut with a few presses on the car’s fender. After sharp pressure, the car must stabilize on its own, otherwise the shock absorber strut is faulty.

If there are no complaints about the shock absorber, then you are guaranteed to replace the support joint. The process is quite complex and requires minimal knowledge in servicing equipment. Unprofessional intervention does not guarantee full functionality of the mechanisms.

In order to carry out comprehensive diagnostics and replace worn-out equipment, contact a certified service station for help.

What indicates a malfunction

It is not always necessary to undergo complex diagnostics and a visit to a service station to understand that the support bearing has come to an end.

In fact, there are two main indicators of a breakdown or, at least, an unsatisfactory condition of the device, which requires mandatory replacement in the near future.

Many cars experience a knocking noise. But this is not true for all cars, since knocking in the struts may be absent due to design features. Therefore, motorists more often pay attention to changes in steering behavior. It is more difficult to steer a car; you constantly need to steer if you are driving in a straight line. Moreover, when it leads in one direction or another, you can understand what kind of persistent problem it is.

Causes of failure

Everything about the signs is very clear. But you need to know why such a malfunction occurs, and try to prevent premature wear of the support bearing on the front struts in the future.

- Natural destructive processes. Each OP has its own resource, which is usually developed after 80-100 thousand kilometers. Sometimes, if operating conditions are difficult, wear occurs faster. Therefore, it is better to check the condition of the OP every 20 thousand km.

- Aggressive driving. If you like to race, corner sharply and literally rape your car, which I categorically do not approve of, then your OP will not last anywhere near 100 thousand km. Such piloting speeds up the wear process significantly.

- Questionable bearing quality. Many car owners try to save money by buying cheap parts. But they serve little purpose and can fail at the most inopportune moment. Therefore, dear car owners, do not skimp on such important things.

Ways to eliminate knocking in the front (rear) suspension of a Lada Vesta car

If you have minimal experience in servicing equipment, carry out repairs yourself. Service station technicians do not recommend independent repairs during the period of the vehicle’s factory warranty.

After the appearance of third-party noises and squeaks, the car enthusiast can carry out initial diagnostics and assess the general technical condition of the car or unit. With the results, contact the workshop to make a decision. The reasons for wear of chassis and transmission elements are varied, ranging from violation of maintenance deadlines to defective parts.

Defects of Lada

Lada Vesta has recently rolled off the assembly line and not all warranty workshops have experience in solving problems on how to eliminate knocking noises that occur in the suspension. The manufacturer constantly maintains contact with the service station and makes changes to the design. Let's consider possible malfunctions and methods for eliminating them in the front suspension of the Lada.

Car enthusiasts may be disappointed by a new car almost immediately. An unpleasant creaking and knocking sound appears when passing speed bumps. Upon analysis, it turned out that the problem was in the stabilizer bar bushings.

It is not recommended to lubricate them with grease; they will stop squeaking, but for a very short period of time, so they only need to be changed. They can be replaced with polyurethane ones from Niva Chevrolet. The bushing has catalog number 17012680. After replacement, the squeaking sound disappears.

You should know that these are not all problems; a characteristic knocking sound may occur from the front right.

This is typical when there is increased play in the right ball joint. Replacement is carried out together with the suspension arms assemblies. AvtoVAZ supplies them complete with a ball joint. Front suspension of the Lada Vesta The main defects that occur in the front part of the Vesta car, which may cause the car to creak or rattle:

- Grinding noise in the anti-roll bar;

- The right ball joint is faulty, it starts knocking;

- The stabilizer links begin to rattle.

It is recommended that all these defects be repaired at AvtoVAZ dealerships.

When driving on an uneven road, you hear a dull knock on small bumps or a sound reminiscent of rubber friction. This problem can be eliminated by lubricating the Vesta muffler mounting with grease. Vesta's front suspension creaking may be due to worn struts.

Review of Manufacturer Prices

| Catalog number / Size / Diameter | Price in rubles |

| Original | |

| 17012680 (inner diameter 21.5 mm.) | From 400 |

| 8450006748 | From 400 |

| Analogs | |

| Polyurethane from Chevrolet Niva 2123 (17012680) | From 350 |

| Polyurethane for Lada Vesta from Kia Rio (548132K100, 548141G000) | From 550 |

| 54813-2K100 (diameter 21.5 mm.) | From 550 – 600 |

| KSBSOULF (diameter 21.5mm) – new sample | From 550 – 600 |

| Vesta front left / right (8450006750), stabilizer struts length 275 mm | From 700 |

| RENAULT Logan suspension mount (30768) | From 130 |

| Nut RENAULT 7703034221 | From 300 |

| Bracket 8450006747 | From 350 |

| Rod 8450006748 | From 450 |

| Toyota Rav4 (48820-42020), length 285 mm | From 2500 |

| CTR (CLT50) | From 650 / piece |

| Renault, SASIC, SIDEM, LEMFORDER, length 275 mm | From 400 |

| Alfa – Fiat – Lancia 46413122 | From 370 |

| MONROE: L15600 | From 380 |

| Multipla, Lybra | From 350 |

| Kia Rio (548132K100) | From 370 |

| Bracket (548141G000) | From 250 |

*prices are as of April 2, 2019.

Conclusion

If you notice a third-party creaking, knocking, or rattling noise in the suspension, don’t panic. Malfunctions are a natural process. At the initial stage, it is important to correctly identify the source of the breakdown and its location.

If you do not have a special tool, such as mounting tools or TORX keys, contact a service station. It is extremely difficult to repair a car with your bare hands.

Regarding the manufacturer of spare parts, the final decision rests with the owner of the technical equipment. The domestic manufacturer is not inferior in quality to foreign analogues. In this case, it is not advisable to overpay for the brand.

When it changes

The instructions for the car indicate that the supports installed on the Lada Vesta can travel about 55 thousand kilometers.

Indirect signs indicating that the bearing has failed:

- A creaking sound is heard in the area of the support cups when cornering.

- A knocking sound is heard from the side member while driving on a bad road.

- Controllability has decreased when cornering.

To exclude or confirm mechanism failure, you can carry out diagnostics in a service setting.

Reviews

| № | Positive |

| 1. | Stepan Vasilyevich , 42 years old (otzovik.com): the suspension is mounted on a subframe, the levers and steering knuckles are of a new shape. Obstacles on the road are overcome smoothly, without impacts. |

| 2. | Gennady Semenovich , 39 years old (www.zr.ru): at speeds up to 125 km/h the suspension works as comfortably as possible. The problems start from above. |

| 3. | Timofey , 22 years old (autobann.su): pleased that gas shock absorbers are installed by default. This is just right for the urban cycle. |

| 4. | Kirill , 33 years old (lada-vesta.net): before the Lada Vesta I had a Granta, it has an old type suspension design. Vesta uses frame technology. The steering rack and stabilizers are fixed to the beam. |

| 5. | Semyon Nikolaevich , 44 years old (otzovik.com): my positive review of the chassis and suspension of the Lada Vesta. The car is in its second year - no complaints, minor bumps are absorbed silently. |

| 6. | Lev Nikolaevich , 45 years old (www.zr.ru): I live in a rural area, you know what the roads are. The suspension works great. My recommendations to motorists. |

| 7. | Dmitry , 20 years old (autobann.su): springs are installed separately from shock absorbers, semi-independent type with a number of improvements that were so lacking in previous generations. |

| 8. | Mikhail Gennadievich , 43 years old (lada-vesta.net): the angle of inclination of the front pillars is 5 °, which has a positive effect on the handling characteristics of the car. The steering from the second generation Renault Megane is better than its domestic counterpart. |

| 9. | Kirill , 40 years old (otzovik.com): good car, good build, no comments on the chassis or transmission. |

| 10. | Petr Semenovich , 42 years old (www.zr.ru): the car is three years old, there are no comments on the components, I systematically carry out technical inspections and diagnostics, and treat the equipment with care. |

| 11. | Alexander , 35 years old (autobann.su): during two years of active operation of the car, I replaced the rubber bushings on the stabilizers once. I am satisfied with the build quality of the domestic car. |

| Negative | |

| 12. | Konstantin Stanislavovich , 43 years old (www.zr.ru): the chassis has not lasted even two years, it thumps, the suspension creaks in the cold. The officials said that this is not a warranty case and they cannot help. I replaced the rubber bands myself with polyurethane ones. |

| 13. | Vitaly , 27 years old (otzovik.com): instead of standard rubber bands, I installed polyurethane ones from Chevrolet Niva. The service life of the last 60 - 70 thousand km. As it turned out, the reason for the knocking was premature wear of the rubber seals of the stabilizer link. |

| 14. | Grigory Vladislavovich , 45 years old (autobann.su): a model with obvious defects, after purchase it needs a comprehensive re-upholstery of components, mechanisms, and partial noise reduction. |

Strut support and support bearing for Lada Vesta

The support bearing of the front strut on a Lada Vesta car ensures rotation of the shock absorber and steering knuckle while the driver is steering. A similar system is relevant for all machines on which MacPherson struts are installed.

The mechanism is used only for the front suspension, since the rear wheels do not participate in steering.

Video - Suspension review and repair

Upper supports of the front struts of Lada Vesta

Standard upper supports for front struts on Lada Vesta VAZ 2180 from . In appearance, these are ordinary supports that are made with jewelry precision. The price and quality of these supports are at their best today. The product is shipped without packaging.

Retail store at Uralmash, Baku Commissars St., 113. 8 (343) 221-35-35

02. By courier for orders over 2000 rubles, in Yekaterinburg from 20:00 to 22:00

Delivery only to the entrance. Additional +100 rubles to the apartment.

02.2. By courier for orders less than 2000 rubles, by EKB from 19:00 to 22:00

Delivery to the entrance or to the gate. To the door +100 rubles for the courier.

02.3. By courier outside the EKAD, up to 20 km, from 20 to 22 h

The manager will calculate the cost of delivery and notify you by phone or mail if your phone number is not available.

After sending, we will definitely send the TRACK NUMBER of the parcel.

On the official websites of the largest manufacturers of spare parts: SS20, Tehnoressor, Demfi, SEVI, online store illva.ru – IP Koroleva, recommended as a reliable supplier of original spare parts.

07. TC SDEK - careful and fast delivery

Recommended for light parcels! Inexpensive up to 10 kg and without queues, many delivery points in all large, medium and small cities, select the closest one to you on Yandex maps by entering SDEK in the search. After sending, we send you a tracking number. Fill in your full name in the Name field. Long distance payment upon receipt. Shipping is free.

05. TC "KIT" - a lot of branches

We recommend! delivery to more than 300 cities of Russia and the EAEU (Kazakhstan, Kyrgyzstan, Armenia, Belarus, Crimea). The delivery price can be checked with our manager or on the TK KIT website. After sending, we send you a tracking number. Delivery to TK KIT is FREE!

Low prices. We recommend for northern and eastern directions and Kazakhstan.

Delivery throughout Russia and the countries of Belarus, Kazakhstan, and China.

Fill in your full name and indicate the series and passport number in the comments to the order below. Delivery to TC Energia is FREE!

06. TC "Business Lines"

Prices are high with lots of markups! Attention!! TC DelLinii automatically includes services in the invoice - Insurance and Delivery by courier - but you may not be able to afford these services upon receipt, otherwise delivery with them will be twice as expensive! It is not profitable for her to carry small and inexpensive cargo. After sending the goods, we send you a tracking number. Please fill in your full name when ordering. In the comments to the order below, indicate the series and passport number. Payment for delivery upon receipt - the cost of sending this shopping center is indicated below.

09. TC “PEK” (series and passport number required)

Choose PEC only if there are no other options. The cost of PEC is relatively more expensive, and cargo in PEC is subject to inspection with violation of packaging, after which it is packed somehow, PEC charges various additional fees and, in general, delivery is more expensive. After sending, we send you a tracking number. Fill in your full name and indicate the series and passport number in the comments to the order. Below is the cost of the courier to the PEC branch.

12. I can’t choose! Offer the cheapest one.

To calculate delivery, please provide your full Address and Full Name; zip code, city, street, house, apt. And for foreign orders Country and exact address.

TK Luch - economical delivery to cities in the Chelyabinsk region, but shipments are not tracked and there will be problems if lost. cities: (Snezhinsk, Verkhny-Ufaley, Kasli, Ozersk, Kyshtym, Kusa, Zlatoust, Ust-katav, Yuryuzan, Katav-ivanosk, Trekhgorny, Satka, Mias, Chebarkul, Kopeisk, Korkino, Yemanzhelinsk, Yuzhnouralsk, Plast, Troitsk, Chesma , Magnitogorsk, Varna, Sibay, Kartaly, Bredy)), as well as Berezniki, Perm, Kurgan, Nizhny Tagil, Yekaterinburg, Surgut, Tobolsk, Tyumen, Shadrinsk, Shumikha, Petropavlovsk, Kostanay, Rudny, Astana, Ufa, Uchaly. Delivery costs from 100 rubles to 30 kg and from 200 rubles for 30-60 kg, between terminals. Check prices on the website of TC Luch - in some cities there are double tariffs.

The time that has passed since the first Lada Vesta rolled off the AvtoVAZ assembly line was quite enough for the owners to leave objective reviews about this car. In particular, readers are interested in the reliability and maintainability of the front and rear suspension.

Vesta's handling has truly become a legend. Even many skeptics were forced to admit the fact that the domestic auto industry had finally presented a model capable of competing with budget versions of German and Korean manufacturers. The fly in the ointment in the overall picture is periodic complaints about extraneous noises and knocks that appear at fairly low mileage rates. In principle, our mentality allows us to forgive some “significant” mistakes made by designers, attributing the blame to the peculiarities of Russian roads. But the issue of the cost of service is acute, because not every average car owner can afford to contact a service center.

On the other hand, there are unpleasant facts when specialists and representatives of the official dealer are engaged in elementary “pumping out funds” without finding the cause of the malfunction. Therefore, the basics of basic suspension diagnostics and the possibility of self-repair should be known to the owner of a domestic car, at least for now.

Posts 1 to 25 of 63

1 Topic from Pluto 2016-03-30 07:25:38 (2018-03-22 02:46:55 edited by Pluto)

Subject: Knocking noise from front left

Has anyone encountered this problem, please tell me what it could be. When driving through potholes with sharp edges, a dull clanging sound is heard from below on the left, reminiscent of the knock of an unscrewed disk on the hub. The sound is best noticeable at low speed when driving in 1st or 2nd gear. Then it just gets muted. The defect occurred immediately after purchase. A visit to the dealer revealed nothing.

Currently, AVTOVAZ produces standard polyurethane bushings for Vesta. The stabilizer does not creak in them.

Outdated information: (I decided to collect information (from the Internet) on stabilizer bushings and struts that fit us. Correct, add, I’ll post it here.

Struts: Renault 54 61 800 02R (274 mm) or 8200 669 065 (283 mm) lemforder 3710901 Bushings: Chevrolet Niva (2123-2906046R?) (small) install without cutting with soap>

2 Reply from Petty 2016-03-30 08:10:00

- Petty

- Participant

- Inactive

- Messages: 966

- Thank you: 271

Re: Knocking noise from front left

Has anyone encountered this problem, please tell me what it could be. When driving through potholes with sharp edges, a dull clanging sound is heard from below on the left, reminiscent of the knock of an unscrewed disk on the hub. The sound is best noticeable at low speed when driving in 1st or 2nd gear. Then it just gets muted. The defect occurred immediately after purchase. A visit to the dealer revealed nothing.

3 Reply from d.PO 2016-03-30 14:07:10

Re: Knocking noise from front left

The defect occurred immediately after purchase. A visit to the dealer revealed nothing.

But did they listen to the knock? what and how did you check? Did you do any broaching at all?

4 Reply from Pluto 2016-03-30 22:27:54

Re: Knocking noise from front left

We stretched out the subframe and everything we could reach from below. We shook the ball joint and hub, and the stub drains. They also seem to have rocked the steering tips. They spread their hands. Today I looked down and there are a lot of nuts and bolts on the subframe. I would have to stretch them all out. The most interesting thing is that when you rock the car in a parking lot, nothing rattles, but on sharp potholes, yes. Maybe the shock absorber is defective, but how can you tell?

5 Reply from Pluto 2016-03-31 22:08:55

Re: Knocking noise from front left

Today I remembered all the problems again and went to the dealer. The source of the sound has been identified. This is the knocking of the anti-roll bar. His lateral movement limiter is faulty, as I understand it. The defect was recognized as covered by warranty. They will change the stabilizer as soon as a new one arrives. Will wait.

6 Reply from Axel 2016-04-02 08:30:11

- Axel

- Participant

- Inactive

- Messages: 973

- Thank you: 139

Re: Knocking noise from front left

The source of the sound has been identified. This is the knocking of the anti-roll bar. His lateral movement limiter is faulty, as I understand it. The defect was recognized as covered by warranty. They will change the stabilizer as soon as a new one arrives. Will wait.

It won't last long. We need to install something else, better quality.

7 Reply from Pluto 2016-04-02 13:28:42 (2016-04-02 13:31:24 edited by Pluto)

Re: Knocking noise from front left

It won't last long. We need to install something else, better quality.

What, have you already had experience replacing the stabilizer?

8 Reply from Dimidrol 2016-04-03 01:31:28 (2016-04-03 02:04:44 edited by Dimidrol)

Re: Knocking noise from front left

Looks like I have the same problem. I went to the officials, but of course they didn’t find anything. What does this limiter even look like, how was it diagnosed?

9 Reply from Axel 2016-04-03 07:04:40

- Axel

- Participant

- Inactive

- Messages: 973

- Thank you: 139

Re: Knocking noise from front left

What, have you already had experience replacing the stabilizer? ai

So they exchange it for the same one. That means the new one will knock too.

10 Reply from Pluto 2016-04-03 23:15:44

Re: Knocking noise from front left

Looks like I have the same problem. I went to the officials, but of course they didn’t find anything. What does this limiter even look like, how was it diagnosed?

I didn’t catch up with the diagnostic process, so I gave the car away for half a day through a personal manager. They found it themselves. I rummaged through the technological instructions (https://yadi.sk/d/zTESYkz0mDbKY; https://yadi.sk/i/jd13nycwoyZVi links from the documentation section) and, as I understood from the explanations, the “belt on the stabilizer bar” fig. 7-2. You can look at it using a mirror. To be honest, I haven’t looked at it myself, but I’ll look in soon. It's a very uncomfortable place - behind the steering rack. By the way, such a knock could have occurred on the right side if the belt had broken on the other side. Honestly, this defect ruined the whole impression of the car.

11 Reply from Pluto 2016-04-03 23:28:52

Re: Knocking noise from front left

So they exchange it for the same one. That means the new one will knock too.

What a pessimist. There is a separate topic for flooding. If the new one knocks, I’ll weld a nut instead of a belt and that’s it!

12 Reply from antifashist 2016-04-05 15:05:12

- anti-fascist

- Moderator

- Inactive

- From: Salavat, Bashkortostan

- Messages: 708

- Thank you: 73

Re: Knocking noise from front left

It may not knock. There was simply a manufacturing defect in the parts.

13 Reply from Pluto 2016-04-12 00:18:56

Re: Knocking noise from front left

The stabilizer was replaced. The new one is no different from the old one.

The problem, they say, is in the soft split bushings of the stabilizer. We modified the stabilizer in place with a heat-shrink tube. Reassembled with grease and sealant. Now it doesn't seem to knock. The manager assured that the modification was effective. But cars with different stabilizer bushings are now coming off the assembly line. In fact, it is not clear why the bushing is split? They have less rigidity. In this regard, the question is: what can be replaced? maybe from Moskvich-2141 along with a bracket? If anyone has the opportunity to measure and compare, please share your experience.

14 Reply from hufsa 2016-04-12 07:08:30 (2016-04-12 07:13:03 edited by hufsa)

Re: Knocking noise from front left

There is also a rattling sound. Maybe you can add something to this belt? The dealer didn't find anything. Is there any way to diagnose this yourself?)

15 Reply from Pluto 2016-04-12 22:09:31

Re: Knocking noise from front left

In this whole story, 2 circumstances confuse me: - I hear clanking only on the left, there is none on the right, but the stabilizer is symmetrical. - again a subjective opinion - the rattling seems to have remained, but it has become muffled and less noticeable.

I came to the thought that a knocking noise occurs when the wheel moves suddenly, maybe it’s the belt itself (the gray rings in the photo) knocking on the subframe or the hub bracket? I myself have not yet been able to crawl under the car to inspect the heat-shrinkable tube, which they put on me in such a way that it overlaps the belt and sleeve. The bushing cut was sealed with sealant.

You can try to diagnose it this way: disconnect the stabilizer link from the stabilizer itself on one side. Strongly shake up and down the free edge of the stabilizer.

For all questions, it is better to contact your personal manager rather than the dealer. They are on top of this issue.

16 Reply from hufsa 2016-04-13 07:03:36 (2016-04-13 07:09:06 edited by hufsa)

Knocks and noises in the front suspension

Even an amateur can recognize extraneous noises that appear in his own car, because an unfamiliar sound is always clearly audible against the background of the familiar “ensemble.” Knocks and noises in the chassis of the car should not plunge the owner into a state of shock, because all components are repairable, but it is necessary to urgently diagnose and fix problems, since the condition of the suspension is not only driving comfort, but also road safety.

Extraneous noise can be produced by rubber with a hard tread or with a broken cord. A wheel bearing that has become unusable has similar symptoms. During the off-season, the accumulated dirt that gets between the brake disc and pads disturbs the ears.

How to identify the cause of the noise yourself?

If the machine is under warranty, if you suspect any malfunction, you must contact your nearest service center. If the warranty has expired or this is not possible, you can try to determine the cause of the unpleasant noise yourself.

To do this, you need to hang the car wheels and move them in different directions. When conducting diagnostics, the following conclusions can be drawn:

- If there is play when the brake pedal is not pressed, then the wheel bearing needs to be replaced;

- If there is something wrong with the suspension, the play will not go away when you press the brake pedal;

- A ball joint defect can be suspected if the play occurs in the vertical plane. This sensation can also occur if the stand is poorly secured;

- Wobbling in the horizontal plane most often indicates a faulty tie rod end.

Having identified the causes of a creaking or rattling noise, it is necessary to eliminate it as soon as possible by replacing damaged parts. It is better to do this at a service station, where specialists will carry out reliable diagnostics and carry out repair work.

Knocks in the rear suspension

Judging by the reviews of car owners, Renault left Vesta a legacy of fairly rapid wear and tear of the silent blocks of the rear beam. They begin to bother you already at the third ten thousand kilometers. Another reason for knocking noises can be the destruction of the shock absorber support.

Diagnostics

Diagnosing a problem with a car's rear suspension is not easy, despite its simple design. The difficulty lies in the massiveness of the parts, so full diagnostics can only be carried out on a special lift.

Repair

To the delight of car enthusiasts, the rear suspension of the Lada Vesta has one advantage: it is easy to repair. You can even replace shock absorber mounts at home. But changing the silent blocks of a beam without a lift is very difficult. It is advisable to contact a car service center with such a problem.

The article does not reveal a step-by-step repair algorithm, but it answers the question of how you can diagnose the malfunction yourself. If you know the list of works, then the likelihood that the car service center will try to impose unnecessary work is reduced to zero, and this is a direct cost savings.

When and how does it change?

According to the manufacturer, the front suspension will last 40-55 thousand kilometers under moderate driving conditions on good road surfaces, taking into account normal weather conditions.

There are several signs by which you can understand that it’s time to change the shock absorbers, and therefore the bearings:

- the tire is not in full contact with the road;

- the braking distance has become longer;

- a knock is heard in the suspension;

- traces of oil leakage;

- the car drives from side to side.

Replacement: support bearing

Install a new part according to the following algorithm:

- Secure the car, lift the front end, remove the wheel.

- Unscrew the stabilizer mounting bolt and remove the shock absorber.

- Loosen the bearing fastening nut, while holding the rod with a 22mm hexagon.

- Place a jack under the ball joint pin, lift the shock absorber, it will begin to “walk”.

- Using zip ties, tighten the spring coils a little, and then you can lower the jack.

- All that remains is to lower the rod and remove the part through the large hole.

- Clean the working surfaces from dirt, install a new part.

Replacement: Rack Support

In this case, the machine will be a little more work. For the sake of convenience, you can put the car not on stands or a jack, but on a lift.

- Remove the wheel.

- Unscrew the nut securing the front suspension to the stabilizer. At the same time, secure the finger with a 5-point hexagon.

- From its brackets, remove the wires leading to the speed sensor. Secure them so they are out of the way.

- Unscrew the nuts of the bolts securing the steering knuckle to the rack with a wrench and a 18mm socket. Disconnect the steering knuckle.

- Lift the window frame trim cover using a flathead screwdriver.

- Remove the bolts securing the upper support to the body, take out the entire assembly with the spring.

- Fix the structure, then compress the spring with ropes.

- Using an 18mm wrench, remove the nut securing the upper part to the rod. Hold the rod with a 6 hexagon.

- Disassemble the structure and put a new part in place of the old one. Reassemble everything in reverse order.