Print this article Font size 16

For any car, the front strut bearings play a big role in terms of handling and safety. If this element fails, the risk of getting into an accident increases many times over.

Practice shows that when the support bearings are heavily worn, the car itself demonstratively lets you know about it. This manifests itself in the form of creaks, noises and other extraneous sounds. So you shouldn’t ignore the signals, but you need to immediately start fixing the problem.

New kit

Which support bearings for the VAZ 2110 are better - Supports from SS20 or SEVI

The main question floating around the internet is which props are better for cars: SEVI or SS20? In their reviews, owners often prefer the second option. SEVI also has its advantages. Firstly, it's the price. The cost of such parts is 800-900 rubles. But the quality of workmanship leaves much to be desired - sometimes the clips can crack after only 10 thousand kilometers.

The SS20 gold element costs a lot of money. Its price is close to 1700-1800 rubles. But such elements are capable of covering significantly greater kilometers. The owners of “ten” on the forums mostly recommend this option. Below is information on how to choose the right ball bearing without running into a fake.

Review of SS20 Gold supports:

Opornik VAZ 2110 from SEVI EXTREME:

Rack support for VAZ 2110 SEVI – fake:

Replacing the front support bearing of a VAZ 2110

1. First of all, remove the cap on the hub, and then loosen the nut.

2. Now, put the assistant behind the wheel, let him keep his foot on the brake pedal. At this moment you must unscrew the nut, or rather tear it off. 3. Jack up the car and remove the wheel. 4. Remove the cotter pin from the steering tip, unscrew the nut and use a puller to press out the pin.

5. Press out the ball joint pin.

6. At this stage you need to release the brake hose; it is held on the strut clamp.

7. Next you need to remove the caliper from the brake disc. When it is unscrewed, hang it to the side so that it does not interfere with you, but at the same time does not strain the brake hose.

8. Now unscrew the 3 nuts holding the strut under the hood. Before doing this, I advise you to loosen the strut nut a little. This will make it easier for you to work with the stand further.

9. Unscrew the CV joint nut and remove the strut so that the CV joint comes out of the splines.

10. Now that the strut is removed, you will need a spring remover, called a spring puller. Having installed them on different sides of the spring, we begin to tighten the nuts on the pullers one by one. This will compress the spring. After the operation, unscrew the support bearing of the VAZ 2110.

11. We put a new one in place of the old support.

Everything is assembled back to the parsing algorithm.

As you can see, replacing the support bearing of a VAZ 2110 is not an entirely simple matter. But if you decide not to spend money on a service station and do this repair yourself, then following these instructions you should not have any difficulties.

When to change

Another equally popular question. In general, bearings have to be replaced as they break and wear out.

If we imagine ideal operating conditions, then factory support elements can last 100 thousand kilometers. This is their declared resource.

In real conditions, taking into account the condition of the roads and the frequent entry of dirt into the bearing, a scheduled replacement should be performed every 50 thousand kilometers or every 2-3 years. This is especially true for situations where bearings have already been replaced before and now you have non-factory products. .

Examination

Before proceeding directly to replacing the suspension element, you should make sure that it is really worn out, broken and needs urgent replacement.

We recommend carrying out these measures not only when signs of wear are detected, but also as preventive measures. This way you can find faults in time and take appropriate action to eliminate them.

The check should be carried out approximately after every 15-20 thousand kilometers. The procedure is carried out as follows:

- Turn off the car, turn on the handbrake and install chocks under the wheels. Safety comes first;

- Lift the hood, remove the cover located on the hub bearing from the glass;

- Touch the support with your palm, and in the meantime your partner should rock the car. Moreover, it should be swung to the sides;

- Make sure that the stand does not “play”;

- If during rocking you hear extraneous sounds, crunches or squeaks with knocks, then all is clearly not well with the bearing. The only correct solution is to replace the element.

What does a breakdown lead to?

When signs of a support bearing failure begin to appear, many car owners simply ignore it. But in vain. In fact, this can lead to very sad consequences for your car and budget.

Worn element

It’s not uncommon for a worn-out prop to break after hitting a pothole, of which there are more than enough on our roads. This led to the formation of a hole on the hood, since the support simply pierced the metal. If at the same time you were moving at low speed, then you are lucky; you will only have to repair the body. And I don’t even want to talk about the support column breaking down at speed. Let's just say that there were deaths.

Broken hood

All this is said not with the intention of scaring, but to make you think about the importance of timely repair of the support.

Suspension cracks

On VAZ cars, both the front and rear suspension may fail over time. You can determine the malfunction by examining the suspension arms near the ball joints, silent blocks, and under the spring stops.

The levers, as well as the transverse link of the front suspension, need to be replaced as soon as possible if cracks are observed on them, even the most minor ones. It is not recommended to fix this problem by welding; it is better to purchase a new part.

Cracks also appear over time on metal wheel rims, forming near bolt holes or ventilation windows. If these shortcomings are present, the disk should be replaced. If this is not possible, you need to carefully inspect the wheel after each strong impact.

Front shock absorber struts can last quite well for more than 100,000 km, but not every owner can boast of such a result. For many VAZ 2109-2108, the front suspension modules have to be changed almost twice as often, that is, every 50 thousand km. Using my own example, I can say that I drove about 80,000 km on factory struts, and only after that one of them leaked.

Below I will describe the procedure for replacing all module parts, from support bearings to springs and supports. To perform this repair you will need the following tools and accessories:

- Socket head for 19 and 13

- Extension

- Ratchet handle

- Vorotok

- Special key for holding the strut rod from turning

- joint puller

- spring ties

- open-end wrench or socket wrench 19

- breakdown if necessary

- hammer

So, first you need to open the hood of the VAZ 2109-2108 car, and after removing the protective cap from the top of the support, slightly loosen the central nut of the front drain. To do this, you need a special key, which can be purchased at any auto store. Or you can use improvised means.

The fact is that the central rod must be kept from turning while loosening the nut. Since in my case there was a 6mm hex hole at the end of the rod, I solved this problem without a key. To do this, I used a spark plug head, which can also be turned with a regular open-end wrench. In short, see the visual example in the picture:

Next, unscrew the front wheel mounting bolts and jack up the car. After this, it is necessary to disconnect the steering tip from the steering knuckle of the strut. Read more about this in the article on Replacing tie rod ends. As a result, we get the following picture:

After this, unscrew the two nuts securing the front strut, as shown in the photo below:

Then you can knock out the bolts to free the lower part of the rack. It is possible that they will be removed without much effort, but nevertheless, just in case, it is worth keeping in mind:

Now you can move the lever to the side, thereby releasing the rack from below:

Now you can start working on the top part of the mount. From under the hood, you need to unscrew the three nuts securing the support to the body glass. This action is clearly shown in the photo below:

When you unscrew the last nut, hold the stand from below so that it does not fall. And now you can easily remove the front strut assembly with the spring, support and bearing outward:

Next, we will need special spring ties to remove the support with the bearing and the front drain spring of the VAZ 2109-2108. We put them on the coils of the spring on both sides and try to evenly tighten them to the required level.

When the upper nut of the support fastening begins to rotate without force, that is, the pressure on it from the spring disappears, then you can finish with the tie and unscrew the nut, again, holding the central rod from turning:

Now you can remove the top cup from the support:

Then remove the support itself:

Well, all that remains is to remove the lower cup:

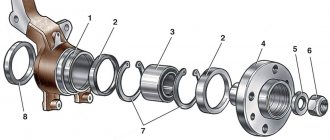

We take out the front strut spring up and now the entire front suspension module is disassembled into parts:

Next, you can begin assembling a new module if you decide to carry out a complete revision of the suspension. By the way, the old protective cover can be removed from the rack if it is normal and not torn, so that you can install it again later:

If you decide to replace the supports, it is better to immediately change them along with the bearings. Installing the new parts is done in reverse order, and again, use zip ties to install the springs and supports. As for the price, I can say for the complete set: I recently had to install new assembled modules on the front drive. All together it cost 13,000 rubles (SS20). Also, do not forget that after replacement it is necessary to go to a service station and get a wheel alignment done.

Replacement

It is not necessary to overpay for the work of replacing support bearings. Having the necessary tools at hand, you can do this yourself.

Tools and tools:

- wheel wrench;

- car jack;

- a special puller for steering tips (as a last resort, a hammer and a small pry bar);

- wrenches 9, 13, 19;

- pliers;

- two spring ties.

Work order

- Park the machine on level ground. Jack up the body on the desired side. Remove the corresponding wheel.

- Unscrew the nut securing the steering tip (pliers) and unscrew it (19mm wrench).

- Using a special tip puller, press out the pin. If you don’t have such a tool, knock out the finger by carefully tapping it with a hammer from below and prying it up with a small pry bar from above. Be careful not to damage the threads on the finger.

- Unscrew the two nuts securing the lower part of the strut in the steering knuckle (19mm wrench). If you cannot unscrew them, treat the connections with anti-rust liquid.

- Under the hood there are three nuts securing the upper support to the body. Unscrew them (key 13).

- Remove the entire shock absorber.

- Using two spring ties, tighten the spring enough to relieve the load on the support.

- Unscrew the nut of the central fastening of the support to the rack (wrenches 9 and 22). Remove the support and disassemble it.

- Replace the support bearing in it with a new one.

- Carry out work on assembling the rack and installing it to the body and suspension in the reverse order. Replacing the second bearing is carried out in the same way.

Tuning and repair of VAZ 2110

I think everyone understands that with roads like ours, the chassis often requires repairs. Quite often after winter, when the snow has melted and the holes are not yet visible due to puddles, shock absorbers and support bearings often get damaged. Because of such situations, it is necessary to repair this component of the VAZ 2110 chassis. It is better to carry out repairs in a timely manner, since in the first stages it will result in you spending less money than if you cause a breakdown and it will lead to a more disastrous result.

This article will provide information so that you can replace the VAZ 2110 support bearings with your own hands. Moreover, we will do this in such a way that we do not have to adjust the wheel alignment. That is, we will not touch the camber bolts.

What tool will you need to replace the support bearing of the front strut of a VAZ 2110?

- Steering wheel and ball joint remover.

- Ties for shock absorber springs.

- Tool for loosening strut nuts.

- Spanners.

- Jack.

- If it is possible to have an assistant, this will be a big plus.

About replacing an assembled part

If there are leaks on the shock absorber, the entire strut needs to be replaced. To do this, you need to carry out the disassembly process:

- Hang up and dismantle the wheel;

- Loosen the top fastenings;

- Remove the brake caliper with hose;

- Disconnect the steering tip and CV joint;

- Disconnect the steering knuckle;

- Dismantle the unit;

- Replace the brake disc, spring and other elements on the new strut, and then reassemble.

It is important to remember that after such a procedure it is necessary to adjust the wheel alignment, because when dismantling the shock absorber, the camber bolts are disconnected.

VARIETIES AND CHECKING THE CONDITION OF THE SUPPORT BEARING

Many owners of VAZ 2114 cars often encounter the problem of extraneous knocking in the struts, the main cause of which is the support bearing. If you suspect a fault in the support bearing, you do not need to immediately rush to replace it; first of all, check its condition.

Before assessing the importance of the support bearing in the overall assembly of the car, it is necessary to understand the structure of the suspension. In the assembly of VAZ models, hydraulic struts are used, the main function of which is to smooth out vibrations in the suspension spring during driving, and also to ensure the quality and safety of its operation.

The support bearing is a component of the front suspension shock absorber strut. Its function is to allow smooth movement of the connection between the shock absorber and the car body. If it malfunctions, problems arise with driving the car, and an unpleasant knocking sound occurs in the suspension, especially when driving on a bad road.

VARIETIES OF SUPPORT BEARING

- With inner built-in ring or outer built-in ring. For installation there is no need to use clamping flanges; in this case, holes are provided for installation.

- The outer ring is detachable.

- The inner ring is detachable.

- The finishing bearing has strong rigidity.

Type of support bearing

The support bearing has a self-explanatory name; it is something like a support for the front shock absorber strut, located in the area of the connection with the car body. This arrangement provides for axial loads that the bearing can withstand.

To make an accurate diagnosis of a support bearing, it is necessary to carry out a number of simple manipulations:

- Under the hood of the car, you need to place your palm on the bearing. At this moment, the second person is pumping the car, the appearance of knocking indicates the need for an urgent replacement of the support.

- But, still, it is better to carry out the necessary procedures for removing and subsequently disassembling the bearing.

A completely deteriorated bearing, in addition to knocking, disrupts wheel alignment; this factor creates a danger when driving and increases wear on the shock absorber struts

Those drivers who categorically do not want to pay attention to the malfunction of their own car increase the chance of complete bearing failure, which will result in a hole in the hood from the strut. And as a result, financial investments increase significantly

Think about whether this is a way to get away from the problem that has arisen.

Functions

As you probably know, the VAZ 2110 model has an independent front suspension and hydraulic struts. The purpose of the struts is to dampen vibrations that occur when the springs move.

Let's look at the situation. You are driving along the road and the wheel falls into a decent hole. One side of the car begins to rock. If there were no rack, your car would rock for a very long time.

Fasteners play an important role. The rack is mounted on top of the body, and on the bottom - to the steering knuckle. To make the connection between the body and the shock absorber movable, an adapter is used - a support bearing. Actually, from the name of this transition element it becomes obvious that the device is designed for maximum axial and radial loads, and is located directly at the junction with the body of your car. It is difficult to overestimate its importance for your comfort and safety.

How to remove and replace with your own hands, is it possible from above?

Now we come to the most interesting part - how to remove it? You know, here I immediately want to answer all those who are trying to replace him from above - GUYS, this is unrealistic! It is locked by the car body (if you want the front “glasses” of the pillars), it is against them that it rests and to remove it is impossible to replace it from above, only from below.

Well, let's go, I'll tell you in detail point by point:

- First we need to understand that we need to remove the front drain completely. To do this, we lift the car, the front part. We remove the wheel.

- We need to disconnect all the auxiliary fastenings from the strut, this could be the fastening to the caliper, the stabilizer link fastening, the ABS sensor and brake hoses fastening.

We unscrew the three nuts from the top (under the hood) and pull out the shock absorber strut.

Now we need to “pull” the spring, because it often rests against the bearing itself, that is, it is the upper thrust cup.

Next we need to unscrew the nut from the strut (the one that secures the bearing and shock absorber rod). This is a problem because if you twist the nut, it will rotate along with the rod. For such work, you need a special wrench, or a head and bit are usually used T We turn the head with a gas wrench, and fix the bit with a holder.

After this, the support bearing will be removed and can now be replaced. Next, we repeat the process in reverse order.

Probably, the instructions are a little unclear, so we’ll watch the video version.

This is how to remove and replace the “support”, I think I explained it clearly. Read our AUTOBLOG, there will be many more useful articles and videos.

The front support struts, as well as the support bearings, are constantly subject to severe loads, especially when the vehicle is driven on uneven roads or rough terrain. Timely replacement of support bearings helps prevent complete failure of the entire chassis and the need for its overhaul.

As you know, a faulty chassis is fraught with loss of controllability, therefore there is a threat to the safety of the life of the driver and other road users.

In this article I will talk about how to replace the front strut support bearing on a VAZ 2110

with your own hands without the need for wheel alignment. The support bearing will be replaced without unscrewing the camber bolts, this will allow us to avoid the need to adjust the wheel alignment.

Before replacing the VAZ 2110 support bearing, you need to take care of the tools. To complete this job you will need:

- Tie for springs, a special device for unscrewing the nuts of the struts.

- Steering wheel end remover.

- Standard set of keys.

- Jack, hammer, mounting.

- Assistant (preferred).

- New support bearing.

What does a breakdown lead to?

If the carrier bearing fails, a muffled knocking noise will be heard from the front of the machine. It is especially pronounced when driving on uneven roads. This means that the integrity of the element is compromised. He is no longer able to perform the task correctly. The reasons may be:

- the service life has been exhausted;

- the suspension was under too much load;

- the bearing is dirty inside or moisture has entered it.

Any malfunction of the vehicle's front suspension can cause partial loss of controllability and deformation of the bearing housing. A defect can cause a breakdown of the “glass” to which the shock absorber is connected. The geometry of the body will be disrupted and handling will deteriorate. In addition, the rack can receive serious damage.

Fault diagnosis

How to prevent possible consequences? To do this, you just need to know the signs of a faulty front strut support bearing. These include knocking (crunching) in the area of the upper shock absorber mount when driving on uneven roads, as well as a decrease in control efficiency.

In order to make sure that the support is faulty, it needs to be checked. This is done as follows:

- Raise the hood of the car, remove the lid from the “glass” being diagnosed.

- Place your palm on the top of the “glass” where the stand is attached to the support.

- With your other hand, rock the car body in vertical and horizontal directions.

If the support bearing of the VAZ front strut is faulty, it will indicate this by the appearance of a characteristic knock and vibration. You will definitely feel the latter with your palm.

Basic faults

When a support bearing fails, a knock resembling dull blows appears in the front part of the car in the area of the pillars. Most often, such symptoms are observed when driving over uneven surfaces.

A knock indicates that the bearing has ceased to cope with its duties due to a violation of its integrity. This is caused by the destruction of its structure due to:

- exceeding the recommended resource;

- excessive dynamic loads;

- dirt and moisture getting inside the bearing.

However, knocking in the area of the racks may have other causes. To check the bearings and make sure that they are the ones knocking, lift the hood of the car, remove the cover of the supposed “glass”, and place your palm on the upper shock absorber support.

Rock the car up and down. If at the same time you hear the same knock and feel the corresponding vibration with your hand, immediately replace the bearing.

Bearing manufacturers

You need to select spare parts before replacing the bearings on the machine. Similar products are installed on Priora and Tens. The highest quality products are produced by the following companies:

- SKF.

- KOYO.

- SNR.

The cost of products is very high - this is a fact. But their service life is longer than that of their domestic counterparts. If you want to save money, purchase domestically produced products, their cost is about 500-700 rubles per piece. It is advisable to choose spare parts from those companies that are recommended by AvtoVAZ. Remember that installing a new bearing will ensure stable operation of the suspension and will eliminate rattling in the place where the strut is attached to the body for a long time.

Tips for choosing

Try to buy bearings for VAZ from trusted stores. Remember, the likelihood of running into a fake is especially high when the item is ordered online.

Be sure to inspect the part before purchasing - it is important to pay attention to the overall quality of workmanship (smooth edges, absence of visible defects, etc.).

Don't forget to ask the seller for a certificate of conformity. Remember, bearings have a warranty, so please fill out a coupon in your passport.

Avoid cheap Chinese ones - of course, they will only cost 250-300 rubles apiece, but they will most likely last a very short time, and it’s not a fact that you won’t have to completely change the stand afterwards.

OP is the most important element in the design

Replacing the support bearing VAZ 2109

As you know, a support bearing or OP, as we will call it in the future, is designed to perform certain functions. Its main task is to rotate the stand around its axis. The OP is located in the front suspension and on a front-wheel drive car, such as the VAZ 2109, however, as on a rear-wheel drive car, in fact, it is the most important link. Before we move on to the direct algorithm for replacing the OP, we will find out important information regarding this bearing. So:

The VAZ 2109, like all modern cars, has in its design not only an elastic, but also a damping device called a shock absorber to control movement. This is one of the main components of the front suspension.

Replacing the support bearing on a VAZ 2109

- OP is an integral part of the rack support. These parts belong to the group of rolling bearings. They have found wide application in domestic mechanical engineering due to many advantages, among which I would like to highlight versatility, the perception of combined loads and much more.

- The OP is directly involved in damping road vibrations, or, to put it differently, in damping and amortizing the VAZ 2109. In this case, the OP makes a movable connection between the shock absorber and the car body, simultaneously influencing the accuracy of the wheel mounting angle settings.

OP Features

Replacing support bearings in a VAZ 2109

The OP still differs from the standard rolling bearing, although it belongs to the same group. Here, the role of rolling bodies is always cylindrical rollers located perpendicular to each other. In addition, each of the rollers is protected from contact with each other by a special separator. Thus, each of the rollers acts as a separate element, independently taking on loads from different directions.

Replacing support bearings for VAZ 2109

In modern cars, such as the VAZ 2109, the following types of OP are usually used:

- A bearing with a built-in ring (it can be internal or external). This type of bearing is equipped with mounting holes and does not require pressure flanges. In addition, this type of OP has built-in gaskets that ensure constant rotation accuracy. This type of OP is used for both rotation of the outer and inner rings.

- There is another type of OP, which is equipped with a detachable inner ring for rotation of the outer one. The outer ring in this type of OP is in contact with the body. This type of OP is used where precision rotation of the outer rings is usually required.

- The third type of OP is a bearing with a detachable outer ring for rotation of the inner one. In this type of OP, the inner ring is in contact with the body, and the outer one is separated. It is used where it is necessary to ensure the accuracy of rotation of the inner ring.

Replacing the support bearing on the strut of a VAZ 2109

The fourth type of OP is called single-split. In such a bearing, the outer ring is divided at one point, which is why the rigidity of the entire bearing increases. It is again used where it is necessary to ensure high rotation accuracy of the outer ring.

Basic rules for using OP

As a rule, malfunctions of the strut support are detected while the vehicle is moving. If there is a problem with the strut, a characteristic knocking sound can be heard, especially when driving on a rough road.

So:

The OP is subjected to enormous loads while the car is moving, because it is this element that restrains the rebound movement of the shock absorber. Because of this, this bearing is checked every 20 thousand kilometers for malfunction, and every 100 thousand kilometers requires mandatory replacement, regardless of the condition of the strut itself.

Replacing support bearings on a VAZ 2109

Symptoms of a problem

The most obvious sign indicating that it is time to change the part is a characteristic knocking sound that occurs in front of the car when making a turn. In some situations, the noise is accompanied by a slight vibration of the steering wheel.

However, the symptom described above does not always appear. In a VAZ model 2110, the inner part of the bearing protrudes slightly. The rod of the shock-absorbing unit passes through it, as noted at the beginning of the article. If the part is seriously worn out, then noticeable play appears, which causes the rack to wobble. All this disrupts the wheel alignment.

In the described case, a malfunction of the support element manifests itself as uneven driving in a straight line. Because of this, the driver is forced to constantly adjust the steering movement.

An incorrect camber angle sharply reduces the service life of the shock-absorbing support - in this case it lasts about 20 percent less than usual. In addition, the work resource is reduced:

- tires;

- steering rods;

- their tips;

- brake hoses, etc.

Changing the support bearing without adjusting the camber

- Unscrew the two bolts used to secure the ball joint. Disconnect the brake line mounting from the shock absorber strut. First unscrew the 17 bolts holding the brake caliper. After this, hang the working part of the brake mechanism to other suspension elements.

- Unscrew the strut nut, but do not do it all the way. Unscrew the three nuts that secure the shock absorber. At the same time, unscrew the CV joint nut completely. Pull the grenade and pull the rack out. Remove the springs from it using a puller.

- After tightening the spring, unscrew the old bearing and install a new one in its place. Then reassemble all components in the reverse order, depending on the chosen replacement method.

- When installing the hub nut, do not use an old fastener. The nut is disposable and is replaced after the first unscrewing. The new nut must be locked after tightening.

Replacing the support bearing VAZ 2115

A characteristic symptom of a faulty bearing is a knocking sound in the suspension while driving. This part needs to be replaced urgently. How to check a bearing? It’s very simple: just grab it with one hand and, either yourself or ask someone for help, begin to rock the car little by little. The appearance of unnecessary sounds will be evidence of a failed bearing.

The replacement procedure is as follows:

- We jack up the car and remove the wheel

- Turn the steering wheel in the opposite direction from the one from which the repair is taking place

- Using a hammer, remove the cotter pin and use a head to unscrew the support mounting bolts

- Release the caliper bolts

- Unscrew the three ball joint bolts

- We unscrew the bearing fasteners, remove the old part along with the stand

Then we install a new support bearing. Then all we have to do is assemble the entire structure in reverse order. Which support bearing is best to choose for the VAZ 2115?

I recommend that you install ss-20. I constantly install these support bearings, they are very reliable and durable. They travel at least 30 thousand kilometers, I have been convinced of this more than once. There are conflicting opinions regarding the product on the Internet; many say that glasses and stands with ss-20 do not last long. But personally, I don’t trust these kinds of statements, but prefer to check everything from my own experience. Therefore, I fully vouch for the ss-20 support bearings.

Hello, dear friends! Let me call you exactly that. Today we have to discuss a fairly relevant topic for almost any car and its owner. We'll talk about the front strut support bearing.

Alas, the quality of our roads leaves much to be desired. Sometimes, when I travel outside the city center or into the suburbs, I am amazed at how anyone can drive there without visiting a service station every week.

The condition of the roads largely determines the need to change the support bearing quite often. The part is not the most expensive, but you will have to tinker with it if it fails.

How to find out that the support bearing is broken

In the vast majority of cases, the support bearing fails due to severe contamination. Therefore, if you often drive in bad weather or travel on almost complete off-road conditions, this part will break down much more often than when using the car in the city.

What symptoms indicate bearing failure? There are several of them:

- knocking of the front suspension when driving even on small uneven sections of the road;

- an unpleasant grinding or crunching sound when turning the steering wheel in any direction;

- clicks that can occur even while driving on a flat road.

Replacement of the VAZ-2110 support bearing should be carried out immediately after detecting any of these symptoms. Otherwise, the safety of car operation is significantly reduced, the risk of rapid tire wear increases, the support struts fail, the restoration of which will cost much more.

Checking shock absorbers

Shock absorbers also have their own service life, which is noticeably reduced when driving on domestic roads. The main damage to a shock absorber is loss of fluid. Eliminating this problem is only possible if the part is collapsible. If a solid shock absorber leaks, you will have to buy a new one.

Checking the condition of shock absorbers does not take much time and is done visually. So, if oil leaks are observed on a part, it must be changed urgently. You can check the condition of this suspension unit by rocking the car on each side. If the car swings for a long time due to inertia (on the springs themselves), then the shock absorber is faulty. The disadvantage of this diagnostic method is that you can only check a truly “dead” shock absorber.

What causes the support bearing to fail?

A journal bearing of any type remains highly vulnerable to sand, salt, water and dirt. All this penetrates into the structure relatively easily and greatly accelerates wear. Reduces service life and mechanical as well as dynamic effects on the suspension. For this reason, the service life of the element is no more than 100,000 kilometers.

The parts discussed in this article seriously suffer if the car is operated in difficult conditions. Accelerated wear of a part is common when:

- you have to constantly drive off-road;

- the driver ignores optimal speed limits;

- turns are made without preliminary braking.

The lack of protection of bearings from dirt and water adds to the problem. Even in situations where the part is equipped with a rubber cap, the vulnerability remains. The trouble is that the last element often slips or breaks.

Dirt, water, sand, etc. penetrating into the support bearings eventually mix with the lubricant and create an abrasive composition that erases the moving elements of the part.

It is not difficult for the owner of a VAZ-2110 to prevent the occurrence of the described trouble - it is necessary to regularly check the integrity of the protective caps and change them in a timely manner. This measure will extend the life of the supporting element by approximately 15 percent.

To avoid serious damage somewhere on the road, think about replacing the elements in question after 60,000 - 70,000 kilometers.

Types of bearings

There are two design versions of the upper part of the rack:

- The support bearing is included in the support design (can be found on a number of VAZ models);

- It is a separate element that is placed between the support and the upper spring cup.

But there are several support bearings themselves that are used in the suspension design:

- WITH BUILT-IN OUTER OR INNER RING. Its peculiarity lies in the possibility of rotation of elements that are in contact with both the outer and inner rings. Additionally, this option provides installation holes, so no pressure flanges are needed during installation;

- WITH DETACHABLE OUTER OR INNER RING. In this embodiment, one of the rings (depending on the design) can be separated, while the second is fixed to the support;

- SINGLE-SPLIT. Structurally, this option is the same bearing with a detachable ring, but has increased rigidity.

In general, there is no particular difference which type of bearing is used, the main thing is that it performs its functions.

Despite the fact that the upper part of the strut is installed inside a special niche in the wheel arch, dirt, sand and dust penetrate the support, and these contaminants are destructive to any bearing.

Additionally, the support bearing is almost constantly subjected to rapidly changing loads, including shock loads (due to the operation of the spring), which, in combination with contamination, leads to intense wear of the bearing components and its failure.

Due to rather difficult operating conditions, the service life of such a bearing is limited. Many manufacturers indicate that it must be replaced every 100 thousand km.

But in reality, due to the poor condition of the roads, they require replacement after 50 thousand km. At the same time, the resource of this node also depends on its quality.

It is not uncommon for a support bearing to be replaced after 10,000 km.

Varieties

At the moment, VAZ 2110 cars are equipped with various types of bearings, which have their own design and functional features. Let's look at them.

Bearing type

Peculiarities

With integrated inner or outer ring

Their peculiarity lies in the presence of special mounting holes provided by the manufacturers. This eliminates the need for additional flanges. Such bearings guarantee rotation of the units when using both the inner and outer rings

In such bearings, the rings are mounted inside

With detachable externally mounted ring

The peculiarity of the element is that the outer ring can be separated if desired, and the inner ring seems to merge with the car body

There is no significant difference from the bearings under consideration, however, the rigidity of the rings is much higher.

When choosing a bearing, you should focus on quality. This is the most important criterion when purchasing.

What to choose?

Now let's talk about what manufacturers are ready to offer us today.

- Regular ones. Purchasing them will cost you about 300-400 rubles apiece, depending on the region and store. Good design, solid resource.

- Cheap Chinese supports. You will pay about 300 rubles for them, but the quality literally screams not to buy.

- Foreign and domestic analogues. Here we advise you to pay special attention to such products as TRACK, ASOMI, SS20, Fenox. Good quality, more reliable resource compared to standard ones. But you have to pay for quality. Any of the presented bearings today will cost no more than 800 rubles per unit.

- If simply replacing the bearing is not enough, you will have to replace the entire upper support. You will spend about 1500-3000 rubles on this. And only on one support.

- Those who do not want to do the repairs themselves, considering the procedure for replacing the support bearing to be too complicated, can contact a service station. To replace one element you will pay at least 500 rubles.

Which of the presented support bearings is better is a popular question. Choose high-quality analogues, or opt for domestic components. But under no circumstances choose China if you value your car.

Conclusion

Having gained an understanding of what a support bearing is, how this part works and what problems can arise if its wear is ignored, every motorist will begin to listen to the movement of his car while driving and when cornering. If you hear a characteristic knocking sound coming from a wheel, don’t be too lazy to go to a service station or service center and carry out a small diagnostic of the chassis, this way you will save yourself time and nerves, and your VAZ 2109 will thank you.

Few people know, but bearings are used not only in rotating parts. This article will focus on the support bearing. You will learn what it is, how to diagnose a malfunction and how to replace a VAZ support bearing?

Cause and symptom of support bearing failure

It goes without saying that timely replacement, repair and, in general, any modernization of a car brings greater effect and success. In particular, if you are late in replacing the bearing, you can damage other important parts and components of the machine. The entire chassis can even fly off if you are not careful about your car. And then just a replacement won’t do, and you’ll have to do a major overhaul. The main cause of failure of this bearing is dirt. We conclude that if we drive often off-road, we will have to replace this component more often. The support bearing itself is practically not protected by anything. A symptom that the bearing has failed is a knocking sound. But to finally be sure that the reason lies in the support bearing, diagnostics by turning the steering wheel to the right and left will help.