Having made sure that the car’s clutch is not functioning at the proper level, it is necessary to replace it as quickly as possible. The following signs may indicate that the mechanism is worn out:

- the clutch release pedal travel increases;

- self-adjustment only allows you to restore the operation of the pedal at the very top;

- Driving uphill is very problematic.

If the above symptoms are present, the clutch should be replaced as quickly as possible to prevent an emergency on the road. You can carry out this process yourself, if you take into account the advice and recommendations provided by experts. However, first of all, you need to determine which clutch is best installed on the VAZ-2110 model, so that in the future you do not have to replace the unit again.

Clutch VAZ-2110

Clutch VAZ-2110.

Despite the fact that the ten clutch is primitive, like a cart wheel, it must meet many parameters in order to flawlessly perform its functions - high-quality transmission and complete interruption of the transmission of torque from the engine to the gearbox.

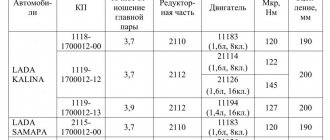

In addition (and few people know this), two types of clutches :

- for cars with a carburetor or injection engine and a torque of 116 Nm ( 2110 and 2111 );

- for 1.6-liter engines with a torque of 128.3 Nm ( VAZ 2112 ).

You can distinguish a VAZ-2112 clutch by the hole in the slot of the petals and the damper springs.

Parameters and requirements

Each clutch set is required to transmit exactly this torque with at least a double reserve, which is why they are labeled differently - 243 and 270 Nm.

In addition, you should not discount the weight of the basket assembly, the weight of the driven disk and such an important factor (which our left foot will immediately feel) as the squeezing force.

And another standard is moving the pressure plate . This parameter should be 7.9-8.1 mm . The thickness of the driven disk is also important, not only in the free state, but also under load. The manufacturer must measure it under a load of 3.4 thousand N. As you can see, not everything is so simple with such a simple kit. Now let's listen to the reviews and reports of the expert laboratory.

Clutch hydraulic drive device

The clutch engagement hydraulic drive consists of the clutch release master and slave cylinders connected by a pipeline. Through the pipeline, pressure is supplied to the working cylinder, which in turn transmits force to the central diaphragm spring of the clutch through the clutch release bearing. The clutch slave cylinder is assembled into a single unit with a release bearing (spare parts catalogs use both of these names to designate the part) and is installed in the clutch housing.

Brake fluid is used as the working fluid in the clutch hydraulic drive. It enters the clutch master cylinder through a hose from the brake master cylinder (MBC) reservoir. For this purpose, a pipe is made on the left side of the tank (No. 3 in the photo). The working fluid must be replaced regularly according to the maintenance plan.

Malfunctions of the master and slave cylinders include:

- wear of the clutch master cylinder cuffs;

- leakage of working fluid at the junction of tubes and fittings and from under the cuffs of the cylinder pistons.

Comment. If the working cylinder is leaking, brake fluid leaks from below from under the clutch housing. The presence of oil leaks in the same place is caused by wear of the gearbox input shaft oil seal. You should also check the clutch hydraulic hose and tube to make sure there are no cracks, cuts or other damage. We replace faulty parts.

Proper operation of the hydraulic clutch release drive is only possible if there is no air in the system, due to which the clutch may not disengage completely. As a result, changing gears will be difficult or impossible. Air can enter the system when the fluid level in the GTZ tank drops below the permissible limit, as a result of a violation of the tightness of the connections.

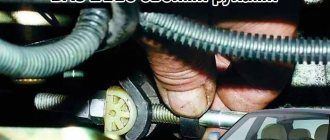

To remove air, it is enough to bleed the clutch release hydraulic drive. The bleeder fitting is made in the tip of the hydraulic drive tube.

Adjustment of the clutch release hydraulic drive during operation is not provided.

Choosing a clutch - articles and brands

From the factory, our car was equipped with kits with factory part number 2110-1601180 on the basket.

VIS clutch kit for VAZ 2110-12: basket, disc, release bearing.

The driven disk must have part number 2110-1601130 . This kit is produced by the VAZInterService (VIS) plant, the external distinctive features are a diaphragm with 12 blades, one-piece smooth friction linings of the driven disk, the disk itself has 6 damper springs. The quality of the original kit is so-so. The high level of imbalance of the driven disk exceeds the permissible limit by almost twice. In addition, the VIS kit is quite heavy compared to its competitors.

This was also reflected in the preferences of the public - only 6-8% of users buy this kit for 2.8 - 3 thousand rubles.

Analogs

This is the most common choice of tens!

In addition to the Togliatti VIS plant, on the shelves you can find a lot of clutch kits from a variety of manufacturers, both domestic and foreign. Among the latter, a huge share is Chinese counterfeit. In principle, the list of the most popular manufacturers looks something like this:

- German clutch LuK (Lamellen und Kupplungsbau), driven disc 320 030810 , basket 2 D24 120 0252 10 .

- Their fellow countrymen, Sachs.

- Also the Germans FINWHALE and QML.

- Turkish companies Starco, Mapa, Kraft (article 2110 W3200C B2240 ).

- VALEO, France, article number 21102 - 21103 - 21108 - 2111 - 2112 826622.

- HOLA, Holland.

- MecArm and PILENGA from Italy.

- South Korean company FORTECH.

Domestic factories from Naberezhnye Chelny and Tyumen, as well as the local Nachalo brand, are also quite widely represented, but the quality of their clutches is difficult to compare with German, say, kits. And now a few words about how to choose a high-quality clutch on a VAZ-2110 without resorting to laboratory tests.

Real reviews

Reviews were collected on automobile forums and websites, where negative and positive impressions were left by people who used the Sax clutch.

| Good feedback | Bad reviews |

| I haven't found any shortcomings yet. I have been repairing cars myself at the service center for many years and know everything about such devices. As a specialist, I can say that the disk of the Sachs mechanism works with reinforced springs. These springs last longer than analogues. The service life of the basket and the entire device as a whole depends on the service life of the springs. In general, just for fun, you can stop by a car service center and ask how often Sachs clutches are repaired and replaced. There was one request for my service with such a device. | I put the Sachs clutch on nine (VAZ 2109). Many people recommended this particular brand. After assembly, I immediately began testing. At first and second speed everything was fine, when I switched to 3, vibration started, and at 4 speed a grinding noise began, as if metal was rubbing against metal. At a speed of 70 km/h the car stalled. The clutch turned out to be bad. |

| Before buying a new clutch for my car, I chose between Sachs or Valeo. Sachs was cheaper, so I chose it. This is my second year using a car with this clutch, and I have no complaints yet. Compared to VAZ clutches, the difference is big. | For the first 1000 km everything was fine, there were no problems with this clutch. Then, sometimes the engine power began to be lost. Then the basket flew. It may have turned out to be a fake, but I bought it from Saks. |

| Sachs has been using its four (VAZ 2114) for three years now, with a mileage of more than 30 thousand km. After installing the turbine, the factory VAZ clutch drove 300 km. | I made a mistake buying Saks. After 200 km of travel, a knocking noise began in the clutch area. It turned out that the release bearing had broken. Then I didn’t change the whole thing, not just the bearing. Then the basket broke. |

| I installed Sachs on a Chevrolet Lacetti and am pleased. Before that, I traveled with the factory device for 5 years. |

Perhaps the bad reviews appeared due to fakes, perhaps they were “roughly” installed, or perhaps, in fact, sometimes original clutches of low quality appear.

If less than 12 Volts or more than 14.5 Volts are supplied to the battery, then the regulator is faulty. We have already looked at how to check the voltage regulator. Follow the link.

Choosing a high-quality clutch for ten

For example, we have already decided on the brand. More precisely, with the price. Since the prices for all kits are different - from cheap domestic ones for 2500 rubles and ending with German clutches for 7-8 thousand.

However, no one is safe from counterfeiting, so we check each element of the kit visually upon purchase.

Driven clutch disc

The driven clutch disc from Valeo is a good combination of price and quality.

- First, we look at the surface of the friction linings - there should be no cracks or irregularities There can be no scuffing or roughness. Moreover, it is unacceptable for oil or other technical fluids to get on the friction clutch . It would seem that these are basic things, but manufacturers of counterfeit or very cheap spare parts are not able to comply with these conditions.

- Next we look at the splines. There should be no damage, scuffing is excluded.

- We pay special attention to the quality of the riveting. If you look closely, you can see that the shape is riveted. It is different for branded wheels and fake ones - the rivet should be uniform and not differ from rivet to rivet.

- We look at the damper springs, which should not have any play or displacement.

- In addition, pay attention to the markings - as a rule, they will be applied to the damper plate. It could be a hologram, a simple stamp or laser marking, but there must be something that says about the manufacturer.

Clutch basket

Here the selection criteria are the same.

LUK clutch basket – German quality for a Russian car.

- Initially, we inspect the quality of the rivets and plates. All rivets must be identical, there should be no backlash. All rivets must be laid without distortions or displacements of the axes; there should be no cracks or chips on the heads.

- The basket body itself is made by stamping, so we look at its quality - there should absolutely be no nicks, cuts, chips or scratches. There should be no burrs in the holes.

- The pressure plate itself deserves special attention . It is cast from cast iron, after which the working surface is polished. It is the mirror of the pressure plate that will tell a lot about the manufacturer - cavities, scratches, microcracks, unevenness, and radial scratches are excluded. If there are no defects, then the disc is made of high-quality cast iron and processed in accordance with technology and high-quality equipment.

What to do when slipping and jerking

It also happens that the clutch does not engage completely; when activated, so-called slippage is observed. In this case, the cause of the malfunction may be:

- failed friction linings that need to be replaced immediately;

- the disk surface is filled with machine oil. To fix the problem, you will need to replace the engine and gearbox seals;

- malfunctions in the car drive. In this case, it is necessary to check the functionality of the entire drive and replace those components that are faulty.

If jerking is observed when the mechanism is activated, the following reasons may cause this problem:

- Automotive oil gets on the surface of the unit. How to eliminate the cause was described earlier.

- Disc deformation. In this case, you will need to replace the damaged element with a new one.

- Sticking when pressing the pedal. To fix the problem, you will need to find out exactly where the mechanism is jamming.

If the clutch completely disappears while driving, you must stop the car and contact a towing service for help. Under no circumstances should you continue driving as this may cause a serious accident on the road.