Which clutch is best for Kalina

| The clutch life of the Lada Kalina depends not only on the quality of the components, but also on operating conditions. If the clutch kit has served for about 100,000 km, then it is considered good. Do you know what clutch to put on Kalina? |

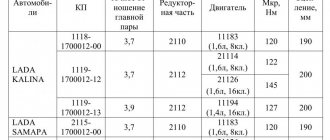

What kind of clutch does Kalina have from the factory? On VAZ 1117, 1118 and 1119 two types of clutch can be installed: 190mm. and 200mm. You can determine which clutch without disassembling the box: if the number of starter mounting bolts is 2, then the clutch is 200mm, if there are 3, then it is 190mm. Accordingly, the clutch manufacturer can also be different: VazInterService (VIS), or LUK.

The Kalina clutch is sold as a kit, which includes a clutch basket, clutch disc and release bearing. The approximate price of a clutch for Kalina is about 2000 rubles, the cost can vary greatly depending on the region.

| № | Catalog number | Name |

| 1 | 2108-1601207 | Bolt |

| 2 | 1111-1601182 | Pressure bearing |

| 3 | 2110-1601180 | Clutch assembly |

| 4 | 2108-1601188 | Spring |

| 5 | 2112-1601085 | Clutch disc |

| 6 | 11186-1601130 | Clutch disc driven |

The most popular clutch kits from companies: Valeo, Sachs, Luk, VIS, Kraft. It is worth noting that the Valeo and Luke clutches are softer than the others.

Is it possible to install a clutch from a VAZ 2110 on Kalina? The clutch must be installed in accordance with the flywheel; the type of flywheel is determined by the starter studs. Two studs - clutch 2110, 2112, 11183, three studs - clutch 2108. If the flywheel is 2110, then you can install a clutch from a VAZ 2110, 2112 or the original Kalinovskoe 11183.

To buy an original clutch for Kalina , and not a fake, it is recommended to contact trusted stores, rely on reviews, or order a clutch kit online directly from the manufacturer. Which clutch kit for Kalina do you think is the best?

Source

What kind of clutch is on the viburnum?

Information taken from here 100% method for determining clutch

Once again I was puzzled by the issue of replacing the clutch. There are plenty of reasons: the pedal travel is small, sometimes the speeds are not turned on and switched the first time, etc. But the question arose which one to take?! When they changed it for the first time, the "servicemen" installed their own clutch and, judging by the receipt, it was

. But maybe this information will be useful to someone

Determining the size of the clutch basket without removing the gearbox. (the starter needs to be removed, but this is not a gearbox, 10 minutes if with smoke breaks)

First, a few facts

190mm (2108) 200mm (2110 aka 2112 aka Priora)

- accordingly, 2 types of flywheels 2108 and 2110 are used on the flywheel 2108 you can only put the basket 2108 on 2110 only 2110 fasteners in different places

-flywheels are of different diameters (2110 is larger) and they have different ring gears (for the starter)

— the distance between the axes of the input shaft and the starter is the same for all types of crankcase (for 2 or 3 studs)

Hence the conclusion that the size of the bendix depends solely on the size of the flywheel.

(center distance = flywheel crown radius + bendix gear radius) A smaller gear diameter corresponds to a larger flywheel and, naturally, a 200mm basket.

Starters can be 2108 (3 studs, front bushing in the crankcase) by the way, my Kalinka has a starter with 2 studs

or 2110 (2 studs for the front hub on the starter itself) In addition, 2108 can be geared or gearless. It doesn’t matter at all. Any starter can fit any clutch. It all depends solely on the Bendix.

PS. For the especially boring ones. In addition, baskets 190 and 200 differ in fastening.

those distances alternate 75mm 155mm 75mm 155 ... perhaps this can be seen through the starter window (with a mirror) I haven’t tried it

What is this?

Structurally, the mechanism is represented by the following elements:

The slightest malfunction in the system affects the operation of the machine. Experienced drivers understand the presence of problems with the clutch by the following signs:

There are many reasons for a faulty transmission mechanism. Among them:

If there is contamination, cleaning is enough to restore the unit's operation. If several elements of the device have failed, then it is more advisable to replace it. Experts advise buying new parts, because old parts soon fail and you have to look for a working spare part again. Car experts note that the average clutch life is up to 100,000-150,000 km. Much also depends on the driving style of the motorist.

VESKO-TRANS.RU

The Lada Kalina car has gained well-deserved popularity among people, which has only increased over time, since this car has proven its highest performance at low maintenance costs.

Video of the clutch replacement process on a Lada Kalina:

Replacing the clutch on Lada Kalina

But, like in any other car, there are some components that need constant replacement after a certain mileage. Such knots. this is the grip without which every machine cannot exist.

In the process of replacing the clutch

Changing the clutch on a Lada Kalina yourself is difficult, although possible. Below in our article we will describe in detail how to complete such work from start to finish without making mistakes.

Types of clutch in Kalina

On the VAZ 1117 , 1118 and 1119 there are two different types of clutch: 190 and 220 mm. Finding your own diameter is painfully simple, just pay attention to the number of starter mounting bolts. There are 3 of them by 190 mm, 2 by 200 mm. Regardless of the manufacturer's office, you will almost always find a clutch disc, pressure plate and bearing in the assembly.

New clutch kit

If there are traction problems on the road, you need to take a tow truck as traffic may be blocked by a roadblock in the future.

What malfunctions can happen to the clutch?

Although this list is small, if problems arise it can cause quite a few problems:

Lada Kalina is a good car, powerful and durable. And yet, the design of the model has a number of unreliable elements that make themselves felt over time. These include the clutch. In order to identify the malfunction and correct it correctly yourself, without contacting expensive car services, it is important to know what the mechanism is intended for and how the clutch on Kalina is replaced.

Replacement instructions

The clutch transmits torque from the transmission to the engine. The transmission is carried out thanks to the clutch cable, which connects the power unit to the gearbox and ensures starting the car, shifting gears and braking. Thanks to the lever mechanism, the car is set in motion.

Which clutch should you choose?

There are several types of clutch, differing:

The clutch is a complex mechanism, so before replacing it on your Lada Kalina yourself, you should carefully study the design and features of the mechanism.

On VAZ 1117, 1118 and 1119 clutches of 190 and 200 mm are installed. The diameter can be determined by the number of starter mounting bolts. For 190 mm there are 3 of them, and for 200 mm - 2. This includes a clutch disc, basket and release bearing. The most popular brands are: Valeo, Sachs, Luk, VIS, Kraft.

When using a drive from other models, you need to pay attention to the flywheel, the type of which is determined by the number of starter pins. There are two of them in the Lada Kalina, and three in the VAZ 2108. The clutch resource depends on the components and operating conditions. A high-quality drive can last for 100 thousand kilometers.

If troubles occur with the clutch on the road, it is better to call a tow truck or have the car towed by another vehicle, otherwise this may lead to gearbox failure.

Tools

To replace the clutch, the car must be raised, since some of the work is performed from below. To do this, you can use a lift, overpass or inspection pit. From the tools and materials for the replacement procedure with your own hands, you need to prepare:

When dismantling the gearbox, the oil must be drained. If you carry out the work yourself, then you need to drain all the lubricant. If you have an assistant, you can drain some of the liquid from the wires so that oil does not leak when they are disconnected.

Stages

To carry out the replacement yourself, you need to place the car on an overpass or provide access to the bottom of the car in another way. Replacing the clutch on a Lada Kalina consists of:

Thus, replacing the clutch on a Lada Kalina can be done with your own hands without the help of specialists from a car service center.

Why did it happen so?

Perhaps the automatic requests do not belong to you, but to another user accessing the network from the same IP address as you. You need to enter the characters into the form once, after which we will remember you and be able to distinguish you from other users exiting from this IP. In this case, the page with the captcha will not bother you for quite a long time.

You may have add-ons installed in your browser that can make automatic search requests. In this case, we recommend that you disable them.

It is also possible that your computer is infected with a virus program that is using it to collect information. Maybe you should check your system for viruses.

If you have any problems or would like our support team, please use the feedback form.

| The clutch life of the Lada Kalina depends not only on the quality of the components, but also on operating conditions. If the clutch kit has served for about 100,000 km, then it is considered good. Do you know what clutch to put on Kalina? |

What kind of clutch does Kalina have from the factory? On VAZ 1117, 1118 and 1119 two types of clutch can be installed: 190mm. and 200mm. You can determine which clutch without disassembling the box: if the number of starter mounting bolts is 2, then the clutch is 200mm, if there are 3, then it is 190mm. Accordingly, the clutch manufacturer can also be different: VazInterService (VIS), or LUK.

The Kalina clutch is sold as a kit, which includes a clutch basket, clutch disc and release bearing. The approximate price of a clutch for Kalina is about 2000 rubles, the cost can vary greatly depending on the region.

| № | Catalog number | Name |

| 1 | 2108-1601207 | Bolt |

| 2 | 1111-1601182 | Pressure bearing |

| 3 | 2110-1601180 | Clutch assembly |

| 4 | 2108-1601188 | Spring |

| 5 | 2112-1601085 | Clutch disc |

| 6 | 11186-1601130 | Clutch disc driven |

The most popular clutch kits from companies: Valeo, Sachs, Luk, VIS, Kraft. It is worth noting that the Valeo and Luke clutches are softer than the others.

Is it possible to install a clutch from a VAZ 2110 on Kalina? The clutch must be installed in accordance with the flywheel; the type of flywheel is determined by the starter studs. Two studs - clutch 2110, 2112, 11183, three studs - clutch 2108. If the flywheel is 2110, then you can install a clutch from a VAZ 2110, 2112 or the original Kalinovskoe 11183.

To buy an original clutch for Kalina , and not a fake, it is recommended to contact trusted stores, rely on reviews, or order a clutch kit online directly from the manufacturer. Which clutch kit for Kalina do you think is the best?

Source

Traditional first aid methods

If suddenly during a trip you discover that the pedal has treacherously failed and there is no longer any hope that the car will last until the planned trip to the car service center, you need to know 3 possible options for further action.

The first is to ask a friend to hold out the frozen car in tow, the second is to call a tow truck. But what to do if your friends are far away and there is no tow truck? In this case, there is a 3rd option: try to restore the clutch yourself so that it works until you get to the service station.

The driver is required to do the following:

Here we go. Slowly? Of course, but don't even count on 2nd gear. If you try to switch, the gearbox will instantly fail, and its repair will cost a lot.

The Lada Kalina car gained well-deserved popularity among the people, which only strengthened over time, because this car showed truly high performance characteristics with minimal maintenance costs.

The video shows a detailed process of replacing the clutch on a Lada Kalina:

However, as with any other car, there are some components that require mandatory replacement after a certain mileage. Such components include the clutch, without which every car simply cannot exist.

In the process of replacing the clutch

Replacing the clutch on a Lada Kalina yourself is quite difficult, although it is doable. Below, in our article, we will describe in detail how to carry out such work from beginning to end without making mistakes.

Types of clutch on Kalina

For VAZ cars 1117

, 1118

and

1119

two different types of clutch are installed at 190 and 220 millimeters. Determining your diameter is very simple, just pay attention to the number of starter mounting bolts. At 190 mm there are 3 of them, and at 200 mm there are 2. Regardless of the manufacturer, in the assembly you will almost always find the clutch disc itself, the basket and the release bearing.

VAZ clutch rating

Existing offers on the market can be divided into several groups. The best manufacturers and modifications of VAZ clutches are presented below.

7th place: STARCO

The ranking of the best market offers opens with a company that is a product that combines the developments of engineers from the USA and Turkey.

In principle, the company is represented on the Russian market as a Turkish brand, but technological developments have been collected from all over the world. Such a symbiosis ensures sufficient reliability, high quality indicators and reasonable cost, which attracts a large number of domestic motorists. Initially, the company was organized in 2005 as a result of the signing of an agreement between several brands located in Germany, Turkey and the USA. At the beginning of its work, the company produced a rather meager range of parts, which scared off buyers. As of 2022, the brand’s range has expanded to 7,000 items. Among other things, the brand has 2,000 models of clutch kits ready for installation.

The manufacturer is focused more on trucks. The choice of passenger modifications is scant, but you can buy a clutch at a VAZ.

- sufficiently strong clutch baskets can withstand inept operation;

- moderate cost;

- sufficient quality of packaging;

- The friction pads are protected against counterfeiting.

- The clutch disc wears out quickly;

- friction linings quickly become loose or fly off the rivets;

- damper springs of insufficient quality quickly sag or break;

- The release bearing begins to whistle almost immediately after installation.

6th place: AMD

The next representative of the ranking comes from Asia. The brand is organized by Japanese corporations to create consumables for their own cars. Thanks to a competent approach, the organization managed to achieve wide distribution of products far beyond the continent.

Replacing the clutch on Lada Kalina

However, as with any other car, there are some components that require mandatory replacement after a certain mileage. Such components include the clutch, without which every car simply cannot exist.

In the process of replacing the clutch

Replacing the clutch on a Lada Kalina yourself is quite difficult, although it is doable. Below, in our article, we will describe in detail how to carry out such work from beginning to end without making mistakes.

Types of clutch on Kalina

1117 , 1118 and 1119 cars are equipped with two different types of clutches of 190 and 220 millimeters. Determining your diameter is very simple, just pay attention to the number of starter mounting bolts. At 190 mm there are 3 of them, and at 200 mm there are 2. Regardless of the manufacturer, in the assembly you will almost always find the clutch disc itself, the basket and the release bearing.

New clutch kit

If problems with the clutch occur on the road, then it is necessary to tow the car with a tow truck, since further movement may damage the gearbox.

Preparatory work

It is no secret that clutch replacement work involves dismantling the gearbox, therefore, it is necessary to take care in advance of the presence of an inspection hole or overpass. We will also need the following tools and materials:

Step-by-step clutch replacement process

The first step is to carry out work under the hood of the car.

Let's move on to working under the car

- If there is crankcase protection, unscrew all the bolts and remove it.

To dismantle the protection, you need to unscrew 4 bolts

We remove the gearbox and move on to working with the clutch.

- First of all, we need to unscrew the release disk housing, which is attached to the flywheel with 6 bolts. When performing this work, the flywheel must not be allowed to rotate and must be held in place with a pre-prepared screwdriver. Unscrew the bolts slowly, one at a time, allowing one turn per circle for each bolt.

Unscrew 2 bolts on three sides

Remove the basket and driven disk

The driven disc is covered in oil - one of the reasons why the clutch does not work well

Development on the “petals” of the basket

Attention!

If you are not confident in your abilities, then you should not proceed with this type of repair and should contact a car service for the most professional assistance.

Source

How to find out what kind of clutch is on a viburnum

| № | Catalog number | Name |

| 1 | 2108-1601207 | Bolt |

| 2 | 1111-1601182 | Pressure bearing |

| 3 | 2110-1601180 | Clutch assembly |

| 4 | 2108-1601188 | Spring |

| 5 | 2112-1601085 | Clutch disc |

| 6 | 11186-1601130 | Clutch disc driven |

The most popular clutch kits from companies: Valeo, Sachs, Luk, VIS, Kraft. It is worth noting that the Valeo and Luke clutches are softer than the others.

Is it possible to install a clutch from a VAZ 2110 on Kalina? The clutch must be installed in accordance with the flywheel; the type of flywheel is determined by the starter studs. Two studs - clutch 2110, 2112, 11183, three studs - clutch 2108. If the flywheel is 2110, then you can install a clutch from a VAZ 2110, 2112 or the original Kalinovskoe 11183.

To buy an original clutch for Kalina , and not a fake, it is recommended to contact trusted stores, rely on reviews, or order a clutch kit online directly from the manufacturer. Which clutch kit for Kalina do you think is the best?

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Good day! So, my instincts tell me that it’s time to change the clutch, but choosing it turned out to be not as easy as on my previous Pepelats.

Given: Kalinosedan born in 2007 with a 1.6 engine and 8 valves. According to the PTS, the engine model is 21114.

It seems that (if you believe the Internet) a Prior clutch is installed on this engine, but... I found several different clutch kits - Kalina/Priora, Kalina/Priora/2110-12, Kalina/Priora/2110-12 dv1.6, 16 cl, etc.

Which clutch kit will still fit my engine? z.y. How much does it cost to replace a clutch these days? ¶

Information taken from here 100% method for determining clutch

Once again I was puzzled by the issue of replacing the clutch. There are plenty of reasons: the pedal travel is small, sometimes the speeds are not turned on and switched the first time, etc. But the question arose which one to take?! When they changed it for the first time, the "servicemen" installed their own clutch and, judging by the receipt, it was

. But maybe this information will be useful to someone

Determining the size of the clutch basket without removing the gearbox. (the starter needs to be removed, but this is not a gearbox, 10 minutes if with smoke breaks)

First, a few facts

190mm (2108) 200mm (2110 aka 2112 aka Priora)

- accordingly, 2 types of flywheels 2108 and 2110 are used on the flywheel 2108 you can only put the basket 2108 on 2110 only 2110 fasteners in different places

-flywheels are of different diameters (2110 is larger) and they have different ring gears (for the starter)

— the distance between the axes of the input shaft and the starter is the same for all types of crankcase (for 2 or 3 studs)

Hence the conclusion that the size of the bendix depends solely on the size of the flywheel.

(center distance = flywheel crown radius + bendix gear radius) A smaller gear diameter corresponds to a larger flywheel and, naturally, a 200mm basket.

Starters can be 2108 (3 studs, front bushing in the crankcase) by the way, my Kalinka has a starter with 2 studs

or 2110 (2 studs for the front hub on the starter itself) In addition, 2108 can be geared or gearless. It doesn’t matter at all. Any starter can fit any clutch. It all depends solely on the Bendix.

PS. For the especially boring ones. In addition, baskets 190 and 200 differ in fastening.

those distances alternate 75mm 155mm 75mm 155 ... perhaps this can be seen through the starter window (with a mirror) I haven’t tried it

Characteristics of motor 11183

The official AvtoVAZ manual contains a description of the parameters of the ICE 11183, according to which the technical characteristics are as follows:

| Manufacturer | AvtoVAZ |

| Engine brand | 11183 |

| Years of production | 2004 – … |

| Volume | 1596 cm 3 (1.6 l) |

| Power | 60 kW (82 hp) |

| Torque moment | 120 Nm (at 2700 rpm) |

| Weight | 112 kg |

| Compression ratio | 9,8 |

| Nutrition | injector |

| Motor type | in-line |

| Injection | electronic multipoint |

| Ignition | modular |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 2 |

| Cylinder head material | aluminum alloy |

| Intake manifold | plastic receiver, electronic throttle |

| An exhaust manifold | combined with catalyst |

| Camshaft | from 21114 |

| Cylinder block material | cast iron |

| Cylinder diameter | 82 |

| Pistons | ordinary |

| Crankshaft | original with increased crank stroke |

| Number of main bearings | 5 |

| Piston stroke | 86 mm |

| Fuel | AI-92-95 |

| Environmental standards | Euro-3 |

| Fuel consumption | highway – 6.2 l/100 km combined cycle 7.6 l/100 km city – 8.8 l/100 km |

| Oil consumption | 0.5 l/1000 km |

| Engine oil for 11183 | 5W-30 and 10W-40 |

| Engine oil volume | 3.5 l |

| Operating temperature | 95° |

| Motor life | declared 150,000 km, real 300,000 km |

| Adjustment of valves | washers between camshaft cams and tappets |

| Cooling system | forced, antifreeze/antifreeze |

| water pump | plastic impeller |

| Candles for 11183 | BPR6ES, A17DVRM |

| Gap between spark plug electrodes | 1.1 mm |

| Timing belt | Gates |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | catalog number 90915-10001 replacement 90915-10003, with check valve |

| Flywheel | from 2110 |

| Valve stem seals | code 90913-02090 light inlet flywheel – 62 – 87 Nm clutch bolt – 19 Nm bearing cap – 68 Nm (main) and 53 (rod) cylinder head – three stages 29 Nm, 49 Nm and 90° |

The operating manual from the manufacturer includes information on lubricants and coolants. In particular, for these engines it is recommended:

By default, the engine circuit contains a potential of 120 - 160 hp, so upgrading it yourself is possible. The 11183 is unpretentious in operation, the power was added initially by the manufacturer, the compression ratio and compression are standard.

Select the vehicle modification to search for a clutch

Engine: volume - 1.6 liters, power - 87 hp, type - petrol, model - VAZ-11186. Drive: front. Year of release: 2013-present time

Engine: volume - 1.6 liters, power - 98 hp, type - petrol, model - VAZ-21126. Drive: front. Year of release: 2013-present time

Engine: volume - 1.6 liters, power - 106 hp, type - petrol, model - VAZ-21127. Drive: front. Year of release: 2013-present time

In the next step, for an expanded selection, you can enter the vehicle's Vin code to go to illustrated catalogs, where you can find the layout of parts down to the bolt and duplicates that are not in the catalog of analogues.

| The clutch life of the Lada Kalina depends not only on the quality of the components, but also on operating conditions. If the clutch kit has served for about 100,000 km, then it is considered good. Do you know what clutch to put on Kalina? |

Design Features

After modernizing the 21114 engine taken as a standard, the 11183 engine has the following design nuances:

To reduce manufacturing costs, a connecting rod-piston group, a pulley and a crankshaft flywheel from the 2110 engine are installed in the engine. The volumes of the combustion chambers are increased for the engine with the sole purpose of ensuring a compression ratio of 9.6 - 10.0.

The manufacturer does not provide hydraulic compensators in this internal combustion engine, therefore, on the one hand, the use of lower quality oil is allowed. On the other hand, the savings in the operating budget when using cheap lubricants are “eaten up” by the costs of periodically adjusting the valves in a service station, since the manufacturer recommends doing it more often.

The main attachments are driven by their own belts. The design of tensioners (for example, a generator) leaves much to be desired. But the internal combustion engine allows you to increase power in the following ways. Moreover, a reasonable boost does not require major repairs to be carried out more often than the established deadline.

Even without improving the performance, the engine is high-torque and torquey, and produces 200% of the service life declared by the manufacturer. The available repair dimensions of the piston group make it possible to increase the service life, taking into account several overhauls, up to a million kilometers.

Advantages and disadvantages

The advantage of the 11183 engine is the cylinder head of the original design. However, it was subsequently further modified into the ICE 11186, adding volume to the combustion chambers. The downside is the generator belt tensioner - the drive is constantly over-tightened, a deflection of 10 mm is not ensured without slipping, so the belt life is reduced and it has to be changed more often. This defect was corrected only in the next version of the motor 11186.

The integrated catalytic collector assembly in the engine was initially unfinished:

When installing the engine on the Lada Granta, the cabin heat exchanger was connected to the thermostat in series. All the coolant passed through it along a small circuit, the response temperature error was 5 degrees instead of the required 2 degrees.

Clutch

Clutch: 1 — release bearing guide sleeve; 2 — gearbox input shaft; 3 — cable lead; 4 — clutch release fork; 5 — fork axle bushing; 6 — pressure disk assembly (basket); 7 — driven disk; 8 - flywheel; 9 clutch pedal; 10 mechanism for automatic adjustment of cable length; 13 — clutch release clutch (release bearing); 15 — bracket installed on the gearbox housing; 14 — lower tip of the casing; A - the distance of the tip displacement, checked when installing the cable (27 mm)

Basic data for monitoring, adjusting and servicing the clutch

| Full travel of the clutch pedal, no more, mm | 146 | |

| Permissible movement of the lower cable guide relative to the clutch release fork lever, mm | 27 | |

| Permissible runout of driven disk linings, no more, mm | 0,5 | |

| Minimum distance between the working surface of the driven disk linings and the rivets for their fastening, mm | 0,2 | |

Tightening torques for threaded connections

| Name of units and parts | Thread | Torque. Nm (kgf-m) |

| Bolts securing the clutch basket to the flywheel | M8 | 19,1-30,9 (2,0-3,2) |

| Nuts securing the clutch cable to the bracket | M12 | 14,7-19,6 (1,5-2,0) |

| Bolts securing the clutch housing to the engine cylinder block | M12x1.25 | 54,2-87,6 (5,5-8,9) |

| Nut securing the clutch housing to the engine cylinder block | M12x1.25 | 54,2-87,6 (5,5-8,9) |

| Nuts securing the gearbox to the clutch housing | M8 | 15,7-25,5 (1,6-2,6) |

| Bolts securing the release bearing bushing | MB | 3,8-6,2 (0,4-0,6) |

| Bolts securing the bottom cover to the clutch housing | MB | 3,8-6,2 (0,4-0,6) |

The car is equipped with a dry-type single-plate clutch with a central pressure spring. The clutch release drive is a cable, backlash-free, with a mechanism for automatically adjusting the length of the cable.

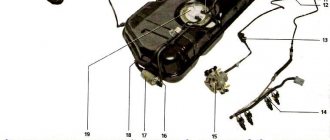

The clutch consists of a basket (pressure plate assembly) and a driven disc. The basket is a steel casing in which a pressure spring and a pressure disk are installed. The pressure disk is fixed in the casing on three pairs of elastic plates. From the casing side, the disk is pressed by a diaphragm-type pressure spring. The clutch basket is attached to the flywheel with six bolts and is covered with an aluminum housing. A driven disk is installed between the pressure plate and the flywheel.

Friction linings are riveted to both sides of the driven disk. To dampen torsional vibrations when the clutch is engaged, a damper with six coil springs is built into the driven disk. The driven disk hub is splined into gear with the input shaft of the gearbox.

The clutch pedal is suspended on an axle and attached to the body through a bracket. The upper part of the clutch pedal is designed as a double-arm lever. At the end of the lever there is a pin to which the clutch release cable is attached. The connection is made through a special ratchet mechanism that regulates the length of the cable (see below). Therefore, during the operation of the vehicle, it is not necessary to regularly check and adjust the working stroke of the clutch pedal. This mechanism also ensures that there is no play in the clutch release drive.

Clutch release cable: 1 — spring fixing bracket; 2 — mechanism for automatic adjustment of cable length; 3 — bracket for the casing; 4 — rubber cover; 5 — cable sheath; 6 — corrugated cover of the lower end of the cable; 7 - threaded (lower) cable end

The cable is laid in a metal sheath with a polyethylene coating. The upper end of the shell has a bracket that is attached to the pedal assembly. The vertical surface of the bracket also serves as a travel limiter for the clutch pedal. A rubber plate is installed on it. The lower end of the cable sheath is fixed in a bracket mounted on the gearbox housing. The lower end of the cable is covered with a rubber corrugated cover. The cable is connected to the clutch release fork lever through a plastic leash screwed onto the threaded end of the cable.

The clutch release fork rotates in two bushings. The upper bushing is plastic, removable, and the lower bushing is bronze, pressed into the clutch housing. When the fork is turned, the force is transmitted to the pressure spring blades through an angular contact ball bearing (throwout bearing). The bearing is placed on the clutch release clutch, through which it contacts the clutch release fork. Constant engagement of the fork and clutch is ensured by a U-shaped spring. Due to the absence of clearance in the clutch release drive, the clutch is constantly pressed against the pressure spring petals, while the release bearing operates continuously. The bearing is lubricated for its entire service life. The clutch release clutch moves along a guide sleeve placed on the input shaft of the gearbox and attached to the clutch housing with three bolts.

During operation, the driven disk linings wear out. To compensate for this wear, an automatic cable length adjustment mechanism is built into the clutch release drive. As the linings wear, the clutch release fork lever turns and tightens the cable. At the same time, the spring located in the bushing of the adjustment mechanism is compressed and tightens the clamps of the toothed tip of the cable. The clamps release the tip, as a result of which it is freely pulled out of the cable leader, compensating for wear on the disc linings. When the clutch pedal is pressed, the upper guide moves upward. In this case, the clamps compress the toothed tip of the cable, preventing it from moving out of the adjustment mechanism housing.

Cable length adjustment mechanism:

1 - bushing; 2 - leash; 3 — toothed (upper) cable tip; 4 — cable end clamps; 5 bracket (with clutch pedal travel limiter)

Note. On early production cars, a spring was installed inside the leash.

Maintenance

According to AvtoVAZ recommendations, the 11183 engine must be serviced according to the regulations:

| Maintenance object | Time (month) or mileage (10,000 km), whichever comes first |

| Timing drive | 36/ 1 |

| Battery | 12/2 |

| Valve clearance | 24/2 |

| Crankcase ventilation | 24/2 |

| Belts that drive attachments | 24/2 |

| Fuel line and tank cap | 24/2 |

| Engine oil | 12/1 |

| Oil filter | 12/1 |

| Air filter | 12 – 24/4 |

| Fuel filter | 48/4 |

| Heating/cooling circuits | 24/4 |

| coolant | 24/4 |

| Oxygen sensor | 10 |

| Spark plug | 12 – 24/2 |

| Exhaust manifold | 12/1 |

By default, the cooling system has a volume of 7.8 liters. Red Felix Carbox 40 antifreeze is usually poured on the conveyor. Replacement is made with any coolant, taking into account the temperature range of 85 degrees. Since the internal combustion engine device is quite simple, the maintenance operation can be performed on your own.

Malfunctions: causes, elimination

If the timing belt of the drive breaks, the 11183 motor does not bend the valve, but it has the following typical breakdowns:

| Floating speed | 1) malfunction of the ignition module 4) failure of the TPS sensor | 1) module replacement 2) installing a new gasket 4) repair or replacement of the throttle position sensor |

| Extraneous noise | 1) misadjustment of valve clearances 4) development of liners | 1)adjustment with valve gaskets 2) replacement of pistons, rings 4) use of new liners |

| Alternator belt break | excessive tension, manufacturing defect | Regular check, replacement as necessary |

Since a feature of the ICE 11183 is a well-thought-out design of valves and pistons, overhauls in most cases are carried out on time without additional user investment.

Engine tuning

To improve the performance of the 11183 engine, several types of tuning can be used:

Practice shows that chip tuning for 8-valve internal combustion engines is not effective, and turbocharging leads to increased wear of parts, so these methods are rarely used.

For example, tuning by replacing the camshaft already adds about 10 hp. s., and in combination with other methods, the power increases to 120 hp. With.

Thus, the 11183 motor has a serious advantage - it does not bend the valves with pistons when the timing belt drive breaks. However, there are a number of shortcomings that were corrected only in later versions of engines from the manufacturer AvtoVAZ.

Source