According to almost all owners of the Russian automobile industry, an incorrigibly annoying problem is that the gearshift lever on the VAZ 2114 constantly rattles. Due to such popularity of the problem, the drivers themselves have found a number of convenient solutions to fix it in garage conditions. A symptom for repairing the gearshift knob is obvious - you get into the car, start moving, start to pick up speed, and in response the stick begins to shake, make strange sounds and vibrate. This happens due to an ill-conceived design, as it happened with VAZ engineers, because the problem extends not only to the fourteenth model. The vibration of the gearshift lever occurs according to the following principle: we are driving, and the bushing that connects the stick and the rod begins to touch the wings of the rod. It is made of metal, which naturally leads to unpleasant metallic rattling. Fortunately, this shortcoming can be corrected in a fairly simple way, without having a brain.

What gearbox is installed on the VAZ-2114?

Since the VAZ-2114 is equipped with a mechanical gearbox, the driver personally selects which gear to engage at what point in time (by changing the position of the driven gear relative to the driving gear - approx.), thereby ensuring the correct position of the lever in the cabin. However, during operation it happens that the handle begins to rattle, causing only discomfort to the car owner.

Below, in our article, we will look at the main causes of this problem, as well as ways to fix them.

Gearbox device

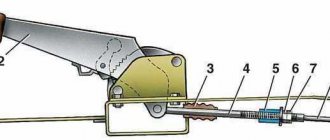

Diagram of the gear selection mechanism with decoding

First of all, before we undertake the repair or alteration of the gearshift knob, we need to learn more about its design (to figure out where the vibration comes from and how dangerous it is for the operation of the car as a whole - approx.), and also become familiar with its main elements.

It’s no secret that the VAZ-2114 is a front-wheel drive car, with front drive wheels; accordingly, the gearbox itself is perpendicular to the direction of movement of the car (this means that the “box” lever does not enter the cabin directly from its body, but through the rocker – approx.) . The same cannot be said about representatives of the “classic” AvtoVAZ family, where the rattling of the gearbox lever may indicate problems with the transmission itself.

The handle on the VAZ-2114 works somewhat differently, using special rods that help the car enthusiast change gears with the greatest comfort. However, among this lie small shortcomings of the creators, which over time lead to the rattling of the handle.

Causes of gearbox bouncing

- The connection bushing is the wrong size.

- The handle gasket is missing.

- Inconsistency of parts that border each other.

All of the above problems can be caused by one small metal bushing that connects the rods under the lever. Therefore, rattling of the handle may appear due to the appearance of a gap in it, or poor contact between two connections . All this leads to impacts of the bushing against the metal of the body, which contributes to the appearance of noise and rattling of the handle.

This is what the old bushing looks like.

On some VAZ-2114 models, such connections were wrapped with a rubber gasket to avoid such malfunctions.

REMOVE THE SHIFT LEVER

Self-repair begins with the fact that you need to figure out how to remove the gearshift knob on a VAZ 2114 . This is usually done simply and the owners of similar 15 and 13 models should do the same, if, of course, they have similar problems. So, the algorithm of actions looks like this:

- First you need to remove all the armrests and bathtubs that drivers like to furnish the space between the seats with. This must be done so as not to spoil them in the process of self-repair.

- Next, you need to carefully remove the casing from the lever, since it can simply be torn, but it still costs money, and it adds significant aesthetics.

- Now you need to find a bolt and nut under the lever, the latter is usually unscrewed with a regular open-end wrench 13, so there should be no problems with this, you just need to have the appropriate wrench. After unscrewing, take the bolt out, it is also advisable not to drop the nut.

- That's it, the lever, together with the very bushing that causes the VAZ 2114 gearbox lever to rattle, remains in our hands.

Comments and reviews

This problem is one of the most common on the 2114. My lever was rattling madly, and so was my friend’s. Everything was decided by pulling the lever.

The instructions say everything correctly. If the lever begins to tap or rattle, or the speeds generally jump out, then this must be addressed immediately, otherwise real problems will begin later. My father had a 2114 and he didn’t solve the rattling issue in time, he drove like this for about six months, and then he got used to it and completely forgot. As a result, I had to do a complete overhaul of the gearbox, and this is not a cheap pleasure.

Thank you for the clear explanation of what needs to be done and how. I couldn’t have done it myself, but this article helped a lot.

Why does the gearshift lever dangle?

The lever's loss of shift clarity, sluggish return or refusal to enter the neutral position, as well as increased backlash are a consequence of intensive use or malfunctions. If the Priora gearbox lever dangles a lot, this is usually accompanied by one or more signs:

- the selected gear refuses to engage;

- the lever touching the interior elements on the driver’s side - seats or casing trim;

- turning on a gear that does not correspond to the selected one;

- the appearance of extraneous sounds, noise, hum and jerking of the Priora gearbox handle when squeezing and releasing the clutch.

The Priora gearbox lever is loose

Accordingly, after finding out the reason why the gearshift lever on the Priora is not working correctly and is hanging loose, adjustment or repair with replacement of the defective part will be required to restore functionality. A chattering of the gear selector lever of a Priora car can be caused by faults in the transmission, such parts as the clutch or gearbox, which force you to make excessive efforts to shift. Insufficient disengagement of the clutch due to the bearing not being fully pressed is accompanied by a crunching and grinding noise, jerking. This accelerates the wear of all elements of the drive mechanism, it makes a lot of noise, the car begins to shake and movement may be accompanied by twitching.

To identify the reason why the Priora gearbox knob is loose, you need to diagnose the condition of the unit from the lever in the cabin to the actuator on the gearbox of the corresponding type.

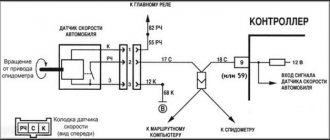

On the rocker box

The reasons for the disruption of the precise operation of the speed shift knob on cars with rocker-type shift control are its breakdowns and misadjustments.

The most common cause of looseness, rattling and vibration of the lever at idle is wear of the bushing between the gear shift knob and the axis of its movement back and forth. A gap appears between the lever and the pressure washers, the quality of fastening deteriorates, vibration from the box is transmitted through the rocker to a loosely tightened hinge and its parts begin to rattle, causing the Priora gearbox handle to rattle.

Loss of stability of the gear selector knob in the neutral position, jerking, knocking and difficulty coordinating gear shifts can occur due to a broken spring on the axis of the gear selector lever in the actuator located in the gearbox housing.

The lever may dangle in the vertical direction due to breakage or failure of the parts of the ball joint of the lever (plastic clip, retaining spring).

Misadjustment of the rocker and the entire mechanism for controlling its operation due to natural wear of the elements is manifested in increased backlash during gear changes, incorrect activation and increased vibration transmitted to the Priora gearbox lever.

On a cable box

If the gearshift lever on a Priora with a cable box dangles, this may be due to wear of the drive cables and the attachment of their dome tips to the ball pins of the pendulum levers or to the speed selector in the cabin. A faulty ball joint may also be the cause. In this case, noise, crackling and rattling of the Priora gearbox handle may appear when you press the gas.

Self-adjustment and replacement of the VAZ 2110 backstage

Welcome, friends, to the DIY VAZ car repair website. There is an opinion that repairs and adjustments to gearbox components can only be done by service station technicians.

Backstage VAZ 2110

Undoubtedly, the gearbox is one of the most important and complex mechanisms in a car, but in practice most of the work can be done with your own hands.

In particular, adjustment of the VAZ 2110 rocker and its subsequent replacement can be carried out in a garage.

Removing the gearshift lever

Before you begin dismantling the handle, you need to carefully examine the entire space next to it and understand how it comes apart. There is nothing complicated about this, the main thing is to follow our instructions exactly:

- If there are additional armrests and other elements installed independently, we dismantle them so as not to damage them during the work.

- Carefully remove the casing (plastic or leather - approx.) so as not to tear or break it.

Dismantling should be carried out carefully so as not to break anything.

If the lever does not budge, you can treat the surface with WD-40.

The old bushing is marked with a red marker.

Vibration Elimination Process

After you have the bushing with the lever in your hands, carefully inspect it visually for visible damage and signs of wear. Because if they are available, you may have to buy the same spare element, so that a little later you won’t have to do the work of dismantling, repairing and adjusting it.

The new bushing looks much better

The procedure for repair work with the bushing

- First of all, we dismantle the plastic cover on the bushing in such a way as to free its metal base.

Disassembled gear lever bushing

We went to the store and measured the new bushing there and compared it with ours!

How to adjust the rocker of a VAZ 2110?

I would like to note that the unit is replaced only after complete adjustment. If this is not done, you can spend a considerable amount, and the reason will turn out to be a completely different malfunction.

It is advisable to adjust the link in the following cases:

If one of the symptoms described above appears;

- After removing the gearbox;

- after replacing the cardan or loosening the fixing clamps;

- after turning the link on the hinge.

Remember that when it comes to adjustment, even the slightest change in clearances matters.

For example, a displacement of the rocker in relation to the cardan by 1-2 millimeters can lead to a complete restoration of the functions of the gearbox.

To adjust the slide, proceed in the following sequence:

- Drive the car onto the overpass (do your best, but try to put it in first gear).

- After driving uphill, do not touch the gearshift knob (let it remain in first gear).

- Engage the handbrake and put the wheel chocks on.

- Get down under the car and find the clamp that secures the hinge and the rocker together.

- Loosen the clamp.

- Get into the car and push the rocker lever to the left position (other directions are prohibited).

- Get down under the car and fix the clamp.

- Check the operation of the gearbox.

Pros and cons of a short-throw rocker

Before considering how to make a short-stroke link with your own hands, let's summarize what was said earlier and determine what pros and cons it gives. Most often, such a replacement is carried out on any VAZ cars (for example, 2110, 2112, 2115, 2114 and 2107, 2106, 2108, 2109), the positive effect is considered:

- reduction of strokes (distances to move the gearbox) when switching the gearbox;

- clearer fixation of gears (by increasing the effort to engage them);

- elimination of play and rattling of the RPP.

However, not everything is so good; some experts believe that installing a short-stroke rocker causes synchronizer failure due to increased shifting effort.

Features of the gearbox device

Before we talk about the causes of vibration, you should first understand the operating principle of the gear shift lever. So, in rear-wheel drive cars it directly enters the box (since it is located parallel to the car body) and its rattling is a sure sign of problems in the transmission itself.

In turn, the VAZ 2114 gearbox handle is connected to the gearbox by a system of special rods (after all, the gearbox on this car is installed perpendicular to the body) and does not have direct contact with it. The main source of sounds and rattling in this case is a small metal bushing, which connects the gear shift lever to the rod.

VAZ 2114 gearbox device

Its most common defects (leading to vibration) are:

- wrong size;

- poor (with backlashes) fit of parts;

- lack of gasket.

As a result of this, during movement the bushing begins to shift and hits the wings of the rod, thus causing metallic sounds and rattling.

Main reasons

What to do if the gearshift lever on a VAZ 2109 and 2110 is loose? To answer this question, it is necessary to determine the reason for this behavior of the lever. There may be several reasons. Some of them are caused by the design of the car and are practically unavoidable. The problem with a dangling lever and rattling occurs for the following reasons:

- Designer error. The metal bushing clings to the rod when moving. The result is a rattling sound. There is no way to fix the problem;

- Bushing failure;

- Lever from Lada Kalina;

- Malfunction of the backstage cardan;

- Wear of the box or its fastenings.

Each of these reasons leads to play in the lever. The first reason only gets on the nerves with a rattling sound, but there are no problems with controlling the box. To determine the reasons, you will have to carefully inspect the car in the pit. In some cases, it will be necessary to make repairs or modify parts.

Bushing failure

. The bushing holds the lever in a certain position. It receives almost all the force when changing gears. Over time it may burst. In this case, the lever will move much more freely, but gear shifting will occur as usual, without any problems. To fix it, simply replace the bushing.

Lever from Lada Kalina

. On Kalina the box has been slightly modified. When installing a lever from it on a regular box, the driver receives several positive bonuses. The disadvantage of this tuning is the appearance of play in the lever and constant rattling noise when moving. The problem arises due to the lack of a softening spring on this lever. To fix the problem, you need to take a standard spring from the nine and attach it to its usual place. To secure one end of the spring to the lever, you will have to make a fastening. For this you will need welding.

Pros and cons of a short-throw rocker

There is a stereotype among drivers that installing KK leads to the fact that when changing gears you can easily miss the right one. There is a problem, but it arises due to the wrong approach to modernizing the car. In addition to the rocker, it is necessary to install a new gearbox driveshaft. The best solution would be a part from the Lada Kalina, since the cardan in new models is not subject to play. Even if the CC is made by hand, the cardan must be installed from the factory.

The next stereotype is that such modernization quickly destroys the gearbox. We are talking about the second gear, which wears out equally with both a regular part and a short-throw one. This problem has been present in Samara since the VAZ 2109. The third stereotype is this: when installing the rocker in the gearbox, you need to file down the plastic in the dashboard. If a high-quality homemade CC or a part from Kalina is installed, then no manipulations with the plastic are necessary. It is also recommended to install sports synchronizers along with the CC, since the load on them increases after such tuning.

What is a short-stroke gearbox?

Here it is necessary to explain what the inconvenience is. Most often it affects VAZ owners with a manual transmission - not only old models 2107, 2106, 2108, 2109, but also more modern 2110, 2112, 2115, 2114. And it consists in too much time spent on gear shifting and the need for increased efforts to fix them. The reason for this is the non-optimal shape of the scenes, which is why such inconveniences arise.

Race car drivers were the first to encounter them; a lot depends on their gear shift time, and they try to minimize it. So they were the first to use a short-stroke rocker (SC), which allowed them to circumvent this drawback. And then a similar innovation spread to ordinary cars. For a better understanding of the subject of discussion, the photo shows a similar part for switching the gearbox of a VAZ 2108 car.

VAZ backstage repair

I’ll tell you the easiest way to repair the gear shifter on VAZ cars. It's nice to drive a car when it's new and the rocker doesn't wobble. But when the car is used, the rocker is usually loose, and in order to engage reverse gear you have to press it into the seat, and when you engage fifth speed, you hit the passenger on the thigh with your hand, but women may enjoy such attention from the driver, and the driver feels ashamed that The speed link is wobbling so much.

The linkage becomes loose due to the fact that the lever axis wears out, and the holes in the gear shift rod are broken, but plastic bushings usually last a long time.

You can repair the link yourself without even disconnecting it from the gearbox.

To do this, you need to remove the cover from the gear shift knob, and you can remove the panel.

The easiest way is this: replace the lever axis with an M10 bolt and tighten it with a nut, adjust the nut so that it is not too tight and allows the speed lever to move without loosening. Use the second nut to tighten the first nut so that it does not unscrew arbitrarily. Even if the hole in the gear shift rod is broken, the bolt tightens, and at most there will be a millimeter play back and forth.

The whole slide will work like new. Below is a photo report on the repair of the backstage.

Photo. The link before repair is a view on the right, the arrow shows how the locking bracket can be removed.

Photo. View of the backstage before renovation on the left.

Photo. View of the backstage with the lever axis removed.

Photo. I was not too lazy and removed the lever of the slide, and sharpened one edge of the bushing, since it was worn obliquely, I simply aligned it on the sharpener, by eye. But I did not disconnect the rocker itself from the gearbox.

Photo. The repaired rocker, the arrow shows the locked nuts.

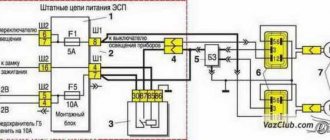

Replacement instructions

Before starting work, we advise you not only to purchase a new spare part, but also to watch training videos on replacing the slide. The procedure is not very complicated, but a visual aid will never be superfluous. Especially if you do not have much experience in repairing a car and transmission in particular.

Replacement procedure

The process involves performing several sequential steps.

- Remove the housing from your gear shift knob.

- Raise the car using a jack. In some cases, an inspection hole will do, if you have one in your garage.

- Now you should dismantle the console, which will give you access to the backstage.

- The element is held in place by six bolts, which can be removed using a regular 13 mm wrench.

- But it's not that simple. You won’t be able to unscrew the top two bolts with a wrench, so don’t even try. They are specially planted as tightly as possible, so to dismantle them you simply need to cut them down with a grinder.

- Now you can safely remove the remaining two bolts in the lower fastening of the rocker, for which your effort and a 13 key will definitely be enough.

- The next step is to remove the clamp and move the boot. You will need to remove the hinge. At the same time as replacing the link, we recommend changing the hinge. It would be a good idea to replace the oil seal and cardan shaft. These elements have a limited service life, and since you decide to change the slide itself, there are objective reasons to do everything as efficiently as possible.

- After this, install the new unit in place of the old one. Act carefully so that the rubber bands of the slides fall on the welded bolts, which you previously sawed off using a grinder.

- The assembly is now reassembled, operating in the opposite sequence to disassembly. It is not necessary to seat the top mounting bolts tightly, but try to tighten them firmly.

Do-it-yourself short-throw scaffold

A similar device can be installed on any VAZ car (both classic and front-wheel drive) with your own hands; below are examples of how this is implemented.

Short-stroke link for classics

For production in this case you will need:

- a piece of pipe with a diameter of fifteen millimeters;

- nut from a classic ball nut;

- RPP from 2108;

- backstage repair kit 2108 (axle and two bushings);

- cardan from the steering mechanism 2104, 2105 or 2107.

The work is performed as follows:

- The ball from the bottom is cut off from the RPP;

- The lower part is sawed off so that a pipe can be inserted into it and scalded;

- The nut is welded to the pipe from below;

- The ball is placed in a convenient place;

- The cardan is attached to the gearshift lever.

The described process is illustrated by the following photographs:

Short-stroke rocker VAZ 2109

One of the main parts will be a cardan from Kalina, which will help avoid play in the lever.

Next you need to complete the modification, as shown in the photographs:

Then two pieces of metal are welded

After finishing the work, you need to clean all the seams and paint them in the desired color.

The short-throw shifter, which you install yourself on many VAZ car models, has its pros and cons, but it allows you to reduce gear shifting time and makes it easier to control the car. Whether to do it or not is everyone’s personal choice, but it cannot be denied that such a modification is perceived by many as necessary and useful.

Rate the usefulness of the article!

- Why do brake pads squeak when braking and what to do about it

- Replacing engine mounts on VAZ and other cars

- Car rental: what you need to know when choosing

- What does the braking distance depend on and what formula can it be calculated by?

- How well do you understand car emblems?

- How to remove the outer CV joint and replace a torn boot

- How to independently replace the internal grenade on VAZ cars

- Wheels for rotating the car in place 360 degrees

- In 3 years, diesel engines will become a luxury

- Review of the most expensive Hyundai Solaris ever

- Test drive Lamborghini Huracan from Mikhail Petrovsky

- Electrical equipment

- Engine

- Brake system

- Other

- Steering

- Transmission

- Suspension

- Tuning

- VAZ 2110

- Other

- Engine

- Steering

- Electrical equipment

- Transmission

- Brake system

- Suspension

- Tuning

Is the gearshift knob rattling?

According to almost all owners of the Russian automobile industry, an incorrigibly annoying problem is that the gearshift lever on the VAZ 2114 constantly rattles. Due to such popularity of the problem, the drivers themselves have found a number of convenient solutions to fix it in garage conditions.

A symptom for repairing the gearshift knob is obvious - you get into the car, start moving, start to pick up speed, and in response the stick begins to shake, make strange sounds and vibrate. This happens due to an ill-conceived design, as it happened with VAZ engineers, because the problem extends not only to the fourteenth model. The vibration of the gearshift lever occurs according to the following principle: we are driving, and the bushing that connects the stick and the rod begins to touch the wings of the rod. It is made of metal, which naturally leads to unpleasant metallic rattling. Fortunately, this shortcoming can be corrected in a fairly simple way, without having a brain.

WE ELIMINATE VIBRATION

Now you need to carefully inspect the bushing externally, after all, it is precisely because of it that the gearbox lever 2115 rattles. If there is any external damage that is too obvious and signs of wear, then you may have to look for a new part so that you do not have to repeat these manipulations in the future . Now let’s figure out what operations need to be carried out in order to understand how to adjust the rocker on a VAZ 2114:

- We remove the outer plastic braid of the bushing to free its iron body.

- Now we need to see if there are any signs of friction on it. Their presence will indicate that the size is incorrect. They will be especially pronounced if the sleeve is slightly longer than necessary. If this is confirmed, then these extra millimeters are the reasons why the VAZ 2115 gearbox lever rattles. In this case, you need to try on how much excess is in the hole and simply grind it off with a file, usually there are only 1-2 millimeters there.

- Now you need to select some kind of gasket according to the shape of the part, or simply wrap it with electrical tape so that it fits into place more tightly and then does not move.

So it became clear how to eliminate the rattling of the VAZ 2114 gearbox lever and why this generally happens. After our simple manipulations, the vibration should completely disappear, now the lever will always be in a calm state.

The described methods do not require any special knowledge and can be performed by an ordinary person in his garage with a minimum set of suitable tools.

Backstage adjustment

Adjusting the slide itself is as easy as shelling pears.

To adjust the rocker, turn on reverse or fifth speed, whichever is easier at the moment. Loosen the nut on the rocker, it is shown in the photo, and put the speed lever in the position you need, if the fifth speed, then in the position of the fifth speed lever. And if the speed is reverse, then put the reverse gear lever in position, and press it deeper forward so that the rocker seats well on the gear shift hinge. And if you have an assistant, it’s even better, let him hold the lever in the desired position, tighten the rocker nut.

Photo. The arrow shows the rocker nut that needs to be loosened for adjustment.

That's it, the backstage adjustment is complete.

Malfunctions of the scenes

As a rule, a faulty VAZ 2110 rocker manifests itself with several main symptoms:

- Gearbox lever play. In this case, one of the reasons is the wear of the scenes. The only way out is replacement;

- clinking noise is one of the most popular problems of the VAZ 2110. The cause of the malfunction may be a factory defect or errors during repairs (often extraneous sounds appear after intervention in the chassis);

- poor-quality switching on of the speed (its “knocking out”). In this case, adjustment or replacement may be helpful;

- switching on instead of first reverse speed. As a rule, in such cases there are no complaints about the operation of the lever;

- increased vibration of the gear lever. As a rule, this means that there is significant play in the gearshift knob hinges.