What are standard parameters

Each engine has its own standard parameters. These are technical characteristics that determine the normal operation of the motor. These parameters are compared with the values obtained during diagnostics. All measurements are carried out with the engine running at idle speed.

The presence of errors that are stored in the car's memory is the so-called DTC parameter. What these errors are can be determined by deciphering their codes, which can be easily found on any resource on the Internet. There are entire tables with interpretations of error codes.

But the engine may have malfunctions and malfunctions and not generate errors. For example, if the idle speed is too high, the control unit believes that the driver pressed the gas pedal, does not perceive the situation as an error and, naturally, does not display it during diagnostics.

Read more: Willson guard liquid glass reviews

If, during engine diagnostics, all measured parameters differ from typical values by no more than 20%, then the engine is operating normally. Components and parts whose performance exceeds the specified value can be considered faulty.

Replacing the clutch release bearing

If the bearing still needs to be replaced, you will have to perform the following sequence of actions:

- dismantling the gearbox;

- disconnecting the ends of the spring clamp from the coupling;

- removal from the bearing guide sleeve;

- disconnecting the spring holder;

- removing the bearing from the coupling and installing a new part.

Before installing the parts on the guide bushing, their surfaces must be generously lubricated with grease.

In conclusion, it should be noted that release bearings can last up to 150,000 kilometers without problems, but they often have to be replaced every 50,000 km due to driver errors and bad roads, which destroy the entire car, including the clutch.

Why is the Check Engine Light on?

Details

Created: January 19, 2016

Why is the Check Engine Light on? Malfunctions and solutions.

VAZs, like the vast majority of modern cars, have a lot of different sensors that monitor engine performance. Like other engines, the power unit of the latest VAZ models has an ECU (electronic control unit), which, if faults or irregularities in the operation of the internal combustion engine are detected, can issue an inscription that many motorists are very afraid of. As you understand, we are talking about Check Engine, this is an error that means “check the engine,” literally.

Verdict

Substandard behavior of the Granta pedal assembly is a malfunction that should be eliminated as soon as possible. The issue may be either in the drive, which here is a cable drive, or directly in the unit connecting the engine and the gearbox.

Most often, the problem lies in an unraveled cable or its limited mobility in the jacket. This problem can be eliminated by replacing the cable and/or lubricating it with oil, silicone or WD-40. The fork shaft often needs lubrication.

Less commonly, the problem is caused by a deformed or cracked fork. Wear on the leaf spring can radically change the amount of force required to release the pedal. A new clutch can also cause it to feel stiff.

Source

Replacing the valve stem seals of the VAZ-21126 Lada Granta engine

Tools:

- Open-end wrench 10 mm

- Open-end wrench 13 mm

- Open-end wrench 17 mm

- 13 mm straight box spanner

- 15 mm straight box spanner

- Driver for socket attachment

- 10 mm hexagonal socket for wrench

- 17mm wrench attachment

- Screw jack

- Wheel key

- Medium flat screwdriver

- Medium Phillips screwdriver

- 5 mm hex key

- Ratchet wrench

- Extension

- Torx E8 head

- 8 mm head

- 10 mm head

- 16 mm high socket or spark plug wrench

- Funnel

- Torque wrench

- Special wrench for turning the tension roller (or circlip remover)

- Camshaft pulley locking key

- Knife (or scraper)

- Calipers

- Small hammer

- Tweezers (or magnetized screwdriver)

- Valve spring compressor

- Oil seal remover (or pliers)

- Mandrel for installing valve stem seals (or twelve-sided head)

Parts and consumables:

- Oil seals (set)

- Sealant-gasket type LOCTITE 5910

- Sealant LOCTITE 574

- Solvent type 646

- Engine oil

- Rags

Note:

Replace valve oil seals if blue smoke appears from the exhaust pipe when starting the engine and when the engine switches from operating mode under load to forced idling mode (engine braking), as well as when there is an increased consumption of engine oil in the engine, when oil leaks are visible from the outside. not detected.

1. Perform all work necessary to remove the camshafts as described here.

2. Remove the valve lifters from the holes in the cylinder head.

3. Install a device for compressing the valve springs by screwing the camshaft bearing cover bolt into one of the holes in the cylinder head and hooking the device onto this bolt. Compress the valve spring with the tool and remove the two cotters from the upper spring plate using tweezers or a magnetized screwdriver. Then remove the valve spring compressor.

Note:

If the force of movement of the device lever increases significantly, and the crackers do not come out of the valve groove, apply a light blow to the spring plate with a hammer to release the crackers.

4. Remove the valve spring retainer.

5. Remove the valve spring.

6. Press the valve stem seal off the valve guide.

Note:

If you do not have a tool for removing the caps, carefully remove them with pliers. The force must be applied strictly upward and not rotate the caps, so as not to damage the valve guides. If the set of new caps includes an installation sleeve, put it on the valve stem to protect the working edge of the cap from damage by the sharp edges of the cotter grooves on the valve stem.

7. Dip the new valve stem seal in engine oil and insert it into the mandrel.

Note:

If you do not have a mandrel, you can use a tall twelve-sided tool head of a suitable size.

8

Carefully press in the oil seal until it stops.

9. Install the springs and valve spring retainers.

10. Compressing the valve spring with a tool, install the cotters so that they fit into the grooves of the valve stem.

Note:

After installing the cotters and removing the device for compressing the valve springs, apply several gentle blows with a hammer to the end of the valve stem so that the cotters are guaranteed to be fixed in the groove of the stem. If the crackers installed skewed remain unfixed, when the engine is started, the “uncracked” valve will fall into the cylinder, which will lead to a serious engine failure.

11. Install the valve lifter.

12. Replace the oil seals of the remaining valves in the same way.

13. Reassemble all parts in reverse order.

Note:

Before installing the camshafts, do not forget to lubricate the hydraulic pushers and camshaft supports in the cylinder head with engine oil, and apply a Loctite-574 sealant, which acts as a cylinder head cover gasket, to the surface of the cylinder head mating with the camshaft bearing housing.

When assembling, do not mix up the shafts: there is a distinctive belt on the intake valve camshaft.

Note:

After installing all the timing parts, be sure to adjust the timing belt tension as indicated here.

The article is missing:

- Photo of the instrument

- Photos of parts and consumables

- High-quality photos of repairs

Reviews

| № | Positive |

| 1. | Gennady: This is my second year driving Grant, there are no special problems. I follow maintenance deadlines, fill with high-quality oils, and have a moderate driving style. I believe that these are the main factors that ensure the “longevity” of a car. |

| 2. | Vasily: after 35,000 km the cable creaked, I thought about replacing it with a new one, but the guys advised me to lubricate it with oil. Thanks for the recommendation, I’m driving, I don’t know any problems. |

| 3. | Vitaly: I heard from motorists about the problem of cable squeaking on Grant. I can’t confirm, since I drove 75,000, the unit is working properly. |

| 4. | Ivan: the total mileage of the car is over 110,000 km. I replaced the clutch cable at 80,000 km; this is a very good resource for the Lada Granta. Of course, the car is not perfect, but with timely maintenance, everything works properly. |

| 5. | Kirill: on a run of 90,000 km the cable flew, I didn’t think that Grant would last that long. The store recommended a number of manufacturers, and made a choice in favor of domestic ones. My recommendations to motorists. |

| 6. | Vladislav: the first creak of the tensioner appeared at 65,000 km, did not lubricate it, replaced it with a new one. I think that this is quite normal for Russian quality. |

| 7. | Igor: the clutch works properly, does not knock, does not stick, mileage is 95,000 km. Taking good care of the machine and quality parts are the main factors contributing to long service life. |

| Negative | |

| 1. | Victor: the first tensioner flew at around 30,000 km. The interval is too short. Manufacturer's warranty is 95-100 thousand km. In the store I chose a foreign-made tensioner. I've been using the machine for two months now and I'm happy with the quality. |

| 2. | Vasily: at the second technical inspection, the master recommended replacing the tensioner, since the pedal travel exceeded 146 mm at maximum tension. I think the resource is too small. |

| 3. | Gennady: the release bearing flew at 60,000 km, which was unexpected, because the replacement interval had not yet arrived. |

Conclusion

The clutch service life is 100,000 km. Such data is indicated by the manufacturer in the manual.

The actual period is 75 - 80 thousand km. Subject to a moderate driving style and careful handling of the car, the service life increases by 10-15%.

When choosing components, give preference to original parts with factory catalog numbers. Carry out repairs yourself, since the design of the clutch mechanism is simple and the operating principle is intuitive.

The clutch fork is loose

To remove the clutch pedal on a Lada Granta car, you must perform the following steps:

- Secure the car on a level surface, squeeze the parking brake lever, and install wheel chocks on the rear row of wheels.

- Using a “14” key, unscrew the three bolts and disconnect the steering shaft (interior of the car, at the base).

- Unscrew the plastic clamp from the clutch cable lead.

Plastic retainer

- Remove the protective bracket and remove the brake pedal vacuum booster pin.

Safety bracket

- We disconnect the block with wires from the dashboard with the sensors on the bracket.

- Using a key set to “13”, unscrew the four nuts and remove the vacuum brake booster.

- Using a “13” wrench, unscrew the five nuts and remove the clutch pedal bracket and brake assembly.

After troubleshooting, we replace the worn elements with new ones and assemble the structure in the reverse order.

Symptoms of malfunction, diagnostics, solutions

| Sign | Cause and remedy |

| Short pedal stroke | Adjust the length of the cable. Check the integrity of metal fibers. Most likely delamination or bending. |

| The clutch drags at speed, it is difficult to shift into higher gears. | The flywheel is bent or damaged. The gripper teeth are worn. Replacing the flywheel and related consumables. |

| Slipping when activating first gear and increasing speed with the accelerator pedal. | Replace friction linings, disk, clean the drive from old grease |

| Sharp jerks when turning on / changing gears. | The pressure plate is damaged, replace the basket. |

| Whistle when activating first and subsequent speeds | Install a new release bearing |

| Crackling, knocking, crunching noise when shifting into up/down gears | Wear out the damper spring, replace it with a new one, lubricate the entire drive mechanism. |

| The lever falls, falls, rattles | Excessive stretch of tensioner. Replace with a new one, install bushings. |

The reason for the squeaking clutch pedal on the Lada Grant

The design of the clutch on the Lada Granta car is different from previous VAZ models. The shaft drive is activated by a cable with an automatic tensioner.

https://youtube.com/watch?v=AvW0dreUQdY

If the adjustment was made correctly from the factory, then the owner does not need to re-adjust the strain relief. In practice, this is far from the case; problems do happen. Especially at the stage of passing the first and second technical inspections.

Stage No. 1 Adjusting the clutch pedal of Lada Granta

The appearance of third-party noises and squeaks indicates the need for preventive maintenance and troubleshooting of clutch elements. First of all, we check the clearance on the drive fork.

In the engine compartment, dismantle the plastic casing of the air element and remove the pipes. Using a caliper, measure the size of the gap between the plastic wing and the fork. The factory standard is 27 mm, exceeding or reducing the length is unacceptable. We correct the gap by unscrewing the nut (key set to “10”).

Stage No. 2 Lubrication of elements

Lubricating the moving elements of the pedal assembly, including the compensator ratchet, clutch pedal bushing, and cable sheath.

To simplify the lubrication process, we use a grease gun, fill a medical syringe with transmission oil, and apply it to the surface.

Sometimes the creaking comes from the engine compartment. The reason is the leash of the tip. To eliminate squeaking, apply oil to the contact area between the nut and the drive fork.

Stage No. 3 Insufficient amount of lubricant

In rare cases, the cause of the squeak is the lack of lubrication on the input shaft of the gearbox. The defect is eliminated by applying graphite lubricant to the surface of the shaft. First remove the rubber bushing and spray lubricant using an aerosol can.

What should be the clutch pedal travel of the Lada Granta?

The free play of the clutch pedal on the Lada Grant is 146 mm - this is the distance from the base of the body to the back of the pedal (frog). The manufacturer allows a stroke play of 2.0 mm.

If the above distance does not meet the standard, we carry out the following adjustment steps:

- In the engine compartment, pull the end of the cable forward as far as it will go. Using a caliper, measure the actual distance from the plastic nut to the drive fork. Factory standard 27 mm.

- We carry out adjustments and adjustments as necessary (key to “10”).

- We pump the pedal 2-3 times and take repeated measurements.

- Inside the car we measure the pedal stroke, it should be equal to 146 mm.

Issue No. 6: Clutch pedal adjustment and oil change

As I already wrote in the last issue of the BZ, I did not change the engine oil at zero maintenance. What was the reason for my refusal?

Since I almost immediately switched my Grant to “methane”, there should be a minimum of deposits on the working surfaces and walls of the engine (compared to gasoline);

I have heard more than once that the servicemen themselves (in an informal conversation) advise changing the oil on a new car not at zero maintenance, but after 5-7 thousand km. mileage (for economic reasons). Of course, it will be better for the engine if we change the oil in it every 1000 km :)). But will this make us any better? I won’t be mistaken if I say that it was the car that was created for man, and not vice versa. Therefore, any manipulations with a car always balance between the benefit for the car and personal benefit for its owner.

So, the odometer of my Grant has already begun to tick seven thousand kilometers. It's time to change the oil. At that time, I didn’t think at all about what kind of oil I was going to fill in, I just went to a neighboring store, located 100 meters from the house, and began to choose in the department where automobile oils were sold. At first I asked the sellers’ opinion regarding the oil, but seeing that they didn’t understand anything about it (... well, they take this, this, this. Pointing to some of the most expensive oils from world brands), I began to remember what I had read about before. in the Internet.

Of course, if money just “jumped” into my pocket, then without hesitation I would take an expensive oil that has already proven itself (I will not advertise any brand). But alas, you still have to put the money in your pocket yourself, so the desire to save money has become the main motivator for the purchase.

Using the “universal balance formula” described above, adding up all the pros and cons, I opted for the fully synthetic Rosneft oil “MAGNUM ULTRATEC 5W-40” at a price of 1,610 rubles. per canister 4 liters (price from January 27, 2022). I also purchased a MANN W914/2 oil filter at a price of 290 rubles.

Most stores selling car oils have their own car service centers that provide free oil replacement, provided that the oil was purchased from them. This time I did not refuse a free replacement, since there were sub-zero temperatures outside and in the garage. They filled out a coupon for a free replacement and I went to the service center, where they changed my oil within half an hour. Everything went without incident.

Adjusting the clutch pedal Lada Granta

By the time the oil was changed, I began to notice that the clutch pedal had “play” or free play of about 40 mm. Could this be the reason for the unsatisfactory gear shift? – I thought. The clutch is not fully depressed (it “leads” a little), so the gears are difficult to engage. The explanation seemed logical and I started making adjustments.

Removing the air filter housing

First step: Disconnect the connector from the air flow sensor and remove the air filter housing from the rubber holders. You can use pliers to pull off each elastic band while simultaneously pushing the body in the opposite direction.

Second step: Disconnect the air filter intake pipe hose

Third step: Remove the air intake pipe

Fourth step: On the right side of the air filter housing, disconnect the bundle of wires in the corrugation

Fifth step: On the rear wall of the air filter housing (on the left) there is a canister purge valve - it must be removed from the housing. To do this, disconnect the connector from the valve (just in case, so as not to damage the wires). Then gently pull the valve up relative to the body. It should come off with a little tension.

Sixth step: Lift the air filter housing and disconnect the pipe at the bottom right

Step Seven: Removing the air filter housing will give you access to adjust the clutch cable.

Adjusting the Lada Granta clutch cable

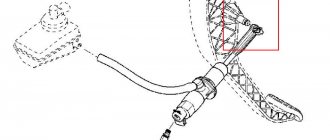

Eighth step: Pull the clutch cable all the way and check the gap between the cable tip guide (the white plastic “lamb”) and the clutch fork. The normal gap is 27 mm. The gap is adjusted by twisting or unscrewing the leash (plastic “lamb”). The photo shows exactly which planes the gap needs to be measured between.

Ninth step: Tightened the clutch cable nut (located directly under the clutch pedal in the car interior). Before tightening the nut, the torso was simply dangling in this place; the nut was loosened.

This completes the adjustment. Pedal free play has decreased significantly.

It felt like the speeds began to switch a little better, but this did not fundamentally solve the problem. Looking ahead, I will say that the box began to work more or less adequately only after 10,000 km. The car now has 14,000 km on it. The way the gears were switched when I just left the salon and now is heaven and earth. Maybe I'm just used to it? What do you think about this?

What are standard parameters

Each engine has its own standard parameters. These are technical characteristics that determine the normal operation of the motor. These parameters are compared with the values obtained during diagnostics. All measurements are carried out with the engine running at idle speed.

The presence of errors that are stored in the car's memory is the so-called DTC parameter. What these errors are can be determined by deciphering their codes, which can be easily found on any resource on the Internet. There are entire tables with interpretations of error codes.

But the engine may have malfunctions and malfunctions and not generate errors. For example, if the idle speed is too high, the control unit believes that the driver pressed the gas pedal, does not perceive the situation as an error and, naturally, does not display it during diagnostics.

Read more: Willson guard liquid glass reviews

If, during engine diagnostics, all measured parameters differ from typical values by no more than 20%, then the engine is operating normally. Components and parts whose performance exceeds the specified value can be considered faulty.

Malfunctions of the clutch mechanism in a car

The most common cause of a malfunction in the clutch system is the clutch disc, since it is the most actively functioning part here.

Possible problems with the clutch mechanism are presented below:

- Pressure plate and release bearing:

- breakage/curvature of the diaphragm spring of the pressure or release disk;

- twitching when the clutch operates;

- instability of the pressure plate.

- Clutch drive:

- hydraulic drive – lack of tightness of the system, malfunction of the working cylinder;

- systems with a cable - the cable lengthened and it broke;

- Manual transmission with electric drive - software disorder in control, breakdown of the actuator electric motor.

- Driven disk:

- friction linings are oily;

- friction adjustments are out of order/damaged;

- Damper springs are broken/deformed.

It is noteworthy that the problems arising in the clutch system cannot be considered insignificant. They usually modify quite quickly from “the car is acting a little strange” to “the car is not moving.” For this reason, it is necessary to immediately eliminate existing problems in the system.

You can determine if the clutch cable is faulty by paying attention to the traffic:

- the clutch pedal starts to bother you;

- the free play of the clutch pedal increases;

- no gear shift when the engine is on.

After diagnosing the vehicle for possible causes of the malfunction, repair work must be carried out. To do this, it’s time to contact a special service center or carry out repairs yourself. In the second case, you will need to first study the necessary information regarding this topic.

Before carrying out work, it is recommended to remove the air filter housing for greater convenience.

Refinement of a new electronic gas pedal

The pedal assembly (11183-1108500-01) does not have oval holes, which does not allow adjustment in the manner described above. Instead, it is proposed to cut off the protrusion (by 2-3 mm), which prevents the pedal from moving completely. This modernization made it possible to increase the pedal travel, which made acceleration with “pedal to the floor” more active. It is also noted that there is no hesitation when pressing the pedal sharply. What I don’t like about the pedal assembly (8450008980), which is installed on Lada Vesta:

- tight gas pedal;

- large free play of the gas pedal (about 8 mm at the tip of the pedal).

What was decided to do:

- remove one of the return springs to make the pedal softer;

- Place a spacer to reduce the free play of the pedal.

How to measure pedal free play:

- Let's start the engine.

- Place a ruler at the tip of the pedal.

- Smoothly press the pedal until the engine begins to gain speed.

- We remember the distance on the ruler.

We remove and disassemble the electronic gas pedal:

- Disconnect the connector (by pressing the inside of the upper part of the latch)

- Unscrew three nuts (head “10”).

- Remove the top cover by unscrewing the fastening screws.

- Remove the rheostat slider by unscrewing the screw.

Refinement process:

- Remove the spring (holding them with a screwdriver from the outside).

- Remove the white support spacers, remembering how they were installed.

- We measure the distance between the support pad of the return spring lever and the support rubber in the body, retracting the pedal to the amount of free play (indicated by an arrow).

- We glue the material of the same thickness (in this example we use 4 mm stickers for furniture legs and doors) using glue or double-sided tape.

We assemble the pedal assembly and install it in the car. The idle motion of the pedal should be minimal, about 1 mm. If the engine idle speed is higher than usual, and there is no free play of the pedal at all, then too much has been added. You will have to repeat the adjustment operation, adjusting the thickness of the lining. The same thing applies if the free play after adjustment remains more than 1-2 mm.

When the throttle assembly of any modern vehicle operates, a lot of contaminants in the form of dust, soot, and oil gradually accumulate on the surface of the throttle. They form a layer of dirt, which makes the air gap between the damper and the car's air duct smaller than the established norm. This gap is important for the normal functioning of the “heart” of the car, since thanks to it the idle speed is maintained at the required level.

When it decreases, the vehicle's electronic control unit (car computer) slightly opens the damper by introducing coefficients that take into account changes in its cross-section. Up to a certain point, the ECU manages to maintain the air gap at a constant level, but sooner or later the throttle valve will still have to be cleaned of dirt.

The need for such an operation, which involves bringing high idle speeds to a standard value, arises not only after flushing the throttle assembly, but also in other cases, in particular in the following:

- after the vehicle battery is completely discharged;

- after replacing or removing the accelerator pedal;

- after replacing or reconnecting the vehicle's electronic control unit.

Undoubted signs indicating that the damper needs to be trained immediately are the following phenomena:

- whistling when revving;

- inadequate behavior of the engine at idle;

- lack of power at idle or failures.

It is advisable to adapt these devices before you teach idle speed. If the cable of the sensor that sends the signal about the accelerator pedal position is disconnected, you must perform the following steps:

- Release the pedal completely.

- Turn the ignition key to “ON” and wait at least two seconds;

- Turn off the ignition, wait 10 seconds;

- Repeat the procedure according to point 2, and then according to point 3.

The described procedure (you must admit, it’s not at all complicated) will teach the damper to open correctly. But to adapt the valve to the “Closed” position, the following operations should be performed:

- Release (fully) the accelerator pedal.

- Place the key in the “ON” position.

- Switch the ignition to “OFF” and wait 10 seconds.

- We make sure that the valve lever moves within 10 seconds (a characteristic sound indicates that there is movement).

Design and operation of the Kalina clutch

The unit is a dry-type mechanism, single-disc, with a central pressure spring. Switching off when pressing the pedal is carried out by a cable equipped with a ratchet. This part allows the cable to automatically change length depending on the wear of the disc linings and ensures a constant backlash-free fit of the clutch with the release bearing to the basket.

The pressure plate together with a diaphragm-type spring are enclosed in a casing. All together is usually called the clutch basket. Between this mechanism and the flywheel there is a driven disk. Its hub is connected to the gearbox input shaft.

When you press on the pedal, the cable tightens, turning the fork. Its lower bushing is pressed into the clutch housing, the upper bushing is removable. The force when turning the fork is transmitted through the clutch and clutch release bearing to the pressure spring and pressure plate, turning off the mechanism.

When the pedal is released, the clutch must fully transfer the engine torque to the transmission. Pressing the pedal normally completely disconnects it from the engine. Signs of the need to adjust the clutch on Kalina include:

- exceeding the full pedal travel (normally 146 mm from the lowered position to the stop on the floor) - adjustment of the clutch cable is necessary;

- when the pedal is pressed, the gear shift occurs with a grinding or crackling sound - the clutch does not disengage completely;

- when starting the engine, you can hear a howling sound in the crankcase - wear of the release bearing;

- jerking when starting to move indicates insufficient smoothness of clutch engagement;

- When driving in 3-4 gears, when you press the gas, engine speed quickly increases, and acceleration slows down - disc slipping, possibly due to wear on the linings or insufficient cable length.

As a rule, it is necessary to adjust the operation of the clutch after it has been repaired to bring the automatic adjustment mechanism into working condition.

In such cases, the wear compensator may lose some of its functions and cannot cope with adjusting the length of the cable.

Auto chemical goods

On elements from VALEO, the nut located on the terminal is coated with zinc, and the contact screw is also galvanized. Therefore, they can only be treated with WD-40 or one of its substitutes. But this processing option is not suitable for copper. All car owners using WD liquid on copper are strongly advised not to repeat their mistake - using WD-40 will lead to destruction of the outer layer.

That is why the threads on KZATE starters made of copper must be cleaned using special means. To do this, you can use: Molykote S-1002 solvent, WL remover, Kontakt 60 or 100 acid and CRAMOLIN ContaClean. When reusing an element after exposure to acid, it must be cleaned with a remover.

Installing a towbar on a Lada Granta What tire size is suitable for a Lada Granta? Lada Granta colors Hydraulic compensators on Lada Lada Granta AMT cars How to disassemble the instrument panel of Lada Granta and Kalina-2

Review of Manufacturer Prices

| Manufacturer | Price, rub.) | Resource (Thousand km) |

| LADA 21901-1602210 |

clutch cable assembly

clutch cable assembly

*prices are current as of October 29, 2018.

Recommendations for the selection of parts and components

The vast majority of spare parts for the Lada Granta are domestically produced. Foreign analogues are not in demand due to their high cost. Compared to “our” products, imports are 10–15% more expensive. The workmanship is at the same level.

When purchasing spare parts and components, always give preference to high-quality, original parts. Check the correspondence of catalog items with the actual data specified in the operating instructions for the technical device.

If you have no experience in car maintenance, seek qualified assistance from service station specialists.

Installation of the Grants thermostat on VAZ 2110, 2112

Will need to buy

- Thermostat Lada Granta (catalog number: 21900-1306010-00), price 640 rub.

- Gasket for the thermostat (same as standard), price 8 rubles.

- Lower radiator pipe for Lada Granta (1 self-tightening clamp included), price 440 rub.

- M8 studs, approximately 85mm long, price 20r.

- Washer for temperature sensor.

- ABRO sealant, clamps.

- Antifreeze.

Replacing the thermostat

- Remove the hoses by unscrewing the clamps (don’t forget about the throttle assembly).

- Unscrew the thermostat mounting bolts (see replacing the thermostat).

- Remove the studs and lower pipe.

- Install a new pipe and tighten the clamp.

Conclusion

- faster engine warm-up, especially while driving.

- the cabin became noticeably warmer

- more stable temperature conditions in different operating modes (during traffic jams, using the stove, in winter on the highway and in the city).

xn--2111-43da1a8c.xn--p1ai

Signs of a faulty clutch cable

Replacing the Lada “Granta” clutch cable is necessary in the following cases:

- the clutch pedal “falls” (the cable is broken);

- The pedal is pressed and returned unevenly, jerking is observed when starting off (the clutch cable gets stuck).

What you need to replace the clutch cable

To change the clutch cable you will need:

- key to 8;

- ruler;

- flat screwdriver;

- pliers;

- new clutch cable.

general information

The drive shaft is equipped with an overrunning clutch with a drive gear moving along the splines of the shaft. It is the clutch that ensures the transmission of torque from the starter to the motor, separating these elements after the engine starts. This condition ensures proper protection of the starter from possible damage that it may receive due to its high rotation speed.

The relay is designed to engage the drive gear with the teeth of the crankshaft flywheel mechanism, as well as to activate the starter power supply. Thus, by turning the key in the lock, the driver begins the process of supplying electric current to the starter from the battery. The starter is set in motion and turns the crankshaft, starting the engine and igniting the combustible mixture.

After starting the engine, the crankshaft speed begins to increase, however, the clutch protects the starter from damage. After the driver returns the key in the lock to the “ignition” position, the relay winding will de-energize and its armature will return to its original position, while the relay contacts will open and the drive gear will disengage from the flywheel teeth. At the same time, the power contacts supplying electric current to the starter motor windings will open.

In addition, the starter is one of the most powerful energy consumers on a car; when starting the engine, the electric current it consumes reaches 400 A or more. For this reason, all electrical connections between the starter and the battery must have reliable contact.

The elements that Grants are equipped with are similar to the starters used by VAZ on its other cars of previous generations. When the engine is in normal condition, two or three turns will be enough to start. Deviations from the norm will be indicated by any of the existing signs of unstable functioning. Possible malfunctions of the drive and starter relay will be revealed by inspection carried out after disassembling the part.

Design and principle of operation of the clutch

To make it more clear, we will briefly describe the design of the clutch. This device is located in a housing installed between the power unit and the gearbox, with the flywheel coming into this housing from the engine side, and the drive shaft from the gearbox side. The end of this shaft fits into the flywheel to maintain alignment between the crankshaft and the drive shaft of the box.

The main element of the clutch is a basket with a drive disc located in it. This disk is spring-loaded, but has the ability to move longitudinally due to these springs, as well as levers. In passenger cars, the spring is combined with levers - a diaphragm spring.

The basket is rigidly attached to the flywheel using a bolt connection. A driven disk is placed between it and the flywheel. The axis for this disk is the gearbox shaft, and it is connected to it by means of splines along which the disk can move.

Briefly about the principle of operation. Since the basket with the drive disk is rigidly mounted on the flywheel, it fully absorbs the engine torque. But the basket is not connected to the box, so it does not convey this moment anywhere. But the driven disk is connected to the box, since it is mounted on the drive shaft. To transmit torque, you need to clamp, and firmly, the driven disk between the drive and the flywheel. The springs that press the drive disk are responsible for this.

If there is a need to separate the engine and gearbox, you need to act on the springs that press the drive disk. The force decreases, the disk, moving away, stops pressing the driven disk against the flywheel - torque transmission ceases.

That is, in order to disconnect the motor from the gearbox, you need to act on the springs of the drive disk. For this purpose, a release bearing is included in the design. It is located behind the basket on the flange of the gearbox drive shaft. Moving along this flange, it can act on the basket springs, but for this it needs force to overcome their resistance. This force is taken from the foot of the person who presses the clutch pedal. Its force is transmitted through the drive system to the bearing and it begins to work.

TsBKE pinout

The location of the TsBKE contact connectors is shown in the figure:

- Enter exit. CAN bus (L – line)

- Enter exit. CAN bus (H – line)

- Enter exit. Rear window heating control

- Exit. Heated windshield relay

- Entrance. Hazard switch

- Entrance. Trunk lock actuator switch

- Entrance. Windshield Wiper Switch (Intermittent Position)

- Entrance. Windshield Wiper Switch (Low Speed Position)

- Entrance. Windshield Wiper Switch (High Speed Position)

- Entrance. Windshield washer

- Exit. Seat heating relay

- Exit. Heated windshield switch

- Enter exit. Lighting control module (Automatic lighting mode) – for 21900-3840080-20 Not activated – for 21900-3840080-10

- Terminal 15

- Entrance. Engine compartment lamp switch

- Entrance. Light switch (Left side direction indicators)

- Entrance. Light switch (Starboard direction indicators)

- Enter exit. Headlight high beam relay control

- Exit. Low beam relay

- Entrance. Lighting control module (Low beam mode)

- Exit. Alarm sound

- Exit. Windshield Wiper Motor (Low Speed Mode)

- Terminal 30 (Turn signals, daytime running lights, low current signals)

- Exit. Turn indicators "Left side"

- Exit. Direction indicators "Right side"

- Exit. Daytime Running Lights

- Enter exit. Park position windshield wiper

- Exit. Windshield Wiper Motor (High Speed Mode)

- Terminal 30 (Windshield wiper motor, interior lighting)

- Terminal 30 (Power windows, door and trunk locks)

- Exit. Trunk lighting – for 21900-3840080-20 Not activated – for 21900-3840080-10

- Exit. Power window switch power supply

- Entrance. Rear left door power window switch – for 21900-3840080-20 Not engaged – for 21900-3840080-10

- Entrance. Rear right door power window switch – for 21900-3840080-20 Not engaged – for 21900-3840080-10

- Entrance. Front right door power window switch

- Exit. Electrically controlled mirror right (Mode “Up / Down”) – for 21900-3840080-20 Not activated – for 21900-3840080-10

- Exit. Electrically controlled mirror right (Mode “Right / Left”) – for 21900-3840080-20 Not activated – for 21900-3840080-10

- Enter exit. LIN bus

- Housing (Low Current Loads)

- Exit. Trunk lock drive

- Exit. Interior lighting unit

- Entrance. Airbag activation signal

- Entrance. Rain sensor sensitivity regulator - for 21900-3840080-20 Not activated - for 21900-3840080-10

- Entrance. Trunk light switch

- Enter exit. CAN bus (L – line)

- Enter exit. CAN bus (H – line)

- Entrance. Front right door switch

- Entrance. Rear passenger door switch

- Autostart (for Lada Connect system)

- Entrance. Front left door switch

- Exit. Car interior lighting (Energy saving mode)

- Exit. Driver's door lock motor

- Exit. Front left door power window

- Exit. Front right door power window

- Exit. Rear left door power window – for 21900-3840080-20 Not activated – for 21900-3840080-10

- Exit. Rear right door power window – for 21900-3840080-20 Not activated – for 21900-3840080-10

- Housing (High Current Loads)

- Exit. Passenger door lock motors

- Exit. General "starboard"

- Exit. General "left side"

Dismantling works

After opening access to the starter, you must perform the following steps:

- First, you should disconnect the control connector, for which the locking tab is lightly pressed;

- Then the rubber cap is moved aside and the nut is unscrewed using a 13mm wrench from the terminal;

The power terminal is removed, after which the three mounting screws located at the top and bottom are unscrewed with a 13 key.

Note that you need to start with the two lower screws, and the top one should be unscrewed last, while the starter housing must be held, then the housing is carefully tilted back. Installation work is carried out in the reverse order of dismantling.

How is the cable constructed?

You can see the condition of the cable through the hood. Despite the simplicity of the element, in fact it is a whole structure consisting of several elements. Moreover, it is equipped with automation. We need to bypass it in order to adjust the cable ourselves.

What do we see? There is a coupling from which the shell comes out on one side and the leash on the other. A thin end of the cable, enclosed in a corrugated tube, is stretched to the leash. The tip going into the fork is hidden under it. We need to tighten it up or change it completely. It is the source of those very extraneous sounds.

By rotating the leash, you twist or twist it, correcting the gap. This is how manual length adjustment occurs. Note that the shorter the cable, the sharper the pedal will respond to pressure. Ideally, it should rise exactly to the level of the brake pedal. At the same time, we check whether it clicks when pressed.

Diagnostic process

Instrument panel with which you can perform diagnostics

So, diagnostic operations using the dashboard are not complicated and almost every Kalina car owner is able to cope with this on their own. Following the step-by-step instructions described below, you can carry out diagnostics on any generation of VAZ 1117-1119.

Now let's move directly to the process of performing diagnostic operations:

- We reset the daily mileage indicator. For this purpose, there is a special button on the instrument cluster.

Using the daily mileage button we reset the indicator

Insert the key into the ignition and turn to position 1

Instrument arrows move from the beginning to the final control point

The instrument panel screen shows the software version (in this case UEr 3.0)

Errors received during the diagnostic process. There are 8 and 4 errors in photo 6.

Decoding instrument panel readings

2 — the on-board network voltage exceeds the norm; 3 - fuel level sensor error detected. Occurs if there is an open circuit in the sensor within 20 seconds. 4 - an error has occurred in the coolant temperature sensor. Appears if an open circuit is detected within 30 seconds. 5 - an error has been detected in the outside temperature sensor in the car. If there are no sensor readings within 20 seconds, “-C” appears); 6 — engine overheating detected; 7 — emergency oil pressure; 8 - error or malfunction of the brake system; 9 - low battery charge;

E - error detection in the data packet stored in the EEPROM.

Now all that remains is to compare all the errors that popped up on the screen with those listed above.

How to adjust the clutch on a Niva?

Conclusion

Although the adjustment work is not a difficult task, it requires some attention and patience. However, with the right approach, success will not keep you waiting. Good luck with the renovation.

During the operation of the car, sometimes it becomes necessary to adjust the clutch drive. This happens because over time, the pedal stroke changes as a result of natural operational wear of the rubbing parts of the clutch (driven and driven disks, flywheel surface) and (or) pulling of its cable.

In another case, the need to adjust the clutch drive may arise due to previous incorrect adjustment. It is possible to reduce or increase the working stroke of its pedal. As a result, malfunctions occur in the operation of the drive - the clutch begins to “slip” or “drive”, gear shifting becomes difficult, jerks appear when starting from a standstill, fuel consumption increases, etc.

Here we will consider a simple adjustment of the clutch drive (clutch pedal travel) on VAZ 2108, 21081, 21083, 2109, 21091, 21093, 21099.

Tools required for adjusting the clutch of VAZ 2108, 2109, 21099

— tape measure with a clearly readable scale

— two 17 mm open-end wrenches

open-end wrenches for 17 and a tape measure - all you need to adjust the clutch drive on eights, nines and ninety-nines

Preparatory work

— fix the car (put chocks under the wheels)

— remove the battery (you don’t have to remove it, but it’s easier to make adjustments with the battery removed)

- press the clutch pedal several times

Checking the working clutch pedal

Let's measure the travel of the car's clutch pedal. Before doing this, we move the carpet on the floor of the car back so that the measurements are more accurate.

- use a tape measure to measure the distance from the floor of the car to the bottom edge of the clutch pedal

The image shows how best to do this.

the actual distance from the bottom edge of the clutch pedal to the floor under the driver’s feet, measured using a tape measure

It should be approximately 18-20 cm.

— press the clutch pedal all the way with your hand and measure the distance from the floor to the bottom edge of the pedal.

the distance from the floor under the driver’s feet to the bottom edge of the clutch pedal when it is pressed all the way - the clutch is “disengaged”

It should be 6-7 cm

- subtract from 18-20, 6-7, it turns out 13-14 cm

This is the norm for the full travel of the clutch pedal of VAZ 2108, 2109, 21099 cars and their modifications. Many repair manuals indicate a working stroke size of 12.5-13.5 cm, which is also very close to our measurement.

If the clutch pedal travel differs more or less, it is necessary to adjust the clutch drive.

Adjusting the clutch drive VAZ 2108, 2109, 21099

The clutch drive adjusting nut is located in the engine compartment of the car on the drive cable sheath, inserted into a special bracket mounted on the gearbox housing. It is protected from unscrewing by a lock nut located there.

clutch drive adjusting nut and its locknut on the bracket

— Holding the adjusting nut with one 17 mm wrench, use another 17 mm wrench to loosen the lock nut a few turns

loosening the locknut using two open-end wrenches 17

— We rotate the adjusting nut clockwise with one key, holding the locknut with the other - this is to increase the clutch pedal travel (the pedal will rise) or counterclockwise to decrease its travel (the pedal will lower to the floor)

rotation of the adjusting nut - adjustment of the clutch drive

How much to reduce or, conversely, increase the pedal stroke is determined based on the results of the check described above.

- Lightly tighten the locknut

— Press the clutch pedal several times and check again

If the resulting figure does not fit within the norm, we carry out the adjustment again. And so on until we achieve the required result.

— After completing the adjustment, tighten the locknut

Notes and additions

— When the clutch is correctly adjusted, its pedal should be approximately at the same level as the brake pedal.

The clutch pedal is approximately at the same level as the brake pedal - the drive is adjusted correctly

— The maximum permissible working stroke of the clutch pedal for VAZ 2108, 21081, 21083, 2109, 21091, 21093, 21099 cars is 16 cm.

Five more articles on VAZ cars

Engine control unit Lada Kalina

The capabilities of autodiagnostics depend on the type and brand of the ECU (electronic control unit, ECU). The type of ECU depends on the year of manufacture of the car and the engine (environmental friendliness and engine number).

On Kalina 1, 2 cars the following are most often installed:

- Engine 21116 - ECU M74

- Engine 21126 - ECU Bosch Me17.9.7 or M75 (with or without CAN bus).

- Engine 21127 - ECU M74 - 638 (analogue of M74 with a modified board).

- January and Itelma ECUs were installed on cars until 2008.

The ECU of the Lada Kalina is located under the central panel, and in order to view the number and type of the ECU, the ECU should be removed (lift the panel).

Engine control units, in turn, have a certain firmware, but for diagnostics via the OBD2 connector, only the presence of a CAN bus is affected. If you have CAN, you must select an appropriate diagnostic adapter that supports this protocol.

IMPORTANT: If ECUs without CAN bus support are installed, you must use the KKL VAG adapter

It is recommended to carry out ECU diagnostics once every 10,000 km, or every maintenance. The example shows a Bosch unit with firmware b173CR03 (serial firmware) without CAN.

Briefly about ECU firmware:

Flashing (reflashing) the Bosch Me17.9.7 control unit on VAZ cars is only possible using a K-Line adapter, which supports data transfer via the corresponding bus.

Source

Clutch squeak

It is problematic to independently adjust the Grant clutch, since the cable is equipped with automatic equipment. The clutch drive is cable driven and backlash-free. Here VAZ used a ratchet-type mechanism, the task of which is to compensate for the changed length of the cable during operation.

That is, over the course of its life, the length of the cable can decrease or, conversely, increase. After all, he is regularly under tension. Therefore, independent adjustment is difficult. But it is the cable that is the cause of many minor troubles that Lada Grant owners encounter. Note that these problems appear on both the sedan and the liftback body.

It follows from this:

- Clutch squeaks when the pedal is pressed

- Pedal clicks, buzzing sounds

You need to check the clutch. And if the box itself is in order (basket, disk), then the pedal is the discomfort factor. Here we need to check the cable, buy a new one if necessary and replace it.

If everything is perfect in the calculations, but the unpleasant sound does not leave you behind, then you need to look for other culprits:

- Plastic pedal bushing. It can “get used” to the bracket and make squeaks. Everything is quite simple here, we are looking for the attachment point, it is probably loose. Let's pull it up. Then be sure to repeat the procedure with the cable

- Tip lead. You will notice this at the first stage. If it squeaks, then it needs to be changed. Fortunately, there are plenty of such parts on sale, and the replacement process itself is not difficult. Unscrewed the old one and screwed on the new one. Then again measure and adjust according to the instructions above

- Loss of input shaft lubrication. This is already a problem with the box itself. Here the solution is clear: lubricant.

There can be several reasons for clutch pedal squeaks, so first you need to trace the source of the squeaks. If they come from the pedals, then the reason may be in the plastic pedal bushing, which, when you press the clutch pedal, presses the microswitch, there is a place where it rubs against the bracket.

If the squeaks come from the motor side, then the tip driver may be creaking; you need to lubricate the contact point between the plastic nut of the cable and the clutch fork. Another reason for squeaks in the clutch pedal may be the lack of lubricant on the input shaft in the box, where the pressure bearing goes, which is pressed on the clutch fork, and he, in turn, presses the clutch disc.

Another reason for squeaks may be in the clutch cable itself; you can try to lubricate it using the same grease and a thin tube, or replace the cable with a new one. If nothing helps, then try contacting an official dealer with your problem; they often remove the Grants checkpoint to solve the problem.