“Fucking basin. "

Hi all!

My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years. Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the Vulcan casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

To replace the “ten” cardan you will need a pit, keys for 10 and 13:

- The gearbox control rod joint is hidden under the boot.

- We remove the boot and move it to the gearbox.

- Loosen the clamp bolt to 13, loosen it a little and pull the link off the hinge. Then unscrew the 10mm bolt that secures the hinge on the gear selector rod and remove the hinge.

- We install a new hinge without play on the gear selector rod and secure it with a 10-point bolt. To prevent it from turning away from vibrations, we lubricate it with a thread locker.

We put the boot and the drawstring in place and adjust it.

After that we do a test drive. If everything is good, then tighten the clamp. There is an opinion that before installing the glass you need to saw off its tip a little, in fact, everything installs perfectly without sawing. After adjustment, the gearshift lever is located exactly in the middle.

Impressions from the backlash-free driveshaft of the Lada Kalina on a VAZ 2110

It seems that the lateral travel of the lever has decreased. The difference is especially noticeable while driving than when parked. Gear changes have become clearer, there is no “yaw” movements of the lever.

However, do not forget about gearbox vibration . If previously these vibrations were transmitted to the rocker and were partially damped by the play of the standard cardan, now they are transferred in full force to the gearshift knob, which causes rattling, which has to be dealt with over time.

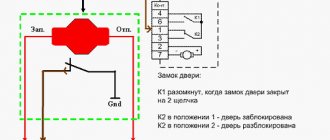

Principle of operation

Study the diagram below to understand how the short throw rocker works. The lever is installed in the neutral position, here it is indicated by the points “O” and “F”. To start the transmission, you need to move the rod - it will connect to the control gear at point “B” - at point “A”. After this, the handle will move to point “E”. Repairs and subsequent replacements are carried out in order to reduce the distance.

This can be done if the lever extends to point “H”. This move will increase the distance. On the diagram, "A" and "B" will become points "C" and "D". Replacing the standard rocker with a short-stroke one allows you to reduce the movement of the handle. We've sorted out the theory, now we can start the repairs.

Replacing the gearbox slide

First, you should decide whether you will buy a ready-made short-stroke part or make it yourself. For Lada Priora drivers who have not upgraded components, we recommend choosing the first option. The instruction will be carried out taking into account modifications.

For work we will need:

- Two metal plates.

- Kardanchik from Kalina.

- Welding machine.

- A set of keys, including spanners.

- A grinder with a cutting wheel; alternatively, you can use a hacksaw.

Step-by-step instruction

- Repair and replacement begins with removing the decorative cover from the gearshift lever. The knob may not give in, but it is not secured by anything, so just pull firmly towards you;

Installing a short-stroke rocker on a Lada Priora - step-by-step instructions

5. We take out the lever together with the rod through the interior; for convenience, you can disconnect the lever from the rod, although you don’t have to do this.

6. Remove the cardan. First of all, you need to pull off the rubber boot, then using a “10” wrench, unscrew the fastening bolt on the left side of the cardan.

7. As you can see in the photo, the cardan rods differ in length. The problem is solved by shortening the Kalinovsky rod; this must be done taking into account the type of short-stroke link. In some cases, the rod may not go in completely, as a result the gearbox lever will move towards the handbrake. If you also need to shorten, then know that you need to cut off about 1-2 cm.

8. So, we install the “Kalinovsky” cardan, having previously lubricated it with lithol from the inside. The bolt screws in easily because it has a cone shape, but do not overtighten.

9. Traction is also installed through the interior. It’s more convenient to do this in pairs with an assistant: one holds it by the elastic band in the cabin, and you carefully pull the traction.

Also check out

- Install the Kalinovsky cardan by applying lithol to its inner surface. Since the bolt is cone-shaped, screwing in is not difficult.

- The thrust should be installed through the interior. It's good if you have an assistant nearby. He will hold it by the elastic band in the cabin, at this time you need to stretch the traction.

Assembly is performed in reverse order

- First, we put the rod on the cardan shaft.

- Then you can begin assembling the reverse gear locking mechanism. Lubricate the spring ball.

- Adjust the gearshift lever.

- Tighten the clamp on the rod.

Attention!

If you first assemble the reverse gear locking mechanism, the long rod will not allow you to put the rod on the cardan shaft. The problem can be solved by shortening it. It is important not to forget to put the boot on the driveshaft.

Adjust the reverse gear locking mechanism, since the consequence of adjusting the scenes is that the mechanism does not match the plate to which it clings. The problem can be solved by removing the plate and adjusting the hook (it is a cutout on the mounting bracket). You can sharpen it with sandpaper or a file.

The photo shows the adjusted toe.

To complete the procedure, you need to put on a manual transmission cover with a knob.

It's no secret that the Priora has a congenital problem - the rattling of the gearbox driveshaft.

In almost all Priors, the rubber boot of the gearbox driveshaft is destroyed after some time. One glance is enough to give a verdict: the boot is made of burnt rubber, so it doesn’t last long! The markings on the cardan shaft boot were not Balakovsky.

It was decided to replace the Priora boot with a Viburnum boot, and also replace the Priora gearbox driveshaft itself with a Kalina driveshaft - it is too praised on various forums.

| The original boot of the gearbox driveshaft was cracked, and there was even a hole in its “accordion” |

| I purchased a Balakovo-made boot and a Tolyatti gearbox driveshaft, all from Kalina |

| I had to tinker a little with the Kalina gearbox driveshaft: the Kalina driveshaft rod is longer than the Priora rod by about 2 cm. Since I didn’t have the opportunity to compare the Kalina driveshaft with my own driveshaft (it was still on the car at that time), I had to cut it “blindly”. I measured 1.8 cm from the edge and started sawing |

| I don’t have a grinder, I sawed with a hacksaw for metal - it took about 40 minutes of time, 2 hacksaw blades and a slightly ground corner on the emery))) It’s very difficult to saw, because the metal is strong! After sawing off part of the rod, I made a conical chamfer using sandpaper and a file. |

| Let's start removing the original gearbox driveshaft. We loosen the clamp and tighten the torn boot. Next, we unscrew the fixing bolt, but unfortunately this is not so easy to do: the bolt is coated with red thread locker and there is no way to unscrew it. The open-end wrench turned, “licking” the edges, but the powerful socket head did not fit; the gearbox housing interfered with it. In general, in order to remove the fixing one, stock up on spanners. Replacing the boot and drive shaft itself takes about 10 minutes |

| I sawed at random, but the size was amazingly accurate - the length of the rod of the original Priora gearbox driveshaft and the Kalina gearbox driveshaft are the same! |

| The original driveshaft of the Priora gearbox is essentially not a driveshaft at all: it bends only in one plane, while the Kalinov gearbox driveshaft bends in 2 planes. In addition, the photo clearly shows a huge gap of 2-3 mm on the original Priora driveshaft |

| The anthers differ slightly, but the Kalinovsky anther has better workmanship than the original Priora anther |

| A little about adjustment. While unscrewing the fixing bolt, the reverse gear jumped out. We had to manually select the desired gear using pliers, but we couldn’t do it the first time. Having assembled the mechanism, it turned out that in place of the reverse gear it turned out to be the first, and the second could not be engaged due to the reverse speed limiter. I had to redo everything. The repeated adjustment turned out even worse, only 3, 4, 5 gears remained. It was possible to adjust it normally only the 4th time, using pliers to find the reverse gear. And we found it this way: having removed the link and clamped the cardan shaft with pliers, turned it counterclockwise until it stops and pushed the hinge forward. In order to make sure that we had engaged reverse gear, I started the engine and carefully moved off - the car went backwards! Let me make a reservation right away: absolutely nothing will happen to the box, nothing will fly out or break. |

| We install the gearbox driveshaft in place. Having straightened the clamp clamp a little, we connected the gearbox driveshaft to the rocker, set the lever to the reverse gear position and tightened the clamp clamp! The check showed that all the gears are there and they work perfectly. The feeling is very pleasant, the gears are engaged very softly and smoothly, no snagging. The lateral play of the lever has not changed, the longitudinal play has become smaller, but this difference is not noticeable either while moving or standing still. The position of the lever has changed a little, it has become a little closer to the driver’s seat, but it doesn’t touch anything, and it’s not noticeable from the outside, just by feeling it! But now you don’t have to reach so far for fifth gear |

Changing crosspieces in steering cardan shafts

Steering cardan shafts are structural elements of the vehicle control system, which must be given attention in the event of such troubles as:

- difficulty turning the steering wheel;

- steering wheel play;

- knocks and extraneous noises.

There are two elements in the car under consideration. One cardan is located behind the engine shield under the hood of the car. It is adjacent to the steering rack. The second is located in the vehicle interior, or rather, at the driver’s feet. The external driveshaft is subject to more intense impacts because it operates in a harsh environment. However, the internal analogue periodically fails.

To install the parts in question, you must have keys of 10 and 12. During the process, the steering wheel must be fixed and locked in the central position, since without a cardan, turning it can lead to a break in the cable.

After fixing the steering wheel, loosen the boot clamp. Next, the fastening elements of the lower cardan on the rack are unscrewed, as well as the bolt that ensures the connection of the two structural elements in question.

The next step is to dismantle the lower cardan shaft, for which it must be moved sequentially up and down. The upper analogue is simply dismantled. You just need to unscrew the bolt that secures it.

The feasibility of replacing the structural parts of the steering column universal joint is determined by checking the mobility of the bearings and the play of the crosspiece. If critical defects or malfunctions are detected, you will have to purchase a new cardan, crosspiece or bearings, depending on which part has failed.

Backstage repair and adjustment

In this section we will describe the replacement of all consumables, as well as all the adjustments to the Priora gearbox that can be carried out on a particular transmission.

To repair a Priora gearbox of any type, you will need:

- pit;

- overpass;

- lift;

- jack with safety stands.

In addition, you will need the following tools:

- a set of spanners and open-end wrenches;

- flat and Phillips screwdrivers;

- ratchet with extension and set of bits.

The replacement takes place in several stages:

- We lift the car off the ground using a lift or by rolling it into a hole, but you can also get by by lifting the front of the car.

- We set the steering wheel at a right angle and fix it, and also fix the steering wheel; during replacement, movement of the wheels and steering wheel is not desirable.

- To access the steering shaft, remove the left (right) wheel. We go into the salon and unscrew the fastening bolt; after a slight effort, the steering shaft should come off the steering wheel.

- Under the car, carefully remove the upper and lower casings, check the amount of dirt on the crosspiece and steering shaft driveshaft; not all cars have them protected by a boot (purchase and installation of such rubber will cost 100-200 rubles).

- We find and unscrew the bolt on the crosspiece; you may have to use a WD tool. Once the bolt is removed, the steering shaft should easily come off the steering rack.

- Pull the shaft down and pull it out. Often the crosspiece mechanism is rusty and dirty; first of all, you will need to wash it.

- For flaring you will need a sprocket of the appropriate diameter; fix the shaft in a vice.

- Using a head (presumably a 8-pointer), we knock out the cross first in one direction (remove the bearing cup), and in the other direction (also remove the cup).

- Then we take a new crosspiece and insert it in the same order - we start one side first, and then the other, press it in using a vice (but not too tightly, the metal may wrinkle).

- We align both cups and roll them with a chisel and hammer.

Main malfunctions of the scenes

All malfunctions of the Lada Priora gearbox and how to eliminate them:

| Symptom | Malfunction | Gearbox model | Way to solve the problem |

| Unclear gear shifting | Worn bushings | 2170–2181 | Replace all bushings |

| Damaged pillow | 2170–2180 | Replace pillow | |

| Cables stretched | 2181 | Replace cables | |

| The tension of the traction clamps is loose | 2170–2180 | Adjust then tighten | |

| The lever has failed | The pillow tore | 2170–2180 | Replace pillow |

| Lever travel too long | Worn bushings | 2170–2181 | Replace all bushings |

| Cables stretched | 2181 | Replace cables | |

| The tension of the traction clamps is loose | 2170–2180 | Adjust then tighten | |

| One or more speeds do not turn on the first time | Forks are deformed | 2170–2181 | Replace plugs |

| The tension of the traction clamps is loose | 2170–2180 | Adjust then tighten | |

| Cables stretched | 2181 | Replace cables |

The main malfunctions of the Priora gearbox are the same for any transmission and are determined by their design. The lever and rigid drive are made of steel, so they do not break. The remaining parts, all kinds of plastic bushings and cables, clamps that secure the rods, often fail (their nuts have a bad habit of becoming loose). In addition, on the so-called rocker boxes, that is, gearboxes 2170–2180, the rubber band (the rubber support of the lever) often fails, which also leads to problems with switching on the required speeds.

One of the rare defects is the rattling of the 2014 Priora gearbox, although it also occurs on cars of other years, but always with a rocker transmission. It is caused by contact between the torque rod and the gear shift rod. Due to the running engine, the contact becomes vibrating, and the collision of parts generates ringing. To eliminate it, just slightly move both rods away from each other.

Product delivery options

Note! Below are the shipping methods available specifically for this product. Payment options may vary depending on the shipping method. Detailed information can be found on the “Delivery and Payment” page.

Parcel by Russian Post

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 5 to 12 days.

Parcel by Russian Post 1st class

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 2 to 5 days. More expensive than regular delivery by Russian Post, approximately 50%. Parcel weight up to 2.5 kg

Express Parcel EMS

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 3 to 7 days. More expensive than regular delivery by Russian Post, approximately 100%.

Transport companies

Available payment methods:

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Delivery is possible to any locality where there is a representative office of the transport company. Delivery time is from 2 to 10 days. Sending large parcels is approximately 50% more profitable than by Russian Post.

Pickup from our warehouse

Available payment methods:

- Cash upon receipt

- Credit, installments

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Pickup times must coincide with store opening hours.

The invention of devices that transmit rotation has long excited the minds of thinkers. The discovery of the wheel gave importance to the rational transmission of torque, ensuring (through varying amounts of energy with conflicting efficiency) the rotation of objects. The remote location of rotational elements has long been a problem area in transferring kinetic energy and converting it into rotational activity.

The placement of rotation elements in different planes required a smart solution to transmit a constant torque ratio. The direct connection through the shaft prevented the transfer of energy when the parts were positioned at right angles. Installing a gear drive requires a base, a housing, several shafts, and lubricating fluid to ensure smooth operation of the gears. In order to simplify the layout of the elements and provide more power during rotation, a clever and, most importantly, effective solution was introduced: allow the shaft located between the two objects to bend through a universal connection, reminiscent of two interlocking chain links. Historically, this has been the simplest solution, but cannot withstand heavy loads and significant friction.

Changing gears on a VAZ 2109

The “nine” is equipped with a five-speed manual gearbox (Gearbox). The connection between the gear selection control lever and the gearbox actuators is purely mechanical. For this purpose, a steel rod is used, the lower end of which is fixed to a ball joint in the housing of the gear selection mechanism, and the upper end is equipped with a knob that fits comfortably in the driver’s hand. This lever, not entirely justifiably, is popularly called the “slide”.

In a classic backstage, the levers are connected using a slider that can move along it. It looks especially impressive when driving the drive wheels of a mainline steam locomotive. In an automobile rocker, the elements have a certain freedom; they are connected by a hinge, but the articulation point cannot move along the rocker. Nevertheless, the name stuck.

The gear change lever of the “nine” has two degrees of freedom with three positions in each: “forward - neutral - back” and “left - neutral - right”. This gives 9 selector position options, of which two (rear left and rear right) are not used. The remaining seven correspond to five forward gears, one reverse gear and neutral.

The standard VAZ 2109 rocker is called long-stroke because the attachment point of the rod leading to the gearbox is located quite close to the ball joint. The distance to the attachment point is approximately 4 cm. With a total length of the lever with a knob of 30 cm, in order to move the gearbox rod by only 2 cm, the gearbox handle must be moved by 15 cm. Plus the play - it turns out to be a very long-stroke option, and it cannot be configured otherwise.

A fashion came from motorsport - replacing the rocker with a decrease in stroke. The repair involves moving the rod attachment point up the slide by 5–6 centimeters. It turns out to be a short-throw shifter on a VAZ 2109, the stroke of the gear shift knob is halved. Many people like it.

The Kalina wing on the VAZ 2109 also improves the situation.

Making a short-stroke slide with your own hands

So, let's begin the modernization process:

- We raise the place of attachment of the piece of iron that goes from the gearbox to the lever inside the VAZ 2110 interior.

- You can do without dismantling the rocker, the main thing is to disassemble the ball joint.

- Now we need to ensure that the plastic paws release the ball. To do this, you need to unclench the metal ring. We disconnect the rod and carefully drag it inside through the cover, which is responsible for protecting it from dirt. It will be much more convenient to work if the clamp near the gearbox is loosened.

Replacement is carried out according to the same scheme. Only instead of welding, a freelance short-stroke rocker from another car is installed. Replacement is a more expensive solution, so doing it yourself is problematic. If you have experience working with gearboxes, then replacing and purchasing a new part will cost about 1,000 rubles.