Some owners of budget Lada Kalina models have problems with the windshield wiper trapezoid due to its unexpected failure. This type of malfunction has become widespread, so we cannot ignore this issue, because the situation when the wipers stop functioning in the rain is not the most pleasant. And the windshield wiper needs repair.

Possible causes of problems

Some experts argue that if the windshield wiper blades do not work when turned on, then the most common reason for this is a failed fuse.

In this case, no special efforts will be required to fix the problem. You just need to open the fuse box cover (on the left under the steering column) and find the appropriate fuse. A diagram printed on the inside of the lid will help you do this. If the wipers do not work intermittently, then the relay may have failed. It is located in the same place as the fuses. It needs to be replaced with a new one. But, as statistics provided by owners of Lada cars show, fuses or relays blow out quite rarely.

A very common reason why the Lada Kalina windshield wiper blades do not work is the destruction of the bushings. As experienced drivers say, plastic bushings fall apart very quickly - their service life is at most 3 years.

Perhaps the reason for their destruction is the quality of the plastic. But, alas, there are no other bushings. The repair kit can be found in specialized auto stores.

When the wiper drive does not work, the reason may be a failure of the motor that drives them. To find out whether the electric brush drive has really burned out, you need to check whether electricity is supplied to it. This can be done using a tester. If power is supplied, then the overheated motor needs to be replaced.

The wipers stopped working: the most common reasons

Over time, every car owner is faced with the fact that the wipers suddenly stop functioning. Problems that arise reveal themselves either by a complete stop or by the appearance of extraneous sounds during operation (for example, creaking).

The mechanical part of the windshield wiper is usually very reliable. Therefore, usually wipers may not work for the following reasons:

- Excessive wear and tear on moving parts of the system or lack of lubrication in required areas. In order for the windshield wiper mechanism to work properly and not fail for unknown reasons, inspection and maintenance are required, albeit not too often.

- Improper use of wipers. As an example, in the winter season, before turning them on, you need to unfasten them from the glass (ideally, melt the ice on them). Failure to do this may result in fuse, motor, or drive rod failure during startup.

As a rule, the cause of windshield wiper failure is often a malfunction of the electrical part of the device:

- The hum of the motor is not heard, the wipers do not work (they do not move in any of the operating modes). In this case, the cause may be a malfunction of the following elements: wiring, connectors, switches or gear motor.

- The wipers work, but very slowly. Most likely, the reason is also in the gear motor. The drive mechanisms may have become oxidized and rusted. Usually they need to be cleaned and lubricated or checked for correct assembly of the mechanism.

- When the intermittent mode is on, the windshield wipers operate continuously. The reason is most likely a broken relay, which will have to be replaced since it is not repairable. If the wipers are working and the sound of the motor is heard, you can also diagnose a malfunction of the breaker relay.

- You can hear the engine running, but the wipers don't move. In this case, the reason is most likely a break in the rod or contact elements.

- The windshield wiper arm does not work. The cause of the malfunction may be oxidation or damage to the contact elements of the traction rod.

- The windshield wipers do not work correctly - they do not move to their original positions. The cause of the breakdown in this case may be improper installation, problems in the contact group of the gear motor, wear or shearing of the splines on the brush drives.

- The wipers do not work when the washer fluid is applied to the windows. The cause may be a broken steering column switch or defective wiring and electrical connections.

Reasons for mechanical windshield wiper failure include:

- Self-unscrewing (full or partial) of the nut connecting the crank to the gear axle. Such a defect is easy to determine when the wipers are on, since the gear motor is working, but the brushes do not move.

- The nut securing the wiper arm is loose or its thread has been stripped. The reason may be incorrect installation of the leash in the initial position. Avoiding this is quite simple - you need to tighten the nuts with the required torque, and before final tightening you need to put the windshield wipers in the desired position.

- The wipers do not clean the glass due to a poor fit. The simplest reason is wear of the brushes themselves. The brushes simply need to be replaced. The second most common reason is poor adherence of the brushes to the glass due to mechanical interference. An option to eliminate it is to clean the wiper of foreign objects that interfere with normal pressure. But if none are found, then it is necessary to inspect the wiper mechanism, disassemble it, find and replace parts with a lot of wear.

From the above it follows that the reason that the wipers do not work can be either a malfunction of the electric motor or wiring, or a failure of the mechanical component of the vehicle unit in question. The trapezoid, the mechanism for driving and moving the wipers, is very often prone to breakdowns. Read further in the article for what to do when your windshield wiper breaks or does not work.

Replacement of Lada Granta windshield wiper, windshield wipers, wiper motor

The Grant is equipped with a windshield cleaner and washer.

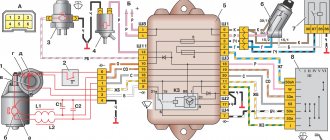

The windshield wiper consists of a gear motor with rods and two levers with brushes. The supply voltage is supplied to the electric motor of the gearmotor through an additional relay when the ignition is turned on. To protect the gearmotor from overloads, a bimetallic fuse is built into its internal circuit.

To supply washer fluid to the windshield, two washer nozzles are installed on the hood. The liquid is supplied to them by an electric pump through an elastic tube from the windshield washer reservoir mounted on the right mudguard in the engine compartment. The pump is installed on the wall of the tank.

In winter, a special antifreeze liquid must be filled into the windshield washer reservoir.

1. Prepare the car for work and disconnect the terminal from the negative terminal of the battery

2. Using a screwdriver, remove the plug from the windshield wiper arm.

3. Using a 13 mm socket wrench, unscrew the nut securing the windshield wiper arm and remove the arm.

If the lever sits tightly on the shaft splines, then in order not to bend the shaft, place a nut on the threads and use sliding pliers to press the lever off the shaft.

4. Similarly, remove the second windshield wiper arm.

5. Remove the air intake grille

6. Release the holder of the connection block of the windshield wiper gear motor.

7. Disconnect the windshield wiper wiring harness block from the vehicle's on-board network.

8. Using a 10 mm socket wrench, unscrew two bolts 1 and nut 2 securing the windshield wiper.

9. Carefully remove the glass cleaner from the air supply box.

If the windshield wiper is new or has been repaired, the arms should be installed last. Before installing the arms, connect the windshield wiper to the vehicle's on-board power supply and turn on the intermittent operation mode. Once the windshield wiper has completed a full cycle and stops, turn it off. And after that, set the levers in the lower position of the glass. If you cannot install the arms so that the windshield wiper works correctly, you should rearrange the crank on the gearmotor shaft (see below, “Windshield wiper - replacing the gearmotor.”

At the request of workers

Posts 12,310

There is a circuit - what is the problem with supplying voltage through it? E - minus. +1 - winding of the first speed of operation, +2 - winding of the second speed. one of them is supplied with a plus. but to determine the initial position of the brushes there is a built-in breaker contact, which operates through terminals B and S. through B the plus is switched, while the position is not zero, there is a plus at the output of S. those. for intermittent mode, through the steering column, plus is constantly supplied to terminal B and plus is supplied once to terminal +1 (to start the motor). then the plus that comes with S still continues to be supplied to +1 through the steering column switch. after a full revolution, the breaker in the motor is triggered and the S plus disappears at the output.

Don’t even think about applying voltage only through terminals +1 and +2! and then there are craftsmen. there is very little resistance, the current is crazy, the motor runs at a very high speed and burns out very quickly.

There is a circuit - what is the problem with supplying voltage through it? E - minus. +1 - winding of the first speed of operation, +2 - winding of the second speed. one of them is supplied with a plus. but to determine the initial position of the brushes there is a built-in breaker contact, which operates through terminals B and S. through B the plus is switched, while the position is not zero, there is a plus at the output of S. those. for intermittent mode, through the steering column, plus is constantly supplied to terminal B and plus is supplied once to terminal +1 (to start the motor). then the plus that comes with S still continues to be supplied to +1 through the steering column switch. after a full revolution, the breaker in the motor is triggered and the S plus disappears at the output.

Don’t even think about applying voltage only through terminals +1 and +2! and then there are craftsmen. there is very little resistance, the current is crazy, the motor runs at a very high speed and burns out very quickly.

The device has found its application not only in passenger cars, but also in all other types of vehicles. Even large submarines, helicopters and airplanes are equipped with windshield wipers, which perform an irreplaceable role and at the same time have a very simple operating principle. When the wipers operate, excess water, dirt and other foreign objects on the windshield begin to be removed.

Car models have several operating modes: with a given period of time; constant; single. The auxiliary mechanism supplies water to remove large amounts of dust or dirt from the windshield.

Size

If you do not know which windshield wiper blades are best to choose, then first of all you need to consider the size of the wipers. Today, the domestic market offers many different variations of purifiers. Moreover, the size of the windshield wiper blades determines how well and efficiently the glass will be cleaned. Front wipers should always be larger than the rear ones, since the view of the situation on the road is mainly through the mirrors, not the glass.

Set of frame brushes

When choosing wipers for Kalina, you should be guided by the following dimensions:

- The longer wiper (facing the driver) should be 24 inches long;

- The passenger windshield wiper should be about 16 inches;

- As for the rear window, you can also choose a 24-inch wiper, but for better cleaning it should be rounded.

Measuring the length of the brushes

In order for the wipers to clear the windshield from one edge to the other, it is important to choose the right length. If your car has factory wipers, just measure them with a tape measure.

Take the time to measure both wipers, as some car models have different lengths. Typically, the driver's side has a longer brush. If the lengths are different, you will have to buy windshield wipers individually of different sizes. They are the same for many models. For example, the wipers on the Lada Priora are both 51 cm long. You can buy a set of two pieces. By the way, manufacturers indicate the length in centimeters and inches. For example, 17 inches is 43 cm.

What to do if your car has non-factory wipers? This happens when the previous owner of the car installed products that are not suitable in size. For example, if they are too long, then the edge of the rubber gets on the body and rides up - the brush does not fully adhere to the glass and does not clean it at all. And there are also short rubber bands that do not reach the edges of the windshield - dirty stains remain there and dry out with a gray frame. In such cases, it is better to find out the factory parameters of the brushes.

Based on the most popular requests from car enthusiasts, we have compiled two tables in which we have collected examples of car models with recommended parameters for windshield wiper blades. For convenience, we divided them into Russian-made cars and foreign cars.

Replacement process

The easiest way to get rid of problems with VAZ-2110 windshield wipers is to contact a service station. There the trapeze will be replaced in an hour or an hour and a half. But if unscrupulous repairmen notice that the owner does not understand the cause of the breakdown at all, they can repair the car for half a day, saying that the problem is very serious.

Therefore, the best option to save money is to replace the part yourself. This process works as follows:

- First of all, you will need to dismantle the old trapezoid. To do this, you will have to disassemble and remove the windshield wiper arms. To do this, you will have to unscrew two nuts with a 12mm wrench. When removing the levers, you need to be careful, since powerful springs create a problem when removing them. It is better to bend the leashes first.

Disconnect the wiper motor gear pads.

Unscrew the nut of the left trapezoid fastening.

Unscrew the nut on the other side.

Unscrew the fastening of the gearmotor bracket.

Remove the trapezoid from the studs and remove it.

Only after this can the trapezoid be removed. The main thing is not to forget to disconnect all electrical connectors.

A new spare part must be assembled before installation, since it is in a disassembled state. When connecting parts, you need to make sure that all parts are aligned and adjusted. Only after this are the nuts tightened.

Before installing a new trapezoid, it is advisable to lubricate all its rubbing parts with graphite lubricant. Some advise using lithol, but it loses its properties at sub-zero temperatures.

Repair of trapezium wipers Lada Granta

I want to warn everyone about such an insidious detail as the windshield wiper trapezoid

Preamble. We arrived at the dacha on December 30, celebrated the New Year and began to prepare to leave on January 2. And the weather in the Moscow region was positive. Before leaving, I turn on the wipers, they move 2 cm and freeze. Well, everyone has arrived... He opened the hood and helped the wipers move further with his hand. Very, very slowly, but we drove on the glass. Okay, I had to go home and this will do.

Upon arrival, I decided to disassemble the windshield wiper mechanism. I took off the leashes and brought the trapeze assembly with the motor home. By the way, I filmed in Murzilka, everything is very easy. You need open-end spanners for 10 and 13 and a Torx T20 screwdriver to remove the frill. I removed the motor to free the trapezoid, having first scratched the marks. I started turning all the parts of the trapezoid with my hands... Poor little motor! How did he even spin it! Now I’ll show you what’s sour.

The right finger in the bushing did not rotate at all, that is, it did not rotate at all, even with a hammer it could not be knocked left or right. If anything, then I have a Lada Kalina KZAE windshield wiper installed on my Grant 2012 Article: 1117-5205015-01 I looked how much a new one costs. Mmm...3800 rubles! The toad said to fix it! We will always have time to buy. So, that means we will knock out the finger that has turned sour and smear, smear, smear. With the help of WD-40, a large hammer and some mother, the finger was successfully knocked out after 40 minutes of torture. To successfully knock out a finger, you need to remove the rubber boot, pull it up, pry off the retaining ring with a screwdriver, remove the washers and use tweezers to pull out the rubber ring from both (!) sides. After this, pour a lot of VD inside, wait, hit with a hammer and start over: spill, wait, hit. Yes, then I had to cut off 1 mm of the thread with a hacksaw, because... I flattened it. Before hitting with a hammer, you had to tighten a couple of nuts, then everything would survive!

Lada Kalina Hatchback -=First car=- › Logbook › The wipers do not work. Problem with gear motor

Hello everyone! I haven’t visited Drive2 for a very long time. I confess, it’s my fault (Several changes have been made to the machine in a few months =) I will write about everything in more detail in separate blog articles.

So, a serious problem suddenly overtook me. I was driving along the highway, it was raining, I turn on the wipers, they do one cycle and freeze forever... With an astonished look, I try to revive the wipers, but they are silent. I pull over to the side of the road, the first thing I do is check the transmission - everything is ok. I open the hood, visually the rack and the motor are in perfect order... thoughtfully tugging at the contacts near the engine, I took out a cloth, wiped the glass and drove quietly to my destination. I’ll tell you honestly, friends, driving in the rain with non-working windshield wipers is an extreme thing))) God forbid, someone should experience this for themselves.

Old windshield wiper motor

When I arrived home, the first thing I did was contact an electrician. He took the electric motor, simply disassembled it, reassembled it and, connecting it to power, saw that it was alive. I happily put it in its rightful place and went about my business. The next day it rains again. I turn on the wipers, they work very slowly, do 2 cycles and die again. This time I already knew roughly what the problem was, so I didn’t stop, and having already practiced extreme driving without wipers in the rain, I went to an electrician. He was again “glad” to see me with a gear motor in my hands. He took it apart again, replaced all the brushes, cleaned the contacts and the engine came to life again. When the electrician returned this engine to me, he said the following phrase: “If it dies again, it’s better to buy a new one.” Well, the man looked at nothing - after 2 weeks the motor died again. It was decided to replace this piece of iron.

New gear motor, which, unfortunately, did not fit.

I arrive at the local Phaeton auto parts store. I’m buying a gear motor for Kalina for 1,900 rubles, the toad, of course, is choking, but there’s nothing to do, you can’t drive like that in the rain. At the delivery of goods they give you a motor without a box, documents and even with a small scratch on the lid. When I asked where the equipment was, the manager replied that the supplier brought them in this form and offered a bag. D When I arrive home, the first thing I do is run to change the motor. I remove the rack, remove the motor, install a new one, connect it to the connectors, and simultaneously check its functionality. I had just started to screw the engine to the mounts when I decided to check whether the rack would fit the new engine, since it differs slightly in size from the factory one. I connect the rail and see that it does not fit the slots at all. There were ideas on how to make it fit, but reason prevailed over flights of fancy and I decided to change the gear motor in the store. 15 minutes later I’m already approaching the store’s checkout counter. As soon as the seller saw me, he asked: “Well, didn’t it fit?” I really wanted to tell him a lot about the low-quality spare parts, but I only said a modest: “Yes, can I replace it?” The store manager said that my case is not the first and that gear motors come from the factory with two types of splines - large and small. I came across just a small one, but they didn’t have a large one in stock, so I wrote a statement and my money was returned.

A box with a new gear motor =) You can immediately see that this is the original.

I drove home upset, but on the way I noticed a small store called “Samara”. I go there, there is a young girl at the checkout who happily helped me choose the right gear motor. Moreover, I got it in a branded box, with quality control marks, a guarantee and instructions for connecting, and even for 1,700 rubles. I was extremely happy when the motor fit without any problems. This is how, for relatively little money and in 3 hours of total time, I got rid of the problem with non-working wipers.

Comparison of two motors - on the right is the factory one, on the left is the new Samara one.

PS, I saw many topics on the forums with the problem of the wipers not returning to their original position. In fact, the solution is very simple - you need to adjust the splines connecting the rack and the gearmotor. You need to let the motor rotate its axis a full cycle and then insert the rack in the desired position and that’s it, the problem will be solved.

Issue price: 1,700 ₽

You are here: Home > VAZ > Kalina > Why wipers don’t work on Kalina

Types of windshield wiper blades

After establishing the authenticity of the wear of the windshield wiper blade and the reasons that led to it, we head to the store. Traders are able to offer a lot of options for these products, but in general they are divided into two categories:

- frame;

- with no frame.

These groups of brushes for Lada Granta have significant differences. Frameless options are able to adhere more tightly to the glass surface, which provides better cleaning quality. These products are not so susceptible to freezing. They also create a relatively less noise effect while driving (at speed).

Frame elements also have a number of advantages.

- They are more gentle on the glass surface because they have less pressure.

- If the glass geometry has an increased bend, like the LADA Granta, then this type of wiper blades is capable of cleaning a much larger area compared to a frameless competitor.

- Lower price of these designs.

The cost of the brush replacement service is identical and does not depend on the type of product design used.

When is it necessary to replace windshield wipers in Kalina?

Over time, owners of practical Lada Kalinas notice the appearance of brush marks on the surface of the windshield. Such “artifacts” create an obstacle to good visibility. In this situation, the designated components will need to be replaced, and the trapezoid will likely need to be replaced. Many experienced owners advise purchasing frameless brushes, which, in their opinion, are able to “bravely” withstand temperature changes and can demonstrate a relatively longer service life of approximately 1.5 million cycles.

Before replacing, you should understand the required size of the products. For Lada Kalina, you should purchase a driver's side brush with a length of 600 mm, and for the glass area opposite the passenger - 400 mm. For stern glass, the brush has a standard parameter of 360 mm. This wiper needs to be replaced much less frequently, since the intensity of its work is significantly lower compared to the front components.

What is included in the Grant standard package?

Lada Granta standard equipment what is included

Photo Lada Granta luxury photo

What are the causes of breakdowns?

The most likely factor causing the wipers to stop is the blown working element in the fuse. Eliminating this malfunction involves performing the simplest action - replacing the fuse link. It is located in the corresponding mounting block, located on the left side of the steering column. It will be useful to stock up on a fuse diagram, which will help you easily find the insert we need.

When the purifiers stopped functioning intermittently, the control relay most likely became unusable. This component is also located in the previously designated block. When a relay fails, it is replaced with a new analogue. However, we note that according to numerous reviews from owners of domestic small cars, certain statistics have been formed indicating the small number of cases of breakdowns of this kind.

The most common cause is the destruction of bushings. They are made of plastic, so they do not boast a long service life, which reaches a maximum of three years. The process of destruction of elements is primarily influenced by the quality indicator of the material. Here, the only effective measure is replacement, and to carry it out you should acquire a repair kit, which is available at a specialized retailer. In this case, the trapezoid is replaced.

Possible windshield wiper malfunctions and repair methods

Fault Remedy

The wiper motor does not work, the fuse in the mounting block is working:

Wires are damaged, oxidized or their tips are loose - Crimp the tips, replace the faulty wires

Faulty steering column switch - Replace the faulty wiper switch

The electric motor brushes are stuck, the commutator is very dirty or burnt - Eliminate the stuck brushes, clean the commutator or replace the gear motor

Break in the armature winding of the electric motor - Replace the gear motor

Auxiliary relay faulty - Replace relay

The wiper motor does not work, the fuse protecting the wiper circuit in the mounting block blows:

The brushes are frozen to the glass - After turning off the cleaner, carefully separate the brushes from the glass, make sure that the rubber scraper is intact, and restore the mobility of the brush joints

Wiper blades touch body parts - Check that the arms are installed correctly, straighten deformed arms or replace the wiper

Short circuit in the motor winding - Replace the gear motor

The wiper motor does not operate intermittently:

The wiper relay is faulty - Replace the relay

The steering column switch is faulty - Replace the faulty switch

The wiper motor does not stop intermittently:

The wiper relay is faulty - Replace the relay

The petals of the limit switch do not press well against the gear of the gearmotor - Bend the contact petals of the limit switch

The contacts of the limit switch are oxidized or burnt - Clean the contacts or replace the purifier gear motor

The brushes stop in any position:

The nut securing the crank to the axle is loose - Having correctly installed the crank, tighten the nut

The contact petals of the limit switch do not press well against the gear of the gear motor - Bend the contact petals of the limit switch

The brushes do not work synchronously:

The lever of one of the brushes on the shaft is loose - Install the brush in the desired position and tighten the lever securing nut

The wiper motor works, but the brushes do not move:

The nut securing the crank on the gear axis of the gear motor is loose - Having correctly installed the crank, tighten the nut

Gear teeth are chipped - Replace the gear motor

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Are the rods the wiper arms or the leash?

Do I hit the brushes on the counter? ¶

Well then everything is clear.

It’s just that before replacing, you should have noticed the position of the gearbox shaft on the trapezoid body, you didn’t do that, and that’s why this shit happened now ¶

Let's sum it up

Such an important process as replacing wipers, or when changing the windshield wiper trapezoid on a LADA Kalina car, is a very simple undertaking. There is no need for special devices or fancy tools. The brushes are removed by opening the locks.

Repairing or replacing a part such as a windshield wiper trapezium appears as a more responsible job, but it is not capable of causing difficulties for an inexperienced owner of a Lada Kalina. In such situations, do not hesitate to take action.

Mercedes janitor

My Instagram: Twitter: VK group: .

The windshield wiper cleans the glass by supplying water from the windshield washer reservoir.

Turn on the water supply from the windshield washer reservoir even when it rains. Wipers on w140 please, why is this and how to turn off the ignition or. Such as vases, so if the second one is turned on, do not spray on the conditioner and about. This will prevent streaks from forming on the windshield.

The rear window wiper automatically wipes the glass when the windshield wiper is on and reverse gear is engaged.

Rear window wiper

The switch is located on the control panel of the center console.

1 Intermittent mode

Make sure the ignition is on

Activating the rear window wiper

Read:

Press the switch at the top 1.

If you open the sliding door or the tailgate/tailgate while the vehicle is stationary, the rear window

stops.

As soon as all rear doors are closed or the vehicle starts to move, the rear window

Turning off the rear window wiper

Press the switch at the top 1 again.

Cleaning glass with water supplied from the windshield washer reservoir

Click the switch at the top 2.

After you release the switch, the wiper will continue to operate for approximately five seconds.

Turn on the water supply from the windshield washer reservoir even when it rains. In any Mercedes, the ring finger and little finger have high beams and wipers, like on the CLs sedan. How to turn on the air conditioner for heating: temperature. This will prevent streaks from forming on the windshield.

Cleaning windows and wiper blades

Risk of injury!

The windshield wiper may start working on its own and cause injury to you.

Recommendations for selection

Let's consider several product manufacturers:

- Frameless Bosch Aerotwin. Belgian-made products are equipped with native fastenings; the main advantage is a long service life, as well as aerodynamics and the absence of extraneous sounds during operation.

- SWF VisioNext - also of the frameless type, equipped with a hook type mount. The products are manufactured by Valeo, which also produces many other types of components and parts for cars.

- Bosch Twin Spoiler frame brushes. Dimensions fit standard Granta windshield wipers. Despite the fact that the products are frame, they are quite reliable and have a long service life.

- Champion Aerovantage. This manufacturer has been on the market for quite a long time, during which time it has been able to win the trust of many of our compatriots. The products belong to the premium segment of the market and are equipped with a steel frame.

Price issue

The cost of products depends on their quality, performance and manufacturer. Average prices for some windshield wiper models are shown below.

What to look for when choosing?

It is no secret that the level of visibility to the rear depends on the efficiency of the brush, which is especially important when maneuvering in cramped conditions and in bad weather. When choosing, you should lean toward high-quality branded products that will not subsequently emit an annoying squeak when rubbing against the glass and do not have to think about how to remove and replace the wiper. You should also inspect the integrity of the working element of the brush, which initially should not have cracks or breaks. An important role is played by the force with which the rear wiper is pressed to the surface of the glass, as well as the material from which the product is made.

Do-it-yourself replacement of the Lada Granta windshield wiper drive - step-by-step instructions

1. First of all, remove the wipers. This is done in the following way: it is necessary to remove two decorative plugs, under which there are mounting nuts with a key size of “13”, they must be unscrewed, and the windshield wipers must be removed from the slots along with the brushes and leads.

Note: After removing the wipers, do not turn them on so as not to have to worry about adjustments during assembly.

2. Next, you need to remove the frill (decorative plastic trim), for this you will need an “asterisk” - TORX T20.

Note: Some mounting screws are hidden under decorative caps.

3. Using a “10” key, you need to unscrew the nut (on the right), as well as 2 bolts (on the left) securing the trapezoid.

4. Now you can turn off the power; to do this, disconnect the wire from the battery and disconnect the connector. Now you can safely remove the entire trapezoid assembly.

Frame, frameless, combined

What a “frame wiper” is is clear to everyone: the design of the unit uses a metal frame. The role of the frame can be performed by a narrow strip made, for example, of plastic. And then the structure is called frameless (see figure). By the way, the plastic itself can differ in rigidity, and it is also sometimes reinforced.

Three types of wipers

Hybrid or combined designs use a frame and a plastic strip (bottom picture). In general, a hybrid differs little from a frame wiper: the height is reduced, other characteristics are the same. So, there is no need to delude yourself about the use of “hybrid wipers”.

Winter brushes

If tourmaline is added to rubber, such material will be good at removing oil films. And if the wiper frame is covered with a cover, this will protect the structure from ice. This means that, in general, winter brushes are frame brushes with a plastic cover.

“Winter wipers” can only be frame ones

And for some reason it is believed that it is necessary to clean glass from oil products in winter.

The disadvantages of winter windshield wipers are listed below:

- Availability of a frame (required);

- Increased weight of the structure;

- High price.

In theory, any winter brush is also suitable for summer. The main thing is not to use frameless brushes in winter, since they are not intended to fight ice.

The many faces of U-Hood

Some brushes compatible with the U-Hood (J-Hood) mount have a tricky lock: to loosen the mount, you need to bend the lever. This lever itself is difficult to notice right away (Fig. 1).

To tilt the lever at least to some angle, you must first squeeze two buttons (Fig. 2). So, the sequence: squeeze the buttons, tilt the lever.

Troubleshooting Methods

If the wipers start to stop in the middle of the car's windshield, you must perform the following steps:

- check whether the windshield wipers are correctly installed on the drive splines and the condition of the trapezoid. Particular attention must be paid to the drive crank. If assembly errors are detected, they must be eliminated;

- carefully inspect the drive splines. They can chip, break or wear out, causing the splines to slip and the wipers not returning to their original position. Sometimes the wiper lever may jump out of its place.

The defect is eliminated by replacing worn parts.

The next operation is to check the integrity of the electrical wiring. To do this, you need to check the voltage at the drive connector without turning off the ignition. The voltage should be 12 V. If there is no voltage at the connector contacts, it is necessary to check the integrity of the electrical wiring and the serviceability of the relay sequentially, starting with the fuse in the mounting block. Detected faults must be corrected.

In addition, taking this opportunity, it is recommended to clean and bend the contacts of the windshield wiper drive mounting connectors. Sometimes this also eliminates the defect.

Also, the windshield wipers may not return to their original position due to a defect in the electric motor itself or its switch. In this case, it is necessary to replace the faulty electric motor. The car enthusiast may encounter other, more complex faults that lead to the wipers stopping either in the middle of the windshield or in any other position. In this case, it would be better to contact specialists who will quickly detect and fix the problem.

Advertisements on NN.RU - Auto

Re-equip, lengthen the frame, truck: Valdai Gas 33104, 33106; Valdai farmer 331043, 331063; Lawn Gas 3307, 3309;.

A certified truck conversion organization invites you to: lengthen, re-extend and convert, p.

With us you can not only extend the frame to fit a body of 5.1 m, 6.2 m, 7.5 m, 9 m for Maz Zubrenok, Maz, Kamaz, Ural, Zil, Mitsubishi, Nissan.

Lengthen Kamaz under a body 7.5 m Lengthen Maz Zubrenok, Maz under a body 9 m Re-equipment of the chassis of an extended truck.

Nizhny Novgorod residents were silent for a long time about the Siberian forest fires, but then there was a reaction in our city: people decided to pay attention to it. Imagine, you wake up in the morning, open the curtains, bright sunlight bursts into the apartment, and outside the window there is a stunningly beautiful landscape

Imagine, you wake up in the morning, open the curtains, bright sunlight bursts into your apartment, and outside the window is a stunningly beautiful landscape.

Airborne Forces Day in Nizhny Novgorod went well, fun and peacefully, contrary to firmly rooted stereotypes. Our paratroopers in quiet times, like...

August 2 is the very day when the heads of the strong are covered with blue berets. The holiday in honor of the airborne troops is exciting.

How brand engine additives work

How to register the replacement of a car's power unit this year? How to register the replacement of a car's power unit this year?

Procedure for dealing with paperwork.

How to adjust the valve mechanism on the engine of a GAZ 3110 Volga? How to adjust the valve mechanism on the engine of a GAZ 3110 Volga?

Why do you need to adjust the valves on the engine?

Adjustment of the valve mechanism YaMZ 238 Adjustment of the valve mechanism YaMZ 238

Precise valve adjustment on diesel YaMZ 238:

Organizational diagram for changing the front door window regulator on the "seven" Organization diagram for changing the front door window regulator on the "seven"

Design and procedure for replacing a window regulator

Chevrolet-Niva heating system: changing the interior heater heat exchanger Chevrolet-Niva heating system: changing the interior heater heat exchanger

Recommendations for replacing the interior heater radiator

Standards for the use of fuels and lubricants at the disposal of the Ministry of Transport of the Russian Federation Standards for the use of fuels and lubricants at the disposal of the Ministry of Transport of the Russian Federation

What basic fuel standards does the Ministry of Transport offer?

Factory and actual fuel consumption for Lada Priora, reasons for overconsumption Factory and actual fuel consumption for Lada Priora, reasons for overconsumption

Declared and measured fuel consumption per

Also check out

- Remove the plastic plug, unscrew the 2 nuts to “13”, then the wipers with their leads.

- Remove the frill using a TORX T20 socket. Perhaps some of the bolts will be covered with plugs.

- Using a “10” wrench, unscrew the nut on the right side and the 2 fastening bolts securing the trapezoid to the body, and then on the left side.

- Disconnect the negative terminal of the battery, disconnect the connector and the trapezoid with the wiper motor.

- Install a new trapezoid. Reassemble everything in reverse order. At the end of the work, adjust the cleaner brushes.

What is needed to carry out the work and the article numbers of parts required for replacement

To carry out work on removing and replacing the trapezoid and wiper motor on a Priora, you will need a minimum set of tools. These include:

- 13" head and ratchet;

- Phillips head screwdriver;

- head at "10".

In addition, if the trapezoid or engine is being replaced, then these parts must also be purchased. It is recommended to choose original devices, so their article numbers are presented below:

- trapezoid - article 2170-5205015;

- wiper gear motor - 842-3730-50 or 2123-523612.040.

The wiper motor is correctly called a gearmotor, since it consists not only of an electric motor, but also a set of gears through which rotational movements are transmitted.

In addition, when removing products you will need to use gear lubricant. It is needed to lubricate the gear unit and rods. When the tools and materials are ready, you can start working.

Diagram of the Priora windshield wiper system

This is interesting! Priora is equipped with geared motors from the factory, which differ in rod diameter. They come in 10 mm and 12 mm. This is important to consider when choosing a new product.

How to determine that a trapezoid is “kirdyk”

Kirdyk is a slang word meaning an extremely bad situation.

It happens that the retaining ring of the bushing breaks and the rod simply flies out.

The slightest disturbance in the operation of the trapezoid can lead to incorrect operation of the wipers. Usually this part is replaced with a new one, although in some cases you can get by with installing a repair kit. Its cost is significantly lower than the price of the entire part, although repairs will take much more time. Here is a list of the main signs by which you can determine that a part will soon fail:

- Windshield wipers begin to do their immediate job poorly. This occurs due to the weakening of pressure.

- An unusual noise is heard during operation.

- A backlash appears, which can be determined even visually, since the glass will be difficult to clean.

- It happens that the brushes move in one direction easily, but back with difficulty, constantly slowing down.

All these problems lead to the fact that the windshield remains dirty, with streaks and smudges.

How to troubleshoot purifier malfunctions yourself?

When the owner of LADA Kalina turns on the windshield wiper drive, the motor works, but the wipers refuse to move, then the bushings will have to be replaced. For this purpose, the trapezoid of the wipers is dismantled, which is covered by a decorative plastic panel. The location of the unit (trapezium) is directly under the windshield. Repair of the windshield wiper is carried out using the windshield wiper trapezoid repair kit in the following order:

- unscrew the fasteners of the brushes and remove them together with the leads;

- then we dismantle the decorative protection panel, for which we stock up on a Torx T20 wrench;

- we move on to removing the trapezoid itself, which is held on the frontal body element by means of a nut and a pair of bolts, using, if necessary, a repair kit for the windshield wiper trapezoid;

- Next, you will need to disconnect the supply lines of the unit from the battery;

- Now you can remove the assembly.

If you resort to replacing the bushings without removing the trapezoid, you create a risk of deformation of the hinges, which will lead to incorrect operation of the brushes. A destroyed bushing will immediately give itself away, so we boldly proceed to the “operation”. The element is removed using wire cutters. Before installing the new bushing along with the lock washer, you will need to preheat it in boiling water, which will allow you to easily slide the specified element onto the hinge. Also, before installing the ring, lubricate the bushing with a suitable substance, for example, lithol.

Where is the wiper relay located on the Granta liftback?

Many motorists are faced with the fact that their windshield wipers periodically stop working properly, suddenly turning on or off. In 95% of cases, the reason lies in the relay - regulator. It is located under the dashboard on the left side. For access with subsequent replacement, you will need to unscrew the plastic cover and remove the relay. Next, replace it with a new one and close the plastic case again.

The Grant liftback rear (front) wiper relay has several pause modes. This is very useful for reducing the frequency of cleaning when there is light rain. The pause range varies from 1 to 65 seconds. The driver independently regulates the most optimal mode. Catalog number: 723.3777. The product is completely identical to the relay on the VAZ, Priora, Kalina, Kalina 2 models. On VAZ models produced before 2001, a relay with four contacts is installed, unlike the new ones, which have six.

Requirements for windshield wipers.

The windshield wiper circuit has several types of design. With any design, windshield wipers must ensure cleaning of the windshield regardless of the amount of precipitation. Automotive windshield wiper drives usually have two speeds. It should ensure that the brushes are placed in the extreme position when turning off, which does not interfere with the driver’s view.

On modern cars, the windshield wiper drive has an intermittent operation mode. It is provided by a thermal or electronic relay included in the power supply circuit of the wiper drive. This mode can be either with a constant period of time or adjustable. During intermittent operation, one or two cycles of brushes pass across the windshield with breaks of 3 - 5 seconds. In addition, on some cars, for example VAZ classic, the intermittent mode serves as a low-speed wiper drive.

On some imported cars, intermittent operation uses a smooth speed control, which is ensured by changing the voltage to the electric motor by an electronic unit.

For Lada Granta, Kalina, Priora

The resistor shown in the photo is responsible for the number of strokes. Our task is to replace (using a soldering iron) it with a resistor with lower resistance. To get two sweeps of the wipers after washing the windshield, it is enough to solder a resistor with a resistance of 47 to 68 kOhm (0.25 W). To make three swings - from 70 kOhm. The result of the modernization on video:

It is worth noting that on sale you can find a wiper relay with advanced capabilities:

- There is a pause adjustment, that is, you can set any time between sweeps of the wipers;

- Three strokes after the washer, instead of four (there is no problem with the wipers squeaking on the glass);

- After the washer, the first stroke is delayed.

However, replacing a resistor in a relay yourself will cost only 5 rubles, and a functional relay will be 70-100 times more expensive.

Beginning of work

To install a windshield wiper relay with an adjustable pause with your own hands, you must first dismantle the wipers. Their design may vary significantly depending on the vehicle model. It is also worth noting that the brushes can be front or rear. However, regardless of their type, the relay is located on the vehicle glass.

If there is no wiring diagram for the wipers, you can find the installation location of the control unit yourself. To do this, you need to inspect the base of the brushes. Most often, in foreign and domestic cars, this element is screwed to the car body.

Most often, the relay is located near the hood release handle. When the part is found, it is dismantled. To do this you need to prepare a simple screwdriver. The old relay is removed very carefully. You must try not to scratch the body or damage other elements of the system. You also need to remove the wiper column.

How to remove the trapezoid assembly

Before proceeding with the removal, it is necessary to remove the wiper arms, as well as the plastic lining at the very bottom of the windshield, which I wrote about in the instructions for replacing the Kalina cabin filter. There you will need just TORX T20.

After these pads are removed from the car, you can begin to unscrew the bolts and nuts securing the trapezium itself. First, unscrew the bolt on the left, as shown in the photo below:

Then in the center:

And you also need to unscrew one nut on the right side, it’s best to use an open-end wrench there:

Now there is nothing holding the trapezoid and now you can tilt it slightly forward:

To remove it from its seat:

And in order to finally remove it, all that remains is to disconnect the power plug of the motor. It was not possible to photograph everything in its original form, but there is nothing complicated there - bend the latch and pull the plug towards you. You will also need to remove it from the hole in the body in which it is mounted on a latch (clip). Here it is after removal:

Dismantling the device

In rare cases, the front or rear windshield wiper motor stops working due to some manufacturing defect. The problem is extremely rare, however, if you become a victim of it, there is nothing left to do but start special repairs.

To complete the procedure successfully, perform a complete dismantling. It is no secret that such a process is quite troublesome and time-consuming. Especially if you have to repair a part from old cars, such as Tavria, KAMAZ, Priora, and so on. In this case, you will have to use several separate steps, including unscrewing the nuts that act as fasteners for the levers.

In the future, you can begin to remove the levers themselves from the tapered splines of the drive. If you have any difficulties at this stage, the splines can be treated with penetrating lubricant. Next, the lever drives are dismantled by unscrewing the nuts, as well as removing the rubber gaskets and plastic bushings.

In the harness, the wiring block is disconnected and pulled out using the raised edge of the seal, through a special slot in the partition of the engine compartment. The next step is to remove the windshield wiper.

Now you will have to unscrew the washer from the removed device and remove the spring retainer. And also you can’t do without disconnecting the rod. As a result, all you have to do is dismantle three bolts and remove the engine. After a full visual inspection, begin replacing any faulty parts.

If this does not give any results, the only way out of the situation will be to buy a new motor. If the problem is resolved, the glass cleaning system must be reassembled in the reverse order.

Replacement features and diagram

If, after a thorough diagnosis, you were able to determine that the motor is faulty, think about replacing the failed unit. At this stage there are no special difficulties, so even an inexperienced beginner can easily solve the problem.

True, you must understand that the features of the procedure vary depending on the model of a particular vehicle.

Therefore, before performing a series of any actions, pay attention to the technical features of the system, read the service manual for the car.

- First of all, you must unscrew the nuts securing the brush arm. The help of a wrench will come in handy here. Then remove them from their installation location. If difficulties arise, use a penetrating lubricant.

- Then you need to remove the lever drives by unscrewing the nuts that secure them.

- The next step is to disconnect the connector with the wires in the harness and lift one part of the seal through the hole formed.

- As a result, all that remains is to dismantle the wiper itself. Then remove the washer and spring mount. After successfully achieving such goals, all that remains is to disconnect the pull rod, unscrew the three screws and remove the motor. Unit repair is characterized by particular simplicity and speed of execution.

I hope the developer of this wiring harness hiccups every day...

This store-bought tourniquet just won’t leave me alone. If only I knew what adventures I was signing up for when I bought it. But there is progress, having gone through 5 connection diagrams, working contacts have been identified and connected.

Task: connect the windshield wiper gear motor according to the diagram or diagrams. Schemes used:

Let me remind you once again of the wiring diagram:

What was done and invented: 1) Both schemes for connecting the gear motor and the steering columns with the gearbox are absolutely working. Or, more simply put, identical. 2) In order to save time, the wiring harness from the gear motor was crimped onto the existing 4 wires of the chip from the steering columns and, in accordance with the diagram, 2 missing wires were added - ground and straight to 31b of the gearbox. 3) But not everything is so simple. The wires going to the relay at terminals 15 and 31b turn out to come from one contact 53a of the steering column, and power is not supplied to the relay and, accordingly, to the geared motor in principle. I had a good word for this electrical engineer who made the harness. 4) The 31b coming from the steering column was disconnected from the relay terminal and the wire from the gearmotor was connected directly to it in accordance with the diagram. On the steering column with 53ah, the wire is routed to 53a. After these manipulations everything worked!

But can it really be that simple? 3 days of torment with electrics, just the windshield wiper motor, and? And it turns out that the trapezoid is laid in such a way that it touches the stove damper lever - “infection”... . How I wanted to destroy this stove with a sledgehammer... .

Bottom line. The steering column harness from the store is not of high quality. The wires are thin, the harness going to the windshield wiper is not working (in relation to gearmotors of new releases). There are wires making incorrect contacts, there are empty wires (“snot”)! One terminal is not even marked on the diagram. I had to call each wire and re-learn the circuits.

The motor is connected and operates in 3 modes (fast, slow and intermittent). Among the newly identified problems, the trapezium of the left driver's wiper rests on the heater flap lever. The gear motor mount bends and prevents the trapezoid from working properly.

But I defeated the main electrician, and only the mechanics remained.

I would be grateful for tips on how to make sure that the trapezoid of the driver's wiper does not rest against the damper lever!

The entire list of manipulations will take no more than 1 hour

In cases where the central bushing breaks, the entire mechanism will have to be replaced. This work is not capable of creating difficulties, so we unscrew the previously indicated list of fasteners and dismantle the assembly, and install a new mechanism in its place. Such a replacement will be more expensive compared to the usual replacement of bushings, but this option is more reliable. The owners of LADA Kalina assure that after replacing the bushings, the mechanism is able to provide a service life of at least two years. Here the choice remains with the owner, which method to lean towards in a given situation.