When on the road, especially in rainy or snowy weather, wipers suddenly refuse to do their job, further movement becomes extremely unpleasant and even dangerous. By the way, the traffic rules prohibit further movement. However, “there are no hopeless situations” (c). Of course, you won’t be able to rewind a burnt-out wiper motor on your knee, but other electrical problems can be dealt with using a piece of wire, a knife and electrical tape. Of course, it’s easier to troubleshoot using a multimeter, but you don’t always have one at hand.

First, let's do some diagnostics. The wiper motor is powered through fuse No. 2. You can check it directly from the driver's seat, without even bending down. Turn on the turn signal: if the indicator light on the dashboard flashes, then the fuse is normal (the indicator light is also connected through fuse No. 2). If it doesn’t blink, check the fuse. Perhaps the contacts have oxidized, and it will be enough to simply move the fuse (the note is true for cylindrical fuses).

Let's move on: we check the relay and the steering column switch. We turn off the engine (if you haven’t already turned it off), but leave the ignition on, and also turn off the radio and ask passengers to be silent. In the ensuing silence, we turn on the wipers in intermittent mode (first speed) and listen. A relay should start working near the driver's left foot. The bimetallic breaker makes clicks at intervals of 6-10 seconds. The absence of clicks may indicate a faulty relay or steering column switch, or a broken wire somewhere in the cabin. It is difficult to eliminate such a malfunction in an open field. In any case, our further path lies away from the warm interior, into the rain and snow.

Open the hood and approach from the battery side. We find the power connector for the wiper motor. It is located between the battery and the air intake, closer to the battery. Disconnect the connector and inspect the contacts. The flat contacts on the connector on the wiper motor side may be oxidized. This may be one of the possible reasons for failure. We connect and disconnect the connector several times to remove the oxide film. Did not help? Then we check the wiper motor.

Checking the wiper motor. All connections are made to the connector on the wiper motor side; the connector going to the vehicle's electrical system must be disconnected. We connect one wire to pin No. 3 (the black wire in the harness going to the wiper motor) and connect it to “-“. In the photo, contact #3 is the lower left:

Setting up a windshield wiper for a Niva VAZ-21213 car

Many owners of VAZ Niva-21213 and 21214 cars have encountered a problem when the windshield wipers (windshield wipers) do not work as expected, that is, at a very slow speed.

The windshield wiper system operates in two operating modes: continuous and intermittent. However, on other cars, for example, Moskvich 2141 or VAZ 2108, or on models of modern production, there is a gear motor with three operating speeds: constant slow, intermittent and constant fast.

In our opinion, for VAZ Niva cars versions 21213 and 21214, such a system is a big drawback, since during heavy rain the wipers work with great difficulty.

It was decided to modernize the windshield wiper drive by integrating into it a more powerful and faster gearbox from Moskvich 2141 (usually VAZ version 2108 is equipped with a similar system). After taking measurements in Niva, it turned out that placing the updated gear motor on the standard windshield wiper trapezoid would not be a labor-intensive task.

Video

We recommend watching the video instructions for replacing the front wiper gear motor

As you can see, dismantling and replacing windshield wiper components does not cause any problems. However, before you start replacing parts, it is necessary to conduct a complete diagnosis of the wipers in order to accurately determine the cause of the breakdown and not replace their “live” parts.

Read also: What signs are canceled by the intersection?

Car : Niva Chevrolet. Asks : Smekhov Igor. The essence of the issue : The wipers on the Niva Chevrolet stopped working.

Good afternoon The wipers on my car don't work well, and sometimes they stop working altogether. Please tell me how to fix this problem and what to pay attention to during repairs?

Installation of wipers on VAZ-21213

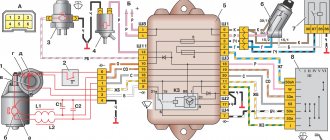

The electric windshield wiper motor on Niva VAZ 21213 and 21214 cars has two blades, permanent magnets and one speed. It is equipped with a thermobimetallic fuse to prevent possible overloads. Each of the operating modes of the purifier is activated using a switch under the steering wheel. The intermittent (intermittent) mode operates through a relay version PC 514 (attached with two nuts to the side panel located in the foreground on the left).

The relay is designed to provide from nine to seventeen activations of the electric motor per minute, while the temperature should be from negative 20 to positive fifty degrees, with a power system voltage of ten volts.

When the wipers are activated on a Niva 21214 and 21213, each brush is capable of producing a maximum of four double strokes in continuous mode. The degree of resistance of the electromagnetic winding on the relay is 66 +-2 Ohms, and the winding on the breaker is 23 +-1 Ohms.

Wiper blades for VAZ-21213 and -21214

When a car owner wants to install wipers on his Niva, he begins to have a large number of questions regarding windshield wiper blades. How often do brushes need to be replaced? Brush, which type is best? And similar ones.

How often do you need to change the blades installed on your windshield wipers? - every owner of a Niva-21213 or Niva-21214 car must decide this question for himself.

It is very important to remember that excellent visibility is the basis for safe travel by car. Therefore, if the current wipers refuse to properly perform their task, then they should be immediately replaced with new copies.

For example, in the city of St. Petersburg, windshield wipers on cars become unusable during the winter months. It is recommended to equip the Niva with new windshield wiper blades twice a year: at the end of the last winter month and in the first summer month.

What kind of windshield wipers are recommended to equip the Niva with? There are two varieties: frameless and framed.

The first type is intended to provide more uniform pressing to the glass surface. If the driver lets his Niva out into the cold, then the frameless windshield wipers will not freeze. At high speeds they will not make much noise.

However, there is one drawback: over time, frameless brushes wear out and begin to scratch the windshield. It’s up to you to decide which brushes to install on the Niva: you can save on quality or buy a first-class, expensive copy.

Dimensions of wiper blades for VAZ 21213-21214 cars

The dimensions of the windshield wiper blades on VAZ 21213-21214 models are absolutely symmetrical, in most cases they are about fifty-one centimeters on all sides. The car owner also has the opportunity to install brushes that will have a different size: on the driver’s side – up to fifty-three centimeters, and on the passenger’s side – up to fifty-one centimeters.

It is worth remembering that when both wipers are supplied, the size of which will be fifty-three centimeters each, a thin stream of water will appear in the middle.

Features of the windshield cleaner and washer

The electric motor of the cleaner is double-brush, excited by permanent magnets, single-speed.

To protect against overloads, a thermobimetallic fuse is installed in it.

The purifier has two operating modes - constant and intermittent; they are activated by the right steering column switch.

Intermittent operation is provided by a RS-514 type relay, attached with two nuts to the front left side panel.

The relay should provide 9–17 motor activations per minute at temperatures from –20 to +50°C and a supply voltage of 10 V. (When the windshield wiper is turned on in intermittent mode, the brushes can make up to four continuous double strokes)

The resistance of the relay electromagnet winding is (66±2) Ohm, the breaker winding is (23±1) Ohm.

The windshield washer consists of a polyethylene reservoir with an electric pump installed in the engine compartment, washer nozzles located on the hood, and flexible connecting hoses.

The washer is turned on by pulling the right steering column switch towards you (non-fixed position).

If the pump malfunctions, it is replaced.

Clogged nozzles can be blown in the opposite direction or cleaned with a fishing line or a thin needle.

- Go to page:

Wipers and where their relay is located

Post by fraer » May 14, 2010, 11:41 am

Why the windshield wipers don't work in the fields

When on the road, especially in rainy or snowy weather, wipers suddenly refuse to do their job, further movement becomes extremely unpleasant and even dangerous. By the way, the traffic rules prohibit further movement. However, “there are no hopeless situations” (c). Of course, you won’t be able to rewind a burnt-out wiper motor on your knee, but other electrical problems can be dealt with using a piece of wire, a knife and electrical tape. Of course, it’s easier to troubleshoot using a multimeter, but you don’t always have one at hand.

First, let's do some diagnostics. The wiper motor is powered through fuse No. 2. You can check it directly from the driver's seat, without even bending down. Turn on the turn signal: if the indicator light on the dashboard flashes, then the fuse is normal (the indicator light is also connected through fuse No. 2). If it doesn’t blink, check the fuse. Perhaps the contacts have oxidized, and it will be enough to simply move the fuse (the note is true for cylindrical fuses).

Let's move on: we check the relay and the steering column switch. We turn off the engine (if you haven’t already turned it off), but leave the ignition on, and also turn off the radio and ask passengers to be silent. In the ensuing silence, we turn on the wipers in intermittent mode (first speed) and listen. A relay should start working near the driver's left foot. The bimetallic breaker makes clicks at intervals of 6-10 seconds. The absence of clicks may indicate a faulty relay or steering column switch, or a broken wire somewhere in the cabin. It is difficult to eliminate such a malfunction in an open field. In any case, our further path lies away from the warm interior, into the rain and snow.

Open the hood and approach from the battery side. We find the power connector for the wiper motor. It is located between the battery and the air intake, closer to the battery. Disconnect the connector and inspect the contacts. The flat contacts on the connector on the wiper motor side may be oxidized. This may be one of the possible reasons for failure. We connect and disconnect the connector several times to remove the oxide film. Did not help? Then we check the wiper motor.

Why the windshield wipers don't work in the fields

Diagnosis of windshield wiper faults

The wires are damaged, their tips are oxidized or loose, fuse No. 2 has blown (No. 1, if the tailgate glass cleaner does not work)

Crimp the terminals, replace faulty wires, fuse. Eliminate the cause of its burnout

The brushes are frozen to the glass

Turning the ignition key to the “off” position, carefully separate the brushes from the glass, make sure that the rubber scraper is intact, and restore the mobility of the brush joints

A foreign object has fallen between the moving parts of the crank.

Check the correct installation of the arms, straighten deformed arms or replace the wiper

The steering column wiper switch is faulty

Replace the faulty switch

The motor brushes are stuck, the commutator is very dirty or burnt

Eliminate sticking brushes, clean the commutator with glass sandpaper, and wipe with a cloth soaked in gasoline. If there is severe wear, replace the gearmotor

Open circuit or short circuit in the motor armature winding

Defective windshield wiper relay

The steering column switch is faulty

Replace the faulty switch

Defective windshield wiper relay

The contact plate of the gearmotor limit switch does not bend when passing the cam

Disassemble the gearmotor and bend the contact plate or replace the gearmotor

Limit switch contacts are oxidized

Clean the contacts or replace the wiper motor

Limit switch contacts do not press well or are oxidized

Clean the contacts, if necessary, bend the switch plate or replace the gear motor

The nut securing the crank on the gear motor shaft is loose

Having correctly installed the crank, tighten the nut (it is advisable to first apply paint or anaerobic sealant to the threads)

The nut securing the crank on the gear motor shaft is loose

Having correctly installed the crank, tighten the nut (it is advisable to first apply paint or anaerobic sealant to the threads)

Reg.: 12/06/2004 Threads / Messages: 628 / 51730

Reg.: 03.30.2005 Threads / Messages: 5 / 936 From: St. Petersburg. Vasileostrovsky district Age: 39 Car: 21214-20/2004/

Reg.: 12/06/2004 Threads / Messages: 628 / 51730

Reg.: 05.19.2005 Threads / Messages: 13 / 589 From: St.-Petersburg Age: 58 Car: 21310-20

Reg.: 12/06/2004 Threads / Messages: 4031 / 23190 From: Moscow Age: 65 Car: 21214M, 2013

oleg_asup

It is possible that there is a bad contact in the second fuse. But then some other circuits will not work, for example, the tachometer. Or - mass (that same pin).

The emergency light operates from the 9th fuse.

Alexey aka ALER.

Reg.: 05.27.2005 Threads / Messages: 3 / 929 From: Moscow Age: 41 Car: VAZ 21213. 2002

questions)? in PM

Reg.: 02.22.2005 Threads / Messages: 1 / 94 From: moscow Age: 55 Car: 21213, 2001, garnet

Reg.: 12/06/2004 Threads / Messages: 628 / 51730

Reg.: 12/06/2004 Threads / Messages: 4031 / 23190 From: Moscow Age: 65 Car: 21214M, 2013

Alexey aka ALER.

Reg.: 05/06/2005 Threads / Messages: 4 / 520 From: Moscow -> Slovakia Age: 48 Car: 21213 99 Kama Flame (slides on ice!) -> Mitsu Outlander 2.0 4wd manual transmission

at minus 25 I started the car.

but - I turn on the dimensions - the panel does not light. I click the turn signals and wipers and they work. oh well, I think I can do without instrument lighting.

warmed up, cleaned up. bam - the instrument lights turned on. oh, I think it's cool.

went. I click the wipers - damn - they don’t work

I turn on the turn signal - it doesn't work

The fuses are (seemingly) intact and firmly seated.

Please advise, dear candy lovers

Reg.: 12/06/2004 Threads / Messages: 4031 / 23190 From: Moscow Age: 65 Car: 21214M, 2013

Alexey aka ALER.

Reg.: 05/06/2005 Threads / Messages: 4 / 520 From: Moscow -> Slovakia Age: 48 Car: 21213 99 Kama Flame (slides on ice!) -> Mitsu Outlander 2.0 4wd manual transmission

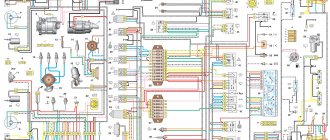

Description of design and operation diagram

Niva Chevrolet windshield wipers consist of the following elements:

- lever (item 1 in the figure);

- brush (item 5 in the figure), read a detailed article about the sizes of brushes, their types and selection rules here;

- drive (item 7 in the figure), which in turn consists of a gear motor and trapezoid;

- wiring.

Niva Chevrolet front wiper device

The trapezoid is one of the most important parts in this mechanism. It serves to transmit movements from the motor to the wipers and controls the synchronization of the movement of the windshield wipers.

Wires are needed to power the wiper motor.

The brushes adhere to the car glass and serve to clean it.

Additional block under the glove box

| Number | What is he responsible for? |

| 1 | Additional relay (turns on the right electric fan through an additional resistor at low rotation speed) |

| 2 | Fuse (50A) protecting the power circuits of the additional relay and the right electric fan relay |

| 3 | Fuse for the fuel pump (fuel pump) (15A), protecting the power circuits of the electric fuel pump relay |

| 4 | Fuse (15A) protecting the controller's constant power supply circuit |

| 5 | Right electric fan relay |

| 6 | Left electric fan relay |

| 7 | Fuel pump relay |

| 8 | Main relay |

| 9 | Fuse (50A) protecting the left electric fan circuits |

| 10 | Fuse (15A) protecting power circuits switched on by the main relay |

| 11 | Controller |

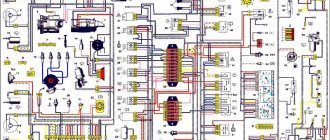

Why might the front wipers not work?

There may be several reasons for problems with windshield wipers.

- Lack of lubrication at the contact points of the parts. If the wipers begin to move more slowly or their movements become intermittent, then first of all you should check the lubrication;

- Loosening the nut at the place where the leash is attached. Here it is worth checking how well it is tightened;

- Worn windshield wiper splines. If this happens, a complete replacement of the trapezoid will be required;

- Malfunction in the wiper motor;

- >Faulty relay or fuse. You can check this in the mounting block, which is located inside the car.

Description of the fuse and relay block diagram

The fuse box can be found inside the car to the left of the steering wheel.

To get to it, you need to remove the cover of the mounting block, which is bolted to the panel. The fuse block consists of 20 fuses, designated by the letter F and a serial number from 1 to 20. There are also relays designated by the letter K and a serial number from 1 to 8.

Relays for windshield wipers

Relay and fuse F9 are responsible for protecting the power circuit of windshield wipers and glass heating systems on a Chevrolet Niva. Relay K2 is responsible for the operation of the front wipers. For rear work - K6.

Location of fuses on vehicles manufactured before 2009.

Location of fuses on vehicles manufactured after 2009

How to change fuses?

Test procedure and tweezers

The replacement itself, for example, a windshield wiper fuse with a rating of 20 A (position F9 on both blocks), is carried out as follows:

- Open the block cover.

- Find the failed insert.

- Take it with tweezers and pull it out of the nest.

- A fuse of the same rating must be installed instead. The use of inserts of a higher rating can lead to burnout of the unit and electrical wiring, as well as to a vehicle fire. Using parts with a lower rating will also not protect the circuit, since such an insert will immediately burn out.

- Turn on the circuit in which the insert was replaced. If re-burnout occurs, then the problem is in the elements of this circuit.

- Place the tweezers in their original place and close the lid.

The process of replacing one of the fuses is shown in the video from the Remgar channel.

How to replace the windshield wiper trapezoid?

The market price of a trapezoid is approximately one thousand rubles. A trapeze with a motor will cost approximately 2 thousand rubles.

There are 2 types of trapezoids on the Chevrolet Niva. Old modification and new. They are practically no different.

The process of dismantling the windshield wiper trapezium is quite simple. You will need keys for 10-12, an open-end wrench for 13 and a tube key for 8-10.

To remove the trapezoid, you need to remove the plastic cover under the windshield.

Then you need to unscrew the 3 bolts securing the trapezoid to the frame. After this, the trapeze can be removed.

Installation of a new trapezoid is carried out in the reverse order of its dismantling. That is, it must be secured with three bolts, and then a plastic cover must be installed under the glass.

How to replace the rear wiper gear motor?

To dismantle and replace the Niva Chevrolet rear wiper motor, you will need 2 keys: 24 and 10.

Motor replacement process:

- The nut securing the brush lever is removed. Then the lever and cap are removed.

- The nut securing the gear motor to the tailgate is unscrewed.

- The block of wires from the motor is removed.

- Unscrew the two bolts securing the motor bracket.

Installation of the gear motor is carried out in the reverse order of dismantling.

Replacing the Niva rear window wiper motor gearbox

Initially, my rear windshield wiper did not work. The protective rubber boot on the leash axle has not been there for a long time, and over many years of such negligence the axle has become attached to the gearmotor. When turned on, a voltage drop appeared, but nothing rotated and the glass was not cleaned. I tried to remove the gear motor, but the large nut got stuck and responded to the manipulation of the wrench by breaking the silumin housing of the gearbox. The gearmotor froze on the door in a position that was neither here nor there. Bulgarian to help, as they say! But... there is no other, and besides it you need a bunch of other things, and it’s not comme il faut to buy a new one. Soaking WDehoy and... it started working. But it didn’t work for long; after a week it jammed again. Well, to hell with him. So autumn and winter passed... In winter it turned out that this was a very convenient device that gets rid of snow on the rear window, but it didn’t work. I decided that I should try to find some used ones. In 2108, Niva, 2104 and Oka, the rear gear motor is the same product. I advertised on the local Saratov forum and... only 2 people responded... I thought somehow there would be more, there are plenty of brewed 08-13, but there are no offers... nonsense. In general, it was bought with the 14th, we agreed with the seller that I would check it and write back. So I did. But mother laziness... I connected the power to the connector and threw it on the floor in the trunk, pressed the button and heard the motor spinning. But I didn’t bother to see if the shaft was spinning or not... and as it turned out in the end, after two weeks, the shaft was not spinning. I unscrew the back cover and notice that several teeth are missing on the sectors. As a result, I have 2 faulty gear motors and, in theory, it would be possible to assemble one from two... but mine has licked off the drive splines on the shaft. The shaft I bought did not have a fly, but the teeth on the sector were broken. But as long as you have hands... you can move mountains, not that there is some kind of gearbox... This is this sector. The sectors are made of silumin and it turns out that such a breakdown is quite common.

0:3356

1:504

And this is a block of sectors from my gearmotor, the sectors are intact, but the splines for the driver have been licked off the shaft

1:686

2:1191

3:1696

I’m knocking out the axle... it’s already clear where I’m going...

3:1773

4:2278

Similarly, I knock the axis out of my sector.

4:82

5:587

Now all that remains is to put everything back together. My sector block and axis are from a purchased one. Just in case, I also placed the axle on a threaded lock.

5:834

6:1339

The sector is ready

6:1366

7:1871

Well, then - assembly. I put new grease in the gearbox housing and assembled everything.

7:2010

8:504

9:1009

10:1514

People bend the leash so that the wiper rests on the lower edge of the glass. There is an aesthetic gain, but with such a rework, the cleaning sector shifts, which is not good.

10:1828

11:2333

I decided to study whether it was possible to combine aesthetics with efficiency. It turns out that without global, almost unrealistic alterations it is impossible. The glass is narrow and with this arrangement of the motor the cleaning sector can be increased only slightly. Further than the red line in the photo, the lower part of the wiper will hit the rubber band. Even if you choose a gearmotor from a foreign car, there is practically no gain.

11:760

12:1265

So I decided to keep the original leash and the original location of the brush on the glass.

12:1425

But if it were possible to drill a hole in the rear window of the Niva, then it would be possible to install a gearmotor from 2111 (aka Shniva) in the European style, then the cleaning sector would be as much as 176 degrees... but that’s only if.

12:1799

https://www.drive2.ru/l/288230376152390810/, https://www.drive2.ru/l/288230376152399640/

12:1891 next article:

Installation of electric windows on the Niva window door

No manufacturer makes ESP for Niva with a window door. I don’t know why, but the fact remains. Usually

13:2750

Rating 0.00 [0 Vote(s)]

19301