The Lada Kalina clutch pedal position sensor is installed on VAZ cars equipped with an electronic gas pedal. For the VAZ-1118 (Kalina) family of cars, as well as VAZ-2170 and 2190 (Priora and Granta), a part with factory article number 11180372001500 is used. The same marking “VAZ-1118 3720015” is applied to a tag attached to the wiring harness of the new part.

When purchasing a clutch sensor for Kalina yourself, it is important not to make a mistake with your choice, since parts of a similar purpose are also available for other VAZ models. On Nivas with electronic gas drive, a part with index 21214-3720020-02 is installed. On cars of the Lada Vesta and X-Ray family, sensors are used that were inherited from RENAULT Logan with the marking 253250007R. All these parts are not interchangeable with each other.

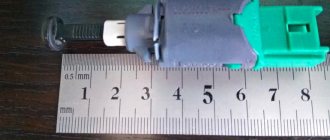

Clutch sensor for Lada Kalina car

The Lada Kalina clutch pedal position sensor is installed on VAZ cars equipped with an electronic gas pedal. For the VAZ-1118 (Kalina) family of cars, as well as VAZ-2170 and 2190 (Priora and Granta), a part with factory article number 11180372001500 is used. The same marking “VAZ-1118 3720015” is applied to a tag attached to the wiring harness of the new part.

When purchasing a clutch sensor for Kalina yourself, it is important not to make a mistake with your choice, since parts of a similar purpose are also available for other VAZ models. On Nivas with electronic gas drive, a part with index 21214-3720020-02 is installed. On cars of the Lada Vesta and X-Ray family, sensors are used that were inherited from RENAULT Logan with the marking 253250007R. All these parts are not interchangeable with each other.

Video “Eliminating squeaks”

You can learn how to solve one of the problems associated with the clutch in a car from the video from the author Konstantin Biyanov.

During the operation of the car, the driver encounters a number of problems that indicate that it is necessary to adjust the clutch on Kalina. Due to the peculiarities of the mechanism installed on these VAZs, even when the driven disk linings are worn, the clutch release cable automatically lengthens.

Operating principle

This part is the simplest normally open limit switch. The contacts close only when the limit switch tab is mechanically pressed, which is produced by the plastic protrusion on the clutch pedal.

Due to the simplicity of the design, there are no requirements for pinout of wires; it can be connected in any way.

The purpose of the part is to transmit a signal to the ECU (engine control unit) that the driver has depressed the clutch, thereby disconnecting the load from the engine. Since the controller receives data from the crankshaft position sensors and speedometer (on the gearbox), it considers the engine to be loaded and issues the appropriate injection commands. When the load is removed by pressing the clutch, there is too much fuel, which is why the engine smokes and tries to sharply increase speed. The controller reacts and reduces the flow, but since this happens in addition to the algorithms embedded in it, the engine operates in a non-optimal mode. The ECU perceives this as an error, generating the appropriate code and lighting the “Check Engine” lamp. To avoid such a scenario, a control element has been introduced into the control system, informing the ECU that the load has been removed.

Drive faults

| Malfunctions | Diagnostics | Elimination |

| When changing gears the car “stops” | Disconnecting the block with wires, checking for changes after disconnecting the DS | Replacing the DS with a new one, since the structure cannot be repaired |

| Uncharacteristic increase/decrease in engine speed when the clutch is disengaged | Connecting a new, working DS | Replacing the DS with a new one |

| P0830 "Check Engine" - clutch sensor error on the dashboard | Connecting a new, working DS | Replacing the DS with a new one |

Each type of drive has its own specific disadvantages. It is worth noting that many problems with clutch operation are related to the drive.

Cars often use a mechanical cable drive. The main malfunctions of a cable-driven clutch are as follows:

- violation of regulation;

- rope break;

- snacking.

The cable is adjusted using a nut, which allows you to change the length of the braid relative to the cable itself. If adjusted incorrectly, the cable becomes too tight or weakened, which leads to incorrect transmission of the driver's force to the mechanism.

Cable breakage is usually due to corrosion. With this malfunction of the clutch, its functioning completely stops.

Where is the sensor located

The sensor is mounted directly on the clutch pedal bracket and is located in a hard-to-reach place behind the steering column. Although replacing it is very simple and boils down to disconnecting the wire block and unscrewing two fastening screws, getting to it from the interior is very difficult.

Some owners solve the problem of dismantling by taking advantage of the fact that in this place next to the vacuum brake booster under the hood there is a hatch closed with a lid. Removing it gives access to the pedal assembly.

To replace a part from the engine compartment, you will need the participation of an assistant, since you will have to simultaneously perform actions both in the engine compartment and in the cabin (by pressing the pedal).

Instructions for replacing the clutch controller

- It is necessary to check the condition of the external wires.

- Unfasten the self-tapping bolts and use a screwdriver to remove the device along with the fixing plates. This should only be done after checking the pedal pusher to ensure it is applying pressure to the controller.

Photo gallery “Dismantling instructions”

1. Find the required part under the steering column.

2. Remove the housing from the pedal to get to the sensor.

3. Unscrew the bolts and remove the device.

Loading …

Clutch pedal sensor Grant, Priora, Kalina 2, Datsun (E-GAS)

Dear customers, in order to avoid errors when sending the clutch pedal sensor, please indicate your car model and year of manufacture in the “Comment” line. Modern cars are equipped with special electronic clutch pedals, which ensure ease of gear shifting and normalization of the transition to a new engine operating mode.

The clutch pedal position sensor is one of the elements of the engine management system with an electronic gas pedal. This sensor provides a more flexible control scheme for engine modes. It simplifies the process of starting to move, eliminates “drops” and jerks of the car when changing gears in the manual transmission, and also allows for a reduction in fuel consumption.

By providing information to the engine controller about the moment the clutch is engaged and disengaged, the clutch pedal position sensor allows it to reduce or increase engine speed at the right moment, as well as adjust the ignition timing.

The clutch pedal position sensor is an ordinary limit switch with two positions - “on” and “off”. The circuit consists of a normally open sensor, a clutch pedal position sensor signal circuit, and a sensor ground circuit.

Its normal position is open, that is, it turns on only when the clutch pedal is pressed.

The clutch pedal position sensor kit 1118 –3720015 includes:

— switch 1118-3720015-00 — 1 pc.;

— protective casing 1118-3720024-00 — 1 pc.;

— fastening screw 1-0076690-01 — 2 pcs.;

— spring 1118-1602179-00 — 1 pc.

The clutch pedal position sensor on VAZ cars is installed directly on the clutch pedal bracket; it can be seen by looking under the steering column.

It would seem like a simple sensor, but how much it can complicate the life of an ordinary car owner.

The following symptoms may indicate a malfunction of the clutch pedal position sensor:

— car “pecks” when changing gears;

— a sharp increase or decrease in engine speed when the clutch is disengaged;

— error 0830 “Clutch pedal sensor error” is recorded in the engine controller and the “Check Engine” light in the instrument cluster turns on.

Error 0830 is detected if the engine controller does not receive a signal from the clutch sensor:

Description of the brake pedal sensor

Below we will find out how it works and how to replace it.

Purpose, location and operating principle

The essence of the system is that when you press on the brake, the piston in the cylinder begins to move. After this manipulation, fluid enters the brake system from the intake valve. It passes through the pipelines towards the main wheel mechanism, thus creating a suitable situation for the pads to move towards the wheel discs and drums. As a result, contact and subsequent braking occur. The controller itself turns on the brake lights.

Brake end piece

Typical malfunctions and methods for their elimination

When “communicating” with a car, you can encounter various problems, but there is the most common and annoying problem. This problem is called error P0504, or otherwise “Brake pedal sensor mismatch.”

Reviews

| № | Positive |

| 1. | Vasily: I’ve been driving a car for two years now and have no complaints about the DS. The pedal squeaked several times, a drop of grease was added, and the sound disappeared. The build quality of domestic vehicles is good. Timely maintenance of equipment is important. |

| 2. | Kirill: a year has passed since the purchase of the car, no investments except for oils and filters. All sensors are working properly. |

| 3. | Vladlen: after 35,000 km. mileage the engine error light came on. I took it to the service center, but they didn’t find the fault right away - it turned out that there was poor contact between the block and the wires on the DC. In all other respects there are no complaints. |

| 4. | Vladimir: for two years of active operation of the machine, there have been no capital investments, the mechanisms are working properly. My positive review of domestic technology. |

| 5. | Georgiy: at 20,000 km the clutch pedal squeaked, I lubricated it myself, there were no more problems. I've been using the car for a year and a half. |

| 6. | Vitaly: I have repeatedly heard negative reviews about the build quality of the Lada Grant. I can’t confirm because everything is fine for me. I carry out inspections in a timely manner, buy only original parts, and have them serviced at certified service stations. |

| 7. | Gennady: two years of active operation of the machine and no investments, with the exception of oils, fuel, filters. Domestic equipment is good, but requires careful inspection and timely maintenance. |

| Negative | |

| 1. | Ignat: The DS has flown for more than 15,000 km, so I went to the service center for a replacement. On top of that, the cable stretched. Primitive quality parts. I plan to sell and buy Lada Granta. |

| 2. | Vitaly: I bought a Grant a year ago, but now I regret that it’s not a Renault Logan. The quality of domestic transport is poor, the models are crude. |

| 3. | Victor: during the year of using the car, I went to the service station twice unscheduled for repairs. |

Conclusion

The design of the clutch sensor is completely copied from Renault Logan, so claims about the imperfection of the system are unfounded.

Violation of service life, aggressive driving style, purchase of cheap spare parts are the main factors contributing to premature wear of mechanisms and assemblies.

The process of replacing the clutch sensor will not take much time. The work can be done by a car owner without skills or special equipment.

Replacement

Replacement is quite simple, but you can’t do it without a special tool, namely a small Phillips screwdriver or ratchet attachment.

Replacement process:

- We remove the wipers;

- We remove the frill by unscrewing all the screws;

- We remove the expansion tank to the side without unscrewing the hoses;

- Bend the rubber cover of the clutch pedal;

- Unscrew the clutch pedal sensor (attached with two screws for a Phillips screwdriver);

- Remove the return spring;

- Disconnect the sensor connector and remove it;

- We assemble in the reverse order;

Clutch pedal position sensor VAZ

On the latest models of VAZ cars equipped with an electronic gas pedal, a clutch pedal position sensor . Let's consider why it is needed, the principle of operation and possible malfunctions.

Where is the clutch sensor installed on VAZs?

The clutch pedal position sensor on VAZ is installed directly on the clutch pedal bracket; it can be seen by looking under the steering column.

What is a clutch sensor used for?

The clutch pedal position sensor is one of the elements of the engine management system with an electronic gas pedal. This sensor provides a more flexible control scheme for engine modes. It simplifies the process of starting to move, eliminates “drops” and jerks of the car when changing gears in the manual transmission, and also allows for a reduction in fuel consumption.

By providing information to the engine controller about the moment the clutch is engaged and disengaged, the clutch pedal position sensor allows it to reduce or increase engine speed at the right moment, as well as adjust the ignition timing.

Working principle of the clutch sensor

The clutch pedal position sensor is an ordinary limit switch with two positions - “on” and “off”.

Its normal position is open, that is, it turns on only when the clutch pedal is pressed.

Clutch position sensor malfunctions

The following symptoms may indicate a malfunction of the clutch pedal position sensor

- car "pecks" when changing gears

- a sharp increase or decrease in engine speed when the clutch is disengaged

Also, if a malfunction occurs in the clutch pedal position sensor , error 0830 “Clutch pedal sensor error” is recorded in the engine controller and the “Check Engine” light in the instrument cluster turns on.

Error 0830 is detected if the engine controller does not receive a signal from the clutch sensor:

- within 2 seconds after changing gear while driving

- after four gear changes at speeds above 10 km/h and engine speeds above 1000 rpm

The main reasons for error 0830:

- malfunction of the clutch sensor itself

- short circuit or open circuit

- Incorrect clutch pedal height

We encountered error 0830 while preparing the material “How to get there without a clutch?” We recorded video instructions on how to change gears without a clutch. After several gear changes without disengaging the clutch, the “Check Engine” light came on on the panel, which went out only after several dozen gear changes in normal mode.

All sensors installed on Kalina: Symptoms of malfunction

The correct operation of an injection car engine would be impossible without a large number of different sensors that ensure the smooth operation of the entire internal combustion engine. Cars with fuel injection use many sensors that are directly involved in the formation of the fuel mixture. There are sensors without which the engine will not be able to start at all.

Due to the large number of sensors, it is quite difficult to determine the problem that led to the engine stopping on a Lada Kalina car, but after studying this article you can easily identify the culprit of the breakdown based on indirect signs and will be able to fix the breakdown yourself.

Electronic control unit (ECU)

The electronic engine control unit is one of the most important elements of the vehicle's electronic system. People call this block “computer” or “brains”. In this unit, just like in the brain, a huge amount of data received from all sensors installed on the engine is processed.

The breakdown of this unit is a fairly rare problem, but it often occurs on the Lada Kalina due to its unfortunate location. The ECU is located inside the dashboard under the interior heater core. When the radiator leaks, coolant enters the control unit, which leads to its failure.

Signs of malfunction:

The unit cannot have any specific symptoms of a malfunction. If the ECU fails, most often it simply cannot detect the sensor. In some cases, ignition coils stop working due to damage to the radio elements inside the unit.

Mass air flow sensor (MAF)

The mass air flow sensor on Kalina is installed in the engine compartment between the throttle valve and the air filter housing. The sensor is responsible for counting the amount of air entering the engine. According to the readings from the sensor, the fuel mixture is formed.

Signs of malfunction:

- Increased fuel consumption;

- Floating speed;

- Difficulty starting the engine;

- Poor traction;

Throttle Position Sensor (TPS)

The throttle position sensor is installed on the throttle assembly and reads the position of the valve in the throttle. This sensor is installed only on a mechanical throttle assembly. On vehicles with an electronic gas pedal, TPS is not used. The sensor is not reliable and can often fail. It is recommended to have a spare in the car.

Signs of malfunction:

- No warm-up speeds;

- Difficult to start in the cold season;

- Floating speed;

- Increased fuel consumption;

Idle air control (IAC)

The IAC is installed on the throttle body. Structurally, it is similar to a DC motor with a worm gear. At the tip of the sensor there is a cone head that closes or opens the idle passage in the throttle, thereby regulating the air supply to the engine at idle. This sensor is installed only on a mechanical throttle and is involved in operation only at idle.

Signs of malfunction:

- The engine stalls at idle;

- The revolutions are floating;

- When starting, you must press on the gas pedal;

Operating principle of the electronic engine control system (ECM)

In a modern car, all process control, except for the rotation of the steering wheel, and even then, is entrusted to the computer, or Electronic Control Unit (ECU). It contains a program with many different tables. In general, the ECU receives data about the state of the car, speed, revolutions, and activated mechanisms from a large number of sensors. Based on the results of these observations, the ECU, using these tables, includes certain ignition modes, fuel supply and other executive functions.

The role of the clutch sensor

It would seem, what does the clutch have to do with it? And here's what it has to do with it. When the clutch engages, the most sensible thing to do is to reduce the engine speed. But not to idle, but according to the speed of the car. This is not always available to the driver, especially a beginner. And here the computer will come to the rescue. Reacting to the signal from the clutch sensor, it can independently adjust the engine speed.

Important! In addition, in accordance with the Priora speed sensor, the ECU can obtain information about the serviceability of the clutch.

Summarizing the above, we can say that the presence of a sensor on the clutch allows:

Therefore, its serviceability is an important factor in the Priora control system.

Design and location of the Priora clutch sensor

In principle, this is the simplest switch. In the position when the clutch is disengaged and the pedal is not pressed, the sensor circuit is open. If you press the clutch drive, the limit switch of the sensor closes and the signal “clutch is on” is sent to the ECU.

It is located on the clutch pedal mounting assembly, where the very tip of this pedal is located opposite the sensor end switch.

What is an electronic clutch?

Like any electronic system, the electronic clutch has its own control unit, which processes the received signals and transmits instructions for performing mechanical actions. In addition, this type of clutch combines various input and actuator devices.

Input devices include the clutch pedal unit and input sensors. The latter are the gas (accelerator) pedal location sensor and the gearbox lever location sensor. Although, according to car enthusiasts, there are many more of them, since the car moves without jerking, and the on-board computer tells you which gear is best to engage.

As for the electronic clutch system (not the pedal part), it has its own control unit. It receives and processes signals from input devices and transfers control to execution by the mechanical part. The unit interacts with the engine control system. This suggests that the car will have keyless entry or similar technology.

The executive part of the mechanisms is represented by an electrohydraulic drive (actuator), which stops the movement of the clutch fork based on a signal from the control unit.

Electronic clutch or also known as eCS - Electronic Clutch System is considered a promising development by Bosch. According to the manufacturer, such an electronic clutch brings a manual transmission closer to an automatic transmission. Unlike an automatic transmission, when using the eClutch system, only the clutch operates in automatic mode.

Thanks to the design and operating principle of the electronic clutch, it can be used not only on conventional cars, but also on the manual transmission of hybrid cars. Unfortunately, Bosch is still keeping many of the nuances of how the electronic clutch works secret.

From the name itself we can conclude that the mechanism is easy to use, does not require much effort to change gears and smoothes out the moment of gear engagement as much as possible. Thus, jerks between gears are eliminated.

see also

How to check the clutch

Clutch faults

How to check a support bearing

Strut support bearing

Pressing out the crankshaft bearing

Today, the most common clutch systems have two discs - a leading one, rigidly coupled to the crankshaft, and a driven one, transmitting torque to the gearbox. To change gears or put the car into idle speed, the clutch discs must be disconnected, which is done using a release bearing that pulls the driven disc away from the drive disc.

Release bearing location

This is an important element of the clutch system, and at the same time one of the most vulnerable parts. The clutch release bearing is at rest while the vehicle is moving, and only comes into operation when changing gears. The breakdown of such a small spare part guarantees the impossibility of further operation of the car, so the bearing must be changed immediately when obvious signs of its malfunction appear.

The part costs from 300 to 1500 or more rubles, depending on the manufacturer and model of the car. Replacing a bearing at a service station will cost 3,000-7,000 rubles, so if you have the desire, opportunity and a normal set of auto tools, it makes sense to do it yourself and save a lot of money.

Correcting the mechanism

If various extraneous sounds appear when the clutch is disengaged during vehicle operation, you need to check the gap on the drive fork and, if necessary, adjust it. Clutch cable adjustment is performed in the following order:

- Remove the air filter and pull out the cable by the tip to its maximum length.

- Using a caliper, measure the distance between the tip and the fork. Normally, this distance should not deviate from 2.7 mm.

- If discrepancies are found, turn the driver on the thread until the desired value is established. Release the end of the cable: it should press tightly against the fork.

- Press the clutch pedal 3-4 times to activate automatic cable length correction, measure again.

When re-measuring, a deviation from the value of 2.7 mm may again be detected. In this case, you need to repeat the described steps to adjust the cable length.

The clutch on Kalina may make squeaks and noises even after adjustment. They can be caused by the tip driver rubbing against the fork. The noise in this case comes from the engine side and is eliminated by applying lubricant to the contact point between the cable tip nut and the fork. Other possible causes - pedal creaking, cable grinding when rubbing against the casing - can be eliminated by applying lubricant. In some cases, the source of the noise may be the clutch pedal sensor.

Operating principle

The release bearing's job is to connect and disengage the clutch when you press the pedal inside the car. The operating principle of the part is quite simple:

- the driven disk is pressed against the flywheel by a pressure disk, due to which clutch is ensured;

- the pressure on the pressure plate is provided by a diaphragm spring, the inner petals of which are acted upon by the clutch release bearing;

- the movement of the bearing, which initiates the separation of the discs, is ensured by the clutch fork.

Release bearing in a car clutch system

Design and operation of the Kalina clutch

The unit is a dry-type mechanism, single-disc, with a central pressure spring. Switching off when pressing the pedal is carried out by a cable equipped with a ratchet. This part allows the cable to automatically change length depending on the wear of the disc linings and ensures a constant backlash-free fit of the clutch with the release bearing to the basket.

The pressure plate together with a diaphragm-type spring are enclosed in a casing. All together is usually called the clutch basket. Between this mechanism and the flywheel there is a driven disk. Its hub is connected to the gearbox input shaft.

When you press on the pedal, the cable tightens, turning the fork. Its lower bushing is pressed into the clutch housing, the upper bushing is removable. The force when turning the fork is transmitted through the clutch and clutch release bearing to the pressure spring and pressure plate, turning off the mechanism.

When the pedal is released, the clutch must fully transfer the engine torque to the transmission. Pressing the pedal normally completely disconnects it from the engine. Signs of the need to adjust the clutch on Kalina include:

- exceeding the full pedal travel (normally 146 mm from the lowered position to the stop on the floor) - adjustment of the clutch cable is necessary;

- when the pedal is pressed, the gear shift occurs with a grinding or crackling sound - the clutch does not disengage completely;

- when starting the engine, you can hear a howling sound in the crankcase - wear of the release bearing;

- jerking when starting to move indicates insufficient smoothness of clutch engagement;

- When driving in 3-4 gears, when you press the gas, engine speed quickly increases, and acceleration slows down - disc slipping, possibly due to wear on the linings or insufficient cable length.

As a rule, it is necessary to adjust the operation of the clutch after it has been repaired to bring the automatic adjustment mechanism into working condition.

This operation may also be required if Kalina has not been used for a long time or worked in winter.

In such cases, the wear compensator may lose some of its functions and cannot cope with adjusting the length of the cable.

Causes and symptoms of release bearing failure

The reason for the breakdown of this part is uneven loads on it at the moment when the clutch is depressed, and it goes back along with the driven disk. For this reason, holding the clutch pedal for a long time while the gear is engaged is strictly not recommended. In principle, this is a reliable and durable part, and it most often fails among novice motorists.

The most important symptom of bearing wear is the appearance of a slight knocking sound when the clutch pedal is depressed . If the sound appeared in the summer, this is almost a guarantee of future problems, but if it came along with frost, there may be an elementary change in the linear dimensions of the bearing cup due to a drop in temperature outside. The release bearing in most cars has an undeniable advantage - high strength, so even if noise appears, you can afford to do nothing for a while and watch to see if it gets worse.

What does the clutch sensor affect?

We have already answered the question of why a clutch sensor is needed. Now let's try to figure out how it affects driving and all the components associated with it.

As you know, when changing gears, the entire load of synchronizing the engine speed and the gearbox input shaft is taken on by the synchronizing gears. Quite often, car enthusiasts are faced with the impossibility of switching any speed - and in most cases the reason for this is a worn synchronizer of one of the gears. The clutch sensor practically eliminates the operation of synchronizers, since the signal transmitted to the control unit forces the electronics to automatically reset or raise engine speed to the most optimal value.

Replacing the clutch release bearing

If the bearing still needs to be replaced, you will have to perform the following sequence of actions:

- dismantling the gearbox;

- disconnecting the ends of the spring clamp from the coupling;

- removal from the bearing guide sleeve;

- disconnecting the spring holder;

- removing the bearing from the coupling and installing a new part.

Before installing the parts on the guide bushing, their surfaces must be generously lubricated with grease.

last up to 150,000 without problems , but they often have to be replaced every 50,000 km due to driver errors and bad roads, which destroy the entire car, including the clutch.

Review of Manufacturer Prices

Technical parameters of the roller: 100 x 60 x 20 mm, weight 0.05 kg.

| Manufacturer | Price, rub.) | Resource (Thousand km) |

| VAZ 11180-1602266-00 cable lead | From 250 | 25 – 35 |

| 11180-1602210-00 cable assembly | From 300 | —/— |

| 21901-1602210-00 cable assembly | From 300 | —/— |

| 1118-3720015-00 DS | From 370 – 450 | —/— |

*prices are current as of October 26, 2018.

- Toad - switch 1118-3720015 – 1 piece;

- Housing 1118-3720024-10 – 1 piece;

- Screws 1-0076690-01 – 2 pcs;

- Spring 1118-1602179-00 – 1 pc.

Crankshaft sensor Lada Granta

The DPKV or crankshaft sensor for the Lada Granta is one of the most important measuring units in the entire car. Its purpose is to measure the rotation speed of the crankshaft, as well as its position. While reading the parameters, the sensor sends signals to the controller, which processes this data and issues the necessary impulses to the injectors.

The unit itself is quite reliable in operation and rarely fails. However, if its performance is impaired, this causes significant problems for the further operation of the engine. In addition, the product itself is non-repairable and therefore must be replaced with a new one.

Where is the crankshaft sensor located in Grant?

The device is located next to the oil filter in the left, rear part of the car engine. More precisely, on the generator drive pulley.