High-voltage wires are an integral part of the ignition systems of cars with gasoline internal combustion engines. Their purpose is to transmit pulse voltage reaching tens of kilovolts to the spark plugs. Such a high voltage is necessary in order to create electric arc discharges in the spark gaps of the spark plugs, thanks to which the fuel mixture in the cylinders of internal combustion engines ignites.

The operating conditions of high-voltage ignition wires can be called extreme:

- the voltage removed from the ignition coil can reach 20 kV;

- The air temperature in the engine compartment of a car sitting in a traffic jam in the hot summer is approaching 100°C.

This explains the increased requirements for insulation material and design of high-voltage wires for a car, which often fail, causing interruptions in engine operation.

In this case, car owners usually purchase ready-made sets of wires. They are not cheap, and the market is flooded with counterfeits and products from nameless manufacturers, which does not guarantee quality.

You can achieve significant savings without compromising quality if you purchase certified high-voltage wire by the meter from a well-known manufacturer, and carry out simple installation work on installing caps and tips yourself.

The best manufacturers of high-voltage wires

These products must have excellent insulation that protects the multimedia system and other devices located inside the car from interference. The quality of high voltage transmission should not be negatively affected by the temperature outside the vehicle. Delivery of high-voltage pulses in the range of 25-50 kV, such wires are carried out without voltage leaks with minimal losses. All the above requirements are met by the high-voltage products of the companies participating in our rating.

Description. The popularity of the Japanese company NGK SPARK PLUG is evidenced by the fact that about 30% of all aftermarket parts are produced by this company.

Their high voltage wires are also in high demand among car enthusiasts. The use of innovative technologies allows the Japanese to produce various types of products. The company produces products with copper conductors and a resistor for suppressing interference installed in the connector, high-voltage wires with inductive and carbon resistance. Armored wires are also in demand among consumers.

The tip of electrical parts withstands high-temperature operation thanks to a special phenolic resin coating. Such protection also prevents tensile forces, which has a positive effect on service life. The contact areas of the wires are protected from moisture by elastic rubber bushings.

Life time. Despite the protection declared by the manufacturers, car owners note the short service life of the wires - about a year.

Source

Characteristics of conductors

The characteristics of high-voltage elements are determined by the length and material of the core. When purchasing a kit, it is recommended to check its authenticity to avoid unscheduled car repairs.

Manufacturing materials

High voltage wires can be made of ferromagnetic alloy, copper or non-metallic graphite-coated filaments. The choice of cable depends on the characteristics of the vehicle's electrical system.

When replacing an element, you can follow the recommendations from the service book or the normal resistance of the wire that was installed previously.

Wire length

The length of the voltage elements depends on the car model. The cables that connect to different cylinders are not the same length. The size of the longest element that fits the first distributor socket and the first cylinder is 36-81 cm. The shortest element that fits the 4-6 cylinder has a length of 11-22 cm.

You can select the right size according to the description of the car model and make or according to the length of the already installed conductor.

Product authentication

To verify the authenticity of a product, you must:

- examine the packaging and wires (they should contain information about the manufacturer, operating conditions and composition);

- evaluate the correct spelling of the brand name and instructions (a typical mistake is the word “silicon” instead of “silicone”);

- inspect the elements, evaluate the quality of workmanship and the tightness of the caps;

- twist the wire tightly (the part should not crunch, and the central core should not move relative to the insulation layer);

- if possible, try to melt the outer insulation with a lighter (the protective layer should not melt).

High-voltage wires for VAZ 2115 8-cl. injector, I never found the company I was looking for.

Posts: 1,284 From: TORTUGA BAY

I visited almost all the car shops in the city of Ch. in search of a finwhale GDP for my 15, but it’s nowhere to be found. I had to buy them as they were. Quite a lot of people criticize this brand, in my opinion undeservedly. Therefore, I decided to create a survey - which manufacturer is better?

PS Forgot to add "Other" to the poll. Let me know if you know other manufacturers. Zyy. If anyone knows where they are sold, please tell me for the future.

Post edited by Cors

— Oct 25 2008, 18:21

Posts: 1,284 From: TORTUGA BAY

High-voltage wires are one of the most important elements of a car's ignition system. The quality of the transmission of electrical impulses from the coil or ignition module to the spark plugs, the uninterrupted operation of the engine and the level of fire safety depend on them.

For this reason, several strict requirements are imposed on high-voltage wires: high quality insulation, minimal level of radio interference, and preservation of functionality over a wide temperature range. All these requirements are fully satisfied by Finwhale wires.

Design features

The conductor consists of a Kevlar core, a ferroplastic sheath and a stainless steel wire wound on it. This design provides optimal distributed resistance and minimal noise. Silicone insulation has two layers separated by a reinforcing braid of synthetic fibers. The contacts are made of copper alloy and have a double groove for secure fixation on the tips of the spark plugs. Silicone rubber caps have improved insulating properties and do not lose elasticity at low temperatures.

Checking resistance and replacing armored wires

Good day!

Literally not so long ago, while flipping through the feed on Drive2, I came across a logbook about armor wires and their quality in the BZ from cergemi and thought, should I check my armor wires that are currently installed to see what their resistance is. It’s just that before, when buying wires, I never thought about what their resistance was, etc. And besides, the car has recently become difficult to start when cold and the traction has dropped a little.

Important!

Since I have a seven on the injection system, this article is about armoring the wires for the injector.

If you have a carburetor, then before you get ready to change it, first try to read on the Internet what resistance goes to the carburetor system. In general, after reading a lot of material on different sites about what kind of wires and what resistance they have and what it should be correctly, I decided to check them in order in my own place. But before that, I will say that each company makes its own resistance, that is, not all armored wires, or rather companies, have the same resistance, and secondly, that when measuring from the first to the fourth wire, the resistance value should be increasing, so like, the longer the wire, the greater the resistance. I won’t go into all the details, because there is enough of this on other sites, but I’ll just briefly describe my situation and write about the most important thing and maybe it will be useful to someone =) And so, let’s continue...

I didn’t take a photo of the measurement process on the car, but I’ll write down on which wire what resistance there was, since at that moment I was just making a note for myself and this is what came out:

1st - 4.41 Ohm 2nd - 3.24 Ohm 3rd - 4.21 Ohm 4th - 3.94 Ohm

As we can see, what the hell is going on with the wires and I realized, here it is, one of the main problems, why starting the engine was not what it should have been and why the engine often sometimes slowed down a lot at idle. As you noticed, the resistance does not go from small to large, but simply looks like an equalizer. In general, having finished my working day, I took a multimeter (tseshka) and went to the auto parts stores that had not yet closed. I managed to visit two stores and, fortunately, in both stores, the sellers, without any objections, allowed me to test their new wires with a multimeter. Why in two stores? And it’s simple, having arrived at the first store and checking at the cash register the first and practically the only set of wires for my car, he did not inspire confidence in me either in terms of measurements or in the way that after arranging the wires in order, or rather length, they were numbered was incorrect, especially when on the longest wire, which was intended for the fourth cylinder, there was the number “1” on it, and on some other wire the numbering was incorrect, but unfortunately I don’t remember, but it doesn’t matter. It’s just that if someone who doesn’t understand this at all buys it and changes it according to the instructions, he will either have a hard time with the installation and maybe still take it to the store, or he will install it and think further about why the car didn’t drive better. So, try to be careful and, if possible, come to the store with a tseshka in your hands. As a result, having managed to fly to the last store still open after 7 pm, they also kindly provided me with the only box they had with wires for measurements from the HOLA company, the price of which was 570 rubles and which I liked more, both in appearance and according to measurements.

Below I present to your attention a photo of the new armored wires and a photo report on the measurements of each wire in order.

Source

High-voltage wires VAZ 2115 injector 8 valves which is better

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Milena work great

In terms of resistance, the longest wire is 8Kohms, the rest are about 6Kohms.

By the way, Milena is the same as Packard, but the labels are different.

For the carb Samara they did very well, I don’t know yet how their injection ones work in practice.

For the carb Samara they did very well, I don’t know yet how their injection ones work in practice.

And that injection engines are very different from carb ones?

Yes, neither wires nor spark plugs are suitable for carb injection engines (the coil is weaker than the MZ). The spark plugs have a larger gap (1.0-1.2), and the wires have a higher insulator breakdown voltage. The price of wires varies significantly. Moreover, the wire sizes for 8 valve and 16 valve are different.

You can set the gap at the spark plugs =)

Well, basically it’s just eggs, the current is connected in different ways.

By the way, I measured the resistance of the elephant wire for 16V and the resistance was no more than 5.5 KOhm, so the current is presumably fake, but not a fact. The code failed verification. I sent them to Moscow =) but they haven’t answered yet whether they are real or not.

Source

Wiring check

Checking high-voltage ignition wires begins with a simple diagnosis, because all of the above symptoms of problems may indicate a breakdown of other parts of the engine system or something else. For a simple check it is better to wait until dark. Then you need to expose a small section of the wire on one side and the other and close one end to the body of the car or battery, and the second is needed for maneuver: we move it along the wiring joints, plugs, and so on. When there is a hole there will be a spark immediately. The result is obvious - replacement is required. But this method is primary; it concerns direct current leakage, which is not always the reason for the non-operating state of high-voltage devices. In the case of voltage, such a number will not work.

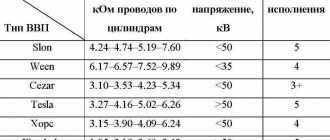

To measure it, you need to know what resistance the high-voltage wires should have. After all, each wire from a specific manufacturer has its own resistance, technical characteristics and dimensions:

1) Tesla - 6 kOhm, it is often counterfeited, then you can squeeze out as much as 8 kOhm

2) Elephant - from 4 to 7 kOhm

3) ProSport tends to zero

4) Kargen - 0.9 kOhm

Checking high-voltage ignition wires with a multimeter

For measuring work, you need a simple multimeter, which we switch to ohmmeter mode. We measure one wire at a time, removing one by one from the cylinders from left to right and from the coil itself. The procedure is simple:

- make sure the car is turned off

- remove the end of the wire from the fastener on the cylinder

- remove the opposite end from the ignition coil mounting

- you need to connect both ends to the multimeter

- read the readings

- write them down so as not to forget

- We do this three more times with the remaining wires

Normal resistance is numbers in the range from 3.4 to 9.8 kOhm. Of course, all this depends on the manufacturer; this parameter is printed on the rubber skin of the wire. If you have a difference with the permissible value, which varies from 2 to 4 kOhm, this is normal. But no more! If more, then the wires are not suitable for driving, they need to be changed.

We always replace wires as a set! Even if one has fallen into disrepair, and the rest are in good technical condition.

That's basically it. Now you should replace the old wires with the purchased new ones.

A little about which high-voltage wires are best for your car

Many drivers do not even realize that high-voltage wires are one of the main ones in the car’s ignition system. Reliable operation of the power unit largely depends on their correct choice. They must provide the following tasks during engine operation:

- Provide voltage transmission of 40 thousand volts;

- The transmission of high-voltage pulses must be carried out with minimal losses;

- Help minimize interference to radio-electronic devices;

- The insulation of the wires must ensure that current does not leak;

- The operability of the wires must be in a wide temperature range from minus 30 to plus 100 degrees or more.

How to make temporary wire repairs

Let's say a check of the high-voltage ignition wires reveals damage to the wiring, and the nearest service station is far away. What to do in this case? First you need to accurately identify the damaged area.

Next, on both sides of this area, the cores are stripped using a knife. The stripped areas need to be connected, creating an electrical circuit, for which any conductor is suitable, preferably copper-based. The connection is made by ordinary twisting.

The main difficulty here is the creation of a high-quality insulating layer. A layer of ordinary electrical tape can withstand voltages of up to 6 kW. In this case, reliable insulation is required for voltages reaching 40 kW. Therefore, to provide this protection, you will need at least 8-10 layers of electrical tape without taking into account the fact that moisture can penetrate between the layers. The tape itself must be of high quality. To ensure that the insulation is also of high quality, it is worth covering the area to be repaired in a plastic box. Before repairing and checking, all wiring must be thoroughly cleaned of dirt and traces of oil.

A few words about their structure

Today, one of the most effective and widespread ways to suppress all kinds of interference is the manufacture and use of wires with resistance distributed along its entire length. Wires usually consist of conductors, an insulating layer, contact plates and protective caps. The main difference between these wires is the conductive cores. They can be:

- Copper stranded;

- Non-metallic with a metal “wrap”;

- Non-metallic with high resistance distribution.

The world's leading manufacturers of automotive spare parts produce several varieties of such products. The most widely used brands are ngk, finwhale, tesla, carden, slon, fenox, bautler, xopc and some others. Let's talk about them in more detail.

What are NGK wires?

NGK offers consumers a large selection of high-quality products that meet almost all requirements for such products.

NGK wires have a long service life and are economical. Other NGK products are characterized by:

- The original design of the products has the same design;

- NGK are copper wires with noise suppression tips or have distributed resistance;

- Once purchased, NGK is ready for immediate use;

- High resistance of NGK to fuel and engine oil;

- Designed to work with high voltage in the ignition system.

As a disadvantage, they note the fact that they are made of the same length, which sometimes causes some inconvenience.

Do-it-yourself wiring replacement

To replace it yourself, you will need a set of high-voltage conductors, rubber gloves, and a camera (to record the layout). New elements are connected in the following order:

- to the distributor outlet and 1 cylinder;

- to the lower tip and 3 cylinder;

- to cylinder 4;

- to cylinder 2;

- central - to the coil.

To simplify fixation, you need to treat the seats with silicone grease. The cap should be put on until it clicks.

Finwhale products

Finwhale products are intended for use in contact and contactless vehicle ignition systems.

The former are intended for use in a contact system, the latter in non-contact devices. Finwhale uses Kevlar core to make the conductors. The shell is made of fluoroplastic, which is wrapped with thin stainless steel wire. Finwhale wire insulation has two layers of silicone, which gives optimal resistance distribution and the lowest level of interference. Finwhale products operate in a temperature range from minus 40 to plus 220 degrees. The Finwhale manufacturing process is controlled by multiple quality checks and compliance with production technology.

Products from Tesla

The Tesla company began its work back in 1958 and today is one of the world's leading manufacturers of automotive accessories. Tesla wires incorporate all the advanced achievements in the field of electrical engineering.

Tesla uses materials that slightly exceed the requirements for such products. So silicone is used for the shell. Tesla products are made without the use of metal as a conductor. For this purpose, fiberglass is used, which is pre-treated with carbon impregnation. Tesla products operate in a temperature range from -40 to +220 degrees.

Tesla SILICONE inductive products have an additional winding made of thin stainless wire. This achieves maximum energy transfer to the spark plug. Experts recommend spark plugs with a built-in noise suppression resistor when using Tesla silicone wires. Tesla guarantees the flawless long-term operation of its products.

Advantages and disadvantages: how to choose

Regardless of the material and manufacturer, high-voltage conductors must meet the following criteria:

- conductive cables operate without failures in the range of -50...+250°C;

- external protection (sheath) reliably protects the internal core from moisture, oil and fuel, there are no signs of contact failure and corrosion;

- no current leakage;

- the caps are installed tightly and can be removed with force (these elements are made of silicone and may contain a resistor or metal screen);

- the contacts are securely attached to the core, firmly fixing the wire to the spark plug.

Advantages and disadvantages of high-voltage conductors depending on the material

| Cable type | Advantages | Flaws |

| Copper | Availability, possibility of self-production | The need to install additional resistors |

| Non-metallic (graphite coated) | High reliability, presence of distributed resistance | Deterioration of conductivity due to prolonged exposure to vibration and temperature changes |

| With ferromagnetic core | Adjustment depending on vehicle operating mode | High price |

The best option is a conductor with a non-metallic core. Copper elements are often used as a temporary replacement while in transit.

A little about carden products

Carden products are widely used on GAZ, VAZ, ZAZ, Bogdan Motors, Sollers-Isuzu and other models. Production was mastered in Tolyatti. Carden products are designed to operate over a wide temperature range, from approximately -40 to +180 degrees. The length of the carden wires may be slightly longer than those installed on the car. Soft, double silicone insulation contributes to the high performance of Carden products. Carden resistance ranges from 4.5 kOhm to 5.5 kOhm and depends on the length of the wires. Carden guarantees the ability of the wires to withstand a voltage of 45 thousand volts. Experts recommend that before installing new Carden wires, check the spread of their resistance; if it is large, it is better to replace them.

Pinout of lock VAZ-2110, VAZ-2111, VAZ-2112

Pinout of the ignition switch VAZ-2110:

- comes +12V for the microphone of the sensor of the inserted key;

- the mass comes when the driver's door is open;

- +12V goes to the starter (pin 50);

- +12V goes out after turning on the ignition (pin 15);

- +12V goes out when the key is inserted to pin 5 of the BSK;

- comes +12V to illuminate the lock cylinder;

- +12V comes from the battery (pin 30);

- not used.

What can you say about slon products?

Products under the slon brand are produced and used by such automobile manufacturers as OJSC AVTOVAZ, as well as GM-AVTOVAZ. Work is underway to use slon brand products for cars of other brands, including foreign ones. Slon products are available with straight and angled tips.

According to consumer reviews, sometimes incorrect marking of slon wires occurs, when the packaging bears the designation 1, 1, 1, 1 instead of 1, 2, 3, 4. In general, reviews of products under the slon brand are not bad. If necessary, you can choose an elephant for your car.

What you should know about Fenox branded products

Fenox brand products are used on both domestic and foreign cars. When choosing, you should follow the operating instructions for the vehicle. The manufacturing technology of Fenox products involves the use of aramid thread, which has high strength. It is covered with a conductive layer of latex and silicone. Fenox products allow you to effectively use your car for a long period of time. The ignition system works well with them.

Choosing wires when purchasing

When purchasing, not only the brand of wires and the manufacturer are taken into account. Particular attention should be paid to the engine model. This is due to the fact that when designing cars, the manufacturer sets certain wire standards that must be taken into account when repairing or replacing.

One of the selection criteria is the voltage for which the wires are designed. If the cable cannot withstand the voltage, an insulation breakdown may occur, resulting in failure of the wire. Also, when choosing, you need to take into account the material from which it is made.