High-voltage wires used in automotive ignition systems are gradually being forced out of the market. The fact is that automakers are actively promoting ignition technology without the use of wires, in which the ignition coil is placed directly on the spark plug. Nevertheless, such conductors have shown themselves to perform well: they are extremely resistant to external influences, durable, and easy to manufacture. A significant number of cars on the roads are equipped with just such wires. Let's figure out how to use them and choose the right ones.

Place of wires in automotive ignition systems

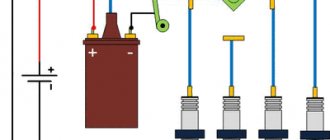

Today, a high-voltage wire is used in conjunction with a distributor or an electronic control unit. The first option is often called simply mechanical, and the second - a static power distribution system. Here's how it works:

- Distributor system . Using the ignition coil, the energy from the 12-volt battery is converted into several thousand volts, which are distributed using a mechanical distributor. There is always one wire from the coil to the distributor and the number of wires that corresponds to the number of spark plugs;

- System with ECU . The modified system is equipped with candles, each of which has a coil. The number of wires is dictated by how many coils will be supplied with voltage from the control unit. We only note that the coil can provide operation of one spark plug or two at once, as is the case in dual-spark DIS systems.

Only one fact remains unchanged: the high-voltage wire must supply voltage from the coil to the spark plug. In accordance with this, wires with specified characteristics are selected. Let's try to explain.

SELECTION OF THE BEST GDP FOR VAZ 2114

When choosing high-voltage wires, preference should be given to trusted manufacturers, among which are Cargen, Finwhale, Tesla, and Slon. They cost an order of magnitude more than Chinese wires, but there are fewer problems with them - set and forget, while the Chinese are not particularly reliable and durable.

It is worth noting that there is no single standard for technical characteristics for all GDPs - products from different manufacturers have different resistances.

Table indicating the resistance of explosive wires

The test of the most popular GDPs showed the following indicators of breakdown voltage: The lower the resistance of high-voltage wires, the better. However, when choosing, it is necessary to take into account the breakdown voltage, the indicator of which should be as high as possible.

- Slon: <50 kV;

- Ween: <35 kV;

- Cezar: <50 kV;

- Tesla: >50 kV;

- Finwhale: > 50 kV.

As evidenced by reviews from car owners, the best option for GDP for injection engines, including the fourteenth, is Tesla wires.

Conductor Specifications

When making a wire, most attention is paid to the core and insulation. The core can be copper, a special graphite thread, a thread made of flax or fiberglass. Non-metal conductors perform well, since they do not require additional resistors.

Insulation is almost always multi-layered. The outer protective layer makes the entire wire resistant to mechanical and chemical influences, the middle of the wire is made of dielectric, and the braiding of the conductor is deliberately made quite rigid. As a result, we get an extremely durable and not too flexible wire. It is not afraid of temperature, exposure to automotive chemicals, dust and moisture. According to the standard , the insulation must cope with a voltage of 40,000 V.

A few words about their structure

Today, one of the most effective and widespread ways to suppress all kinds of interference is the manufacture and use of wires with resistance distributed along its entire length. Wires usually consist of conductors, an insulating layer, contact plates and protective caps. The main difference between these wires is the conductive cores. They can be:

- Copper stranded;

- Non-metallic with a metal “wrap”;

- Non-metallic with high resistance distribution.

The world's leading manufacturers of automotive spare parts produce several varieties of such products. The most widely used brands are ngk, finwhale, tesla, carden, slon, fenox, bautler, xopc and some others. Let's talk about them in more detail.

More about zero resistance wires

On older cars you can often find high-voltage copper wires with zero resistance. They have a number of disadvantages:

- Electromagnetic interference . We have already talked about the fact that modern spark plugs can require up to 35,000 V. When the system operates, the so-called skin effect and energy distribution in the space around the conductor are observed. Of course, the energy losses are not too great, but they are enough for the same radio to start working with interference. The problem is partially solved by installing additional resistors to suppress interference;

- Impact on insulation . Unfortunately, the insulation quality of a zero-resistance wire deteriorates too much as it is used. You cannot turn a blind eye to this for a number of reasons, one of which is the deterioration of the spark plug. The result: dirty exhaust, loss of power due to incomplete combustion of the fuel mixture.

However, these shortcomings do not always manifest themselves fully. Simply, wires with nylon or cotton threads impregnated with soot, replacing the “zero” ones, turn out to be noticeably better. The most modern wires have glass fiber inside, on which graphite is sprayed.

How to check the wiring if there are no obvious signs of damage, but the engine malfunctions

If this method of checking does not live up to expectations, test the wiring with a voltmeter. How to check high-voltage wires on a VAZ 2114?

Checking explosives with a multimeter

Signs of direct damage are easiest to spot after dark. It is necessary to strip the wiring sections from opposite sides and short-circuit one side to the housing or battery. With the other side we move along the plugs, wiring contacts and other conductors. If there is a breakdown, a spark will appear.

The voltmeter is switched to ohmmeter mode. Measure all the wires, sequentially removing them from the cylinders and coils from left to right. Each indicator must be recorded, so prepare paper and pen (pencil) in advance.

How to measure the voltage resistance of VAZ 2114 wires:

- Turn off the car.

- Remove the end of the wire from the cylinder.

- Remove the opposite end from the ignition coil.

- Connect both ends to the multimeter.

- After counting, write down the readings.

- Repeat the sequence for the remaining three wires.

What resistance is considered normal? Depending on the brand of wiring, from 3.4 to 9.8 kOhm. Normal values are usually stuffed on top of the insulation. If the measurement difference does not exceed 2-4 kOhm from the control value, this is within normal limits. Otherwise, the kit must be replaced immediately.

Before replacing, you need to reanimate the oxidized contacts, then ring again. To do this, clean the contacts with WD-40 or carburetor cleaning fluid.

Normal wiring resistance of different brands:

- Tesla - 6 kOhm (in case of fakes it can reach up to 8 kOhm);

- Elephant - 4-7 kOhm;

- Kargen - 0.9 kOhm;

- ProSport tends towards zero.

Even if one wire has become unusable, the entire set must be replaced.

Advantages and disadvantages of each type

Now let's try to summarize the information about each type of wire:

- Copper . They may have additional internal resistance, or they may be created without it. If their internal resistance is zero, i.e. Inside there is a regular core made of copper wire, the installation of additional resistances is required;

- With distributed resistance . Consist of several layers. They themselves are difficult to manufacture, but they have improved insulation (there is a complex inner and outer layer) and core. In European wires, the distributed resistance is 9-25 kOhm/m. As a result, radio and television interference is not created at all. We installed the wire and off we went;

- With inductive reactance . A very interesting solution. A so-called pulsating magnetic field appears in the wire. The ignition coil accumulates energy during operation and then releases it. As a result, the inductive voltage in the cable can increase. In such wires, the resistance is a variable value, which depends on the frequency at which the motor operates. The most modern solution, but, alas, expensive.

The simplest copper wires are still used only because their production, as well as additional noise suppression resistors, does not require large financial expenditures. For this reason, workshops can easily make you a high-voltage wire using terminals and a coil of ordinary Chinese wire with a blue silicone sheath.

Products from Tesla

This brand began operating in 1958, so in our time it is a leader in the relevant market. The wires combine the main advances in the field of electrical engineering.

Tesla high voltage wires

Tesla uses materials that comply with the specified norms and standards. High-strength silicone is used to make the shell. Metal is not used to create the current-conducting core, as it has been replaced by more reliable fiberglass. It must be supplied with carbon impregnation. Such products can operate at temperatures from -40 to +220 degrees.

The product is complemented by a winding made of thin wire. It is made of stainless steel, which is not afraid of corrosion processes. Experts recommend supplementing the products with noise-suppressing resistors. The company guarantees its customers stable and uninterrupted operation of their products.

More information about high-voltage wire terminals

The terminal is needed for high-quality and durable contact. Since the junction of the wire with the energy-consuming device can be called weak, it is covered with a special cap. As a result, the system will work reliably even in hostile environments. Automotive terminals are usually protected with silicone caps. This material is not afraid of water, dust, or auto chemicals.

There are the following connectors for automotive spark plugs : SCREW/VRUT, M4, SAE, DIN, D4. As a rule, in modern cars the terminals are removable, so there is a SAE connector for a latch and an M4 for a thread.

Wire lifespan

According to the recommendations of the manufacturer (AvtoVAZ), the wiring should be replaced every 30 thousand kilometers. Most often, car enthusiasts ignore these recommendations and do not change them for 100-150 thousand kilometers when there is no mechanical damage.

However, when the service life is exceeded, even if there is no visible damage, the internal resistance increases, which affects the transmission of the electrical impulse. There may be problems with ignition and acceleration. Due to the delay in supplying current to the spark plugs, the normal rhythm of engine operation is disrupted. It is necessary to follow the manufacturer's advice, changing the wiring every 25-30 thousand kilometers.

When connecting new wires, do not use plastic clamps for fixation. It is imperative to separate them using the comb holder that is included in the delivery package.

Finding out when to replace wires

Please note that there are no regulations for replacing explosive wires. You need to navigate along the way. There is a lot to consider:

- The engine began to “trouble” and run rough, and fuel consumption increased. Most likely the wire has broken. The engine freezes at high speeds, since the electromagnetic pulse in the ignition system has decreased and the spark is either weak or absent at all;

- The wire began to spark and glow. You can observe this phenomenon if you look under the hood of a running car. The problem is insulation or contacts. This wire is only for replacement;

- Inspection revealed the presence of external damage. The easiest way is to simply replace the wire with a new one.

As a rule, high-voltage wires fail without any intervention, although sometimes they are “killed” by a technician who carelessly removes the spark plug. You can accurately determine their malfunction by observing the engine at idle speed, as well as using a tester. If it shows an open circuit (resistance is infinity), the wire will need to be changed.

We also note that unknowing people confuse wiring faults with those of a spark plug. Yes, the high voltage wire determines the operation of the spark plug. However, without “experiment” it will not be possible to determine the broken part. Since checking spark plugs is a very troublesome task, it is more advisable to remove the wire and check it with a multimeter, setting the measurement limit to 20,000 Ohms.

GENERAL INFORMATION AND FEATURES OF GDP DESIGN

Unlike the rest of the car's wiring, high-voltage ignition wires have a rather complex design. They consist of plastic caps, metal contacts, an insulating layer and a copper conductor.

GDP insulation can be either single-layer or multi-layer, depending on the quality and cost of the wire. As a rule, all products from leading manufacturers have multi-layer insulation. The protective layer of GDP performs two main functions:

- Acts as a barrier that prevents current leakage;

- Performs the function of protecting the conductor from mechanical damage and aggressive environmental influences: fumes, fuels and lubricants, moisture, low and high temperatures.

The conductive core of the GDP is made of copper, since this material has minimal resistance and durability (about 8 years of operation). The conductive element of the GDP, according to GOST 14867-79, must meet the following requirements:

- Limit permissible voltage – 22 kV;

- Minimum breakdown voltage – 40 kV;

- Maximum electrical capacity – 100 pF/m;

At both ends of the wire there are metal tips that act as contacts, through which the VVP are connected to the coil and spark plugs.

Various types of explosive wire lugs

When purchasing, it is worth checking the high-voltage wires for the quality of the connection between the contacts and the core; it is necessary that they are firmly attached to the core and tightly connected to the spark plugs, since the lack of normal contact is one of the most common problems with VVP.

Plastic caps perform a protective function. They prevent moisture and dust from entering the contacts, and protect them from changes in ambient temperature.

Correct installation

If the explosive wires are installed correctly, they do not require further intervention in their operation. Of course, it makes sense to check the cleanliness of the engine compartment. Here's what you need to watch out for during installation:

- The quality of contact fastening must be high;

- Protective silicone caps must cover the terminals;

- There should be no tension or sagging of the wires.

We still advise you to maintain the “salable appearance” of the wires. Clean them from dust and automotive chemicals using a damp cloth and detergents. You should not use force if, when trying to replace the wire, the terminal gets hot and does not come off.

Selecting new wiring

You are convinced by external or indirect signs that the wires are faulty. Which wiring is better to choose to replace the retired one?

The products of the Czech company Tesla received the largest number of positive reviews. The wiring has good breakdown voltage, high resistance, and the quality is such that it does not tarnish or crack even at low temperatures. Also in auto stores there are products of the brands Slon, Ween, Cezar, Horse, Finwhale. All of them are suitable for operation in Russian conditions.

Understanding the choice

You probably already guessed that the high-voltage wire kit includes the conductor itself of a certain length and equipped with a certain terminal with additional protection. So you will have to choose based either on the VIN code of the vehicle, or on the instructions for the car, or on its technical parameters. The new wires should be the same length and connector type as the old ones.

In order not to increase the wear of old wires, it is worth changing everything at once. This will reduce the risk of one of the spark plugs failing. If you have a new car, you will have to use the most expensive and modern wires. The fact is that spark plugs in new vehicle models consume up to 35,000 V, which means they have high requirements for the quality of conductor insulation. Typically, under the hood of foreign cars there are wires with distributed resistance with silicone insulation.

Products from Carden: main features

Products from this brand are used on cars of various brands: GAZ, ZAZ, VAZ and so on. The products are designed to operate at temperatures up to +180 degrees. The minimum indicator is minus forty degrees. The length of the wires may exceed the length of those products installed on the vehicle.

Carden high voltage wires

The characteristics of products from this company are high, since they contain two layers of silicone insulation. The company guarantees that the wires will withstand considerable voltage - up to 45,000 volts. Before installing new products, it is necessary to check the spread of their resistance. If it is too high, then you should think about replacing the old options.

Practical recommendations

In order to buy the best wiring, you should not forget about some things. In the selection process, you should always focus not even on the recommendations of the car manufacturer, but on the recommendations of the engine manufacturer. It would also be appropriate:

- Study the packaging. It contains very important information: manufacturer data, engine and car models. Also, a separate sticker indicates the product’s compliance with the ISO 3808 , if it is a wire from a foreign factory, or GOST 28827-90 , if from a domestic one. Specified operating temperature range: -40°C to 200°C;

- Check to see if it's a fake. Making a fake wire is not very profitable, but the same cannot be said about caps and terminals. If both are of disgusting quality, the transmission of the discharge can deteriorate by one and a half times. Although only a specialist can tell you in detail about some elements of the wire, in order not to buy a fake, you should get a general impression of the product: the terminals should not be skewed, have traces of rust, and the caps should not seem “oaky” to the touch;

- Check insulation. Long-term storage and low suitability of the product are indicated by cracks appearing on it and uneven color of the insulation.

If you decide to switch to a different type of wire, you will have to measure the resistance parameter . There is another, more crude and extremely inaccurate method: if after replacing the wires the car radio began to work with interference, you selected a product with a small additional resistance.

Replacing Erz high-voltage wires with Tesla. — logbook Lada 2114 Code 134 2006 on DRIVE2

In a previous entry, about replacing spark plugs, I wrote that I had tuned the engine. The spark plugs turned out to be not to blame. Diagnostics using the ELM OBDII adapter persistently showed misfire in cylinder 3. It turned out that the wire to cylinder 3 was broken (or rather burned out). I decided to change all GDPs. I was choosing between finwhale and Tesla (NGK was not in the store). I chose Tesla T684H because the price is under 1000 rubles. I was not satisfied with the kit from finwhale. The packaging for the wires says Czech Republic, the wires themselves have the inscription USA, and the price tag indicated the city of Tolyatti! Who actually produces them?! Tell me, who knows. The wires feel and look very high quality. Resistance measurements also showed good results. Measurements were taken along the length of the wire in descending order. They do not have cylinder numbering, as on the previous VVP.1-5.06 kOhm2-5.09 kOhm3-5.56 kOhm4-4.24 kOhmThe old wires showed a resistance of 8.3 to 8.8 kOhm, except for the 3rd (broken).

After the replacement the car ran better than before!

Diagnostics using the ELM327 adapter and OpenDiag Mobile.

Explanation of the error and a hint where to look for the cause.

Full size

Broken wire to 3rd Cylinder

Price: 645 ₽ Mileage: 87555 km

Brand tour

We recommend using the VIN code of your car to choose original OEM wires that meet all the parameters.

As for alternative spare parts, things are going well with him. Those manufacturers that supply quality spark plugs also supply excellent high voltage wire. We can note Magneti Marelli from Italy, as well as the German company Beru and the French Valeo.

The most popular among motorists are the German Bosch, the Czech Tesla and the well-known Japanese NGK. From budget solutions, we choose products from the Danish company JP Group and the Czech company Profit.

How the wires are arranged

The wiring structure is the same as that of the electrical wiring in the apartment. A large number of copper wires are combined into a core. On top of the core there is a core and an insulator. The outer insulating layer usually consists of a silicone, polyethylene, polyvinyl chloride, rubber shell. The additional shell protects against the destructive effects of fuels and lubricants.

High-voltage wires VAZ 2114

What are the signs of faulty high-voltage wires:

- Broken wiring.

- Leakage current.

- Warming up wiring.

- Rupture of current-carrying conductors and insulation.

Broken wiring

If the wiring is faulty, the engine will stall and stall. If you find sparking wiring under the hood, it must be replaced immediately.

Conclusion

In the case of high-voltage wires, there is no problem of choice as such. Firstly, you can always buy the original or an analogue. Secondly, almost at home you can create a car wire according to instructions on the Internet, and you can also save a lot of money. However, we do not recommend that you engage in such experiments, especially if your vehicle is a new foreign car. The high-voltage wire is not so expensive that you can skimp on it and risk breaking other components of the ignition system.

What you should know about Fenox branded products

Fenox brand products are used on both domestic and foreign cars. When choosing, you should follow the operating instructions for the vehicle. The manufacturing technology of Fenox products involves the use of aramid thread, which has high strength. It is covered with a conductive layer of latex and silicone. Fenox products allow you to effectively use your car for a long period of time. The ignition system works well with them.

BB: professional replacement

If you have decided to contact the service for the process of replacing high-voltage wiring, then it is, of course, a good thing, but not worth the money that will be asked of you. They can also confuse your brain on the topic of how often high-voltage wires need to be changed, with the logic that it is better to take care of prevention in advance than to get stuck on the highway. You won’t get stuck on the highway, the contact is not a sensor, even the last one doesn’t die right away. Replacement will cost from 1000 rubles. The advantage of service in this case will be the fact that they will look at the candles for you. And they will definitely be cleaned (they tend to become oily, which negatively affects the throughput for pulses through high-voltage wires).