High voltage zero resistance wires are the best wires for almost any car. In this article you will learn how to make wires using high-voltage wires from gas trucks and wires from a ZIL-130 car , as well as using PMVC .

Making high-voltage wires with your own hands is not only easy, but also cheaper than buying original ones, and the quality will be better! I will tell you how to make high-voltage wires with your own hands. The instructions are universal, such high-voltage wires are suitable for VAZ, Audi, or even Hyundai and Kia.

Why do I need high voltage resistance wires?

Every car has high-voltage wires, their task is to pass a lot of volts through themselves - up to 20,000 volts!

If we take that the volt wire is a highway, then the volt is a car. There are obstacles in the wires - resistance, and the fewer obstacles there are on the highway, the faster and more often they get to the place - the spark plugs.

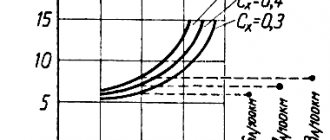

Nowadays they make wires of poor quality - no copper at all, as thin as a hair, which is why such wires are scarce. Engine performance deteriorates, to the point where it stalls or it becomes impossible to start it at all. Therefore, zero-resistance wires will come to the rescue; thanks to them, engine performance will improve , traction will appear at the bottom , and fuel consumption will also decrease . It doesn’t matter whether it’s an injector or a carburetor - high-voltage wires with zero resistance are often better than the original or factory ones.

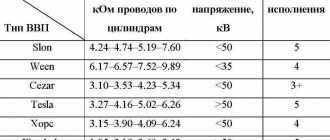

To check the resistance, simply take the simplest multimeter and attach the probe to the ends; the screen will show the real resistance of the wire. Ideally, for most cars, a resistance of more than 3 kOhm is not the norm . Therefore, we begin the work of manufacturing high-voltage wires.

High voltage wire device

Until the 30s of the last century, the influence of impulse noise on automobile devices was neglected. The resistance of the copper core was close to zero. With the advent of car radios, it turned out that interference from high-voltage electrical cords creates such strong radio interference that the devices crackle and cannot be sources of pleasant sound. Engineers came up with the idea of installing a 4-15 kOhm resistor in series with the current-carrying conductor. This reduced radio interference.

Modern high-voltage wires are made with a conductive layer of graphite with a resistance of 5-20 kOhm. They can be used without an additional current limiter.

Twisted steel conductors reinforced with strong Kevlar threads with a ferrimagnetic core are also used.

The following materials are used as insulators:

- polyethylene;

- polyvinyl chloride;

- feroplast;

- silicone;

- metal winding, like a screen.

Insulation is a combination of layers, distinguished by the presence of one or the other component, depending on the preference of the manufacturer.

Symptoms and faults of high voltage cables

Among the main symptoms:

- engine troits;

- thrust changes unjustifiably sharply;

- the engine stalls and does not start well;

- fuel consumption has increased;

- CO emissions increased;

- BB wires spark;

- engine power has decreased.

Symptoms show that the malfunction is caused by incomplete combustion of fuel and is associated with the ignition system, although similar signs of breakdowns are also typical for other car systems.

Where to buy zero resistance wires

PMVC is a high-voltage installation wire with a stranded copper core (TCC) with silicone insulation “SILICONE”, flame retardant.

High-voltage silicone wire PMVC, used:

Nowadays it is no longer difficult to buy it on the Internet. Let’s say that in Ukraine there are several stores selling this product with a price of 30-40 UAH/m.

There are also different color options and the possibility of purchasing even lugs, so as not to waste time cutting up old wires.

We purchased black wires with tinned copper for the next set of explosive wires

An example selection board looks like this:

Source

Diagnostics of high-voltage wires

If you find the above malfunctions in the operation of the car, then pay attention to the high-voltage ignition wires. In modern cars they work for quite a long time, more than 100 thousand km. But cars that have only traveled a thousand kilometers, but have been sitting in a garage without moving for more than five years, have the same problems. Microcracks appear in the insulation, and the cable penetrates the housing with high voltage.

Find a dark place, preferably in the garage, and clean the wires from any burning and grease. Start the engine and see what's going on under the hood. You will see a slight glow around the armored wires. If you don’t see it, but the engine is running, then that’s quite good. But if the glow is bright or the wires spark, then these are signs of dielectric failure.

Sometimes leaks are caused by grease or oils trapped in the tips. In this case, the voltage becomes an extremely dangerous source of car fire.

It is easy to diagnose the ignition system by the sound of the audio system. The method is only suitable for car owners with old analogue radios. As soon as problems with the cables begin, the radios crackle in sound and no power filters will help.

How to check armored wires? You can determine which one is faulty using a conventional analog or digital tester. Checking high-voltage wires does not require the qualifications of an electrician; it is enough to know how to use a multimeter and remember that no matter what product you use, the grease on the insulation must be thoroughly cleaned.

Types of conductive cores of high-voltage cables:

- copper;

- copper with built-in resistor;

- graphite;

- twisted steel winding on a dielectric.

In the first case, the resistance of the high-voltage wires will approach zero; in the next three cases it should range from 4 to 20 kOhm, depending on the brand. If the multimeter displays readings higher than this, then this is a sign that the cord is unusable. Grease on an uncleaned probe and a dirty insulation surface will distort the readings of the device. The grease can be conductive and by measuring the resistance of the wire, you can actually see the result of the resistance of the grease and not the wire.

Testing with a tester will not be able to detect dielectric failures and problems with contacts in the clamps if they are covered with grease.

How to check high-voltage wires without a multimeter? Only by bringing them with their bare end to the body of the car. The presence of a spark indicates that the circuit is working properly. The spark must be powerful and stable.

During measurements, be sure to bend the braid and insulation, especially at the connector fastening points. If the device readings change, then the device is unreliable and it is better to replace it.

Checking for a wire short circuit

Required equipment: 12-volt phase indicator

Connect the indicator to ground. Start the engine and run the indicator along all the wires. The appearance of a spark indicates damage to the wire insulation and the need to replace it.

Note When checking for shorted wires, try to avoid contact with metal parts in the engine compartment.

How to make and replace an HF cable yourself

For example, you have determined that the armored cord of the fourth cylinder penetrates the body or is completely broken and does not affect the spark plug. Replacement required.

Replacing high-voltage wires is a simple operation that can be performed by any car enthusiast.

It is safer to purchase a complete set. Practice has shown that products from the same manufacturer produced at the same time fail almost simultaneously.

Set of high voltage wires

If this is an expensive solution for you, then you can make armored wires yourself. It will be much cheaper. Before you make them yourself, make sure that the connection diagram is clear to you.

To make a kit with your own hands, just purchase:

- silicone vacuum hose with a diameter of 7-8 mm;

- tips, you can use old ones if they are in good condition;

- copper stranded cord with any suitable cross-section;

- half-watt resistors with a nominal value of 1-1.5 kOhm.

The additional element necessary to smooth out radio interference in modern cars should be in the range of 10-20 kOhm. If you install one element of this rating, then there is a high probability of its failure during peak loads. It is better to distribute the load across several series-connected devices with a nominal value of 1 kOhm.

We insert a chain of do-it-yourself resistors into a silicone hose, cut it off and clean it. Then crimp the ends. To improve contact, graphite lubricant is used at the joints.

If the insulators are difficult to put on, lubricating them in a soapy solution helps.

Disadvantages of the method:

- there is a high probability of contact soldering failure in high temperature conditions;

- dependence of the ruler on one part;

- difficulty in identifying a failed element.

If you decide to make the cables yourself, then do not forget that high-voltage wires of zero resistance are connected only through a series resistance.

Miracle wires with zero resistance - benefits for cars or an advertising ploy for 2021?

For the operation of the gasoline power unit of modern cars, the ignition system is of great importance, the main elements of which are a coil, spark plugs and high-voltage wires.

The level of resistance of the conductor determines the strength of the electrical impulses passing from the coil to the spark plugs. The smaller this value, the less the voltage drop at the end point. It is important to understand whether wires with a minimum value of this characteristic really have a positive effect on engine operation.

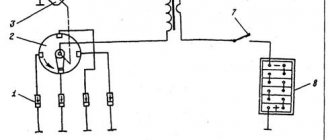

High-voltage wires, order of their connection

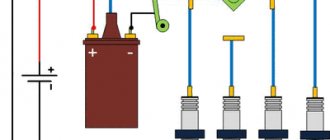

If the distributor cover is installed correctly with your own hands, then the connection diagram for the high-voltage wires will be as follows:

- distributor outlet, looking towards the front bumper, to the first cylinder;

- tip looking down towards the third cylinder;

- looking back to the fourth cylinder;

- looking up to the second cylinder;

- the central current-carrying current always goes to the ignition coil

Classic connection according to the scheme: 1-3-4-2.

Do not forget that the order of connecting high-voltage wires in cars is such that their length will not allow for an incorrect connection. Therefore, when making cords with your own hands, try to follow the same principle so as not to get confused.

Checking the resistance of the wires that lead to car spark plugs

Equipment Required: Digital Multimeter

Set the digital multimeter to measure resistance (Ohms, ?). Hold the tester's pins on both ends of the wire and determine its resistance. The Society of Automotive Engineers (SAE) has set the upper limit of the resistance value at 3,600 ohm-m. However, car manufacturers may recommend different values, so it is best to consult your vehicle's repair manual for reference.