To avoid mixing up the wires on the ignition coil (ignition module), it is more convenient to change the high voltage wires one at a time.

— Disconnect the high-voltage cables from the spark plugs.

Disconnect the ends of the high voltage cables from the ignition coil

Using a tester (in ohmmeter mode) we measure the resistance of the wires.

In working cables, the resistance (depending on the length) should be from 3.5 to 10.0 kOhm. No more than 15 kOhm

Replace the high voltage cables as a set.

— We connect the wires to the spark plugs and the ignition coil according to the cylinder serial numbers marked on the wires and the ignition coil.

It is necessary to connect wires to the ignition coil only in accordance with the serial number of the cylinder. The serial number of the cylinder is marked on the wire insulation.

The best manufacturers of high-voltage wires

These products must have excellent insulation that protects the multimedia system and other devices located inside the car from interference. The quality of high voltage transmission should not be negatively affected by the temperature outside the vehicle. Delivery of high-voltage pulses in the range of 25-50 kV, such wires are carried out without voltage leaks with minimal losses. All the above requirements are met by the high-voltage products of the companies participating in our rating.

Description. The popularity of the Japanese company NGK SPARK PLUG is evidenced by the fact that about 30% of all aftermarket parts are produced by this company.

Their high voltage wires are also in high demand among car enthusiasts. The use of innovative technologies allows the Japanese to produce various types of products. The company produces products with copper conductors and a resistor for suppressing interference installed in the connector, high-voltage wires with inductive and carbon resistance. Armored wires are also in demand among consumers.

The tip of electrical parts withstands high-temperature operation thanks to a special phenolic resin coating. Such protection also prevents tensile forces, which has a positive effect on service life. The contact areas of the wires are protected from moisture by elastic rubber bushings.

Life time. Despite the protection declared by the manufacturers, car owners note the short service life of the wires - about a year.

Source

High-voltage ignition wires for Lada Granta 8 valves, which are better?

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Milena work great

In terms of resistance, the longest wire is 8Kohms, the rest are about 6Kohms.

By the way, Milena is the same as Packard, but the labels are different.

For the carb Samara they did very well, I don’t know yet how their injection ones work in practice.

For the carb Samara they did very well, I don’t know yet how their injection ones work in practice.

And that injection engines are very different from carb ones?

Yes, neither wires nor spark plugs are suitable for carb injection engines (the coil is weaker than the MZ). The spark plugs have a larger gap (1.0-1.2), and the wires have a higher insulator breakdown voltage. The price of wires varies significantly. Moreover, the wire sizes for 8 valve and 16 valve are different.

You can set the gap at the spark plugs =)

Well, basically it’s just eggs, the current is connected in different ways.

By the way, I measured the resistance of the elephant wire for 16V and the resistance was no more than 5.5 KOhm, so the current is presumably fake, but not a fact. The code failed verification. I sent them to Moscow =) but they haven’t answered yet whether they are real or not.

Source

WHICH GDP IS BETTER TO CHOOSE?

When choosing GDPs, two key factors must be taken into account: their strength and breakdown voltage. The lower the resistance, the better the transmission of the electrical impulse will be, and the resistance to failure of high-voltage cables on the VAZ 2114 depends on the value of the maximum short circuit voltage.

The strength of products from different manufacturers differs from each other. For example, we give you the power of the most popular types of GDP:

| Director | Resistance on cylinder n. 1 (kOhm) | Cylinder resistance n. 2 | Cylinder resistance n. 3 | Resistant to cylinder #4 | Fault Voltage (kV) |

| Tesla | 3,27 | 4,16 | 5,02 | 6,26 | 50 |

| Caesar | 3.1 | 3,53 | 4,23 | 5,34 | 50 |

| whale fin | 1,95 | 2,18 | 2,6 | 3,42 | 50 |

| Ween | 6,17 | 6.57 | 7,52 | 9,89 | 35 year |

| Slon | 4,24 | 4,74 | 5,19 | 7,6 | 50 |

The largest number of positive reviews from the owners of the fourteenth comes from the products of the Czech company Tesla. Their strands have optimal strength and high breaking stress and at the same time are made very conscientiously - they do not tan or break.

The cost of the Tesla GDP kit is about 500 rubles, Cezar - 450 rubles, Ween - 270 rubles, Finwhale - 600 rubles, Slon - 500 rubles.

A little about which high-voltage wires are best for your car

Many drivers do not even realize that high-voltage wires are one of the main ones in the car’s ignition system. Reliable operation of the power unit largely depends on their correct choice. They must provide the following tasks during engine operation:

- Provide voltage transmission of 40 thousand volts;

- The transmission of high-voltage pulses must be carried out with minimal losses;

- Help minimize interference to radio-electronic devices;

- The insulation of the wires must ensure that current does not leak;

- The operability of the wires must be in a wide temperature range from minus 30 to plus 100 degrees or more.

The first samples of such products were produced with minimal internal resistance to ensure impulse transmission to engine spark plugs. After the appearance of radio receiving devices inside cars, problems arose in their reception of signals from transmitting centers due to interference from ignition systems. Therefore, significant modernization of these products was carried out to ensure reliable operation of radio-electronic devices.

How to check current leakage on a used car with a multimeter

The check includes:

- Turn off the engine, remove the key. Close the doors, but open the windows - the battery will not work continuously, and the car may be locked with a central lock.

- Make sure that the additional lighting and radio are turned off.

- Remove the negative terminal from the battery.

- Place one probe between the negative terminal and the negative terminal of the battery - the device will show the leakage current value.

The normal value is 15-70 mA. If the numbers are higher and you and the seller have time, try to find the reason. To do this, also connect a multimeter, then start removing the relays and fuses one by one.

The readings have returned to normal - you have found the cause of the current leak. Perhaps further repair or replacement of a part, or even the entire wiring, will be required. You can confidently ask the car seller for a discount or refuse the purchase altogether.

There may be several reasons for the leak. The following may be involved:

- battery;

- sensors;

- high voltage wires;

- generator.

Each element can be checked using a multimeter.

A few words about their structure

Today, one of the most effective and widespread ways to suppress all kinds of interference is the manufacture and use of wires with resistance distributed along its entire length. Wires usually consist of conductors, an insulating layer, contact plates and protective caps. The main difference between these wires is the conductive cores. They can be:

- Copper stranded;

- Non-metallic with a metal “wrap”;

- Non-metallic with high resistance distribution.

The world's leading manufacturers of automotive spare parts produce several varieties of such products. The most widely used brands are ngk, finwhale, tesla, carden, slon, fenox, bautler, xopc and some others. Let's talk about them in more detail.

What are NGK wires?

NGK offers consumers a large selection of high-quality products that meet almost all requirements for such products.

NGK wires have a long service life and are economical. Other NGK products are characterized by:

- The original design of the products has the same design;

- NGK are copper wires with noise suppression tips or have distributed resistance;

- Once purchased, NGK is ready for immediate use;

- High resistance of NGK to fuel and engine oil;

- Designed to work with high voltage in the ignition system.

As a disadvantage, they note the fact that they are made of the same length, which sometimes causes some inconvenience.

Diagnostics of Lada Kalina wires

Before connecting high-voltage wires on Kalina purchased at a car dealership, you need to assess the current state of the car's wiring. For diagnostics, the car owner will need an analog or digital multimeter.

Before connecting the device, you need to inspect the wires for external defects. These include:

- ruptures;

- abrasions;

- cracks;

- broken.

If no external damage is observed, you need to connect a multimeter. You need to check the resistance of the armor wire, so you need to switch the device to ohmmeter mode. After this, the armored wire is disconnected from the spark plug and ignition coil. The ends of the wire are connected to the contacts of the multimeter, after which the device will show the current resistance level.

Data on normal resistance values are applied to the insulating layer. For passenger cars, normal values are in the range of 4-10 kOhm. In this case, on one specific car, the data values for individual wires should not differ by more than 2.5-3 kOhm. If this threshold is exceeded, then there is a problem in the ignition system.

There are several ways to check the functionality of the wiring without using measuring instruments:

- Use of additional insulated wire. You need to strip both ends of the additional wire. Short one end to ground, and run the other bare end along the caps, joints and the entire contour of the wire being tested. If there is a defect, the tester wire will give a spark;

- You need to drive the car into an unlit box, open the hood, and start the engine. If there is a breakdown in the VP insulation, the damaged area will spark.

The easiest way is to take a working high-voltage wire and test it on each cylinder by elimination.

Finwhale products

Finwhale products are intended for use in contact and contactless vehicle ignition systems.

The former are intended for use in a contact system, the latter in non-contact devices. Finwhale uses Kevlar core to make the conductors. The shell is made of fluoroplastic, which is wrapped with thin stainless steel wire. Finwhale wire insulation has two layers of silicone, which gives optimal resistance distribution and the lowest level of interference. Finwhale products operate in a temperature range from minus 40 to plus 220 degrees. The Finwhale manufacturing process is controlled by multiple quality checks and compliance with production technology.

Products from Tesla

The Tesla company began its work back in 1958 and today is one of the world's leading manufacturers of automotive accessories. Tesla wires incorporate all the advanced achievements in the field of electrical engineering.

Tesla uses materials that slightly exceed the requirements for such products. So silicone is used for the shell. Tesla products are made without the use of metal as a conductor. For this purpose, fiberglass is used, which is pre-treated with carbon impregnation. Tesla products operate in a temperature range from -40 to +220 degrees.

Tesla SILICONE inductive products have an additional winding made of thin stainless wire. This achieves maximum energy transfer to the spark plug. Experts recommend spark plugs with a built-in noise suppression resistor when using Tesla silicone wires. Tesla guarantees the flawless long-term operation of its products.

A little about carden products

Carden products are widely used on GAZ, VAZ, ZAZ, Bogdan Motors, Sollers-Isuzu and other models. Production was mastered in Tolyatti. Carden products are designed to operate over a wide temperature range, from approximately -40 to +180 degrees. The length of the carden wires may be slightly longer than those installed on the car. Soft, double silicone insulation contributes to the high performance of Carden products. Carden resistance ranges from 4.5 kOhm to 5.5 kOhm and depends on the length of the wires. Carden guarantees the ability of the wires to withstand a voltage of 45 thousand volts. Experts recommend that before installing new Carden wires, check the spread of their resistance; if it is large, it is better to replace them.

Conductors and dielectrics

Naturally, in order for an electric current to appear in a certain material, the atoms of the latter must contain electrons that have weak electromagnetic connections with the nucleus. Under the influence of external electromagnetic forces, they are separated, and their place is taken by electrons from neighboring atoms. It is this chain of movements that is called electric current, and the material in which it occurs is called a conductor.

The division of materials into conductors and dielectrics is quite arbitrary. The same material under different conditions can exhibit different properties, it all depends on the force applied to it. It is called electromotive force (EMF), and within human-observable manifestations it is called electrical voltage. That is, the higher the voltage at the ends of the conductor, the greater the load the electrons in its structure experience. Accordingly, the probability increases that electrons will escape from their orbitals and directed motion will begin.

The force that prevents the passage of electric current is called electrical resistance. The greater the length of the potential conductor, the higher its electrical resistance and the greater the EMF must be for an electric current to appear. Metals have very low resistivity, and therefore there are almost no obstacles to the passage of electric current through them. As for wood, glass or air, their natural resistance is quite high, and therefore current does not pass through them if the voltage is not high enough.

What can you say about slon products?

Products under the slon brand are produced and used by such automobile manufacturers as OJSC AVTOVAZ, as well as GM-AVTOVAZ. Work is underway to use slon brand products for cars of other brands, including foreign ones. Slon products are available with straight and angled tips.

According to consumer reviews, sometimes incorrect marking of slon wires occurs, when the packaging bears the designation 1, 1, 1, 1 instead of 1, 2, 3, 4. In general, reviews of products under the slon brand are not bad. If necessary, you can choose an elephant for your car.

What you should know about Fenox branded products

Fenox brand products are used on both domestic and foreign cars. When choosing, you should follow the operating instructions for the vehicle. The manufacturing technology of Fenox products involves the use of aramid thread, which has high strength. It is covered with a conductive layer of latex and silicone. Fenox products allow you to effectively use your car for a long period of time. The ignition system works well with them.

Crackling or crunching.

If your car is front-wheel drive and at low speed you hear some crunching or crackling (especially when you turn the steering wheel all the way when turning), then the probable cause of this crunching or crackling noise in the car is a faulty CV joint.

These rather complex parts of the car transmit torque from the gearbox directly to the wheels. If friends do not change the CV joint in the car in time, then the drive of the car can severely break the mounting sockets in the gearbox, and this is fraught. Therefore, dear motorists, remember, if you hear a crunching or crackling sound in the front suspension of your car, immediately contact a car repair shop to diagnose and eliminate this malfunction.

Also remember, periodically inspect the CV joint boots themselves to identify cracks and damage in the boots. The CV boot protects the drive from dust and sand getting into it, which can severely damage the CV joint.

What else can I recommend?

In addition to the listed components, there are also such as Bautler, xopc.

Bautler uses rubber for the insulating layer, which causes a slight thickening of the product, but allows the ignition parts to work in more difficult conditions.

We also can’t help but say something about xopc’s products. It has been present in the automotive market since 1995. Experts note that today xopc is one of the largest manufacturers of silicone cables in the Russian Federation. To manufacture its products, xopc uses imported raw materials. The production process is carefully controlled at all stages of production.

I would also like to say a few words about armored wires for car ignition systems. The first samples of such parts began to be used on vehicles intended for the Armed Forces. They were subjected to additional shielding with metal braiding to protect radio-electronic devices from interference. Currently, such armored wires can only be found on older cars. The achievements of the developers make it possible to produce armored wires without visible metal shielding.

In conclusion, I would like to recommend that car enthusiasts, if they need to replace armored wires or high-voltage wires, first of all follow the vehicle’s operating instructions. You can choose an elephant or another brand, but this should not be to the detriment of the power unit.

Source

Knocking under the hood, whistling.

If you hear a knocking noise under the hood of your car, please be very careful, as the cause of such a knocking noise may be a specific engine malfunction. These sounds can primarily be associated with three main causes of fuel ignition (combustion) malfunction in the engine combustion chamber. The first reason may be related to ignition problems (malfunction of the ignition coil, high-voltage wires). Another (second) cause of this malfunction may be a clogged injector.

Please remember that due to poor ignition, pops or knocks can occur under the hood of the car, which can lead to excessive detonation when burning fuel in the engine itself. And detonation, friends, can damage the engine.

Due to incorrect or faulty ignition, several flame sources can form in the combustion chamber, which, when meeting each other inside the engine, will create excess pressure in the combustion chamber. Detonation is a big problem for an engine. It can significantly damage the engine pistons.

If your car has an ignition problem and this is due to low-quality fuel and possibly for other reasons, then fill the fuel tank with high-octane gasoline and this way you can correct the problem that has arisen in the car.

They break through armored wires, what does it affect?

Basic malfunctions of ignition wires

The main faults of the wires include electrical circuit breakage and current leakage.

An electrical circuit break usually occurs at the point where the metal contact of the wire is connected to the conductor, as well as to other elements of the ignition system. This happens when the wire is removed, when the wire is destroyed or oxidized, as well as when there is poor contact with the terminals of the elements in the ignition system. The place where the connections are broken heats up and sparks, which aggravates the situation and causes the core or metal contacts to burn out. Electricity leaks through contaminated wires, ignition coil, distributor cap, spark plugs, caps and damaged insulation, which contributes to the deterioration of their dielectric properties during operation.

Low temperatures increase the rigidity of high-voltage wires, which increases the possibility of damage to their insulating layer and caps. Constant vibrations from a running engine loosen the contact points, which leads to their deterioration. Rising temperatures have the greatest impact on the spark plug caps, as they are located closest to the heated engine parts. In addition, very often they become unusable when removed. Over time, dirt, dust, moisture, and secretions of fuels and lubricants, which serve as current conductors, collect on the elements of the ignition system. Leaks become even more noticeable when the insulation is damaged and in humid weather. In addition, dirt and moisture increase microcracks.

How to choose high-voltage wires - what to look for

When choosing high-voltage wires, you need to focus on the recommendations of their manufacturer, as well as the engine manufacturer. First of all, you need to study everything that is written on the package. It would be good if it indicated in Russian the models of cars or engines for which the wires were intended.

Do not rush to buy them if the packaging does not contain the manufacturer’s “coordinates” and instructions for their use. Spelling errors in captions are also a warning. There is a very common mistake in the word silicon. It should be taken into account that the international standard ISO 3808 applies to wires for cars, so all inscriptions are determined by the manufacturer.

Wire resistance is measured using a tester. But this method is not acceptable for wires with a current-carrying core wrapped around them, since due to their design features, the resistance value on the motor changes.

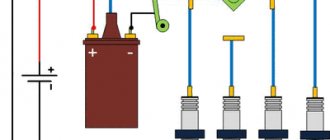

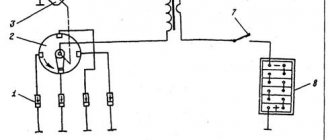

The level of interference from the vehicle's electrical equipment and from high-voltage wires is assessed using a car radio. The verification procedure can be seen in the diagram.

The insulation of the wires should not allow breakdown, therefore, when choosing it, take into account the maximum voltage that can be in the ignition system. The insulation and caps must be made of a material that retains its properties over large temperature differences, for example, silicone.

Many car enthusiasts consider car wires to be of secondary importance, and specialized publications do not pay due attention to them. The sellers also cannot say anything intelligible. Nevertheless, this detail is important and deserves attention, both when choosing and operating a car.

Crunch in the gearbox.

If your car is equipped with a manual transmission and while driving you hear some kind of crunching noise when changing gears, this may be the first symptom of various problems appearing in the car. As a rule, this is primarily due to the fairly high mileage of the car itself and, secondly, to the natural wear and tear of certain gearbox parts.

To begin with, this crunching sound in the gearbox when changing gears can clearly indicate wear and tear on the synchronizers themselves and other components of the gearbox. Synchronizers, as many of us know, play an important role in any gearbox, equalizing the speed of rotation of the shafts and gears in the transmission to subsequently transmit the required torque at a certain speed.

This crunching noise may also indicate clutch wear. Typically, with this malfunction, this crunching noise appears when the clutch pedal is fully depressed while shifting gears. The same thing usually happens with a working clutch, when you do not fully depress the same clutch pedal.

on “Faults in high-voltage ignition wires and what to look for when choosing”

High voltage wires of a car can fray the nerves of a novice car enthusiast. It is their incorrect operation that is a sign of uneven engine operation. The beginner begins to move the wires with his hands and immediately receives an electric shock. By the way, there were cases of death. Everything depends only on the person’s health. Therefore, touching the wires with your hands is strictly prohibited.

There is an easy way to check if the high voltage wires are faulty. You need to start the engine, open the hood, turn off the lights in the garage. If you see a “garland” with small sparks “running” along the wires, then without hesitation, go to the store and buy a new set of wires.

I recommend sticking with silicone LDPE. They may cost more, but they will actually last twice as long as their rubber counterparts. Silicone does not harden over time, it is elastic. The caps fit perfectly onto the spark plugs and create the necessary tightness. Even during a heavy downpour, your ignition will work like a clock.

Installation of royal candles and explosive wires

I always installed royal Iridium platinum Denso

and forgot about the existence of this node)) Now I got around to grants.

BB Bautler wires

with zero resistance are simply born for royal candles)))

Let's call them the Tsar of Wires))).

1.

High-voltage wires VAZ 2108-2111 engine injector 8kl., 9.8 mm

BAUTLER

article

BTL-0010IWS. 2.

Spark plug

Denso IW20TT

“Iridium TT” 4 pcs.

article number IW20TT#4.

The engine now runs very quietly and smoothly, I was even surprised)) let's see how all this affects consumption. I only use 95.

Because according to the passport,

the engine compression ratio is 10.5,

which is the limit of 92 and the beginning of 95 of that. But knowing the quality of our gasoline, it’s better not to risk the limit of 92))))

Wires Elephants stood from the factory))))

Briefly about the structure of conductors

Previously, traditional explosive wires with a copper stranded core (in jargon - armored wires) were used to supply a discharge from the coil to the spark plugs. The disadvantage of such products is the gradual breaking of thin wires due to low elasticity. In modern cars, manufacturers install flexible cables with a non-metallic core made of carbon-impregnated fiberglass. The current-carrying part is wrapped in several auxiliary shells:

- polymer shielding layer;

- silicone-based internal insulation;

- frame in the form of a braid made of durable synthetics;

- external silicone insulation.

Old products with copper conductors had practically zero resistance, causing the radio installed on the car to “wheeze” from interference. Today's high-voltage wires have increased resistance, allowing them to screen out interference.

To connect to the spark plug “cradle” contact, the carbon core is brought out beyond the insulation and bent in the opposite direction. From the outside, the core is crimped with a copper terminal placed on the spark plug contact. The connection is protected from above by a dense dielectric cap. The second end of the conductor is connected to the ignition coil in a similar way.

An important advantage of the new high-voltage armored wires is elasticity and flexibility. Thanks to these qualities, the product lasts much longer than its copper predecessors. But sooner or later there comes a time when the carbon-silicon explosive wires wear out and begin to “mope.”

Typical ignition cable faults

There are 3 main problems associated with high-voltage wires:

- Internal break of current-carrying conductor.

- Breakdown of external silicone insulation.

- Unreliable contact at the junction of copper tips with the terminals of spark plugs and high voltage coils.

A break or fracture of the carbon core does not always lead to complete failure of the explosive wire. Since a high voltage pulse with a nominal value of more than 20 kilovolts is applied to the spark plug, the current still “breaks through” the break point and reaches the spark plug electrodes. But the power of the spark noticeably weakens, hence problems arise with the high-quality ignition of the air-fuel mixture in the combustion chamber. In the worst case, there is no spark at all and the cylinder fails completely.

Note. Complete cylinder failure in a car is characterized by a drop in idle speed, “shaking” of the power unit and a significant decrease in power. Accordingly, gasoline consumption increases by 25%.

A similar picture is observed with weak contact of copper conductors at the joints. Due to an oxidized or poorly fitting terminal, the power of the electrical impulse is lost to overcome this obstacle, and the discharge on the spark plug electrodes weakens.

When two insulating layers break down, the voltage is lost differently . The principle is as follows: the current that detects a circuit of lower resistance tends to pass along that path. If the point of insulation breakdown is located close to the metal parts of the machine connected to the “minus” of the on-board network (ground), a spark discharge is formed between them. As a result, the spark plug receives only half the impulse, causing the ignition of the combustible mixture to occur sluggishly. By the way, it is impossible to check armored wires with a multimeter for insulation integrity; you will need special equipment.

Interruptions in the supply of spark discharges are monitored by the following signs:

- the engine is unstable due to misfires and insufficient spark power;

- one or more cylinders periodically fail, the engine vibrates at idle;

- while driving, acceleration dynamics deteriorate, a weak response to the accelerator pedal is felt;

- more fuel is consumed.

Similar symptoms appear on faulty spark plugs, but checking their performance is more difficult. Therefore, start diagnostics with high voltage wires.

Clattering.

If your car makes a clunking sound when driving over bumps, bumps or potholes, do not rush to worry, it is likely that this is the norm.

But, if such a sound occurs on a flat road or even on small bumps, then you should conduct a thorough diagnosis of the car’s chassis, looking for defects in the suspension or other parts of the car.

It is quite possible that the cause of extraneous noise on the road will be a malfunction of the same silent blocks, the same ball joints, stabilizers or steering tips. A faulty car exhaust system can sometimes make similar noises.

Verification methods

In garage conditions, you can check high-voltage wires in the following ways:

- Alternately replacing the conductors with a working cable.

- Search for broken insulation using an additional wire.

- Inspecting a running engine at night.

- Measuring resistance with an ohmmeter (multimeter).

The first option is based on the elimination method. Take a long, serviceable armored wire and install it instead of existing high-voltage cables. If, when connected to one of the cylinders, the performance of the power unit improves, the explosive wires are considered unusable (the entire set must be replaced). Otherwise, the search for the problem continues in another place, for example, the spark plugs.

Reference. High-voltage cables can be checked using the old antiquated method. Leaving the engine running at idle, put on a thick rubber glove and alternately remove and connect the “cradles” to the contacts of the spark plugs, without touching the car body with your body. If the behavior of the motor does not change when the circuit of any cylinder is broken, you have discovered an unusable conductor.

Obviously broken insulation of high voltage cables is detected on the car at night. It is enough to open the hood and start the power unit, observing the wires. If you see a “light music” consisting of sparks, feel free to install new products and throw away the old ones.

Another way to find a breakdown is to take an insulated copper conductor, connect it to the negative terminal of the battery and start the engine. Lead the bare core of the second end along each high-voltage cable, starting from the protective caps. A spark that jumps at the breakdown site will indicate a malfunction.

An internal break in a carbon conductor is determined by measuring the resistance of the current-carrying part. Take a multimeter or other device with an ohmmeter function, disconnect the ends of the cables from the coils and spark plugs, then take measurements one by one. The resistance on high-voltage wires should be in the range of 3.5–10 kOhm; the exact values are indicated by manufacturers on the silicone insulation of products.

When the first conductor becomes unusable, in the near future the others will also begin to “mope.” Therefore, faulty cables are replaced in sets. You still won't be able to buy one wire in a store.

For a gasoline internal combustion engine to operate, two conditions are necessary: the presence of fuel and a spark to ignite it. High-voltage wires serve precisely to “deliver” the spark from the ignition coil to the spark plugs in the cylinders of the power plant.

Diagnosis of faults based on extraneous sounds in the car.

By turning the ignition key in a car or pressing the start/stop button when starting the engine, you (every motorist), as a doctor, should be able to listen and hear your car. This is necessary in order to promptly detect extraneous noises in the car, which may indicate to you various malfunctions in the car.

Unfortunately, many car drivers completely forget that any car is a complex technical device that can periodically break down over time. Remember, friends, that any car in good condition should not make any extraneous noise or strange sounds.

If for some reason your car begins to make unknown extraneous noises, then it is likely that your car is in a faulty condition. Here, dear motorists, are the 10 (ten) most common reasons why you can hear various extraneous sounds in your car.