Author:

Maxim Markov

The ignition system is one of the most important in any internal combustion engine. Almost all operational characteristics depend on its correct operation. And often the main reason why a car engine does not start is that there is no spark from the ignition coil. To understand why it is such a critical element, you need to understand the operating principle of the entire system as a whole and become familiar with its various types.

What are the types of ignition systems?

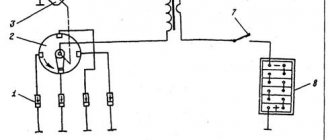

Ignition systems that use coils in their operation are divided into two groups: contact and non-contact.

- Contact systems (classic VAZ models). Here, the distribution of the electric current supplied to the spark plugs is carried out using a moving contact (“slider”), which is installed in the distributor housing.

- Contactless systems. High-voltage pulses are also created here, and they are distributed among the cylinders by a special contactless slider and switch. Such systems are installed on carburetor models of front-wheel drive VAZs, as well as Tavria. On engines equipped with an injection system, the spark distribution is handled by the engine control system (all injection VAZ models), and the coils themselves are made either as a single unit (one for each cylinder) or as separate modules (installed directly on the spark plugs).

see also

Pouring candles when cold

- 4 0 3k

Replacing spark plugs on a Z18XE engine

- 6 0 3k

Spark plug and coil lubricant

- 64 3 80k

Checking the ignition with an oscilloscope

- 45 0 42k

How to check spark plugs

- 68 4 94k

When the spark is lost, you will, of course, never start the car, and in such a situation, first of all, you need to check the ignition system.

The vehicle's ignition system plays a key role in its operation. If in case of many other malfunctions the car can be taken under its own power to the service station, then in case of problems with the ignition it is unlikely that it will be possible to start the engine at all.

Characteristic signs

The following phenomena usually indicate poor performance of the ignition system:

- difficulty starting the engine;

- increased fuel consumption;

- unstable idle;

- weak traction and lack of power, failures in engine operation, poor throttle response;

- the appearance of black soot on the candles;

- periodic shutdown of one of the cylinders.

Replacing spark plugs

There are spark plugs (SZ) and glow plugs (CH). The former are used for gasoline engines, the latter for diesel engines.

Symptoms of SZ problems:

- The internal combustion engine does not start well;

- the engine “troubles” (accelerates poorly, lacks traction and “power”);

- fuel consumption has increased;

- the share of carbon dioxide in the exhaust has increased;

- engine dynamics are reduced.

For SN the list is as follows:

- it is difficult to start the car in cold weather;

- at idle the internal combustion engine operates unevenly;

- white smoke from the exhaust pipe;

- spiral indicator failure.

You can replace the elements yourself or entrust it to experienced car service employees.

Diagnostics and troubleshooting

It should be remembered that deviations in the normal operation of the engine are almost always caused by only two groups of reasons: malfunctions in the power supply or ignition system. Therefore, you should proceed to diagnosing the ignition operation only after clearly eliminating causes related to the fuel supply.

Troubleshooting should only be done after eliminating all other possible causes. To do this, perform the following steps sequentially:

- Check the presence of plus and minus on the wires going to the ignition coil. If not, then you should understand the reasons why there is no power.

- Check for the presence of a spark at the spark plugs. If there is no spark or it is weak, then the reason may be in the spark plugs themselves, the high-voltage wires, the central wire, the distributor or the coil itself. Spark plugs are checked as follows. To do this, you need to unscrew the spark plug, put a high-voltage wire on it and attach its body to the “ground” (cylinder block), and then crank the engine 1-2 turns with the starter. The presence of a spark indicates the serviceability of both the spark plug, the wire, and the output of the coil or distributor. Attention! Holding a candle with your hand can result in a strong electric shock, so be sure to hold it either with protected pliers or in electrical gloves.

High voltage wires

After the spark plugs have been checked and it turns out that they are not the problem, you need to test to see if anything has happened to the high-voltage wires. Diagnosis is carried out in four simple steps.

- If there is no spark on only one cylinder, swap the wires

- Let's check if the problem is resolved after this action

- If a spark appears on a cylinder, but it disappears on another cylinder, then the problem is definitely in the wire.

- The faulty wire must be replaced with a new one.

Likewise, it would not hurt to check whether the central wire that supplies current to the ignition coil is working properly. Sometimes a spark appears after this wire is pressed harder against the transformer, which is located on the distributor cover.

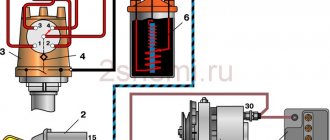

Checking the operation of the ignition coil

First of all, you should make sure whether the ignition coil sparks at all. To do this, you need to remove the distributor cap and turn the crankshaft so that the contacts close, and then bring the end of the central wire going to the coil to the ground (engine cylinder block) at a distance of 5-6 mm, and then turn on the ignition.

If it is working properly, a bright spark will be observed. If the spark is weak or not observed at all, the problem is in the coil (or in the central high-voltage wire). In some cases, a situation is possible when, due to poor insulation, sparking of the ignition coil itself is observed, right along its surface.

The next step is to check its low-voltage and high-voltage circuits. To diagnose the primary winding, you need to use an ohmmeter to measure the resistance on the coil between the positive and negative contacts. It should be about 3-5 ohms. To check the secondary winding, the resistance between the positive contact and the central terminal of the coil is measured.

Here the readings should be about 6-7 kOhm. These values are indicative and may vary depending on the specific vehicle model. If the winding is broken, the ohmmeter will show zero; if there is a short circuit, the readings will tend to infinity. In this case, replacement is indicated, since, most likely, its body is leaking. On an injection engine, the coils are measured individually.

Prevention methods

To extend the life of system elements, you should, firstly, keep them clean. This applies to all components in the engine compartment. The fact is that dirt is a conductor of electricity and part of the high-voltage pulse can be lost through it.

Missing sparks can also be caused by old, oily spark plugs with cracked insulators that have expired. The spark gap should also be set according to the recommendations in the operating instructions. It is necessary to ensure that all high-voltage wires are securely and tightly connected to the terminals and spark plug tips.

conclusions

Identifying the malfunction and the reasons why the ignition coil does not spark depends primarily on its correct and consistent diagnosis. In addition, its long and trouble-free operation largely depends on care and maintenance. Only in this case will the car always delight you with impeccable performance, and its operation will bring only joy.

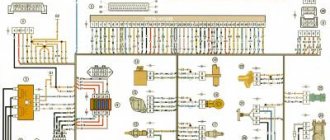

The operation of the VAZ 2106 power unit is inextricably linked with the formation of a spark, which is influenced by almost all elements of the ignition system. The appearance of malfunctions in the system is reflected in the form of problems with the engine: tripping, jerking, dips, floating speeds, etc. occur. Therefore, at the first symptoms, you need to find and eliminate the cause of the malfunction, which every Zhiguli owner can do with his own hands.

Let's sum it up

Spark plugs play a vital role in the performance of a vehicle. If at least one spark plug fails and does not produce a spark, accordingly, one of the cylinders will not work, the car will have increased fuel consumption and will be less dynamic. Finding the reason for the disappearance of the spark is a very difficult task, since several units may be “to blame” for this. However, for normal functioning this is simply necessary.

What to do if there is no spark on a VAZ-2106 car? As is known, this phenomenon leads to the fact that the air-fuel mixture does not ignite and the engine stops starting. Therefore, you will have to look for the causes of the problem without fail.

On VAZ cars, and on the “six” in particular, the spark can disappear due to a variety of malfunctions. But in this article we will describe only the most common of them, and also give useful tips for identifying and troubleshooting problems.

No spark on VAZ 2106

Sparking is an important process that ensures the startup and stable operation of the power unit, for which the ignition system is responsible. The latter can be contact or non-contact, but the essence of its work remains the same - to ensure the formation and distribution of a spark to the desired cylinder at a certain point in time. If this does not happen, the engine may either not start at all or run intermittently. Therefore, it is worth dwelling in more detail on what kind of spark there should be and what the reasons for its absence may be.

Why do you need a spark?

Since the VAZ 2106 and other “classics” are equipped with an internal combustion engine, the operation of which is ensured by the combustion of the fuel-air mixture, a spark is required to ignite the latter. To obtain it, the car is equipped with an ignition system, in which the main elements are spark plugs, high-voltage (HV) wires, a distributor-breaker and an ignition coil. Both spark formation as a whole and the quality of the spark depend on the performance of each of them. The principle of obtaining a spark is quite simple and comes down to the following steps:

- Contacts located in the distributor provide low voltage supply to the primary winding of the high-voltage coil.

- When the contacts open, a high voltage is indicated at the coil output.

- High-voltage voltage is supplied through the central wire to the ignition distributor, through which sparks are distributed to the cylinders.

- A spark plug is installed in the cylinder head for each cylinder, to which voltage is supplied via explosive wires, as a result of which a spark is formed.

- When a spark appears, the combustible mixture ignites, ensuring the operation of the engine.

What should be the spark?

Normal engine operation is possible only with a high-quality spark, which is determined by its color, which should be bright white with a blue tint. If the spark is purple, red or yellow, this indicates problems in the ignition system.

Signs of a bad spark

The spark can be either bad or completely absent. Therefore, you need to figure out what the possible symptoms are and what could be the cause of problems with sparking.

No spark

A complete lack of spark is manifested by the inability to start the engine. There can be many reasons for this phenomenon:

- wet or failed spark plugs;

- damaged explosive wires;

- break in the coil;

- problems with the distributor;

- failure of the Hall sensor or switch (on a car with a contactless distributor).

Video: searching for a spark on a “classic”

Weak spark

The power of the spark also has a significant impact on the functioning of the power unit. If the spark is weak, the combustible mixture may ignite earlier or later than necessary. As a result, power decreases, fuel consumption increases, failures occur in different modes, and the engine may also misfire.

Tripletion is a process in which one of the cylinders of the power plant works intermittently or does not work at all.

One of the reasons why the spark may be weak is the incorrect clearance of the ignition distributor contact group. For classic Zhiguli cars this parameter is 0.35–0.45 mm. A gap less than this value results in a weak spark. A higher value, at which the contacts in the distributor do not completely close, can lead to a complete absence of a spark. In addition to the contact group, other components of the ignition system should not be overlooked.

An insufficiently powerful spark is possible, for example, when spark plug wires break down, i.e., when part of the energy goes to ground. The same thing can happen with a spark plug when the insulator is pierced or a significant layer of soot forms on the electrodes, preventing the breakdown of the spark.

Spark to the wrong cylinder

Quite rarely, but it happens that there is a spark, but it is supplied to the wrong cylinder. At the same time, the engine runs unstable, troits, and shoots into the air filter. In this case, there can be no question of any normal operation of the motor. There may not be many reasons for this behavior:

- the explosive wires on the distributor cap are mixed up;

- the cover on the distributor is installed incorrectly;

- The spark plug wires are not connected correctly to the spark plugs.

The last point, although unlikely, since the length of high-voltage cables is different, is still worth considering if problems with ignition occur. The listed reasons arise, as a rule, due to inexperience. Therefore, when repairing the ignition system, you need to be careful and connect the explosive wires in accordance with the numbering on the distributor cover.

Why does the VAZ-2107 twitch - let’s understand the operation of the “distributor”

Well, if the engine of your VAZ-2107 suddenly stalls and does not start, we will find the reason and eliminate it quickly. Everyone knows that this happens if the “spark” disappears or there is no gasoline supplied at all. It’s much worse when the car seems to be moving, but the nerves are fraying - uneven idling, jerking and twitching when driving. Finding the root of the problem can take a lot of time and take a lot of money out of your pocket. And more often than not, these searches ultimately lead to a distributor. This material will help you correctly replace it with a working one, select a suitable replacement, and understand the device and operation.

Before delving into the “electrics”, it must be said that the reason for the “jerking” of the VAZ-2107 and other “classic” VAZ models may be an unsuccessful combination of the clutch driven disc damper and the elastic coupling of the driveshaft. Spare parts are supplied with parts whose characteristics may differ greatly from the factory ones, therefore, if the “jerking” intensifies after replacing the clutch or “soft connection”, you need to look for the cause there. Try installing a unit from another manufacturer - its characteristics will be different, the resonance in the transmission will disappear and the “jerking” will stop.

Checking the contact distributor

The need to check the distributor-breaker arises if problems arise with sparking, but during the diagnostics of the ignition system elements the problem could not be identified.

Cover and rotor

First of all, we inspect the cover and rotor of the device. The check consists of the following steps:

- We dismantle the distributor cover and inspect it inside and out. There should be no cracks, chips, or burnt contacts on it. If damage is found, the part must be replaced.

contact Group

The main malfunctions of the ignition distributor contact group are burnt contacts and incorrect clearance between them. In case of burning, the contacts are cleaned with fine sandpaper. If they are severely damaged, it is better to replace them. As for the gap itself, to check it it is necessary to remove the cover of the distributor-breaker and turn the engine crankshaft so that the cam on the distributor shaft opens the contacts as much as possible. We check the gap with a feeler gauge and if it differs from the norm, then we adjust the contacts by unscrewing the corresponding screws and moving the contact plate.

Capacitor

If a capacitor is installed on the distributor of your “six”, then sometimes the part can fail as a result of a breakdown. The malfunction appears as follows:

- problems starting the engine;

- sudden engine stop while driving.

You can check an element in the following ways:

- Control lamp. Disconnect the wiring coming from the coil and the capacitor wire from the distributor according to the figure. We connect a light bulb to the open circuit and turn on the ignition. If the lamp lights up, it means that the part being tested is broken and requires replacement. If not, then it's OK.

Checking the contacts of the distributor

If after the steps described above the spark still does not appear, proceed to the next stage. We open the distributor cover and inspect the contact groups extremely carefully. It is quite possible that the problem arises due to carbon deposits, which must be carefully removed using a regular knife.

Also at this stage you can check the functionality of the contacts, for which you need to turn the starter several times with the cover open. If all contact groups open normally, then they are working properly. Otherwise, it makes sense to set the correct gap between them.

The main reasons why there is no spark

- problem with spark plugs (flooded or faulty);

- breakdown of high-voltage wires or loss of contact;

- the reason is the crankshaft sensor (requires checking with a multimeter);

- malfunction in the ignition module;

- failure of the ignition coil;

- problem in the switch;

- Distributor malfunction (burned contacts, loss of clearance);

- poor ground wire contact;

- failure or malfunction of the ECU;

No spark injector

It is recommended to use a spark gap to understand at what stage there is no spark on the spark plugs (no spark from the distributor, no spark from the coil, or directly from the spark plug itself). If there is no spark in all cylinders at the same time, there may be several culprits:

- controller;

- entire module;

- coil or center wire.

If there is no spark from the ignition coil, then the reason may be hidden in many places. First of all, you need to check the high voltage wire, which must be in perfect condition and without damage to the insulation. Otherwise, the wire needs to be replaced.

No spark, check spark plugs

If the problem is not solved, then check the spark plugs. The spark plug contacts must be clean. The fact that there is no spark may be caused by dirty spark plug contacts. It is best to replace the spark plugs, but you can also clean the contacts. But before changing the spark plugs, check whether the discharge reaches the spark plugs themselves. To do this, remove the spark plug wire and bring it to the car body at a distance of 0.5 cm. Turn the starter several times and see if there is a spark between the wire and the body. The spark should be white with a slight blue tint. If it is absent or present, but with a different shade, we can say that the spark plugs are fine, and the problem is in the heart of the car’s ignition system – the coil.

What to do?

Based on the advice of experienced car enthusiasts, we suggest checking the possible causes of the malfunction. First of all, use a spark gap to know where exactly the spark disappears

If the cylinders are faulty, pay attention to the controller, the module as a whole or the coil

Start with a visual inspection of the high-voltage wire (the ideal is good external condition with intact insulation). Repair or replace the element as necessary.

If the problem is not found, we go directly to the SZ. Clean or replace rusty contacts if necessary. Before making a decision, test the presence of a discharge on the spark plugs: bring the wire 0.5 cm to the metal and spin the starter. A blue-white spark signals normality. Another color (purple, for example) - go to the coil (KZ).

The operation of the coil is tested in the same way as the discharge on spark plugs (see above). Two scenarios:

sparked - see distributor-breaker (R/P);

did not “ignite” (deal with the coil).

In the R/P it is necessary to exclude oxidation, insulation failure and test the rotor. Inspect the inside of the cover to ensure there are no cracks. Check the carbon contact with your hand to see if it is stuck. Insulation check:

place the central high-voltage wire 0.8 cm from the electrode;

connect and disconnect the contact (turn on the ignition first).

If the rotor is faulty, sparks are visible.

In a short circuit, exclude damage to the winding and short circuit (burnt points).

The low voltage circuit is tested with a twelve-volt light bulb with a power of no more than 3 W. It is connected to the breaker and the hardware of the car. Next, close the R/P and turn on the ignition. If the circuit is working properly, the standard lights up when it opens and goes out when it closes. “Controller” does not go out under the following circumstances:

How to check spark on ignition coil

To see if the coil is working at all, pull the wire from the breaker distributor that comes from the coil. The same test is carried out with it as with the spark plug wires, namely, they bring the wire to a distance of 0.5 cm and turn the starter. Now, regardless of the result, we can accurately talk about the cause of the breakdown.

In the first case, you need to check the contacts in the distributor-breaker for oxidation, insulation damage, and also check the serviceability of the rotor. If there is no spark due to it, the rotor must be replaced.

Checking the ignition coil

If, after checking, you realize that there is a spark in the car, but it does not start, then the ignition switch may need to be replaced.

What to do when the starter cranks without engaging

First of all, you should make sure that the starter is not broken. If the starter is faulty, when you try to start the engine, unusual sounds will come from under the hood: crackling, knocking, humming, clicking.

If the starter is working properly, you will hear the characteristic buzzing of the electric motor of the starter itself. Thus, you need to act by elimination.

Regardless of whether the car runs on gasoline or diesel fuel, fuel is supplied to the cylinders through a carburetor or injector. The car engine may not start, even if the starter is functioning properly, due to problems with this unit.

If the car has a carburetor

You can determine whether the carburetor is working properly in this way. When the throttle is opened sharply, a portion of fuel should be injected into the diffuser from the accelerator pump nozzle. If this is not the case, it means that gasoline is not entering the combustion chambers. Both the carburetor and other elements of the fuel system may be faulty.

Tips for injector owners

If the starter spins on a fuel-injected car, but the internal combustion engine does not start, we can assume a breakdown in the fuel supply system.

This problem often occurs on VAZ 2110, 2112, Kalina, Priora, Granta, Daewoo Nexia and Matiz cars. But the injectors of modern foreign cars Opel Astra, Chevrolet Lacetti, Hyundai Solaris and Accent, Toyota, Ford, Peugeot and Kia do not have such diseases.

What to do with diesel

The owner of a car with a diesel power unit, first of all, if the starter turns, but the engine does not start, should check whether there is air leakage into the system

This is especially important in winter. The fact is that under the influence of low temperatures, solarium waxes (freezes)

In this state, fuel simply will not physically flow into the combustion chambers of the internal combustion engine.