The ability to implement feedback is an advantage of electronic fuel injection systems and their fundamental difference from other power systems of internal combustion engines. In this case, we are talking about controlling the mixture composition and directly regulating the engine operating mode itself - the injection ECU can either adjust the speed in a certain range (cars with a “mechanical” throttle) or control them (an “electronic” throttle).

However, situations are possible when the ECM is not able to support the desired mode. One of the characteristic symptoms of this is the “swimming” of revolutions, their constant change with clearly defined periodicity.

Why Lada Kalina idle speed fluctuates: reasons

Many car enthusiasts have come across the concept of floating engine idle speed. For the Lada Kalina, as practice shows, this is a common malfunction that can be fixed with your own hands, but sometimes you will need to use a car service.

Possible faults

RPM fluctuates at idle

This may be due to many factors.

Let's consider the main reasons for the occurrence of floating engine speeds:

- Fuel system malfunction.

Malfunction of fuel system elements

Problems with the ignition switch or wiring

Troubleshooting ECU errors

Low-quality gasoline directly affects the operation of the power unit

All these reasons contribute to the appearance of such an effect. The most common reason is problems with injection.

Treatment methods

So, let's consider the sequence of actions to eliminate the causes of floating engine speed.

Fuel system

As practice and experience show, floating speeds appear in the event of an uneven supply of fuel to the combustion chambers, or a constant change in the amount of the fuel mixture.

Cleaning a removed injector

First of all, this is due to the injectors, which may be dirty. At the same time, this may not be felt when driving, but at idle the tachometer will immediately show it. Therefore, it is necessary to dismantle and check the injectors on a special stand.

Clean fuel pump mesh

Also, the malfunction may be caused by a breakdown of the gasoline pump, which does not supply fuel evenly, or a clogged fuel filter. If necessary, you need to replace the filter element and check the fuel pump.

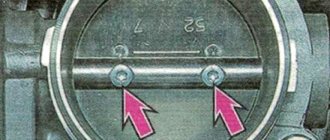

Cleaning the throttle body

A change in the amount of fuel mixture may be due to a clogged throttle or worn air filter. Therefore, the filter element is changed and the throttle valve must be cleaned.

Removed throttle before and after cleaning

Ignition problems

Problems with idle speed may occur due to incorrect operation of the ignition system. Namely, it may be related to the lock or wiring. So, it is worth checking and, if necessary, replacing damaged elements. It is best to change the ignition switch assembly and test the wires that go from it to ensure they are working properly.

ECU errors

Often, a car malfunction is associated with errors in the electronic control unit, as well as a malfunction of the controllers on the board. Of course, another reason could be the firmware that is out of order. Many car enthusiasts change the operating system, but this does not always help.

ECU removed from the vehicle

As practice shows, an ECU malfunction can pose a problem for the performance of many systems. Therefore, if the fault cannot be eliminated using the previous methods, it is necessary to replace the control unit. Of course, installing the operating system from the Lada Kalina Sport K-Line can help, but the problem does not always disappear completely.

Poor quality fuel

In many cases, poor quality of fuel poured into the car tank can cause clogging of the fuel pipeline and injection system, which in turn gives the effect of uneven fuel supply. To eliminate the malfunction, you should drain the old fuel, clean the fuel system and fill in with new high-quality gasoline.

It is worth understanding that not only the operation of the engine, but also its durability depends on the quality of the fuel.

conclusions

Floating idle speed of the Lada Kalina engine can cause other, more serious problems to appear. So, if such an effect occurs, it is necessary to find the cause and eliminate it. If you can’t do it yourself, you need to contact a car service, where they will quickly find and fix the problem. Repeatedly, due to the constant effect of floating speed, car owners have had to change the electronic control unit.

Like many people, I had this problem. Believe it or not, I just changed the air filter and everything is fine, everything has been fine since the summer (ugh, ugh, ugh). Only now the fan is soaring and turns on when the engine is cold. Can someone talk to me about this topic?

conclusions

Floating idle speed of the Lada Kalina engine can cause other, more serious problems to appear. So, if such an effect occurs, it is necessary to find the cause and eliminate it. If you can’t do it yourself, you need to contact a car service, where they will quickly find and fix the problem. Repeatedly, due to the constant effect of floating speed, car owners have had to replace the electronic control unit.

Like many people, I had this problem. Believe it or not, I just changed the air filter and everything is fine, everything has been fine since the summer (ugh, ugh, ugh). Only now the fan is soaring and turns on when the engine is cold. Can someone talk to me about this topic?

Source

Unstable idle speed

Have you encountered engine problems when the car stalls in traffic jams or the engine speed is unstable? There may be several reasons for these malfunctions. It is recommended to start searching for a problem with diagnostics, and if this is not possible, then first perform a check, and only then change the faulty parts.

AvtoVAZ installs the same type of engines on modern Lada cars (Kalina, Granta, Priora, Largus, Vesta, Niva or XRAY), so the solution to problems for all these cars is similar.

The idle speed fluctuates, the engine stalls when moving (on the move) or at a standstill, the reasons may be the following:

- The engine air filter is clogged.

- The spark plugs are faulty.

- High voltage wires are faulty.

- Ignition module/coils are faulty.

- The idle air control (IAC) or its electrical circuits are faulty.

- The throttle position sensor (TPS) is faulty or the throttle assembly is dirty.

- The mass air flow sensor (MAF) is not working.

- The oxygen sensor (OS) or circuits are faulty.

- There is insufficient pressure in the fuel rail.

- Compression in the cylinders is low.

- The exhaust system is leaking.

- Air leaks through the crankcase ventilation hoses and the hose connecting the intake pipe to the vacuum brake booster.

- The cylinder head gasket is damaged.

- The timing belt or tension roller is worn.

- The camshaft cams are worn.

- The valve timing is off. Check the alignment of the marks on the crankshaft and camshaft.

- The engine control unit (ECU) or its circuits are faulty.

The Lada Kalina idle speed sensor or IAC is a device that is responsible for the necessary air supply to the internal combustion engine when it is idling (in the absence of pressure on the gas pedal). For example, the driver releases the accelerator pedal and the air supply to the internal combustion engine stops. To prevent the engine from stalling, the idle speed sensor comes into operation, which is involved in the process of supplying the required amount of air bypassing the throttle assembly.

In other words, IAC is a kind of valve-regulator

It is very important for every car owner to know and understand the principles of operation of the product, because if it breaks down, in most cases the car’s self-diagnosis system does not determine the reason for the incorrect operation of the engine

The Lada Kalina car engine stalls immediately after starting it

One of the reasons why the Kalina engine stalls immediately after starting is an insufficiently charged battery (frequent short trips in the cold season, the battery life is close to the end, long-term parking of the car without recharging the battery, etc.). The capacity of such a battery is enough for the starter to crank the engine at the frequency necessary to start it. But when the engine starts, the voltage at the battery terminals drops so much that the immobilizer, reacting to this voltage drop, blocks, through the computer, the supply of gasoline to the fuel rail by turning off the power to Kalina’s electric fuel pump. The residual gasoline pressure in the fuel rail is enough for 2-3 seconds of engine operation, after which it stalls due to lack of fuel.

Another reason for the Kalina engine to stop working immediately after starting it is the location of the electronic control unit, which is located under the interior heater housing. And in the event of even a small leak of antifreeze from the heater radiator, it gets onto the electronic unit and, if it is not properly sealed, penetrates inside, causing this malfunction.

A similar problem with starting the Kalina engine also appears when air is sucked into the pipe behind the flow meter. In this case, the flow meter provides incorrect information to the electronic control unit about the amount of air entering the engine cylinders. These data turn out to be underestimated, since part of the air goes into the cylinders, bypassing the flow meter, which sharply depletes the combustible mixture and the engine stalls.

FakeHeader

Comments 21

When the rpm drops to 600 - is it once every about 30 seconds or constantly?

Once every 1-2 seconds

Then it's definitely not an adsorber. If the AIR fitting of the canister is clogged, then when the canister valve is opened, air will be driven out of the tank (the speed will drop exactly once every 30 seconds), but the canister works for no more than 3-4 seconds, after which it turns on again only after about 20-30 seconds. You can safely cross it off the list.

I’m having this problem myself now, but I have it once every 20-30 seconds, and that’s exactly when the adsorber valve opens for purge. I disconnected the hose from the adsorber going to the valve, the speed stopped falling. It seems to me that this is exactly the situation when the AIR on the adsorber is clogged with dirt or coal. The valve opens and, instead of fresh air, draws gasoline vapor directly from the tank, then the rpm drops to 500 and a sharp rise to 1200. The valve closes and everything is fine until the next opening. =(

And what should I do with it so that the revs don’t fluctuate?

When the rpm drops to 600 - is it once every about 30 seconds or constantly?

And so on constantly in neutral until you turn it off. The voltage in the onboard after a drop in rpm also drops to 13.6 and rises with the rpm

The revs are fluctuating - first of all, look for air leaks. Whistling occurs more often. Possible places: a rubber plug on the intake manifold, a stuck absorber valve, a vacuum booster, stiffened injector rings and intake manifold seals at the joints. Everything is checked by clamping the pipes or temporarily replacing them with plugs. That is, for example, you pull out the vacuum pipe from the manifold and stupidly plug it with your finger, etc.

I have the same problem, but only in winter you stop at a traffic light and the revs start to float, also e-gas, the check does not light up, I changed the spark plugs, it helped, the factory spark plugs lasted 3000 km, new ones for another 4000 km, then I installed NGK, so far it’s ok

Engine operation at warm-up speeds

In general, high revs on a cold engine in cold weather is normal. However, their meaning and the duration of operation of the motor in this mode may vary. So, if you start the engine at a temperature, for example, from +20°C and above, then the time when the idle speed value returns to that specified in the manual (approximately 600...800 rpm) will be several seconds (2...5 seconds in summer time and about 5...10 seconds in winter). If this does not happen, then there is a breakdown, and additional inspection and appropriate repair measures must be performed.

High speeds when starting the engine when cold are necessary for two reasons. The first is a gradual warming up of the engine oil, and accordingly, a decrease in its viscosity. The second is gradual heating of the engine to the normal operating temperature of the coolant, which is about +80°C...+90°C. This is achieved by increasing the amount of fuel burned.

Therefore, the appearance of high speeds when starting the engine when cold is normal. However, it is necessary to take into account their value and the time after which they return to the value corresponding to idle speed. The speed and time values are indicated in the technical documentation for a specific vehicle. If the speed and/or return time are increased, then it is necessary to look for the cause of the breakdown.

How can I check the regulator and flow meter?

If the speed begins to fluctuate with enviable regularity, it is better to start diagnostics by checking the air-fuel mixture flow sensor. The following symptoms indicate a malfunction of the air flow sensor:

- A cold motor “floats” and there are interruptions.

- The engine does not start the first or even the second time, sometimes it does not start at all.

- Fuel consumption exceeds all permissible limits.

How can you determine when it’s time for the sensor to retire? It’s very simple - use a regular tester. It should show 1 V if the MAF is ok. Otherwise, you will need to make a replacement.

We've sorted out the flow meter - now let's talk about the regulator. The speed in your engine may fluctuate due to the fact that the idle speed regulator has failed. It is responsible for quickly increasing or decreasing the fuel supply, using a rod with a needle for these purposes. Among the key malfunctions of the regulator are:

- Quite unstable, “ragged” operation of a cold engine when idling.

- In neutral, the engine suddenly turns off.

- Unexpected changes in speed even when the engine is well warmed up.

- Lack of normal power growth when the engine is already running.

Power (more precisely, engine speed) drops when several consumers come into operation at once. Even ordinary headlights can make noise. If the above symptoms are observed, the regulator will need to be replaced.

High engine speed at idle: injector

Engine speed and operation at idle actually means that air is supplied to the engine bypassing the throttle valve. In other words, at idle the specified damper is closed. Note that the normal idle speed for different units is about 650-950 rpm. In parallel with this, a common malfunction is that when the engine is warm, the idle speed remains at around 1500 rpm and above. This indicator is a sign of a malfunction that should be eliminated.

It should also be noted that the idle speed “floats”, that is, for example, it increases to 1800 rpm, after which it decreases to 750 and increases again. Very often, increased idle speed and floating speed are the result of the same breakdowns. Let's take a look at a gasoline-injected unit as an example. In such an internal combustion engine, engine speed depends on the amount of intake air. It turns out that the more the throttle valve opens, the more air enters the intake manifold. Then the ECU determines the amount of incoming air, simultaneously takes into account the throttle opening angle (throttle position) and a number of other parameters, after which it supplies the appropriate amount of gasoline.

Another case is when the engine keeps the idle speed at about 1500-1900 rpm, while running smoothly, the speed does not fluctuate. In this case, we can assume that the injector supplies enough fuel in idle mode that it is enough to operate at such high speeds. In other words, there is excessive fuel consumption. These features may be typical for some engines and absent for others, since there is a dependence on the design of a specific injection system (units with an air flow meter, engines with a pressure sensor in the intake manifold). It is obvious that air leaks are a common cause of increased engine speed or floating speed at idle.

Now let's figure out where excess air can enter the intake. You should look for the problem in four main directions:

- throttle valve;

- channel XX;

- device for maintaining “warm-up” speed;

- servomotor for forced increase in speed XX;

As for the first case, the opening of the throttle valve is controlled by the gas pedal. At idle, the engine should run without pressing the accelerator. It is worth considering that on many cars the gas pedal is mechanical, that is, it is connected to the throttle opening mechanism with a regular cable. If this cable is soured, kinked or overtightened, and problems arise with the mechanism itself, then a banal effect of pressing the gas pedal may occur. In this case, the engine will maintain increased speed, since the ECU believes that the driver is pressing the accelerator and the throttle is slightly open.

Signs of IAC malfunction

Among the signs that directly or indirectly indicate incorrect operation of the idle speed sensor are the following:

- the engine does not start well - it becomes impossible to start the engine without pressing the gas pedal;

- when switching to neutral gear, “dips” in speed and their instability are observed;

- when changing gears, the speed drops or the engine stalls completely;

- the engine does not warm up well at low temperatures, since increased speeds (1500 rpm) are not reached;

- after turning on energy consumers (high beams, heater, air conditioner), the speed begins to “sag” or “float”;

- The engine spontaneously increases and decreases speed.

The IAC cannot be repaired; the device must be replaced. Before changing the idle air regulator, it is advisable to flush the throttle assembly.

How to check the regulator

There are a lot of ways to diagnose ICC. The most effective and simple methods for checking the Kalina idle speed control:

- Routine IAC testing for performance. To do this, the device must be removed from the throttle assembly and the terminal block connected if it was disconnected for dismantling. After this you need to start the engine. At the moment of startup, the needle of a working device should extend. If this is not observed, the regulator is broken.

- Checking the supply of the required voltage to the sensor. You need to disconnect the terminal block from the IAC and connect a voltmeter to the terminals. After this, one person turns on the ignition, and the second measures the resistance at all terminals of the block. If there are no faults, the voltmeter reading should be approximately 50 ohms. The voltage should be at 12 V. If it is significantly less, this indicates a battery malfunction or an electrical circuit break in one of the sections.

- Measuring the resistance of the internal and external windings of the regulator. To do this you need to use a multimeter. The measurement results should not be lower than 40 Ohms and higher than 80 Ohms. If you deviate from the specified range, the idle air control must be changed.

Knowing the signs of problems, you can promptly diagnose IAC malfunctions and take measures to eliminate them. Although the regulator cannot be repaired, it is worth trying to clean it. In some cases this is enough.

Engine temperature sensor

If the device breaks down, the dashboard provides incorrect data regarding the engine temperature. To check and change the temperature sensor, proceed according to the following algorithm :

- Prepare an autothermometer for working with high temperatures, a tester and a metal basin with water for heating on the stove.

- Disconnect the connectors and, substituting the basin, remove the sensor from the socket. A plug is placed in place of the sensor.

- The device is placed in cold water with the side screwed into the cylinder head. Measure the resistance and put the basin on the gas.

- Measurements are taken several times at different temperatures and compared with the standard data in the service book.

Significant discrepancies indicate the need to replace the temperature sensor with a new one.

FakeHeader

Comments 21

When the rpm drops to 600 - is it once every about 30 seconds or constantly?

Once every 1-2 seconds

Then it's definitely not an adsorber. If the AIR fitting of the canister is clogged, then when the canister valve is opened, air will be driven out of the tank (the speed will drop exactly once every 30 seconds), but the canister works for no more than 3-4 seconds, after which it turns on again only after about 20-30 seconds. You can safely cross it off the list.

I’m having this problem myself now, but I have it once every 20-30 seconds, and that’s exactly when the adsorber valve opens for purge. I disconnected the hose from the adsorber going to the valve, the speed stopped falling. It seems to me that this is exactly the situation when the AIR on the adsorber is clogged with dirt or coal. The valve opens and, instead of fresh air, draws gasoline vapor directly from the tank, then the rpm drops to 500 and a sharp rise to 1200. The valve closes and everything is fine until the next opening. =(

And what should I do with it so that the revs don’t fluctuate?

When the rpm drops to 600 - is it once every about 30 seconds or constantly?

And so on constantly in neutral until you turn it off. The voltage in the onboard after a drop in rpm also drops to 13.6 and rises with the rpm

The revs are fluctuating - first of all, look for air leaks. Whistling occurs more often. Possible places: a rubber plug on the intake manifold, a stuck absorber valve, a vacuum booster, stiffened injector rings and intake manifold seals at the joints. Everything is checked by clamping the pipes or temporarily replacing them with plugs. That is, for example, you pull out the vacuum pipe from the manifold and stupidly plug it with your finger, etc.

I have the same problem, but only in winter you stop at a traffic light and the revs start to float, also e-gas, the check does not light up, I changed the spark plugs, it helped, the factory spark plugs lasted 3000 km, new ones for another 4000 km, then I installed NGK, so far it’s ok

Floating engine speed

Engine speed problems can easily be identified by looking at the tachometer. Stable operation of the power unit at idle should not exceed 850 rpm. A small spread of 750 to 850 rpm is allowed. If the tachometer needle jumps chaotically—it goes down, then it goes up—there is a malfunction. This is a fairly common problem, and it is easy to identify why the speed of the Lada Granta is floating. It is enough to listen to the engine running - with unstable idle speed, the noise either decreases or increases.

Why are the revs jumping?

The cause of the problem is the specifics of regulating the operation of the power unit at idle by the control unit. It continuously reads data about the status of various engine systems from sensors. If the idle speed becomes unstable, the sensors are given a command to correct the functioning of the system.

A malfunction of the mass air flow sensor may be one of the causes of the problem. During operation, it becomes covered with a thin oil film, the formation of which will certainly lead to breakdown. When excess air is sucked through the inlet into the cylinders, idle speed is disrupted. As a result, the air flow sensor transmits incorrect information to the ECU about the excessive consumption of incoming air. The failure is displayed on the dashboard - a “check”, or engine error, lights up on the screen of the Lada Granta’s on-board computer. In this case, the control unit commands the valves to admit more fuel into the cylinders and equalize the ratio of air and gasoline to prepare the optimal mixture. As a result, the speed increases sharply, and the ECU realizes that there is too much fuel and gives the command to limit the supply. As a result, the speed drops sharply.

IAC (idle air control) can also cause jumps in engine speed, in which case a “check” will light up on the dashboard. The regulator is an electric motor with a cone-shaped needle. Its direct purpose is to adjust and maintain stable idle speed. A faulty regulator stops working normally, and the engine, left without it, begins to randomly increase or decrease speed.

Unstable idle may be caused by a problem with the oil pan ventilation valve. Engine operation is accompanied by the release of gases that accumulate in the pan. If there is a large amount of crankcase gases, they are discharged through the ventilation system through the intake manifold to the throttle assembly. With their help, part of the air-fuel mixture is formed in the combustion chambers. If the valve loses its normal throughput, then less gases enter to enrich the mixture, and the speed begins to float.

Methods for eliminating floating speed

Any cause of idle fluctuations can be neutralized in the following ways:

- Excessive air leak. The intake system needs to be checked for leaks. You can treat the hoses with WD liquid - there is a crack in the place where it instantly evaporates. You cannot seal it with tape or tape; only replacing it with a new part will help.

- IAC breakdown. The serviceability of the idle air control can be checked with a multimeter by measuring the resistance. If the readings are between 40 and 80 ohms, the regulator must be replaced.

- Malfunction of the oil sump ventilation valve. You can get to the part only after removing the pallet. The valve is dismantled, thoroughly washed in gasoline or kerosene and, after drying, installed in its place.

- Problem with DMRV. If the mass air flow sensor fails, it cannot be repaired; it can only be replaced with a new part.

- Problems with the throttle valve. If the problem is incomplete closure, the throttle assembly can be washed, for example, with carburetor cleaning fluid or the like.

It is quite easy to fix problems associated with floating engine speeds on your own, especially when you have minimal skills and experience. If you think that you cannot cope with such work, it is better to contact a service station.

So why is this happening

Root causes of problems

The most common situations in which floating speeds occur:

- Cars with a built-in electronic fuel injection system suffer from such problems much more often than others. And this happens due to the constant suction of excess air, the volume of which still increases, which leads to the formation of a malfunction. The sensor responsible for gasoline injection simultaneously calculates the volume of air entering the cylinders. Based on these and some other indicators of the sensors, the electronic unit opens the electromagnetic injection valves for some time. It follows from this that when there is an excessive amount of air in them, the sensor, which is responsible for the position of the throttle valve, shows the driver that the task assigned to the system is impossible - the check light is on. During this, the temperature sensor indicates that the engine is exiting the warm-up mode. This indicates that it needs less fuel. Just at such a moment, floating speed appears in the car at idle, because the electronic unit does not understand what to do with the accumulated excess air in the system.

- This reason also partially relates to air suction and occurs mainly on 16-valve engines. The main place where air leaks still occur is the gluing contour of the receiver elements. Even minor damage to this area will lead to unstable operation of the motor.

- Constant jamming also easily becomes a reason for the occurrence of floating speed. It occurs in the crankcase ventilation valve. Therefore, if the reason is precisely this phenomenon, the systematic operation of the automatic power regulation sensor is disrupted. As a result, the same sensor signals instability of the engine. In a faulty state, the speed ranges from 1,300 to 900 per minute.

- In models with a carburetor engine, floating speed occurs due to a violation of the control of the servomotor. To correct this problem, simply unscrew the adjustment bolts in the area of the servomotor where the sensor points to the loose drive.

- Low pressure in the fuel system causes the same problems.

- Breakdowns in the ignition system are sometimes also classified as causes of floating speed. The problem is primarily related to high-voltage wires and spark plugs. But only with a visual inspection will it be possible to understand whether they are really the problem.

- A breakdown of the IAC (idle air regulator) causes floating speeds, because it is responsible for their initial stability. The element is inexpensive and can be replaced, so there may not be any significant problems with this.

- The electronic gas pedal has a lot of disadvantages, especially if tuning the car is only in the process, but the car is actively used. Floating speed is a fairly common occurrence in such a situation.

The speed can fluctuate not only when the engine is cold, but also when the engine is hot. It all depends on the cause of this phenomenon.

So what to do if floating speeds appear with enviable frequency and significantly interfere with the quiet use of the vehicle?

Operating principle of IAC

When the engine is running without increasing speed, that is, at idle, a minimum volume of air enters the combustion chambers of the cylinders. This occurs regardless of the throttle valve being in the closed position. The volume of intake air consumed is monitored and measured by the MAF (mass air flow sensor), which sends data to the ECU.

Based on the information received, the control unit supplies the required amount of fuel to the cylinders through the injectors. At the same time, the controller monitors the crankshaft speed using its position sensor (DPKV). According to the data obtained, the IAC needle opens or closes, controlling the air supply past the throttle valve, which at this stage is not involved in the operation of the engine.

Technically, the IAC is not a sensor, it is an actuator, so the controller cannot diagnose its malfunction. This means that the “Check Engine” icon will not light up on the instrument panel if the regulator breaks down. In their symptoms, IAC malfunctions are similar to TPS (throttle position sensor) malfunctions. But in the case of the latter, the icon will definitely light up, indicating engine problems.

Where is the IAC located and how does it work?

The Kalina idle speed sensor performs four main functions:

- Maintaining a certain number of engine revolutions.

- Providing conditions for starting the engine in winter at sub-zero temperatures. This means that the IAC can increase the speed so that the engine warms up faster. As operating temperature is reached, the speed gradually decreases.

- Maintaining minimum engine speed when the gas pedal is released. Many motorists underestimate this function until problems with starting and unstable engine operation begin.

- Creation of a fuel-air mixture with the required percentage of fuel and air. This ensures optimal fuel consumption and stable operation of the power plant.

Since the IAC is responsible for supplying air to the cylinders, it is located on the throttle assembly. The regulator on almost all naturally aspirated gasoline engines is located next to the throttle position sensor, and Kalina is no exception.

Low speed when starting cold in Kalina

On Kalina, when starting cold, the revs are low. The relay clicks in the light switching area and the speed becomes normal.

- Lada Kalina won't start - 5 answers

- In the morning it works for 2-3 seconds and then stalls, Kalina - 2 answers

- When the speed increases, the VAZ Kalina stalls - 2 answers

- At cold start 500 rpm in Lada Kalina - 1 answer

- Sometimes the engine on Kalina does not start - 1 answer

Are you sure that it is clicking in the cabin? Maybe it’s the IAC clicking on the engine, it needs to be removed and washed with carb cleaner, because it is the step-by-step IAC motor that is responsible for the speed when warming up, through commands from the controller, of course.

And look how it clicks. That it's going crazy.

And tell me which one.

It seems that your starter does not turn off after starting the engine. Change the relay as soon as possible.

Even more useful tips in a convenient format

On a cold engine the speed fluctuates, what should I do?

Has the revs been fluctuating on a cold engine lately? Do not rush to conclusions - this type of malfunction can be caused by a number of reasons. In any case, the problem with unstable operation of the engine must be solved immediately, so that floating speed does not end in a complex disassembly and repair of the entire engine. And these are completely different prices.

Does the speed fluctuate on a cold engine, but the reason is not clear? Start with the mass air flow sensor, whose second name is the mass air flow sensor. The stable operation of the engine directly depends on how correct and proportionate the fuel mixture is.

It is known that the composition of the fuel mixture includes the fuel itself and the air mass. In order for its composition to be optimal, a flow meter is needed. He monitors the formation of the correct proportions and provides information to the car’s on-board computer. In addition to forming the mixture, the mass air flow sensor is responsible for the volume of air that saturates the cylinders, as well as for the timely start of the engine.

The revs are floating - logbook of the 2010 Lada Kalina Station wagon on DRIVE2

I drive a Lada Kalina Universal Krasnodar, Russia

A couple of weeks ago I noticed that sometimes in traffic jams the car can quickly gain and drop speed several times in a row in the range of 500-1500 rpm when switching to neutral or after stopping. And as the temperature began to drop below 0, when starting for 5-7 seconds, the revolutions jumped as if someone was accelerating. The assumption immediately arose that the problem was the TPS, but I decided not to get excited with the conclusions, especially since there was an adapter for diagnostics.

So the autopsy showed

1. When the engine is not running, the voltage on the mass air flow sensor and air metering sensor is higher than normal

2. Air consumption is higher than normal when the engine is running

At the TPS, although the voltage is increased, the opening angle of the throttle valve is at zero, and if you press and release the gas pedal, it always returns to 0, without any hesitation. Tomorrow I'll try to find and plug in the old TPS to see how the readings change. Well, everything is clear with the mass air flow sensor - it is dying. Now I’m thinking: should I change it right away and not fool myself, or should I still dance with a tambourine in an attempt to delay the inevitable by washing it?

Kalina engine speed fluctuates when the fan is turned on

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

The vacuum brake booster or its hose is leaking air.

could this happen because of a dead rocket motor?

AMAROCK

Yes, the fan is a fan, after starting why it tries to stall.

serrodjja_603_

, if at the moment the Carlson is turned on, the temperature according to the display meter on the tidy remains in place, then you need to definitely look at the positive circuit: battery - generator - mounting block. When the voltage drops on the positive side, the injectors begin to work sluggishly, hence the instability in the operation of the internal combustion engine. First, look (stripe/stretch) the small positive terminal on the battery:

and then the terminals under the nut on the gene.

Yes, to hell with the fan, it’s more important for me to find out why after starting the engine the speed fluctuates and sometimes even stalls

I searched but didn’t really find anything, the problem is this: I start it hot often, after starting it sometimes stalls or the rpm jumps from 500 to 1000, then it stabilizes, sometimes while standing in a traffic jam after the fan turns on, about the same thing starts, jumps from 700 to 1000 , happens after sharp braking... what could be the problem. The generator is new, the voltage is normal, the DPZ, IRR, DMRV are new, the fuel pump is new.

to hell with the fan

you are advised correctly. First, deal with the obvious jamb, and then see if the rest disappear or not. Those. clean, tighten the masses especially near the brains, the same with the battery and generator terminals.

After starting the engine, the speed fluctuates and sometimes even stalls

Source

The revs are floating - logbook of the 2010 Lada Kalina Station wagon on DRIVE2

I drive a Lada Kalina Universal Krasnodar, Russia

A couple of weeks ago I noticed that sometimes in traffic jams the car can quickly gain and drop speed several times in a row in the range of 500-1500 rpm when switching to neutral or after stopping. And as the temperature began to drop below 0, when starting for 5-7 seconds, the revolutions jumped as if someone was accelerating. The assumption immediately arose that the problem was the TPS, but I decided not to get excited with the conclusions, especially since there was an adapter for diagnostics.

So the autopsy showed

1. When the engine is not running, the voltage on the mass air flow sensor and air metering sensor is higher than normal

2. Air consumption is higher than normal when the engine is running

At the TPS, although the voltage is increased, the opening angle of the throttle valve is at zero, and if you press and release the gas pedal, it always returns to 0, without any hesitation. Tomorrow I'll try to find and plug in the old TPS to see how the readings change. Well, everything is clear with the mass air flow sensor - it is dying. Now I’m thinking: should I change it right away and not fool myself, or should I still dance with a tambourine in an attempt to delay the inevitable by washing it?

Sensor selection and price

This element is not very expensive, but at the same time it is not cheap. Its price depends primarily on the manufacturer. And especially, the price tags began to differ due to the growth of the dollar exchange rate.

- KZTA 573 rub.

- Omega 639 rub.

- AvtoVAZ 695 rub.

- GM 1074 rub.

There are several other manufacturers, but there is no point in listing them, since the average price range is, in principle, understandable. If you have any questions about replacing, removing or installing the IAC on a Priora, please discuss it below in the comments.

Replacing the air flow sensor

The replacement procedure is as follows:

- First you need to loosen the clamp that secures the air duct, for this you use a Phillips-head screwdriver. The pipe itself can be dismantled.

- Disconnect the power connector from the regulator; to do this, simply press the latch at the bottom and pull the plug itself to the side.

- Next, using 10mm wrenches, you need to unscrew the two bolts. It may be difficult at this stage, so you can use a ratchet to unscrew the bolts quickly.

- The regulator can then be moved to the side and removed.

- The installation procedure is carried out in reverse order.

Step-by-step replacement instructions

- Using a Phillips screwdriver, remove the two screws securing the idle air control valve to the throttle body.

- Removing the idle air control

- Using an ohmmeter we measure the resistance between the terminals of the windings.

- Using a caliper with a depth gauge, we measure the protrusion of the new valve needle.

- If the valve protrusion is more than 23 mm, recess the valve into the body as follows:

- We connect the positive terminal of the battery with a wire to terminal D of the regulator (the connection of the wire to the terminal must be insulated);

- With the bare end of the wire connected to the negative terminal of the battery, briefly touch terminal C of the harness block. Since the valve moves very slowly, we touch it repeatedly, reproducing the operation of a switching power supply.

- Visually check the condition of the o-ring. We replace the damaged ring.

Install the regulator in reverse order

In the morning the idle speed of the Lada Kalina is floating

In the morning at -1, the revs on the tachometer are first 500, and after 1-2-3 seconds the warm-up speed is 1100. I changed the wires, changed the idle, changed the TPS, changed the spark plugs, changed the coil, called with a multimeter. I checked the DMRV readings 0.98. I installed a new air filter. I changed the idle sensor, removed the throttle, it was clean.

And still the relay makes one click and from 500 it is set to 1100, as it warms up everything is fine, then it is set to 900 and it starts without any hang-ups. I don’t know where to dig, what to look for?

The firmware has not changed, original Bosch. I don’t really know what the numbers are, just if you can write something. I’m already thinking, maybe there’s something wrong with the firmware during a cold start? So the main thing is that it warms up for 1 minute, I turn it off, start it again, this is no longer the case. It’s just some kind of trouble, and if the frost hits -30, it will completely shut down, well, in general, such things.

- At XX, the engine runs intermittently in the Lada Kalina - 7 answers

- The idle speed on the VAZ Kalina jumped up - 6 answers

- VAZ Kalina stalls 2-4 seconds after starting – 6 answers

- It revs itself in the morning at idle, Kalina – 6 answers

- VAZ Kalina stalls when cold or in the cold - 5 answers

If the engine is already running and produces 500 rpm. Then for some reason the relay clicks, right? There the IAC can only click, then yes, the speed will change if it is faulty. Do you have an IAC or a throttle assembly without it? As for changes in the weather and the dependence of engine operation - this could be due to a faulty mass air flow sensor or just because of the “wrong” air filter.

Which relay clicks? Which relay makes the click?

There in the engine only the IAC can click when starting. And these Russian regulators are of disgusting quality (I bought a new remote control, it was clogged and the heating did not work, and on the new IAC it jammed, replaced it, installed the old IAC and the motor worked fine).

You can read about the same story (about the wrong IAC) here.

You don’t have to bother with the firmware, you have a normal controller. And you can’t fix this question with firmware.

Preparing to clean the idle speed sensor

In order to clean the IAC, you need to prepare in advance a small set of tools and materials that will be needed during the work: a small Phillips screwdriver, aerosol liquid, rags and carburetor cleaner.

After everything necessary for work has been prepared, you need to turn off the power to the car from the battery. Next, you should find the IAC located on the throttle assembly and use a small screwdriver to unscrew the two fixing screws.

IAC cleaning

Place the idle speed sensor on a clean rag and spray the idle speed sensor needle with cleaning fluid from an aerosol can. While spraying, be careful not to get any liquid under the spring. If this happens, you will need to purge the sensor under high pressure, but this procedure will not guarantee that the IAC will work correctly. Next, wipe the needle with a clean piece of rags and wait until it dries completely.

Idle speed sensor on Lada Kalina - the photo shows the cleaning process

If this is not done, you will subsequently have to dry and clean the car spark plugs. Use engine oil and wipe the idle speed sensor O-ring. After that, install it in the seat and securely fasten it with two screws.

When installing the sensor, care must be taken, since the IAC will not operate normally with a damaged seal. If after cleaning the idle speed sensor does not want to function normally, it must be replaced with a new one.

Why does the injector stall at idle?

The advantage of VAZ injection systems, which were first installed on the 2110 family, and then on the subsequent G8, slightly updated in appearance 2114-2115, is that they are simple in design, and as a general example of injection system malfunctions are the most obvious.

The injection ECU has feedback algorithms and influences the idle speed both grossly (using the idle speed controller or “electronic” throttle) and subtly (by varying the ignition timing), so it is more difficult to make the injection engine stall. In addition, the abandonment of the distributor and the installation of either a dual ignition module (eight-valve models) or individual coils (sixteen-valve engines) also increased the reliability of the ignition system: at least on two cylinders, the engine will work. Air leaks have also become less critical. The revolutions will begin to fluctuate, but if the idle speeds disappear, then the reason is hidden elsewhere.

Here, one of the most likely culprits is significant contamination of the injectors. Four-nozzle injectors of eight-valve engines are sensitive to dirt: their flow area is the same as that of two-nozzle injectors of 16-valve engines: the area of each individual hole is half the size, and it is easier to clog it. There are cases worthy of jokes: on an excessively clogged fuel filter, the pressure developed by the fuel pump is enough to tear the filter curtain, and the flow of fuel will carry the accumulated dirt into the fuel line and ramp. This is likely on engines with a drain ramp, where a fine filter is located before the pressure regulator, and the fuel flow from the pump passes through the filter. For engines with a drainless ramp, the pressure is cut off in the fuel pump module, and only the volume of fuel that is consumed by the injectors passes through the filter.

If the injectors are dirty, mixture formation is disrupted due to a change in the shape of the spray pattern, and the mixture itself may become lean beyond the limits of stable ignition. The injection ECU has a margin for adjusting the opening time of the injectors to compensate for their clogging, but this margin is not unlimited.

Leaking injectors can become a problem: due to the constant flow of gasoline into the intake, the spark plugs become overgrown with soot and filled with gasoline, which immediately affects the stability of idle speed. The more carbon deposits accumulate on the spark plugs, the more difficult it is for the engine to operate. However, with leaks that can cause the engine to stall, the enrichment of the mixture is immediately noticeable by the characteristic black smoke and “lumbago” in the muffler.

The same enrichment of the mixture is created by a faulty mass air flow sensor. The author has repeatedly encountered sensors that showed air flow several times higher than normal. At the same time, the engine still worked somehow when the gas pedal was pressed at high speeds, but at idle, with a loud burst from the muffler and clouds of black smoke, it finally stalled. Everyone knows the quick check: disconnect the connector from the mass flow sensor to force the injection computer to switch to an emergency program for calculating cylinder filling based on throttle position and revolutions. The mixture will be within acceptable limits.

And malfunctions of the actuators that control idle speed can cause problems. Jamming the idle air control in the closed position (and it closes completely every time the ignition is turned on so that the injection ECU sets the zero reference point for controlling the IAC) can prevent the engine from operating when the gas pedal is released. The “electronic” throttle has problems with the servo drive and excludes the possibility of maintaining the operation of the pedal, since there is no direct mechanical connection between the pedal and the throttle.

Another cause of problems with idle speed, difficult to detect without diagnostic equipment, is hidden in the position sensor and its reference ring, which in VAZ is threaded onto the crankshaft pulley and also has a damper. Wear of the damper causes beating and deviation of the crown position: at idle, when the amplitude of the signal from the DPKV is minimal, the DPKV processor may miss pulses - in this case, the engine control unit will lose the ability to correctly determine the speed and points of fuel and spark supply, after which it will block the ignition and fuel injection .

But the oscilloscope immediately detects the problem - the illustration above shows that the signal amplitude changes periodically. With such a violation of the DPKV signal, problems with idle speed are already possible.

Something else useful for you:

What else could cause a failure?

Unstable speed when cold can be caused by damaged wires, faulty spark plugs and module. Do not forget that spark plugs are changed every 20-25 thousand km (they can change less often - it all depends on the specific model of spark plugs)

It is equally important to periodically check the spark plugs for functionality. For example, if you notice that they are covered with soot, very wet, traces of fuel or oil are visible, it’s time to think about buying new spark plugs

You can make the replacement yourself, without resorting to the help of service station specialists. But for this you will need to purchase a special spark plug wrench.

Returning to the topic of faulty high-voltage wires, you need to find out the reasons why the current does not reach the spark plugs. In most cases, this is due to a wire break or insulation failure. A strong breakdown occurs, the resistance grows to prohibitive values, the contact group does not work well.

In principle, these are all the reasons why the speed of a cold engine fluctuates significantly. Sometimes the problem may be with the solenoid valve, but it rarely breaks.

The cause of a stalled engine is a power supply failure

In this type of problem, 3 reasons may be involved:

- Poor contact with the terminals of the new battery;

- Detection of poor contact or breakdown along the entire length of high-voltage wires;

- The appearance of malfunctions in the generator or ignition coil system of the car.

If the problem lies in damp high-voltage wires, then it is best to replace them completely along with the battery contacts. If the terminals make poor contact, you need to carefully clean them with sandpaper and try to reconnect them. If the generator is found to be inoperable, the problem usually boils down to problems in the following parts:

- Broken timing belt;

- There is a malfunction inside the housing of the unit itself.