Crankcase ventilation system Kalina 8kl

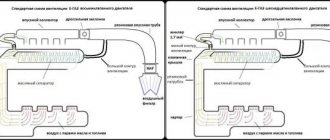

Today we’ll talk about the crankcase on Kalina with an 8-valve engine. And to be more precise, about cleaning this system. Crankcase gases straight from the crankcase (hence the name) are sent mixed with air to the intake manifold for re-burning, thus saving a certain percentage of fuel. So, along with the gases, oil particles enter the system and clog it.

It is this oil that needs to be cleaned from the crankcase ventilation system. Over time, plaque forms on the walls of the hoses, which impedes the passage of gases.

In the Kalinovsky engine, in the valve cover, there is a special separator that separates crankcase gases from the oil. It gets clogged the most. So, let's get started. The entire ventilation system consists of 3 pipes. We need to unscrew them.

Then remove the valve cover. There are two bolts on the back side, unscrew them and get to the separator.

The easiest way to clean it from oil and deposits is in a bath of gasoline or solvent.

While the separator is acidifying, you can work on the pipes. In general, if they are heavily soiled, it is advisable to replace them with new ones. In my case, I replaced only one - coming from the valve cover to the air filter pipe. The rest were washed with carburetor cleaning fluid (great stuff, it corrodes absolutely everything). The separator itself can also be washed a second time with this thing.

We wipe everything with a clean cloth and put it back together as it was. Pay attention to the condition of the valve cover gasket. It is considered disposable and it is better to replace it with a new one each time you remove it in order to avoid oil leaks.

Do you need a pipe from the breather to the pan? (do not delete)

Administrators 6,160 messages Registration 15-April 06

Users 1,341 posts Registration 04-October 09

- From: Ukraine

- Car: VAZ 2104, VAZ 2101

Message modified: July, 02 July 2010 - 10:05.

Users 3,692 posts Registration 18-September 09

Users 596 messages Registration 21-Jan 10

Users 3,692 posts Registration 18-September 09

Moderators 3,278 messages Registration 13-April 10

#8 Anndreykov

Users 2,489 messages Registration 01-April 10

Definitely needed. 1. The engine is constantly breathing (as stated above) and dust in the engine is not good. 2. Unlike chisel engines, the classic one needs a constant vacuum, otherwise you’ll spin well and you’ll be looking for HF seals along the way (just kidding, but they start to leak quickly, and they can squeeze out). Old motorists said that the breather can be lowered down when the engine is completely dead and you need to REACH for a while. 3. If environmentalists stop you with a sniffer, then the minimum is a good fine, and at most you will have to take the car from the impound lot. 4. It’s better for yourself that when you climb under the hood, at least you don’t breathe this muck. And in order not to pollute the filter, they make various devices - an enlarged jar with labyrinths, a water filter, or simply install a crankcase gas filter.

Added after 3 minutes

Users 2,986 messages Registration 09-December 05

#10 Anndreykov

Users 2,489 messages Registration 01-April 10

Then this engine simply does not exist. And the oil consumption is the same as gasoline. And if something goes wrong, don’t turn the engine too hard, and change the filter not after 10 thousand, but after 5 thousand. It's not that expensive. Wash the jar with powder one more time. And the engine needs to be repaired on time. Then there will be no problems with the breather.

Added after 2 minutes

Administrators 6,160 messages Registration 15-April 06

Users 969 messages Registration 02-Mar 09

Users 3,692 posts Registration 18-September 09

Users 4 118 messages Registration 16-December 06

- From: Kyiv, Bereznyaki

- Car: VAZ 21011 + ZAZ Lanos 1.5

Users 33 posts Registration 10-Jul 08

Modification of the crankcase ventilation system Kalina 8 valves

This system could be improved a little. One of the 3 pipes supplies crankcase gases directly to the throttle valve assembly next to the IAC. If they contain oil, it will definitely settle there. This is how the IAC becomes clogged. So, to avoid this, you can embed a regular fuel filter right in the middle of this pipe.

It will trap oil particles contained in crankcase gases. After a few hundred kilometers, you will see for yourself. Monitor the condition of this filter and promptly change it to a new one. On average, as practice shows, it needs to be changed every 1000 kilometers.

Symptoms

The first, main symptoms that a diesel engine has begun to breathe are lubricant leaks and a decrease in the oil level in the crankcase. Having noticed such characteristic phenomena, it is necessary to make sure that the suspicions are correct. To do this, you need to warm up the engine to operating temperature, unscrew the oil filler cap and check for bluish smoke.

If suspicions are confirmed and smoke is present, the diagnosis is obvious. Let's try to figure out why the diesel engine is breathing and how to fix it.

Crankcase ventilation system Kalina 8 valves

Today we’ll talk about the crankcase on Kalina with an 8-valve engine. And to be more precise, about cleaning this system. Crankcase gases straight from the crankcase (hence the name) are sent mixed with air to the intake manifold for re-burning, thus saving a certain percentage of fuel. So, along with the gases, oil particles enter the system and clog it.

It is this oil that needs to be cleaned from the crankcase ventilation system. Over time, plaque forms on the walls of the hoses, which impedes the passage of gases.

In the Kalinovsky engine, in the valve cover, there is a special separator that separates crankcase gases from the oil. It gets clogged the most. So, let's get started. The entire ventilation system consists of 3 pipes. We need to unscrew them.

Then remove the valve cover. There are two bolts on the back side, unscrew them and get to the separator.

The easiest way to clean it from oil and deposits is in a bath of gasoline or solvent.

While the separator is acidifying, you can work on the pipes. In general, if they are heavily soiled, it is advisable to replace them with new ones. In my case, I replaced only one - coming from the valve cover to the air filter pipe. The rest were washed with carburetor cleaning fluid (great stuff, it corrodes absolutely everything). The separator itself can also be washed a second time with this thing.

We wipe everything with a clean cloth and put it back together as it was. Pay attention to the condition of the valve cover gasket. It is considered disposable and it is better to replace it with a new one each time you remove it in order to avoid oil leaks.

Crankcase ventilation system Kalina 8kl

Today we’ll talk about the crankcase on Kalina with an 8-valve engine. And to be more precise, about cleaning this system. Crankcase gases straight from the crankcase (hence the name) are sent mixed with air to the intake manifold for re-burning, thus saving a certain percentage of fuel. So, along with the gases, oil particles enter the system and clog it.

It is this oil that needs to be cleaned from the crankcase ventilation system. Over time, plaque forms on the walls of the hoses, which impedes the passage of gases.

In the Kalinovsky engine, in the valve cover, there is a special separator that separates crankcase gases from the oil. It gets clogged the most. So, let's get started. The entire ventilation system consists of 3 pipes. We need to unscrew them.

Then remove the valve cover. There are two bolts on the back side, unscrew them and get to the separator.

The easiest way to clean it from oil and deposits is in a bath of gasoline or solvent.

While the separator is acidifying, you can work on the pipes. In general, if they are heavily soiled, it is advisable to replace them with new ones. In my case, I replaced only one - coming from the valve cover to the air filter pipe. The rest were washed with carburetor cleaning fluid (great stuff, it corrodes absolutely everything). The separator itself can also be washed a second time with this thing.

We wipe everything with a clean cloth and put it back together as it was. Pay attention to the condition of the valve cover gasket. It is considered disposable and it is better to replace it with a new one each time you remove it in order to avoid oil leaks.

What is the EGR valve for?

We should start with the fact that the USR system is installed on most diesel engines and gasoline, naturally aspirated units. The essence of this system is that at certain moments the valve

EGR and a portion of exhaust gases

.

Schematic representation of the operation of the USR system.

Thus, the amount of oxygen in the fuel mixture is reduced, which in turn reduces its combustion temperature. And at a lower combustion temperature, the amount of nitrogen oxides in car exhaust decreases quite significantly. If the engine is turbocharged, then the range of application of the USR is significantly narrowed, which makes its installation irrational. In such cases, other solutions are used to reduce the amount of harmful components of automobile exhaust.

Exhaust Gas Recirculation does not work at idle speed, it is not used when the engine is cold, and the EGR valve closes when the throttle valve is wide open.

Engine breather causes and consequences

Before answering the question: “Why is the engine breathing?”, it is necessary to understand what exactly is meant by this formulation.

As a rule, this phrase characterizes the manifestation of excess gases in a power plant. Characteristic signs of this phenomenon can be considered smoke from the neck where oil is poured, leakage of working lubricant in various parts of the engine (breather, seals, etc.). Oddly enough, if the engine starts to breathe, it’s too early to talk about any breakdown; you need to figure out what the reason is, since this phenomenon can manifest itself not only in units with high mileage, but also in completely new units, both gasoline and diesel

The breather is a special valve-type device designed to equalize the pressure inside the crankcase of the power plant with the ambient pressure. The process is quite simple: when pressure rises above atmospheric pressure, the valve opens and releases excess vapors to the outside, thereby ventilating the crankcase and removing gases.

Modification of the crankcase ventilation system Kalina 8 valves

This system could be improved a little. One of the 3 pipes supplies crankcase gases directly to the throttle valve assembly next to the IAC. If they contain oil, it will definitely settle there. This is how the IAC becomes clogged. So, to avoid this, you can embed a regular fuel filter right in the middle of this pipe.

It will trap oil particles contained in crankcase gases. After a few hundred kilometers, you will see for yourself. Monitor the condition of this filter and promptly change it to a new one. On average, as practice shows, it needs to be changed every 1000 kilometers.

The principle of operation of the breather

During operation, gases accumulate in the engine crankcase. To remove them, there is a ventilation system called a breather. This makes it possible to reduce the pressure in the motor itself. Because there are always air masses with tiny particles of oil in the crankcase, a little lubricant sometimes passes into the breather along with the air flows.

There is a mesh here to catch the oil. But some drops still manage to penetrate. So slight contamination of the filter system is quite normal. But if there is too much oil, then it is worth thinking about the reasons for its entry. Oil particles contribute to clogging of channels and increase the amount of soot. The latter gets into the crankcase and cokes the channels through which the oil flows. As a result, the performance of the entire lubrication system will deteriorate.

If there are specific signs by which you can determine what is driving oil through the breather. In a carburetor engine, traces of lubricant may appear in the filter housing. Significant lubricant marks may also be observed on the filter component itself.

In injection engines, deposits appear on the throttle assembly. In this case, the engine may lose its power, and fuel consumption may increase.

Cleaning the crankcase ventilation system of VAZ (Lada) Kalina 1118

Tools:

- Open-end wrench 10 mm

- Open-end wrench 13 mm

- Open-end wrench 17 mm

- Medium Phillips screwdriver

Parts and consumables:

- Gasoline/kerosene

- Rags

- Sealant

- Automotive compressor

- Cylinder head cover gasket (if replacement is needed) -2108-1003270-10

The crankcase ventilation system of the VAZ Lada Kalina 1118 tends to accumulate tarry deposits from crankcase gases, which make it difficult to remove these gases into the engine cylinders for combustion. Because of this, the gas pressure inside the engine increases and oil leaks through the seals appear. We recommend cleaning the crankcase ventilation system before each oil change.

1. Remove the decorative plastic engine cover.

2. Loosen the clamp and disconnect the hose of the large branch of the crankcase ventilation system from the air supply pipe.

3. Disconnect the second end of the large crankcase ventilation system hose from the fitting on the cylinder head cover and remove the hose.

4. Similarly, remove the hose of the small branch of the crankcase ventilation system by disconnecting it from the fittings of the throttle assembly and the cylinder head cover.

5. Remove the supply hose of the crankcase ventilation system by disconnecting it from the fittings of the cylinder block and the cylinder head cover.

6. Rinse the hoses with gasoline or kerosene, blow with compressed air and dry. Clean the holes in the fittings and pipes for connecting the hoses.

7. Unscrew the two fastening nuts and remove the cylinder head cover.

8. Unscrew the long 1 and short 2 bolts securing the oil separator from the inside of the cylinder head cover and remove the washers.

Selection of products by issue

Engine

The engine problem, mentioned in the title of the article, manifests itself as follows: passing through the oil dipstick, smoke enters the ventilation system pipe due to increasing gas pressure in the crankcase. Why is the engine breathing? Among the reasons, it should be noted contamination of the crankcase ventilation system, wear of parts belonging to the cylinder-piston group, as well as stuck rings and lack of valve tightness.

Recommendations from XADO specialists

If the cause of the engine problem is leaking valves, they should be replaced. If the engine is breathing for another reason, it is possible to eliminate the problem with pressure in the space above the crankcase using special auto chemical products. Thus, to clean the ventilation system, it is recommended to use the universal oil system cleaner VitaFlush or the equally effective TotalFlush product. Both compounds must be added to motor oil.

First option

Modification of crankcase ventilation can be done in several ways. For example, on the M50 you can install an oil separator unit from the M52 model. However. This manipulation does not solve the problem of having a container for draining liquid, external aesthetics and the need to place a water seal.

One of the current solutions to the problem under consideration would be the installation of a HEPA filter, which contains wire and filament components that make it possible to adjust as accurately as possible the amount of gases released. The inside of the oil separator is filled with copper wire wool. In the standard version, the packing should protrude slightly beyond the base of the lid. The corrugated inlet and throttle assembly are thoroughly wiped. After performing the manipulations, the element is checked by mechanical purging for changes in air flow.

, operating a car with an improved crankcase ventilation system does not give you any reason to worry about excessive oil separation. The modification carried out according to the “NERA” principle, after a run of 15 thousand kilometers, shows that the appearance of oil stains in the system has disappeared, and the corrugation remains absolutely dry. The throttle block is also clean. Impurities settle on the wire packing, which, according to the laws of physics, move towards the oil separator cover. The filler periodically requires cleaning by performing a simple procedure of removing the cover and rinsing it with gasoline.

Video

If, while operating a LADA car, you notice that during load (when the air conditioner is running, the heating is on, etc.) in a traffic jam, the engine begins to operate unstably (troits, pulls poorly, etc.), perhaps the reason lies in the ventilation system crankcase The article proposes to solve the problem by installing a PCV valve from a foreign car.

Where is the engine breather located?

From engine to engine, different car manufacturers may place the breather in different places. But in most cases it is located on the valve cover, next to the filler neck. Although there may be options: it is better to clarify in the description instructions for the car or find out on thematic forums.

In the picture on the right is the crankcase ventilation system of the VAZ 2111 engine, which includes a breather:

- Crankcase.

- Breather.

- Hose from the breather to the valve cover pipe.

- Oil separator under the valve cover.

- A thin hose from the valve cover to the fitting with the throttle body nozzle.

- Fitting with jet on the throttle valve block.

- Thick hose from the valve cover to the intake pipe..

But the breather is installed not only in internal combustion engines. It is in:

- Gearbox. Otherwise, the gearbox would begin to operate jerkily, and the wear of the gears on the secondary shaft would increase many times over. Something similar is observed when the breather becomes clogged and ceases to perform its function.

- If the design of the car provides for a separate transfer case, then a similar mechanism may be in it.

- Front, and in rear-/all-wheel drive vehicles - in the rear axle. Moreover, this inconspicuous detail not only equalizes pressure, it protects the mechanisms from dirt and moisture when overcoming water obstacles.

However, even their appearance is often similar, and often identical: they perform the same function.

Breather pipes

An engine breather (breather valve) is a device used to equalize the pressure in a closed chamber with atmospheric pressure. Therefore, it allows the camera to communicate with the atmosphere. In modern internal combustion engines, the device equalizes the pressure in the crankcase, which can increase and lead to oil squeezing out. If it falls, then air from outside enters the chamber, eliminating this difference.

In domestic cars, breathers are installed on:

- power unit;

- checkpoint;

- front and rear axles.

Moreover, their functions are similar, regardless of the installation location.

If the breather gasket fails, the pressure is not equalized, which leads to a number of very serious problems. Therefore, it is recommended to carry out timely maintenance of the unit by replacing hoses.

You will find high-quality pipes here. They are made from multi-component materials, therefore they have high technical and operational parameters. The original pipes have the required configuration and can be mounted on the target unit without any problems. They are made taking into account the harsh Russian climatic conditions, so they do not lose their properties even in severe frost or heat.

To buy breather pipes for VAZ and Lada, simply select the part you need and add it to your cart on the website. Orders are also accepted by our managers by telephone at 8 800-2228-163.

The second method of upgrading crankcase ventilation

The meaning of the following is to transfer the small ventilation circuit from the throttle part to the receiver, which helps reduce differences when switching modes. To complete this design, you will need to perform the following manipulations:

- The thin crankcase ventilation hose is disconnected from the throttle;

- The free end is connected to the free inlet fitting on the receiver, with preliminary removal of the plug;

- The free opening of the remote control is blocked by installing a plug;

- As a result, the flow of air mass increases, eliminating the possibility of a sharp response of the throttle valve to a jerk of the engine;

- In addition, crankcase ventilation increases and additional draft appears in the lower part of the mechanism.

Changing the purge valve on Kalina

The replacement procedure itself is not a complex undertaking. To perform this, the owner will need to acquire a regular Phillips screwdriver and know where the valve is located.

Below we provide an algorithm of actions that allows you to quickly and efficiently complete this procedure.

- Disconnect the corresponding terminal from the negative terminal of the battery.

- You will need to disconnect the power connector from the valve itself.

- For ease of access to the unit, we move the suction pipe of the intake system slightly to the side together with the “Max Air Mass Airflow” sensor. For this purpose, use the indicated screwdriver to loosen the clamp of the pipe and perform the action.

- Now we proceed to dismantling the unit. To do this, disconnect a pair of fittings located on the sides of the product. One of the fastening elements is fixed with a latch and to dismantle it, you will need to recess the latch, then lift the antennae and finally tighten the fitting to the side.

- Before installing a new component, we check that the markings on both valves match and make sure that they are identical.

- Installation and fixation of the product is carried out in the reverse order.

The canister purge valve has been replaced.

Cleaning the crankcase ventilation system

Over time, tarry accumulations of gases accumulate in the crankcase ventilation structure, which blocks their release into the engine cylinders for combustion. In this regard, the gas pressure increases, the oil gradually flows through the seals. To avoid this situation, keep the structure clean.

Helpful advice

Clean the crankcase ventilation after changing the oil.

To clean VAZ-21116, VAZ-11186 engines, take a “10” wrench, a Phillips screwdriver, and pliers.

1. Loosen the breather clamp of the large branch of the crankcase ventilation structure and unfasten it from the air supply hose.

2. Unfasten the other end of the breather from the pipe on the cylinder head cover and remove the hose.

3. In the same manner, remove the breather of the small branch of the crankcase fan structure. Unfasten it from the cylinder head cover and the intake module pipes...

4. ...and the inlet breather of the ventilation structure, unfastening it from the fittings of the cylinder block and the cylinder head cover.

5. Wash the breathers with gasoline. Clean all spans of pipes and fittings.

7. Unscrew the oil separator fixing bolts and remove the washers.

8. Unfasten the oil separator housing.

9. Remove the head screens from the block head.

10. Wash the grids, cylinder head cover, and oil separator housing thoroughly with kerosene.

11. Place the grids equally and fix them so that the grids rest against the bulges in the lid on one side, on the other...

12. ... the hole for fastening the bolt was visible. Place the oil separator housing and screw in the bolts.

13. Secure the cover to the block head.

14. Fix the structure’s breathers in the opposite order to disassembly.

To clean the crankcase ventilation structure of VAZ-21126, VAZ-21127 engines, do the following.

The work is depicted using the example of a VAZ-21126 engine. Identical work is carried out with the VAZ-21127 engine. The difference is in the intake pipe model.

Take an 8mm wrench, a screwdriver and pliers.

1. Unfasten the air filter.

2. Loosen the tie and unfasten the large branch breather from the air hose.

3. Having loosened the tie, unfasten the large branch breather from the cylinder head and remove it.

4. Using the same method, unfasten the breather of the small branch of the crankcase ventilation structure by removing it from the throttle body pipe and the cylinder head.

5. Loosen the tie, unfasten the supply breather of the ventilation structure from the cylinder head cover fitting.

6. In the same manner, remove the second end of the breather from the cylinder head pipe and unfasten the breather.

7. To connect the breathers, wash them thoroughly with kerosene and dry them, clean the pipes with compressed air.

9. Unscrew the 6 fastening bolts of the separator inside the cylinder head cover and remove it.

10. Grab the separator oil deflector fasteners with a clamp and remove it.

11. Carefully pry up the rubber ring using a screwdriver. Replace the ring that has lost its elasticity with another.

12. Secure the breathers and parts in the opposite order of removal.

Why does crankcase pressure increase?

Having noticed oil leaks in the engine compartment and/or a decrease in the oil level in the crankcase, it is necessary to accurately determine that the diesel engine is breathing. This can be done in the following way. It is enough to unscrew the oil filler cap on a warm diesel engine. If you notice bluish smoke coming from the throat, then the problem is obvious.

Cylinder piston group and cylinder head

The main reason that a diesel engine is breathing is the wear of the cylinder-piston group. During the operation of the internal combustion engine, scuffs form on the cylinder walls, the cylinders themselves gradually break and acquire a changed shape of the walls, and the piston rings wear out or break. As a result of heating, the thermal gaps between the piston and the cylinder walls become too large.

If the diesel engine is very worn out, then a major overhaul is necessary, which will mean boring the cylinders, replacing pistons, rings, etc. Accurate diagnosis of CPG problems requires measuring compression to determine the spread of indicators across the cylinders.

In the event that the diesel engine does not breathe much and the malfunction is only at the initial stage (wear of the cylinder walls is within acceptable limits), some auto mechanics resort to the method of decarbonizing the piston rings. This measure is considered temporary, since further long-term operation of the unit after decarbonization of the rings should not be expected. The best solution would be to replace the rings with new ones.

A diesel engine can also vent due to wear of valves, guide bushings, valve seals, etc. Similar to piston malfunctions and ring decarbonization, timing problems can only be effectively eliminated by comprehensive repairs. Replacing valve seals alone does not have a lasting effect.

Engine crankcase ventilation system

Second on the list of main reasons why a diesel engine is breathing is a clogged crankcase ventilation system. The symptoms of a decrease in the throughput of this system resemble wear of the CPG: increased consumption of engine oil, diesel smoking with blue smoke, etc. In some cases, it is possible to normalize engine operation and eliminate excess oil consumption by cleaning the breathers.

Purpose of the adsorber purge valve

In the Lada Kalina model, as in principle in any other car equipped with distributed fuel injection, an adsorbing system is necessary to localize the resulting gasoline vapors. They accumulate inside the tank after the engine stops, and after a certain time necessary for the transformation of these vapors into a condensation state, they turn back into liquid fuel. The remaining volume of vapor that failed to return to the tank moves to the adsorber, where it is retained by two valves. The first (gravity type) is necessary to prevent fuel spillage when the LADA Kalina body turns over (in an accident, etc.), and with the help of the 2nd, the pressure indicator inside the tank is monitored.

see also

- Forced ventilation in plastic windows

- Automation of ventilation systems

- Plastic check valve for ventilation

- Installer of ventilation air conditioning systems, pneumatic transport and aspiration

- Ventilation for piglets

- Cutting shaped parts for industrial ventilation

- Museums art galleries heating ventilation air conditioning

- Aerodynamic ventilation tests

- Ridge ventilation for soft roofs

- How to make ventilation in the kitchen

- Fuel tank ventilation system

Alternative options

The next version of the improvement involves installing a hose with a small diameter into the crankcase ventilation circuit of the EPK valve of the “Cascade” model. In idle mode, the valve for standard exhaust gas outlet should be opened. Considering the fact that when installing the system in question, the supply of harmful impurities through the throttle valve stops due to the circuit opening. This is very important in the case of a transition of the engine operating mode from idle to light loads, when a lean air-fuel mixture is categorically unacceptable. Ventilation is carried out through the entire line, including the carburetor unit.

After further replacing the durite with a hose from the vacuum ignition advance device, it is reasonable to increase the diameter of the main jet of the first combustion chamber or simply reduce the input fuel flow to 4.5 mm. The scheme under consideration was tested on a model of the domestic VAZ 2101. At the same time, the following positive aspects became noticeable:

- The pedal drop during acceleration has disappeared;

- The engine's operation became smooth;

- There are no intermittent oscillations at idle.

Let's sum it up

The work of replacing the valve is simple, however, when the owner of a Lada Kalina is not confident in his capabilities or does not show the desire to carry out repair operations in such a high-risk unit as the fuel supply system, we recommend using the services of a specialized workshop.

The car's EGR Exhaust Gas Recirculation system is a very vague and rather capricious thing, especially with the very low quality of fuel that is found in our area, quite often. The ambiguity of this system lies in the fact that its purpose is purely environmental. waste recycling system

gases or USR, is designed to reduce the amount of nitrogen oxides in the car exhaust. What is the USR, why is it needed and how its malfunctions are expressed, we will talk about all this for now.

Reasons why oil flows through the breather

- CPG wear. With serious wear of the cylinder-piston group (CPG), in particular the rings, a certain amount of exhaust gases penetrates into the crankcase, resulting in the formation of excess pressure and, as a result, oil loss begins. The oil is squeezed out under great pressure and no mesh can save you from this.

- The oil deflector is clogged. If ventilation is disrupted, oil vapors begin to bypass the purifier, resulting in oil expelled from the breather.

- The air filter is clogged. A clogged filter does not allow the motor to “breathe”. As a result, air is taken from alternative sources, including through the breather, only together with oil.

- Increased oil level. Some motorists do not comply with the requirements specified by the manufacturer and prefer to pour oil to the upper level or higher, citing the fact that there is never too much oil. As a result, the excess oil, as expected, begins to work not in favor, but on the contrary, to the detriment and some of this oil is squeezed out through the breather, in addition, it appears on the air filter.

- The breather valve has failed. A faulty or jammed valve causes exhaust gases to begin to enter the crankcase, as a result the pressure increases and oil is released through the breather.

Modification of the crankcase ventilation system Kalina 8 valves

This system could be improved a little. One of the 3 pipes supplies crankcase gases directly to the throttle valve assembly next to the IAC. If they contain oil, it will definitely settle there. This is how the IAC becomes clogged. So, to avoid this, you can embed a regular fuel filter right in the middle of this pipe.

It will trap oil particles contained in crankcase gases. After a few hundred kilometers, you will see for yourself. Monitor the condition of this filter and promptly change it to a new one. On average, as practice shows, it needs to be changed every 1000 kilometers.

Recirculation mode enabled

One of the reasons for fogging up the windows in a car is when air recirculation is turned on without taking it in from the outside. The damper blocks the flow of air from the street, resulting in air circulation in a circle in the car interior.

IMPORTANT! Recirculation is a useful function, as it makes it possible to avoid unpleasant odors and dust from entering the cabin, and also, if necessary, to warm up the cabin. But you can’t keep recirculation on all the time.

The optimal operating time is 20 minutes. Otherwise, the windows begin to sweat, and the passengers and driver feel worse due to lack of oxygen and high humidity.

But you can’t keep recirculation on all the time. The optimal operating time is 20 minutes. Otherwise, the windows begin to sweat, and the passengers and driver feel worse due to lack of oxygen and high humidity.

USR system management

recirculation system is controlled by the electronic engine control unit. And the command to open or close the EGR valve can be given based on:

- coolant temperature sensor;

- crankshaft sensor;

- throttle position sensor;

Read

In various car models, either all of the listed sensors are used to control the USR valve, or some of them, and in some cases, only the coolant temperature sensor.

What does the EGR valve look like on a Chevrolet Lacetti?

One way or another, the operation of the USR valve is always controlled by automotive electronics. And while this system functions normally, the driver practically does not feel its operation at all. The useful work of the USR system outside of environmental issues is very unnoticeable. This system allows you to save about three percent of fuel on gasoline engines. Also, in some cases, the USR system prevents fuel detonation in the engine. But this phenomenon in itself is rare and extraordinary. As for diesel units, if they have a properly functioning EGR system, they operate more smoothly, softly, and quietly. In addition, in diesel engines, the formation of soot is reduced through the USR. That's all the bonuses that the exhaust gas recirculation system provides the owner.

What is an EGR valve and what is an exhaust gas recirculation system for?

REAL TAXI DRIVER A huge flaw in the design.

EGR (Exhaust Gas Recirculation) System - Evil or Good?

In this video I explained in Russian why the EGR valve is needed

, but to jam it or not, draw your own conclusions.

What color does a YaMZ engine smoke?

To determine the malfunction, you need to pay attention to the color of the exhaust gases. Smoky exhaust can have the following shades:

- Gray blue. The exhaust gases may contain oil that burns during engine operation. The breakdown is associated with minimal efficiency of fuel atomization, as well as its ignition.

- Black or grey. Diesel fuel does not burn completely, which is why the exhaust gases take on such an unnatural hue.

- Thick white cloud. It appears from the pipe when coolant gets inside the chamber.

These are the main factors that indicate the presence of malfunctions and breakdowns.

Troubleshooting

- The first thing you need to pay attention to is the color of the exhaust, blue or black smoke, a sign of burnt valves or problems with rings.

- Next, you should check the compression in all cylinders. The value on gasoline internal combustion engines should be within 11-13 MPa.

- Disconnect the pipes from the valve covers, air vent and breather. Assess the degree of contamination. If the pipes are very dirty or clogged with oil deposits, use gasoline to clean them or a special carburetor cleaner.

- Check the condition of the oil separator. Unscrew the required bolts to get to this unit. Remove the oil separator and assess its condition. If necessary, clean or rinse followed by drying.

- Inspect and, if necessary, flush the breather valve. There are situations when the valve gets stuck, resulting in exhaust gases entering the crankcase and creating excess pressure. Remove the part and wash it; in most cases, this will resolve the issue of squeezing oil out of the breather.

Helpful advice! To distinguish stuck rings from a burnt-out valve, it is enough to perform several manipulations. After checking the compression in the cylinders, determine the cylinder with the lowest value. Then inspect the spark plug of this cylinder; if the rings are lodged in this cylinder, the spark plug will be covered with a thick oil layer. If the valve is burnt out, the spark plug will appear normal without any major abnormalities.

Finally…

The problem of oil escaping through the breather worries many motorists and causes a lot of trouble, but if the problem is detected in a timely manner and the right approach is taken, serious consequences can be avoided. It is important to ensure that the oil level is normal; as soon as you find that the engine is taking oil, monitor its level and constantly monitor it so that it does not fall below the permissible level. Also pay attention to the breather and filter; oil on the air filter in large quantities also does not bode well. Regularly monitor the condition of the engine and all systems, and also promptly correct any malfunction. This will save you from engine overhauls and unnecessary waste.

Source

Carrying out diagnostics of lubricant output

To identify the causes of a defect in the flow of lubrication through the breather of a diesel and turbo diesel engine, it is necessary to conduct a comprehensive check of the power unit. This does not require disassembling the engine. Experienced craftsmen measure certain parameters and visually assess the condition of the elements included in the ventilation system.

If plaque and oil deposits are detected in the intake manifold, it is concluded that there is a lubricant outlet through the diesel breather seals. To carry out diagnostics, you will need a set of tools consisting of open-end wrenches, screwdrivers, and a compression tester.

Algorithm of verification activities:

- Analysis of the state of exhaust gases. This turns on the engine and checks the color of the exhaust. A black or bluish tint indicates that oil is getting into the cylinders, because there is wear and sticking of the oil scraper rings, and there are also problems in the operation of the gas distribution mechanism.

- Check compression in each cylinder. The compression value, equal to 11 - 13 MPa, indicates proper operation of the cylinders and pistons. The difference between compressions in the cylinders should not exceed one megapascal. Low compression of one of the cylinders may cause lubricant leakage.

- Using a spark plug, the specific cause of a defect in a given cylinder is determined. The spark plug is removed and checked for strong traces of carbon deposits, which indicate defects in the cylinder-piston group.

- The absence of carbon deposits on the spark plug indicates that the valves need to be checked.

- If compression is normal in all cylinders, it is necessary to further check and clean the elements of the ventilation system. All incoming devices must be dismantled and thoroughly washed, dried, and then reinstalled.